SpaceLift 5200 Series User manual

Model 5200 Series Attic Lifts

Installation and Operation Manual

Page 1 SpaceLift 5200 Series Attic Lift Manual (10/14)

Protected by U S Patent No 8,292,031

Model Number:

Serial Number:

Installation Date:

Installer:

Place of Purchase:

Date of Purchase:

Congratulations on the purchase of your new SpaceLift

Products 5200 Series attic lift system. Expect to receive

many years of reliable service moving household items

between the floors of your home.

BEST-IN-CLASS FEATURES INCLUDE:

■Low-profile design no vertical restriction

■Automated lift with 200-pound load limit

■Platforms have up to 24 cubic feet capacity

■Factory assembled for ease of installation

■Wall-mounted control unit with key lock

■Load management system

■Two-year factory warranty

5200 SERIES SPECIFICATIONS

■Lift Weight Capacity: 200 lbs

■Lift Speed: 3 inches per second

■Max Vertical Travel: to 15 feet

■Joist/Ceiling Depth: 7 to 14 inches

■Platform Leveling: Variable adjustment

■Power Requirement: 110 VAC – 120 VAC

■Tethers: Stainless steel cable

■Remote Control: Momentary up/down buttons

Model 5222 Model 5228

Dimensions (inches}: 22 W x 59.5 L x 7 H 28 W x 59.5 L x 7 H

Rough Framed Opening: 22.5 x 60 (+/- 1/8) 28.5 x 60 (+/- 1/8)

Internal Platform Area: 18 x 41 24 x 41

Ceiling Drywall Cutout: 22.5 x 46 28.5 x 46

Landing Space Area: 24.5 x 48 30.5 x 48

Unit Weight: 75 lbs 88 lbs

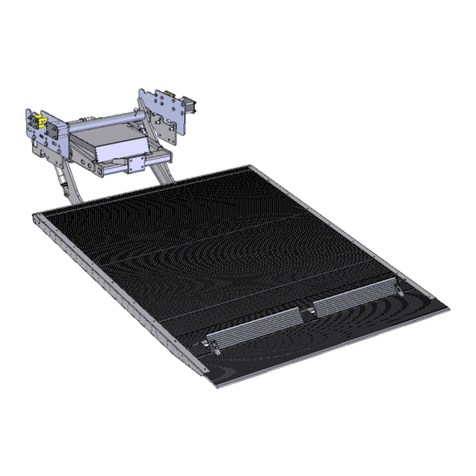

SpaceLift 5200 Series, view stowed in attic floor

SpaceLift 5200 Series, operational perspective

Page 2 SpaceLift 5200 Series Attic Lift Manual (10/14)

IMPORTANT NOTE: Please read this manual completely before you install

and operate the lift. Installation of the SpaceLift 5200 Series attic lift

system should ONLY be performed by a qualified professional. Installation

of the 5200 Series lift systems require skills in carpentry and electrical

wiring. If you c oose to ave t e lift system installed wit out t e use

of a certified installer, you may void portions of t e warranty.

BEFORE YOU BEGIN

1. Open the shipping container and verify contents are

free of any damage that may have occurred during

transport. Check the Contents List to be sure everything

is included.

2. Contact your dealer if the lift system appears damaged.

3. Record the Model Number and Serial Number of the

lift system on the front page of this manual.

IMPORTANT NOTE: Secure ALL packing

and shipping material until installation is

complete and the unit is operating as

intended. These materials are required

should the unit be returned. If you discard

and unit must be shipped there will be

delays and additional charges.

INSTALLATION INSTRUCTIONS

SECTION 1: LOCATION SELECTION

Select a location for installation. Your home must

have an acceptable ceiling and joist structure.

Consult a structural engineer before making any

modifications to the ceiling and joist structure and

to determine the load bearing capacity of the

selected installation area.

LOCATION AND ORIENTATION REQUIREMENTS

•Orientation: Lift must be oriented such

that its length is parallel to the floor joists.

•Finished Floor: Top floor must be

finished with 1/2-inch to 3/4-inch plywood

or comparable material.

•Electrical Outlet: An electrical outlet must be

located within 4 feet of mounted lift system.

•Load Support: Floor must support loads as

specified in local residential building codes.

•Power Requirement: A dedicated 15 amp

circuit is required.

•Landing Area: Landing area for cargo tray with

attached ceiling cover (both on top and bottom

floor) must be clear of any obstructions.

•Travel Distance: The Maximum Vertical Travel

distance of the lift system is 15 feet with the

preferred travel distance set on the control

panel during the installation process.

•Ceiling Height: If the Floor to Ceiling Height is

greater than 15 feet even at maximum deploy-

ment the cargo lift platform will not reach the

floor before stopping. The platform tray may be

loaded and unloaded above the floor but the

operator should be sure the platform tray is not

swaying before raising the lift.

•Overhead Space: Allow at least 4 feet of

overhead space above the installation area

to provide lift access.

•Remote Control Unit: Remote Control Unit must be

mounted on an adjacent wall at least 4 feet above the

ground. Allow a clear line of sight between the

Remote Control Unit and the lift system clear of any

moving parts of the lift and any obstructions. Must

provide a wired Ethernet connection from Remote

Control Unit to lift system using standard CAT-5

cable.

SpaceLift Model 522 installed in attic floor section

with 16-inch on center joists.

FLOOR SECTION

FRAMED ROUGH OPENING WITH 16-INCH ON CENTER JOISTS

Floor finished with 1/2 to 3/4 inch plywood before installation.

Measure and cut drywall carefully with unit in place. Leave

drywall section beneath motor side of unit.

NOTE: Model 5222 installed in attic floor with 24-inch on center

joists requires no joist cut or stringer.

SECTION 2: PREPARE THE OPENING

STEP 1: PREPARE A FRAMED OPENING IN THE CEILING

The optimal dimensions of the framed opening are

shown below. The framed opening must be square.

NOTE: Rough opening size must include allowance for

all penetrations such as joist hangers (if required). It may

be necessary to increase rough opening size slightly to

accommodate penetrations.

CONTENTS INCLUDED WITH LIFT

•Remote Control Unit

•One Gang Electrical Box and Cat-5 Cable

•Ceiling Cover and Hardware Kit

ADDITIONAL MATERIALS REQUIRED

•Wood strips two (2) 2-inch W x 2-inch H strips cut

to width of framed opening

•Sixteen (16) 16D nails (3-1/2”) and wood glue

•Additional wood strips mounted on sides of

opening as desired for finished look two (2)

1-inch W x 2-inch H wood strips approximately 56

inches long.

•Depending on attic access a material lift may be

required to move the unit into attic space through

an attic door or the rough-cut opening in ceiling

drywall.

STEP 2: INSTALL MOUNTING STRIPS

1. Cut 2-inch x 2-inch wood Mount Strips to width

of framed opening to fit inside short side of frame.

NOTE: If the rough opening size is increased to

accommodate joist hanger or other protrusion into

the recommended rough opening size then increase

dimensions to accommodate the larger rough

opening size.

2. Set Mount Strips to be flush with bottom

of headers (see illustration). Level and install

with 16D nails (four each side) and glue.

3. Install Side Strips as desired for finished look. Measure

and cut 1-inch W x 2-inch H Side Strips (approximately

56-inches long) install 2-inch sides level with Mount

Strips on long sides with 16D nails (four each side)

and glue.

Page 3 SpaceLift 5200 Series Attic Lift Manual (10/14)

Model 5222 Model 5228

Rough Framed Opening: 22.5 x 60 (+/- 1/8) 28.5 x 60 (+/- 1/8)

Ceiling Drywall Cutout: 22.5 x 46 28.5 x 46

Landing Space Area: 24.5 x 48 30.5 x 48

NOTE: Ceiling drywall opening is smaller than and centered

within the Ceiling Cover. Measure and cut drywall carefully with

unit in place. Leave drywall section beneath motor side of unit.

Required Installation Dimensions

•Maximum Vertical Travel: 15 feet

•Joist/Ceiling Drywall Depth: 7 to 14 inches

Remote Control Unit

1 Gang Electrical Box

SpaceLift 5200, view stowed in attic floor

SECTION 3: INSTALL THE LIFT SYSTEM

1. Remove the 5200 Series unit from shipping

container. NOTE: Save the container and packing

materials until the installation is complete.

2. The 5200 Series models weigh 75 to 88 lbs. Lift the

unit into the attic space through the attic door or

use a material lift to raise and guide it through the

ceiling drywall opening.

3. Lower the lift system into the framed opening

so that it rests centered on the Mount Strips.

Be sure to orient lift so power cord can reach

electrical outlet.

4. Place additional shims (3 inch minimum length)

snugly around perimeter of the cargo lift system

so that it is centered and prevented from horizon-

tal motion within rough opening. (Do not deform

unit walls.)

SECTION 4: MOUNT THE REMOTE

CONTROL UNIT

IMPORTANT NOTE: The Remote Control Unit must

be mounted to allow a clear line of sight to the 5200

lift system and be at least 4 feet above the ground

clear of any moving parts of the lift and clear of any

obstructions.

1. Install low voltage One Gang Electrical Box

into adjacent wall.

2. Run CAT-5 cable from lift system to inside

of One Gang Box.

3. Connect CAT-5 cable to plug at rear

of Remote Control Unit.

4. Attach Remote Control Unit to One Gang Box

using screws.

5. Connect cable to CAT-5 receptacle on top cover

of lift system.

6. Attach main unit power cord to lift system and

plug into adjacent electrical outlet.

Page 4 SpaceLift 5200 Series Attic Lift Manual (10/14)

SECTION 5: INSTALL THE CEILING COVER

Model 5222 Model 5228

Ceiling Drywall Opening: 22.5 x 46 28.5 x 46

Landing Space Area: 24.5 x 48 30.5 x 48

IMPORTANT NOTE: During initial lift operations

place a 25 lb. weig t on t e platform to keep t e

cables taut, t ereby elping seat t e cables after

s ipping. Before installing the ceiling cover observe

the lift stow cycle. The tray will slow before making

contact continuing to proceed slowly until stowed.

The ceiling cover should make contact with the

ceiling approximately ½” from the stowed position.

This determines the final length of the standoffs.

The springs work well as long as they are not over

stretched. If the threaded rod standoffs need to be

shortened the springs can be attached to a higher

position on the chain.

INSTALL CEILING COVER

1. Consult the SpaceLift 5200 Series operating

instructions and lower the lift tray 3 to 5 feet

above floor level and stop.

2. Install the four springs on the loops beneath

the tray.

3. Install the four Threaded Standoffs into the

threaded holes on each corner of the tray with

the square jam nuts loose. Run the lift up until the

lift reaches the final stowed position.

4. Adjust each standoff so the bottom of the flange

nut is 1/4-inch below the ceiling. Tighten the

square jam nuts.

NOTE: The ceiling cover will be stretched away from

the standoffs as the tray comes to its final stow posi-

tion. This should be approximately ½” as mentioned

above. This provides a good tension of the ceiling

cover to the ceiling.

5. Place the ceiling cover on a table then lower the

SpaceLift tray so they are aligned. Using a pair of

pliers attach the bottom of the springs to the

ceiling cover connections.

6. Affix the four landing pads (supplied with 5200

Series unit) to the bottom of ceiling cover. They

must be installed directly under the standoff rods

so the weight of the tray and load is transmitted

to the floor without deforming the ceiling cover.

Page 5 SpaceLift 5200 Series Attic Lift Manual (10/14)

Springs, standoffs, tray caps and landing pads

Spring to cover with standoff

Attached cover

For more information check the SpaceLift 5200

Series Product page and FAQ on our website.

SECTION 6: SET THE TRAVEL LIMIT

1. Start Remote – Insert key and turn to right to

power lift operation.

2. Up/Down Buttons – Arrows display GREEN to

indicate directions possible (i.e. stowed lift will

only go down).

3. Obstacle Detection – If lift hits obstruction both

arrows display RED.

4. Set Bottom Limit – To set the lift bottom travel

limit (with ceiling cover installed):

Lower lift until it almost touches the floor.

NOTE: S ould t e lift reac t e floor DO NOT

continue to pus DOWN as t is may cause t e

cables to unspool. Leave 1-inch clearance

between the bottom of the ceiling cover and

the floor.

a. Turn remote key to OFF position.

b. Press and hold BOTH buttons and

return key to ON position.

c. Release both buttons. Arrows will flash

RED three times.

d. Press the DOWN button to set the

bottom limit.

e. BOTH arrows will flash RED three times

then remote will return to normal operating

mode.

f. Press UP button and return lift

to stowed position.

5. Power Off – Turn key to left and remove.

6. Reset to Maximum Vertical Travel

If the lift is stopping at some inconvenient height

(showing only the up arrow) the bottom limit can be

restored at any time to the maximum vertical travel

limit by the following method.

a. Turn remote key to OFF position.

b. Press and hold BOTH buttons and

return key to ON position.

c. Release both buttons. Arrows will

flash RED three times.

Page 6 SpaceLift 5200 Series Attic Lift Manual (10/14)

d. Press the UP button to reset the

bottom limit.

e. BOTH arrows will flash RED three times

then remote will return to normal operating

mode.

f. Press UP button and return lift to

stowed position.

Page 7 SpaceLift 5200 Series Attic Lift Manual (10/14)

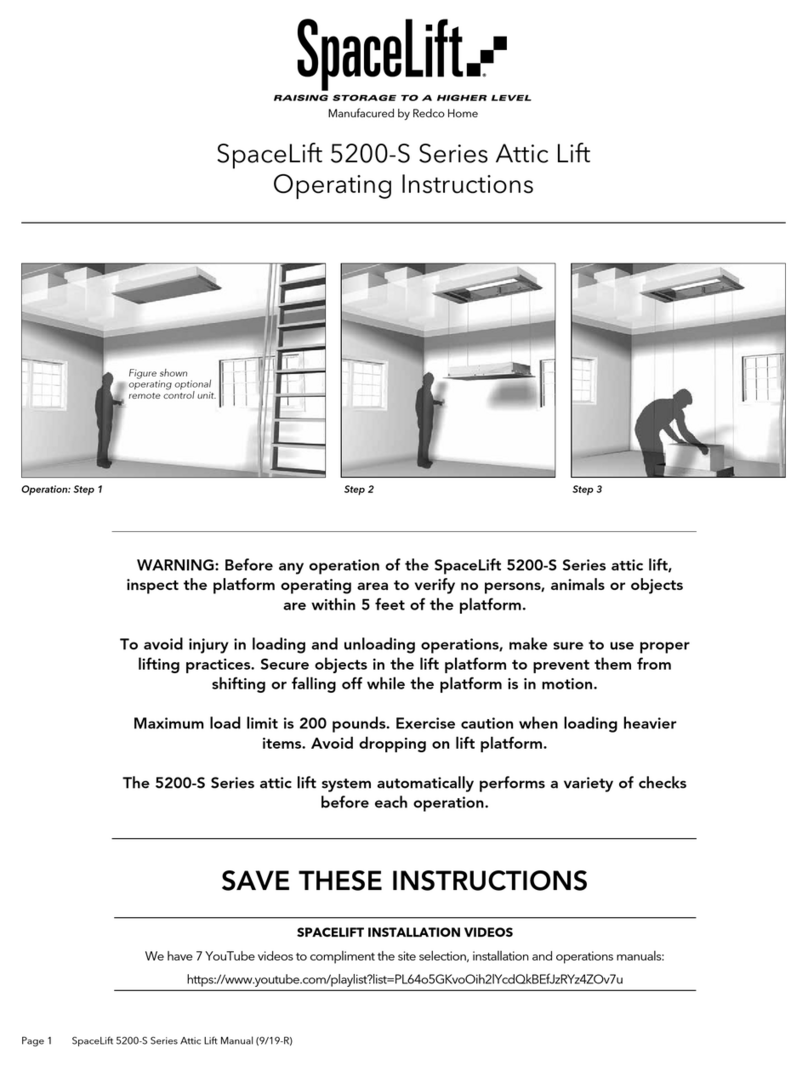

SpaceLift 5200 Series Attic Lift

Operating Instructions

WARNING: Before any operation of t e SpaceLift

5200 Series attic lift system, inspect t e platform

operating area to verify no persons, animals or

objects are wit in 5 feet of t e platform.

To avoid injury in loading and unloading operations,

make sure to use proper lifting practices. Secure

objects in t e lift platform to prevent t em from

s ifting or falling off w ile t e platform is in motion.

Maximum load limit is 200 pounds.

T e 5200 Series attic lift system automatically

performs a variety of c ecks before eac operation.

FIRST READ: NORMAL SEQUENCE OF

OPERATION

With lift in the fully stowed UP position the Remote

Control Unit will display only a Down Button. When

stowed pressing the Up Button will do nothing.

Pressing and holding the Down Button will start

the following sequence:

•The microprocessor weighs the tray. Only if the

tray has a load of less than 200 pounds will it be

allowed to move downward. If the load exceeds

200 pounds both arrows will display RED indicat-

ing an error.

•When the load is less than 200 pounds the tray

will start moving downward a short distance then

stop momentarily. As long as the Down Button

is continuously pressed the tray will continue

traveling downward at the normal run speed.

The tray will continue down until it approaches

the bottom limit where it will decelerate stop

and automatically slowly settle onto the floor

(provided bottom limit is set correctly).

•With tray on the floor only the Up Button will be

illuminated green indicating only upward travel

is possible. Pressing the Down Button will do

nothing.

Pressing and holding the Up Button starts the

following sequence:

•Tray will slowly lift off the floor allowing the micro-

processor to weigh the load. If the load exceeds

200 pounds the tray will lower back to floor level

and the Remote Control Unit buttons will show

RED indicating an error.

•Provided load is 200 pounds or less the tray will

accelerate to normal run speed going up until tray

is near the top where it will decelerate and stop

momentarily. Then continue slowly up to the stow

position. When stowed the Remote Control Unit will

display one GREEN Down Button indicating only

downward motion possible.

While traveling Up or Down:

•If the tray is stopped by the operator releasing a

travel button at any point between the “stowed”

and “on floor” positions both Remote Control Unit

arrows will show GREEN indicating travel is possible

either Down or Up.

•While tray is moving upward or downward the load

management system continuously monitors the load

and drive motor in order to detect an imbalance

overload or motor over current. If any of these errors

occur both arrows on remote will display RED.

After a few seconds arrow indicators will revert to

green indicating travel may resume.

NOTE: It is up to t e operator to determine

w et er or not any condition still exists t at

would generate anot er error (i.e. an overload

or imbalance).

Step 2 Step 3

Operation: Step 1

Page 8 SpaceLift 5200 Series Attic Lift Manual (10/14)

WARNING: Before any operation of t e SpaceLift

5200 Series attic lift system inspect t e platform

operating area to verify no persons, animals or

objects are wit in 5 feet of t e platform.

To avoid injury in loading and unloading operations,

make sure to use proper lifting practices. Secure

objects in t e lift platform to prevent t em from

s ifting or falling off w ile t e platform is in

motion. Maximum load limit is 200 pounds.

T e 5200 Series attic lift system automatically

performs a variety of c ecks before eac operation.

STEP 1. Turn on Remote Control Unit with Key.

•Up/Down Buttons – Arrows display GREEN to

indicate directions possible (i.e. stowed lift will

only go down).

•Obstacle Detection – If lift hits obstruction both

arrows display RED.

STEP 2. Use the Down Button to lower the cargo lift

platform to the lower level landing position.

STEP 3. Load the lift platform with items to be trans-

ported. Weight of items should be centered in tray.

Maximum load must be limited to 200 pounds per

trip. Be sure objects are secured to prevent load shift-

ing during lift operations.

STEP 4. Depress and hold the Up Button until the lift

cycle is complete. To halt operation release the but-

ton any time during the lift cycle.

STEP 5. Unload lift platform.

STEP 6. Turn Key OFF when lift operations are complete.

NOTE: If power is lost during operation the lift will

stop. When power is restored depress the Up

Button and return the lift to the fully stowed and

locked position. This enables the system to reset to

assure consistent operation.

WARNING: W en using t e cargo lift system

Remote Control Unit, keep t e lift platform in sig t

until completely stopped in eit er t e bottom or

top position. DO NOT allow c ildren to play under

or near t e lift platform.

WARNING: T e lift platform moves rapidly.

Keep pat clear.

SAVE THESE INSTRUCTIONS

Contacting SpaceLift Products

If your product fails during the warranty period and the

product documentation does not solve the problem you

may receive support by:

1. Check Model 5200 Series FAQ on the SpaceLift

website.

2. Contact the dealer from whom you purchased.

3. Use SpaceLift website Contact form for inquiry.

Before contacting your dealer or SpaceLift Products

have the following:

•Product serial number

•Product model name and model number

•Detailed notes for questions

SpaceLift 5200 Series Attic Lift

Operating Instructions

Step 4

Step 5

Step 2 Step 3

Operation: Step 1

SpaceLiftProducts.com

© 2014 SpaceLift Products, Inc All rights reserved (10/14)

Extent of Limited Warranty

SpaceLift Products Inc. warrants that the cargo lift

product will be free from defects in material and work-

manship for two years. SpaceLift Products does not

warrant that the operation of the product will be unin-

terrupted or error free.

This limited warranty covers only those defects that

arise as a result of normal use of the product and does

not cover any other problems including those that arise

as a result of: (i) improper maintenance or modification;

(ii) operation outside the product’s specifications; or (iii)

unauthorized modification or misuse.

If SpaceLift Products receives during the applicable

warranty period notice of a defect in any product

which is covered by this warranty SpaceLift Products

shall either repair or replace the product at its sole dis-

cretion and option.

Limitations of Warranty

TO THE EXTENT ALLOWED BY LOCAL LAW NEI-

THER SPACELIFT PRODUCTS NOR ITS THIRD PARTY

SUPPLIERS MAKES ANY OTHER WARRANTY OR

CONDITION OF ANY KIND WHETHER EXPRESS OR

IMPLIED WARRANTIES OR CONDITIONS OF MER-

CHANTABILITY SATISFACTORY QUALITY AND FIT-

NESS FOR A PARTICULAR PURPOSE.

Limitations of Liability

To the extent allowed by local law the remedies pro-

vided in this Limited Warranty Statement are the cus-

tomer’s sole and exclusive remedies.

TO THE EXTENT ALLOWED BY LOCAL LAW EXCEPT

FOR THE OBLIGATIONS SPECIFICALLY SET FORTH

IN THIS WARRANTY STATEMENT IN NO EVENT

SHALL SPACELIFT PRODUCTS OR ITS THIRD PARTY

SUPPLIERS BE LIABLE FOR DIRECT INDIRECT SPE-

CIAL INCIDENTAL OR CONSEQUENTIAL DAMAGES

WHETHER BASED ON CONTRACT TORT OR ANY

OTHER LEGAL THEORY AND WHETHER ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES.

Local Law

This Limited Warranty Statement gives the customer

specific legal rights. The customer may also have other

rights which vary from state to state in the United

States from province to province in Canada and from

country to country elsewhere in the world.

To the extent that this Limited Warranty Statement is

inconsistent with local law this Statement shall be

deemed modified to be consistent with such local law.

Under such local law certain disclaimers and limitations

of this Warranty Statement may not apply to the cus-

tomer. For example some states in the United States

as well as some governments outside the united States

(including provinces in Canada) may: (i) preclude the

disclaimers and limitations in this Warranty Statement

from limiting the statutory rights of a consumer (e.g.

United Kingdom); (ii) otherwise restrict the ability of a

manufacturer to enforce such disclaimers or limitations;

or (iii) grant the customer additional warranty rights

specify the duration of implied warranties which the

manufacturer cannot disclaim or allow limitations on

the duration of implied warranties.

THE TERMS IN THIS WARRANTY STATEMENT

EXCEPT TO THE EXTENT LAWFULLY PERMITTED DO

NOT EXCLUDE RESTRICT OR MODIFY AND ARE IN

ADDITION TO THE MANDATORY STATUTORY

RIGHTS APPLICABLE TO THE SALE OF THE

SPACELIFT PRODUCTS TO SUCH CUSTOMERS.

Register Immediately Online to Initiate

Your Warranty:

SpaceLiftProducts.com/warranty

Or use the SpaceLift Warranty Card provided.

Protected by U.S. Patent No. 8 292 031.

SpaceLiftProducts.com

Limited Warranty

SpaceLift Products Model 5200 Series Lift System

Page 9 SpaceLift 5200 Series Attic Lift Manual (10/14) © 2014 SpaceLift Products, Inc All rights reserved

This manual suits for next models

2

Table of contents

Other SpaceLift Lifting System manuals

Popular Lifting System manuals by other brands

Snap-on Equipment

Snap-on Equipment EELS542A Installation, operation & maintenance manual

Titan Lifts

Titan Lifts RJ-6K-HP Installation, operation & maintenance manual

Bishamon

Bishamon LV50W Operation and service manual

ANthony

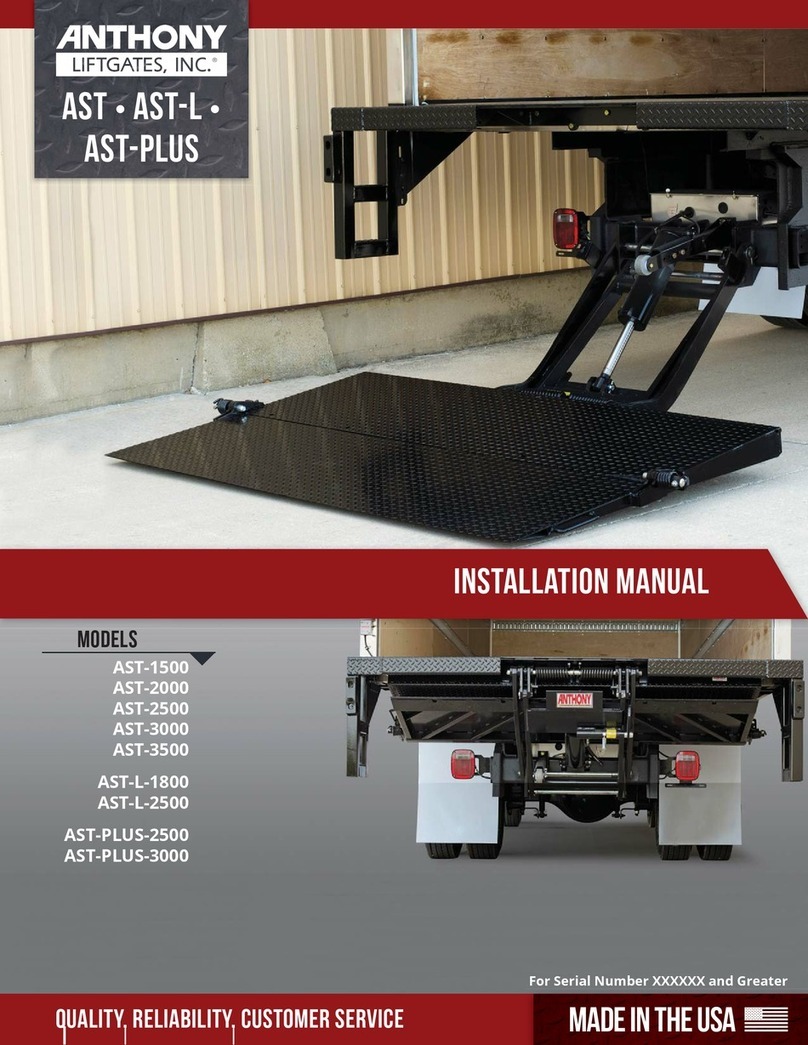

ANthony AST-1500 installation manual

Screen Technics

Screen Technics INTERFIT Vertical Up Lift instructions

Harmar Mobility

Harmar Mobility AL625 Installation & owner's manual