SpaceraiL 5.1 User manual

Instruction Manual Level 5.1

2

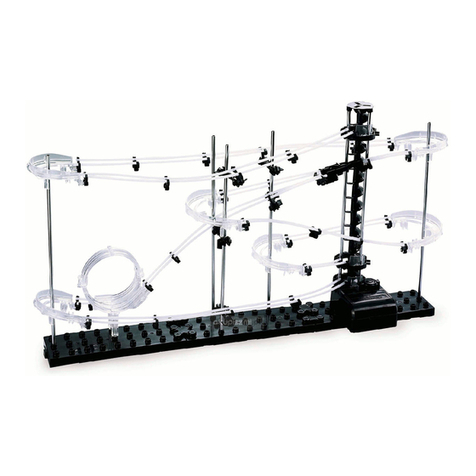

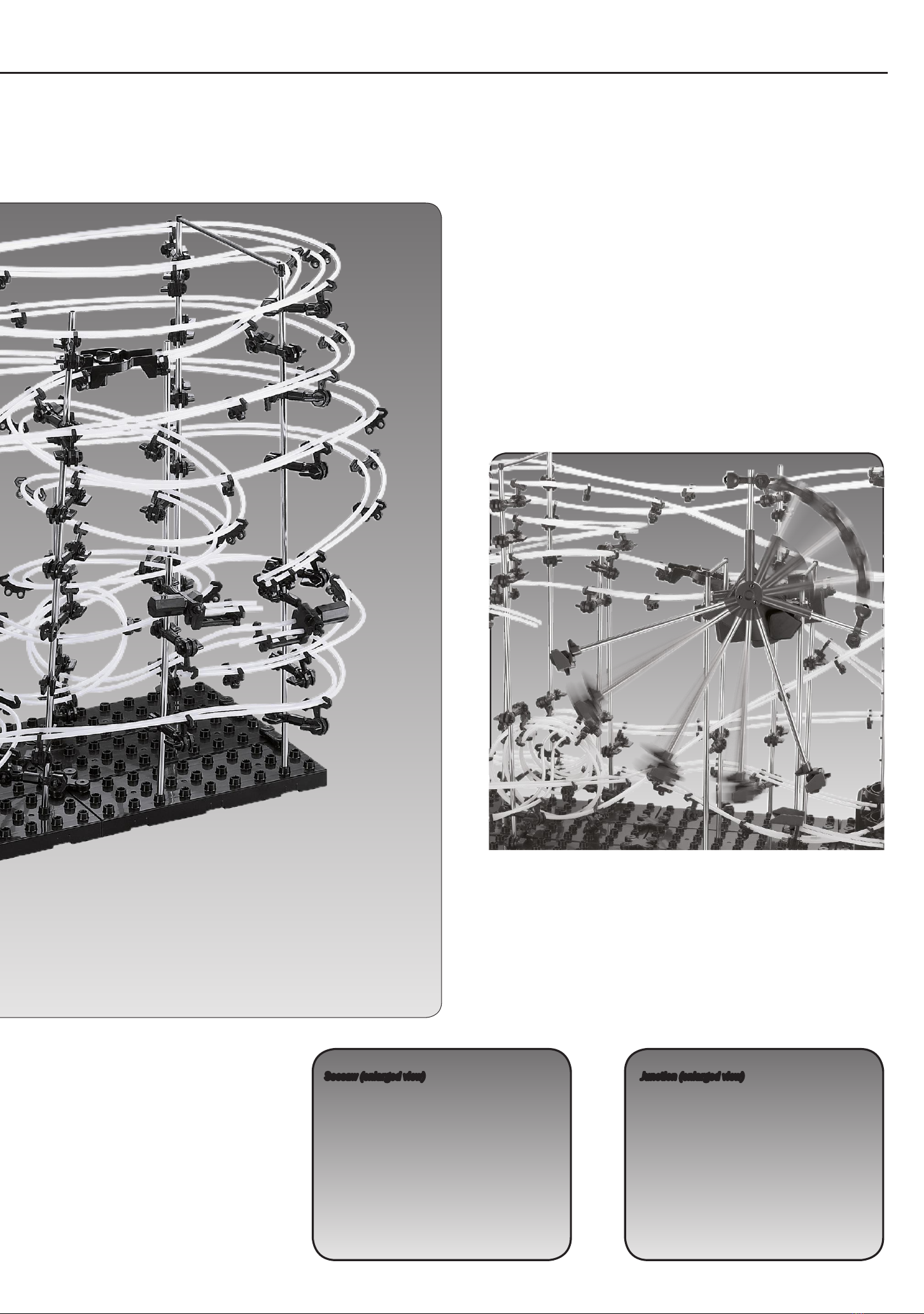

Elevator (enlargedview)

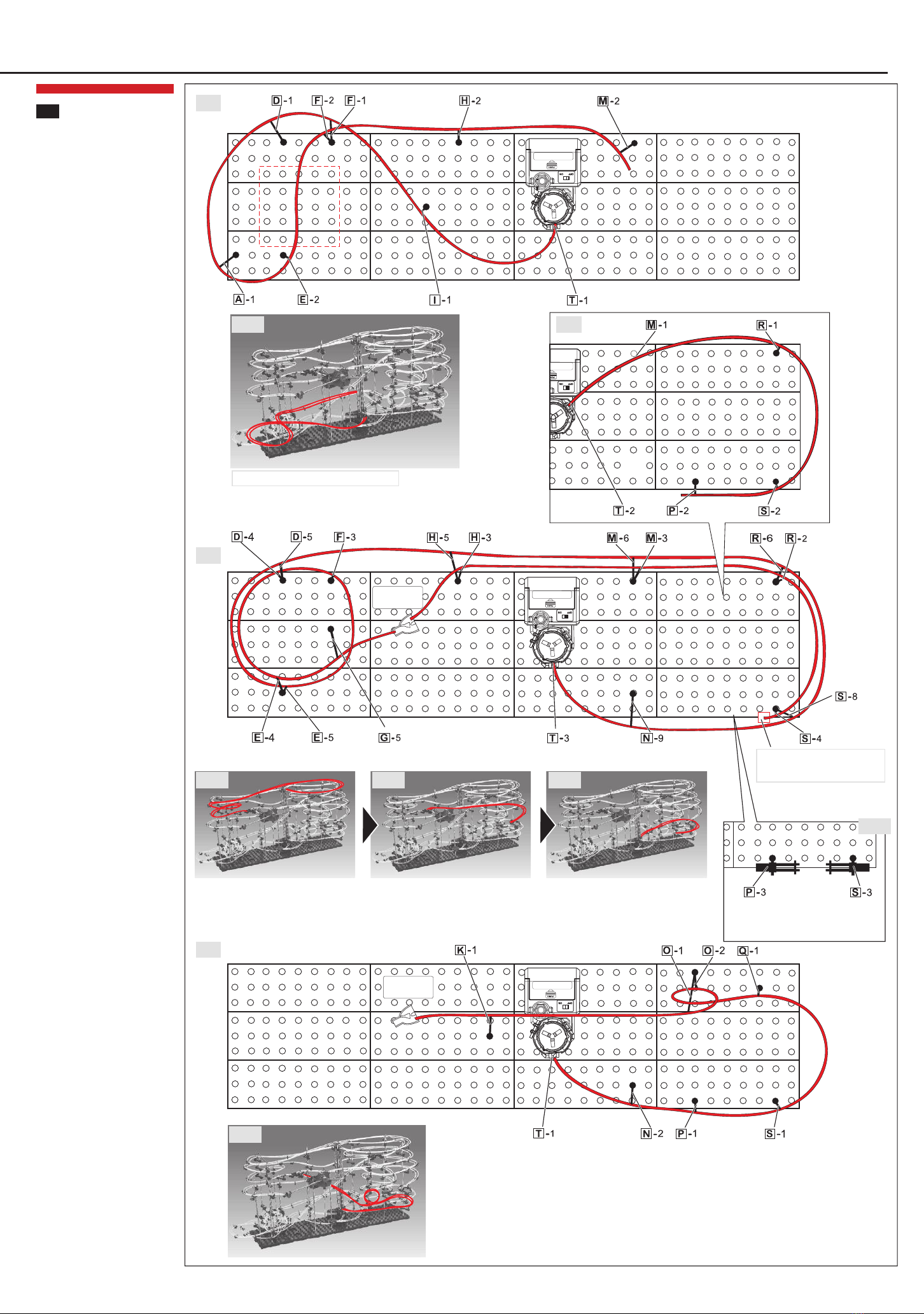

fg. 1

Quadloop(enlargedview)

SpaceRail Level 5.1

3

Table of Contents

Pendulum(enlargedview)

Seesaw(enlargedview)

Figure1..................................................... P. 2-3

Figure2-6..................................................... P. 4

PartsList...................................................... P. 5

Assemblyofthebaseplate.............................P. 6

Assemblyofthearms.................................... P. 6

Assemblyoftheseesaw..............................P. 6-7

Assemblyoftheelevator................................P. 7

Assemblyofthependulumandstarterkit.....P. 8-9

Assemblyofthebaseplate, gearbox,

pendulumandstarterkit.............................P. 8-9

Locationsof theelevatorrings.....................P. 8-9

Positionsofarms........................................P. 8-9

Rail assemblysteps.................................P. 10-11

Rail mounting.............................................. P. 12

Loopmounting............................................ P. 12

Elevatormounting(entryandexit).................P. 13

ConstructyourownStarCoasterdesigns........P. 14

Assembledproduct.......................................P. 15

Warnings.....................................................P. 16

Junction(enlargedview)

SpaceRail is a spectacular marble-run coaster that guarantees high-speed action rides cosisting of wild rotations, daring loop-

the-loops and spectacular swivel motions.These ball roller coasters are an ultimate challenge for teenagers and adult

enthusiasts alike. SpaceRails are available in different sizes and different levels of difficulty.

4

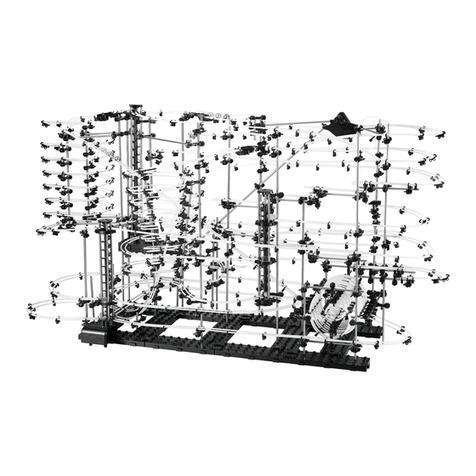

fg. 2 (front)

fg. 3 (left) fg. 4 (top)

fg. 6 (back)

fg. 5 (right)

These pictures show

the SpaceRail Level

5.1 from several

different viewpoints.

This is very helpful to

reference during

assembly.

[B2] Baseholder (big) [B3] Baseholder (small) [G2] Gearboxsocket

[S6] ConnectingpieceA(176mm)

[S7] ConnectingpieceB(154mm)

[S8] ConnectingpieceC(90mm)

Steel balls

[R2] Rail joining [Ex2] Pendulum [Ex3] Starter Kit [Ex4] Breakcover for starterkit [Ex5] Ball catcher [Ex6] Counterweight [Ex7] Pendulumtrayfor steel balls

5

Parts List

Pliers

Use1 xC/ LR14 battery(not included).

Handlethecomponents withcareto prevent themfromgettinglost.

Tapemeasureorfoldingruler

Toolsforinstallation:

Partslist

[B1]

[A1]

[G1]

[B2] [B3] [S6] 176mm [S7] 154mm [S8] 90mm [G2]

[R2] [Ex2] [Ex3] [Ex4] [Ex5] [Ex6] [Ex7]

[E1] [E2] [E3] [Ex1] [P1]

[A2] [A3] [A4] [A5] [A6]

[S2] 300mm [S3] 200mm [S4] 159mm [S5] 65mm [R1] 32.000mm[S1] 391mm

[B1] Baseplate

[A1] Arm

[G1] Gear Box [E1] Elevator helix [E2] Elevator ring

[A2] ArmholderA [A3] Armtube [A4] ArmholderB [A5] Armwrench [A6] Rail stand

[S1] Shaft 391mm [S2] Shaft 300mm [S3] Shaft 200mm [S4] Shaft 159mm [S5] Shaft65mm [R1] Rail (32,000mm)

12x

80x

1x

6x

10x

80x

16x

4x

1x

80x

3x

1x

1x

85x

1x

3x

1x

165x

2x

2x

1x

90x

2x

1x

1x

5x

1x

11x 10x 2x 1x 1x 2x

[E3] Elevatorcover [P1] Junction[Ex1] Seesaw

6

Assemblyofbaseplate

1. Assemblethebaseplate

(12 pieces). Payattentionto

aproperseatingof theclips

and slots (fg. 01)

2. Fastenthebaseholders

(B2 +B3) inthecorrect

positions (fg. 01-2)

1

2

3

Assemblyofarms

1. Assemblethearms

accordingtofg. 02. Caution:

ArmholderA(A2) +arm

holderB(A4) aredifferent.

73arms areneededforthe

completeset-upof„Star

CoasterLevel 5“

2. Insert thearmwrenchinto

thearmholderAandturnit

by90 degrees tof xthearm

(fg. 03). Note:Tomodifythe

angleofthearm, releasethe

fxationfrst

3. Attachthearmtotheshaft

(fg. 04): Insert shaft intothe

armholderBandturnthe

armwrenchby90 degrees

tof xthearm(fg. 04). Note:

To modifythe angleof the

arm, releasethefxationfrst

Assemblyofseesaw

Insert 4x55mmrail intothe

holes of theseesaw. Then

attachtherail standtothe

seesaw(fg. 05)

Assembly of base plate, arms & seesaw

1

01

[B2] Baseholder(big)

[B3] Baseholder(small)

[B1] Baseplate

02

2[A3] Armtube

[A4] ArmholderB

Top-downview

Top-downview

[A2] Armholder A

[A5] Armwrench

Insertshaft intothearmholder B. Donot

applyforceinordertoavoiddamages

[A1] Arm

Note: When turningthearmwrench, makesurenot

to change the right positionof thearm

Note: When turningthearmwrench, makesurenot

to change the right positionof thearm. Refer to the

assemblyof arms (page E1-E4)

03

04

05

01-2

[A6] Rail stand

[Ex1]Seesaw

Approx. 55mm

[A6] Rail stand

[A6] Rail stand

[A6] Rail stand

[A6] Rail stand

[E2] Elevator ring

[E2] Elevator ring

[E3] Elevator cover

[G1] Antrieb

[G1] Gearbox

Assemblyoftheelevator

1. Insertthe391mmshaft into

thegearbox(fg. 08-1)

2. Slidetheelevator(16pcs)

ontotheshaft (fg. 08-2).

Insert shaft intobase(fg.

08-1). Pleasenotethecorrect

directionof rotation

3. Insert 3further391mmshafts

intotheexact pre-defned

positions onthegearbox(fg.

08-3)

4. Allowthe3 shafts to snapinto

place(pic. 08-4). Takecare

that theelevator rings are

properlylocated. Seepage8

+9 for theproper locations of

theelevatorrings

5. Insert the4 shafts intothe

elevatorcover(fg. 08-5).

Takecarethat theshafts are

properlylocated

6. Nowattach3 rail stands [A6]

totheelevatorring(fg. 08-6)

7

3

4

Assemblyofseesaw

Attachseesawtotheshaft

(fg.06+07)

1. Connect seesawwitharm

holderB(fg. 06)

2. Attacharmholder Btothe

shaft (fg.07). Refer tothe

assemblyof arms (page10

andfollowing). Insertarm

wrenchintoarmholderBand

turnit by90 degrees (fg. 03).

Note: To modifytheangle of the

arm, releasethefxationfrst

Assembly of base plate, arms & seesaw

06 07

08-1

08-4

08-5 08-6

08-2 08-3

[A3] Armtube

[A4] ArmholderB

mountrighthandside

mountlefthandside

Install 1pcs

Install 1pcs

Holeprofle

Lochprofl

Holeprofle

Holeprofle

Holeprofle Adjust seesawafter assemby

Note: Whenturningthearmwrench, makesurenot tochange

theright positionof thearm

[S1] Shaft 391mm

[S1] Shaft 391mm

[E1] Elevatorhelix

Avoidthat thereis a gap between

gearboxandelevatorhelix.

Otherwisetheelevatorwill not

operateproperly. Pleasenotethe

correct directionof rotation

Makesureconvexred parts point

up andeverythingis correctly

seated.

Assembly of gear box and base plate

[G1] Gearbox

[S6- S8] Connectingpiece

Connect withholes onbaseplate

Seesaw(turnright)

8

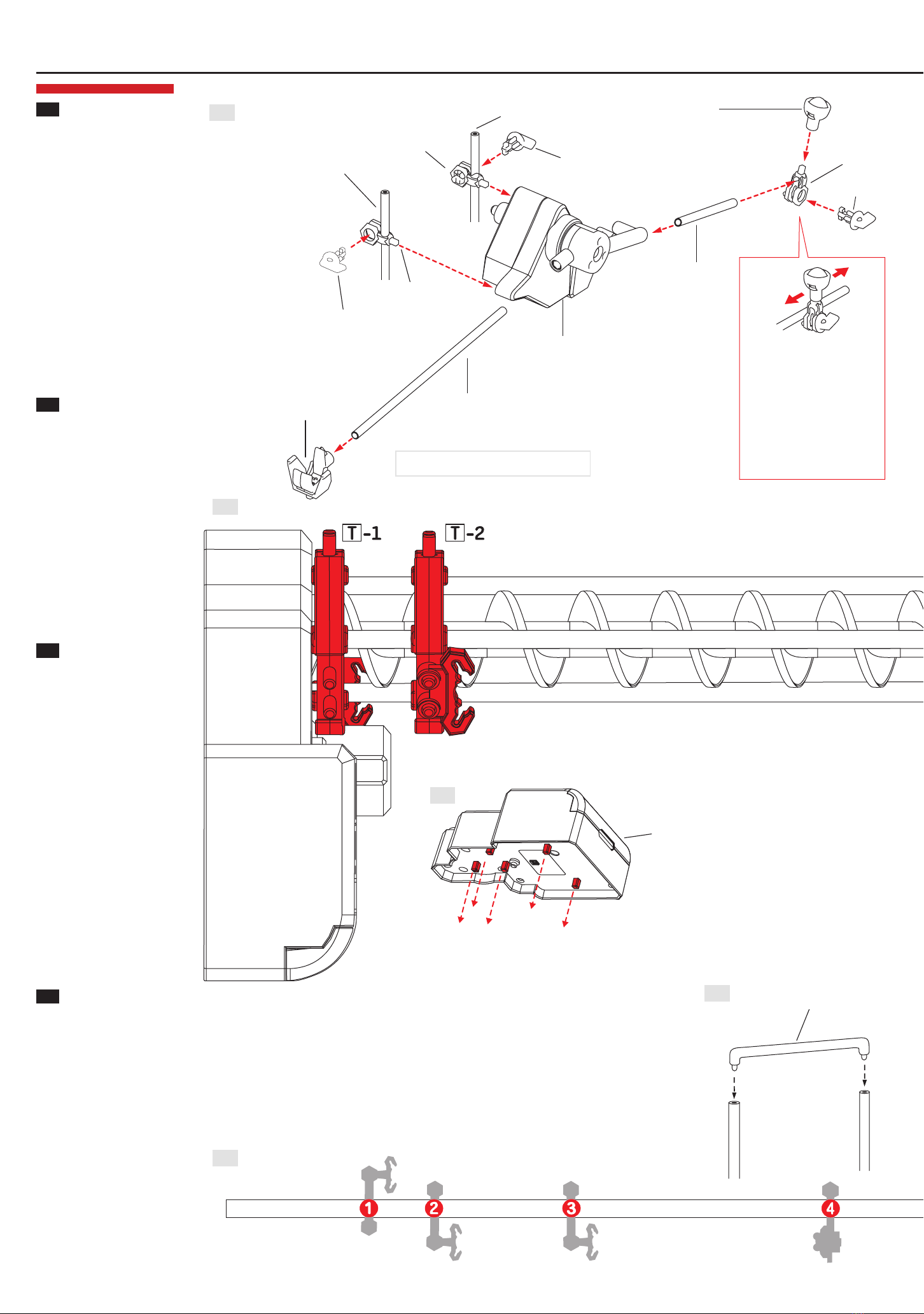

Installationofthependulum

andstarterkit

1. Connect attachment parts with

pendulum(f g. 09). Note: To modify

thepositionof armholder B, release

thefxationfrst

2. Connect attachment parts with

starter kit (fg. 10). Note: To modify

thepositionof armholder B, release

thefxationfrst

5

6

7

8

Locationsof theelevatorrings

Elevator(fg.11): Elevatorisshowninascale

of1:1.Attachtheelevatorringstotheexact

pre-defnedredpositions (T-1,T-2,T-3)

Attachthe5clipsat thebottomofthe

gearbox(seeredmarkings infg.12) to

theexactpre-defnedpositionsof thebase

plate(fg.13)

Installationofgearbox,

pendulumandstarterkit

Locationof pendulumand starter kit on

base(fg.13)

Attachpendulum(fg. 09) andstarterkit

(fg.10) tothebaseplate(fg. 13)

Gearboxlocationonbaseplate(fg. 13)

Attachthe5 clips at thebottomof the

gearbox(see redmarkings inf g. 12) to

the exact pre-def nedpositions of the

baseplate(fg.13)

Positionsofarms

Attachthearms totheshafts (fg.14).Picture

showsascaleof1:1

Attachthearms totheshafts (seeillustration

forarminstallationonpageE1-E4)

Attachconnectingpiecestoshafts(fg.15+13)

Inserttheshaftsintothebaseplate(fg.13)

09

11

12

14

15

[S2] Shaft 300mm

[S2] Shaft 300mm

[S5] Shaft 65mm

[S4] Shaft 159mm

[A4] Armholder B

[A4] Armholder B

[A4] Armholder B

[A5] Armwrench

[A5] Armwrench

[Ex5] Ball catcher

[Ex6] Counterweight

[Ex2] Pendulum

[A5] Armwrench

Referto theassemblyof arms (fg. 04)

Thecounterweight positionis adjustable

on theshaft if the pendulumdoes

not workproperly.Note: Tomodifythe

positionof counterweight, releasethe

fxationfrst

Referto theassemblyof arms (fg. 04)

Attachstarterkit (armholder B) totheshaft andcreateaslope, sothat

thesteel balls canrun smoothly

[S1] Shaft 391mm

9

10

13

[S2] Shaft 300mm

[S2] Shaft 300mm

[A4] Armholder B

[A4] Armholder B

[A6] Rail stand

[A6] Rail stand

[Ex3] StarterKit

[A5] Armwrench

[A5] Armwrench

Pendulum

[Ex4] Brakecoverforstarter kit

Connect rails withtheentryof thestarter kit

and makef neadjustments to slowdownthe

speedof thesteel balls (balls will rebound if

toofast). Attachthebeakcovertothestarter

kit as shownin theillustration

Positionfor connectingpieceB

(154mm) [S7] Positionfor connectingpieceC

(90mm) [S8] Positionfor connectingpieceA

(176mm) [S6]

StarterKit Elevator

Vorderseite

Front

Back

Assembly of rails

JunctionA

[Ex7] Pendulumtrayforsteel balls

10

16

17

18

JunctionA

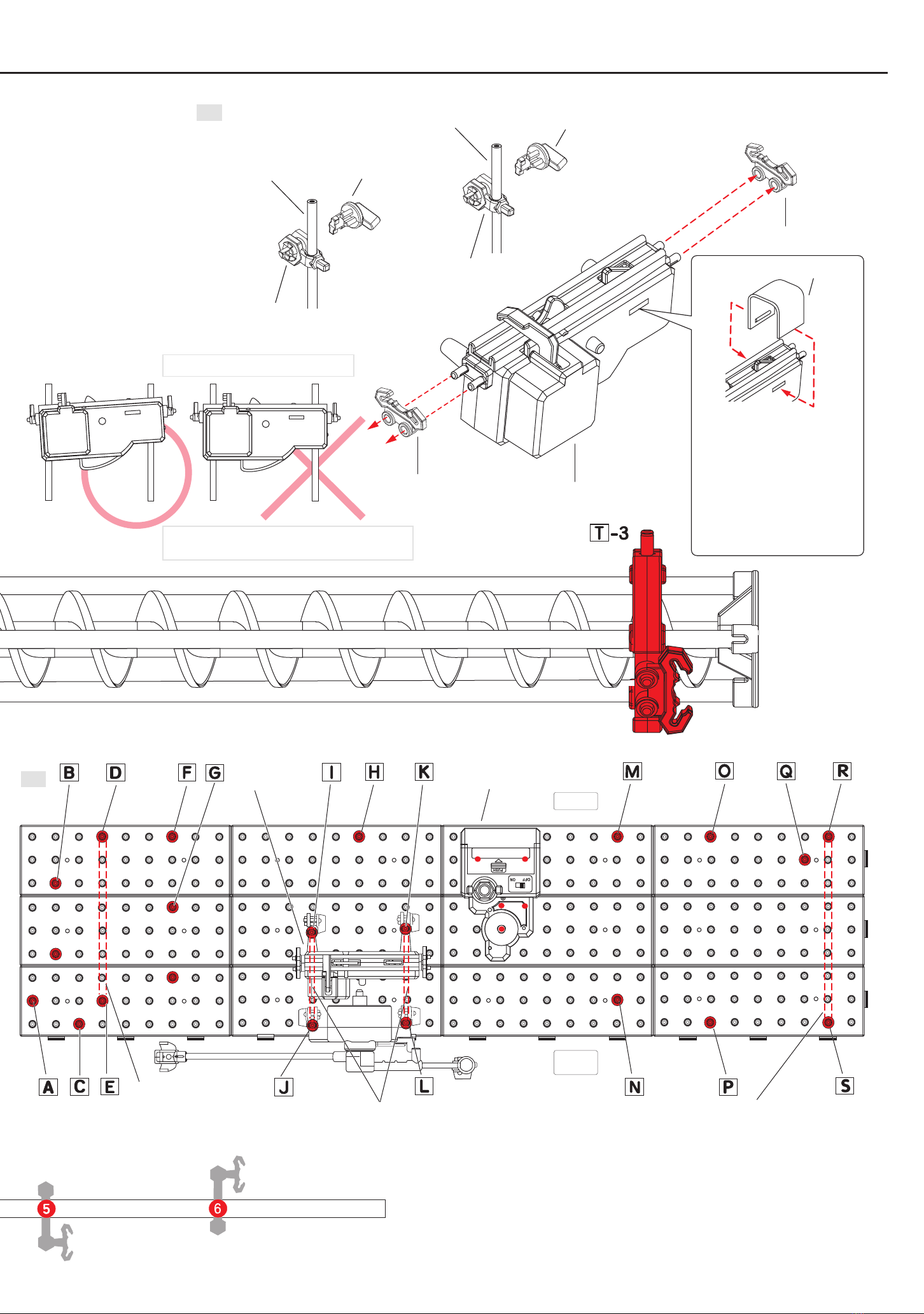

Rail assemblysteps

This ball roller coasterprovides 3

exits (start) and5 entries (end).

Pleasenotefg. 16-22andthe

illustrations onpage2-4 during

assembly

Install rail standstogetherwith

therails (fg. 26)

1. Fromelevatorexit (start) tothe

junctionAentry(end): Install 2

x61cmrails (fg. 16-1)

2. FromthejunctionAexit(start) to

thestarterkitentry(end):Install

2x117cmrails(fg.16-2)

Connect rails withtheentryof

thestarter kit andmakefne

adjustments to slowdownthe

speedof thesteel balls (balls will

rebound if toofast)

3. Fromstarterkit exit(start) to

theball catcher(end): Install 2

x58cmrails (fg. 16-3)

4. Frompendulumtrayforsteel

balls (start) toelevator entry

(end): Install 2 x40cmrails

(fg. 16-4)

5. FromthejunctionAexit (start)

tothelowerelevatorentry

(end): Install 2 x270cmrails

(fg. 17)

6a.Fromtheupperelevatorexit

(start) tobehindthetraverse

loops: Install 2 x507cmrails

(fg. 18). Caution: DoNOTcut

therails here(sectionwill be

continued as showninfg. 19)

9

Install 2x61cmrails Install 2x117cmrails Install 2x58cmrails Install 2x40cmrails

Do NOTcut therails here(section will be continued as shown in fg. 19)

16-1 16-2 16-3 16-4

Fromelevator exit (start) tothejunctionAentry(end) FromthejunctionAexit (start) tothestarter kit entry(end) Fromstarter kit exit (start) totheball catcher (end) Frompendulumtrayfor steel balls (start) to elevator entry (end)

Rail trackuntil junction. Install junctionat theveryendof theinstallationprocedure Releasearmtube[A3] beforemountingtherails

Assembly of rails

Rail assemblysteps

6b.Fig. 19 shows thecontinuation

of fg. 18: Continuedsection

startsbehindthetraverseloops

and ends at thelower elevator

entry(fg. 19)

7. Fromupperelevator exit (start)

tothejunctionBentry(end):

Install 2 x235cmrails (fg.

20-1)

8. FromjunctionBtotheupper

seesaw: Install 2x96cmrails

(fg. 20-2)

9. Fromlowerseesaw(start)

tothemiddleelevator entry:

Install 2 x80cmrails (fg. 21-1)

10.FromjunctionB(start) tothe

middleelevatorentry(end):

Install 2 x142cmrails (fg. 22

+22-1)

9

19-1

20-1 20-2

20-3

21-1

22-1

11

19

21

20

22

Fig. 19 +19-1showthecontinuationof fg. 18

Fromupper elevator exit(start) tothejunctionBentry

Install 2 x235cmrails (f g. 20-1) Install 2 x96cmrails (fg. 20-2) Install 2 x80cmrails (f g. 21-1)

Correct assemblyof seesaw(fg. 20-3)

FromjunctionBto theupperseesaw Fromlower seesaw(start) to themiddleelevator entry Insert rail stand at the end of the rail to

ensurebestseesawstability

JunctionB

JunctionB

12

Installationoftherails

Attachmentofrailstoarmsandshafts(fg.

23+24)

Attachrail toarm(fg.23)

Rail joining(fg.25)

Adjustandconnecttherails.Inserttherail

joinings[R2]intotheholesatthecenterof

therails(fg.25)

Informatonsaboutrail stands(fg.26)

Thedistancebetweenthearms shouldbe

between8to10cmtoensurebeststability.

Whenthedistanceis larger,rail stands [A6]

havetobeinstalled

Attachrail stands insteepsections and

elevatorentry/exitpointstoensurebest

stabilityoftherails

Steepsections(fg.27)

Install thearmsinaninclinedpositionto

eachothertocreatesteepsections,sothat

thesteel ballscanrunsmoothly(fg.27)

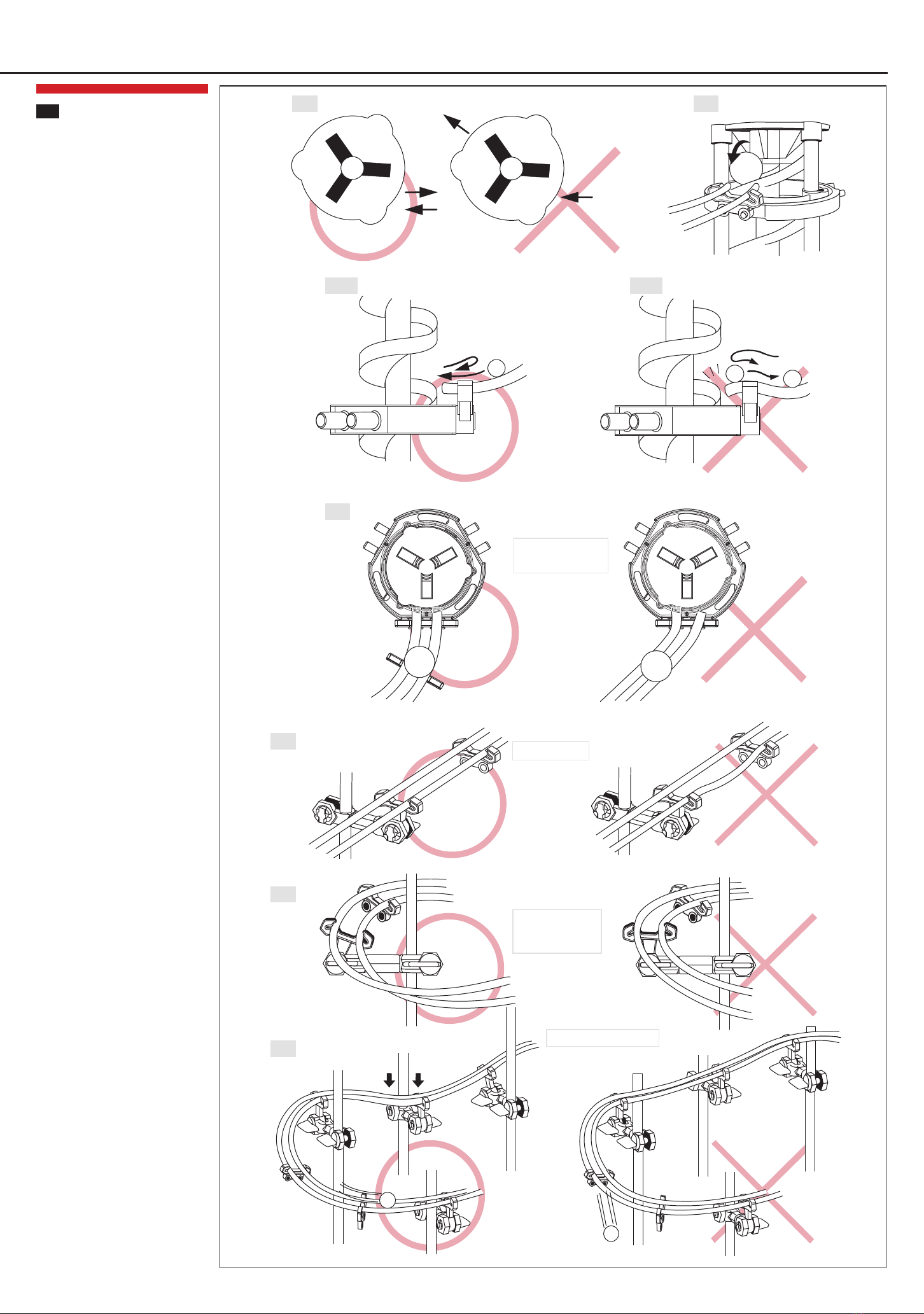

Installationofaloop

Ensurethe steel balls runningsmoothly

(fg.28)

Thediameter of the outer loopshould

havetwice thediameter of theinner loop

Important informationfor theassemblyof

loops (fg. 29)

Rails havetoformacircle that remains

inanupright positiontoensurethesteel

balls runningsmoothly(f g. 29)

Installationof aloop (f g. 30)

Whenmountingloops, thesecondloop

has to besmaller thanthef rst loop to

ensurethe steel balls runningsmoothly

Installationof pendulumtrayandjunction

(fg.31-1+31-2)

Insert rail stands into thejunction(fg.

31-1)

Simplycut therails to thecorrect length

(seeenlargedpictureontheright)

Insert rails into thependulumtray(f g.

31-2)

10

11

Assembly of rails

23 24

25

26

27

28 29 30

[A1] Arm

[R1] Rail

Insert rails intoarm

Install thearms inaninclinedposition

toeachothertocreatesteepsections

-

Pleaserefertotheillustrationabovefor

diameters of aquadloop (increasediameter

witheachadditional loop)

Userail stands likerailwayties

Thedistancebetweenthearms shouldbebetween8 to10cm. When

thedistanceis larger, rail stands [A6] havetobeinstalled

[R1] Rail [R1] Rail

[R2] Rail joining

Height

Innerlooping

Cut here

Innerlooping

Outer looping

[A6] Rail stand

[A6] Rail stand

[P1] Junction

[Ex7] Pendulumtrayfor steel balls

31-1

31-2

Installationofelevator(entry&exit)

Important informationfortheassemblyof

elevatorentryandexit (fg.32)

Steel balls will not runcorrectlyif entry

andexitpoint inthesamedirection

Payattentiontoa proper installationof the

entryandexit(fg.33)

Install rails as closelyas possibletothe

entryandexit of theelevator to ensurethe

steel balls runningsmoothly(fg. 33)

Payattentiontoa correct angleof therails

whenthesteel balls entertheelevator (f g.

34-1,34-2,35)

Makesurethesteel balls enter theelevator

slowly.Otherwisetheywill reboundandfall

off therails (fg. 34-1)

Steel balls that enter theelevator may

reboundandthownbackontotherails

afterhittingthehelix. Payparticular

attentionhereto thecorrect seatingof the

rails.Otherwisethesteel ballswill stopand

cannot re-entertheelevator(fg.34-2)

At theentryall rails must beat right angles

totheelevator(fg. 35)

Distancebetweenrails (fg. 36)

Install therail standtokeeprails parallel

(fg. 36)

Curves (fg. 37 +38)

Curves needtobeassembledinacertain

angletoprevent steel balls frommissing

theturn(fg. 37). If steel balls miss the

turn, speedhas to bereducedright before

thecurve

Adjust rails to reducespeed of thesteel

balls (fg. 38)

12

Entry

Entry

Exit

Exit

13

Assembly of rails

32 33

35

36

37

38

All rails must beat right

angles totheelevator

Keep rails parallel

Curves needto be

assembledina certain

angle

Adjust rails to reduce speed

34-1 34-2

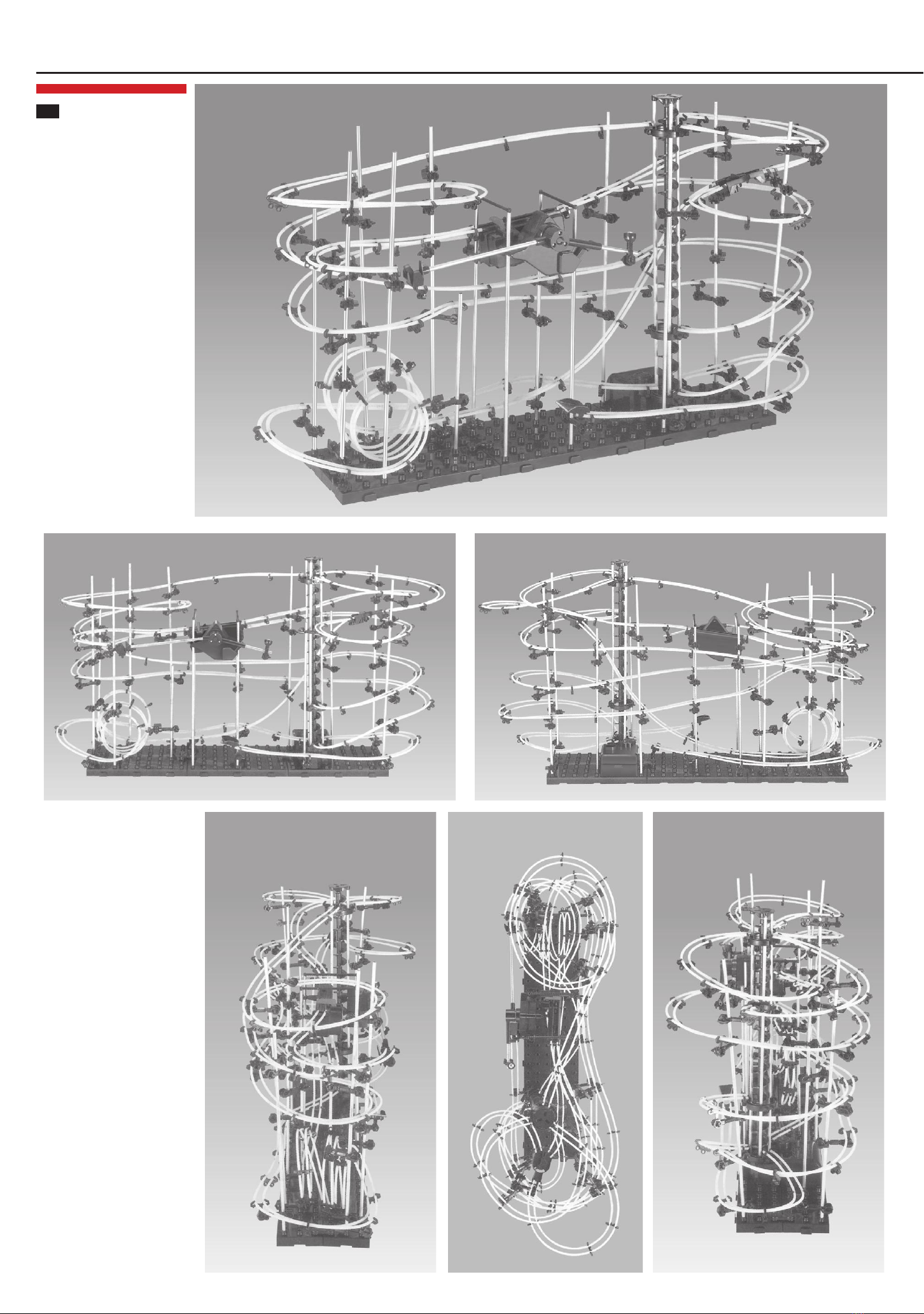

13 fg. 1 (diagonal)

fg. 2 (front)

fg. 4 (left) fg. 5 (top) fg. 6 (right)

fg. 3 (back)

14

Construct Your Own SpaceRail Designs

Construct your own

SpaceRail designs

Let the imagination run wild

and create your own

SpaceRail coasters.

Pictures 1-6 show another

alternative example with 6

base plates and the parts

from the Level 5.1.

Rail length16,000mm

Rail length10,000 mm

Rail length26,000mm

Rail length68,000 mm

Glowinthedark

15

Product Range

Level 2.1

Level 3.1

Level 4.2

Glow in the Dark

Level 9.1

Disposal Restrictions(WEEE)

Electrical andelectronicequipment shouldbedisposedseparatelyfromthehouseholdwaste. Takeyourunwantedequipmenttoyourlocal communitycollectionpoint. This requirement applies tomembercountries

of the EuropeanUnionas well as othernon-Europeancountries witha separate wastecollectionsystem. Neverthrowbatteries intonormal householdwaste, but disposeof discharged batteries at

thecollectionpoints providedforthat purpose(e.g. yourlocal toxicwastedisposal centre).

RecommendedAccessories: 1xC/LR14 battery1.5V

Insertingthebattery: Usea Phillips screwdriver toopenthebatterycompartment cover. Insert 1 xC/ LR14 batterywiththecorrect polarityandreplacethebatterycompartment cover.

Distributedby:

16

Safety Instructions – Keep After Reading

General SafetyInstructions

This ball roller coaster is NOTATOYandonlysuitablefor persons 14 years and older!

Warning: Readthemanual carefullybeforeusingtheball rollercoaster. Keepthemanual afterreading.

Always followexactlytherecommendations givenintheinstructions.

Errors and negligences inoperatingyour ball roller coaster canresult ininjuries and damageto

property. As manufacturers andvendors haveno inf uence ontheoperationand maintenanceof your

ball roller coaster, webringthesehazards expresslyto your attentionbut denyall further liability.

Keepawayfromchildren. Theball rollercoastercontains small parts. Chokinghazard.

Warning: Sharp edges - watchyour fngers.

Warning: Donot drapetherail around your neck, as this couldresult insuffocationor injury.

Strangulationhazard.

Keep thepackagingfor futurereferenceas it contains important information.

SafetyInstructionsDuringOperation

Movingparts area constant source of injury. Nevertouchmovingparts.

Keep hands, hair, looseclothingandfurther objects awayfrommovingparts.

Persons (includingchildren) withreducedphysical, sensoryor mental capabilities or lackof experience

arenot allowedtousethis ball roller coaster, unless theyaresupervisedbya personresponsiblefor

their safetyandabletogiveprofessional advicehowtheproduct shouldbeused.

Donot bendtheshafts and other parts to avoid injuryandensure safeoperation.

Keep fngers awayfromthemovingelevator toavoidinjury.

Onlyuseoriginal steel balls topreventdamageof theball rollercoaster.

Caution: Violent jamming(stopping) duringoperationmaydamagethemotor. Donot cumberthe

elevator.

Always storeand operatetheball roller coaster at asafeplace.

Besuretocheckbatteryregularlyto ensure aproper operationof theelevator.

Checkrails regularlyfor af rmseatingandadjust if necessary!

Protecttheball rollercoaster fromheatandsun.

Caution: To protect motor fromdamageandoverheating, donot operatethe ball roller coasterfor more

than 5hours at atime.

SafetyInstructionsForBatteries

Onlybatteries of thesameor equivalent typeas recommendedareto beused.

Exhaustedbatteries shouldberemovedfromtheball roller coaster.

Donot disposebatteries infre– batteries will explodeor leak.

Batteryis to beinsertedwiththecorrect polarity.

Non-rechargeablebatteries arenot tobe recharged.

Remove batteryif the ball roller coaster is not tobeusedfor anextendedperiodof time.

Besuretocheckbatteryregularlyto ensure aproper operationof theelevator.

Table of contents

Other SpaceraiL Toy manuals

Popular Toy manuals by other brands

Oregon Scientific

Oregon Scientific Smart Globe Discovery SG268 manual

Power Wheels

Power Wheels Jeep Safary 86250 Assembly manual

LEGO

LEGO Mindstorms NXT 8527 Building instructions

Fisher-Price

Fisher-Price iXL instructions

GRAUPNER

GRAUPNER POWERKAT X operating instructions

Protos

Protos MAX2 instruction manual

Mega Bloks

Mega Bloks SABAN'S Power Rangers MEGAFORCE Robo Knight VS.... Assembly instructions

Fisher-Price

Fisher-Price LOVING FAMILY H5790 instructions

Betzold

Betzold Kiga-Konstruktion 761415 manual

Twister

Twister Micro Twister quick guide

miniland

miniland emotions buddy manual

Mattel

Mattel HotWheels FTH79 instructions