SpaceraiL Spacewarp Level 2.1 User manual

Instruction Manual Level 2.1

SpaceRail Level 2.1

2

Table of Contents

Figure1............................................P. 2

Figure2-6.........................................P. 3

PartsList..........................................P. 4

Assemblyofthebaseplate............P.4

Assemblyofthearms......................P.4

Assemblyoftheseesaw..................P. 4

Assemblyoftheelevator.................P. 5

Assemblyofshaftsandarms.....P. 6-7

Installationofbaseplateandshafts........P.6-7

Installationofgearbox...............................P. 6-7

Rail assemblysteps.....................................P. 8

Rail mounting...........................................P. 9-10

Loopmounting............................................P. 11

Elevatormounting(entryandexit).............P. 11

Warnings.....................................................P.12

SpaceRail is a spectacular marble roller coaster that guarantees high-speed action rides

consisting of wild rotations, daring loops and seesaw swivel stunts. These marble roller

coasters are an ultimate challenge for teenagers and adult enthusiasts alike. They are

available in different sizes and with different levels of difficulty.

SpaceRail

Level 2.1

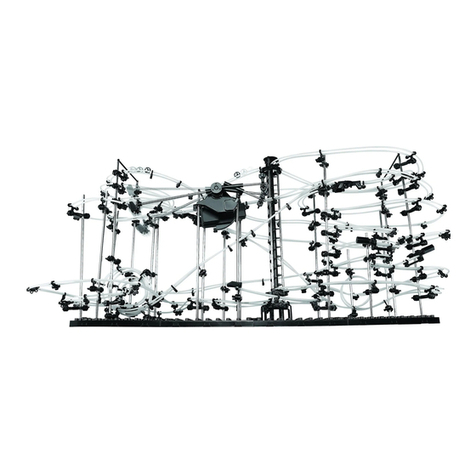

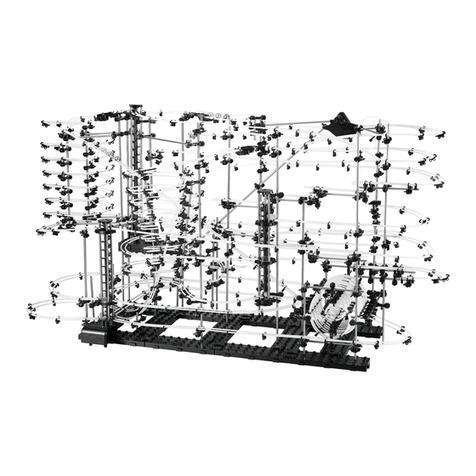

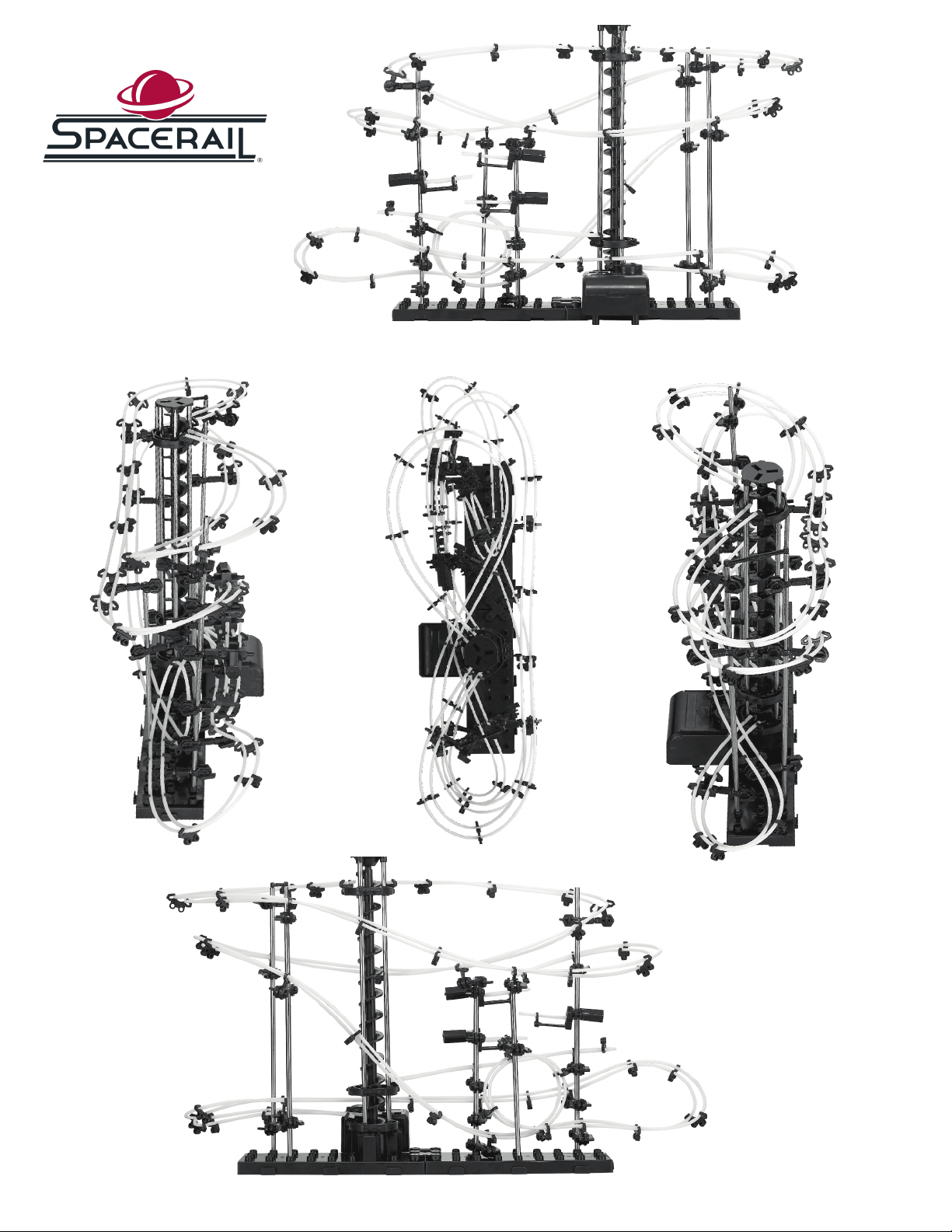

These images show the fully built model of Spacerail Level 2.1. Correct fitting and interaction of all

components and connections has a significant influence on the stability and strength of the complete

construction.

SeeSaw Stunt Loop Elevator

3

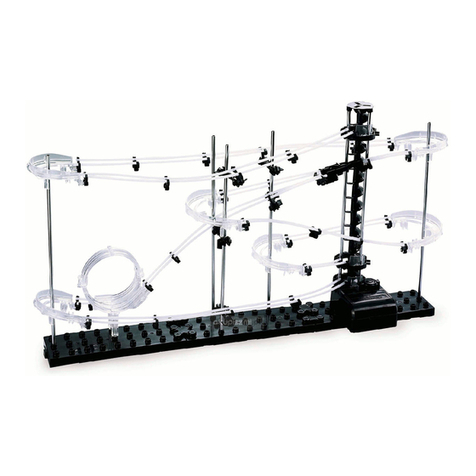

These images show the

SpaceRail Level 2.1 from

multiple angles. They will

be helpful while you are

building.

Front

Left Top Right

Back

Use1 xC/ LR14 battery(notincluded). Handlethecomponents with careto prevent themfromgettinglost.

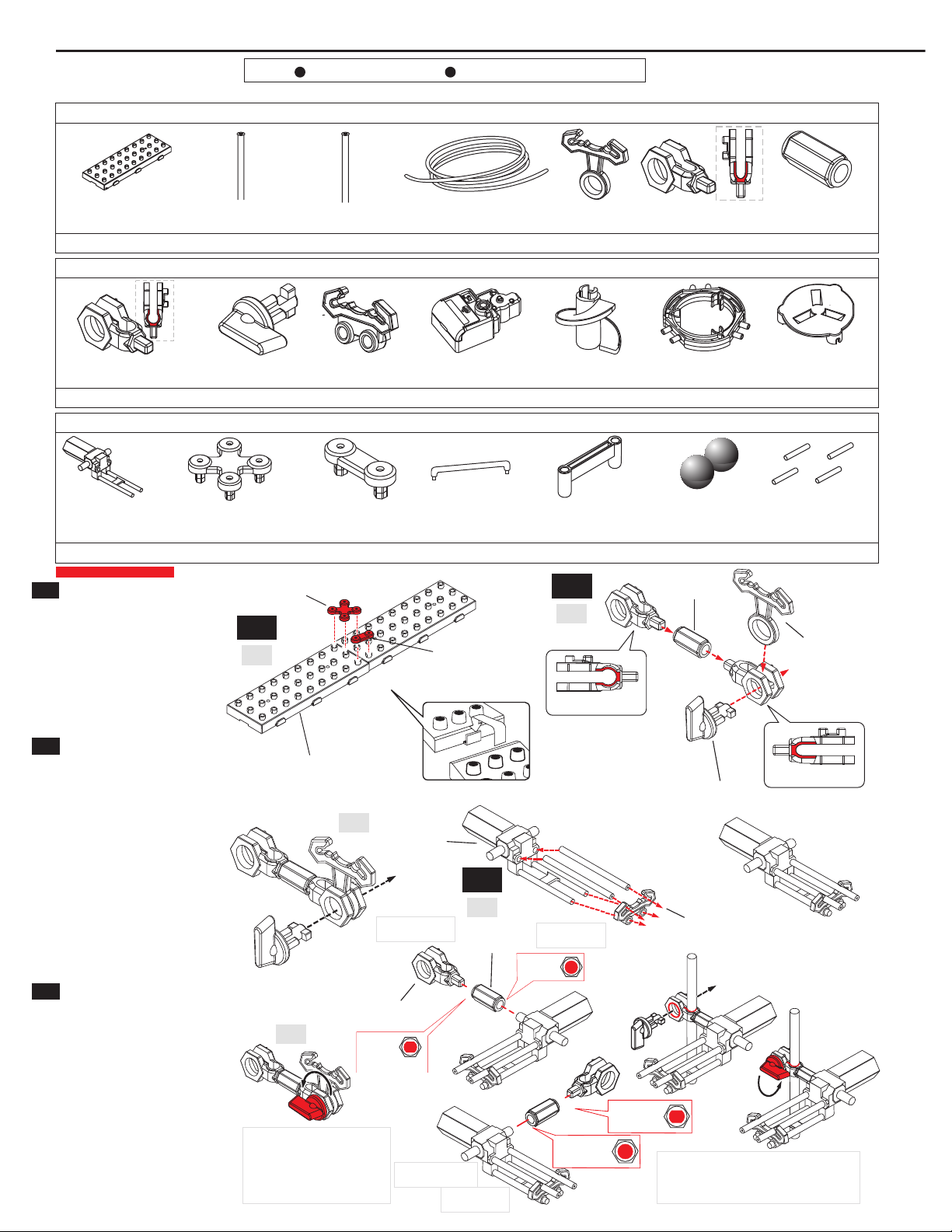

Partslist

4

[B1]

[A4]

[F1] [B2] [B3] [S3] [G2] [R2]

[A6] [G1] [E1] [E2] [E3]

[A5]

[S1] 300mm [S2] 200mm [R1] 10.000mm [A1] [A2] [A3]

[B1] Baseplate

[A4] ArmholderB

[F1] Seesaw

[A5] Armwrench

[B2] Baseholder(big)

[A6] Rail stand

[B3] Baseholder (small)

[G1] Gearbox

[S3] Connectingpiece

[E1] Elevator helix

[G2] Gearboxsocket

[E2] Elevatorring

Steel balls

[E3] Elevator cover

[R2] Rail joining

[S1] Shaft 300mm [A1] Arm[S2] Shaft 200mm [R1] Rail 10,000mm [A2] Armholder A [A3] Armtube

2x

20x

3x

7x

37x

1x

2x

40x

1x

1x

1x

1x

17x

12x

1x

17x

3x

2x

20x

1x

4x

[B2] Baseholder (big)

[B3]Baseholder(small)

[F1] Seesaw

[A4] ArmholderB

[A3]Armtube

[A6] Rail stand

Note: Whenturningthearmwrench, makesurenot to

changetheright position of thearm

Install 2pcs

Mount lefthandside

Note: Whenturningthearmwrench,

makesurenot tochangetheright

positionof the arm

Approx. 55mm

[A5] Armwrench

[A1] Arm

[A4] ArmhalterB

[A4] Armholder B

Holeprofle

Holeprofle

Holeprofle

Holeprofle

[A2] ArmhalterA

[A2] Armholder A

Top-downview

Top-downview

[A3] Armtube

[B1] Baseplate

-

-

Assemblyof baseplate

1. Assemblethebaseplate(6 pieces).

Payattentiontoa proper seatingof the

clips and slots (f g. 01)

2. Fastenthebaseholders (B2 +B3) inthe

correct positions (f g. 01)

1

2

3

01

02

03

04

05

1

2

3

Assemblyof arms

1. Assemblethearms accordingto f g. 02.

Caution: Armholder A(A2) +armholder B

(A4) aredifferent. 17 arms areneeded for the

completeset-upof „Star Coaster Level 2“

2. Insertthearmwrenchintothearmholder

Aand turnit by90 degrees to f xthe arm

(f g. 03)

Note:Tomodifytheangleofthearm, releasethe

fxationfrst

Assemblyof seesaw

1. Inserttheseesawinto therail stand

(f g. 04)

2. Inserttheseesawinto armholder B, then

attachthecompletecomponent tothe

shaft(fg. 05). Refer totheassemblyof

arms (f g. 02+03). Note: To modifythe

angleof thearm, release the fxation frst

Mount righthandside

Install 1pc

Parts List

Tools for installation Pliers Tape Measure

5

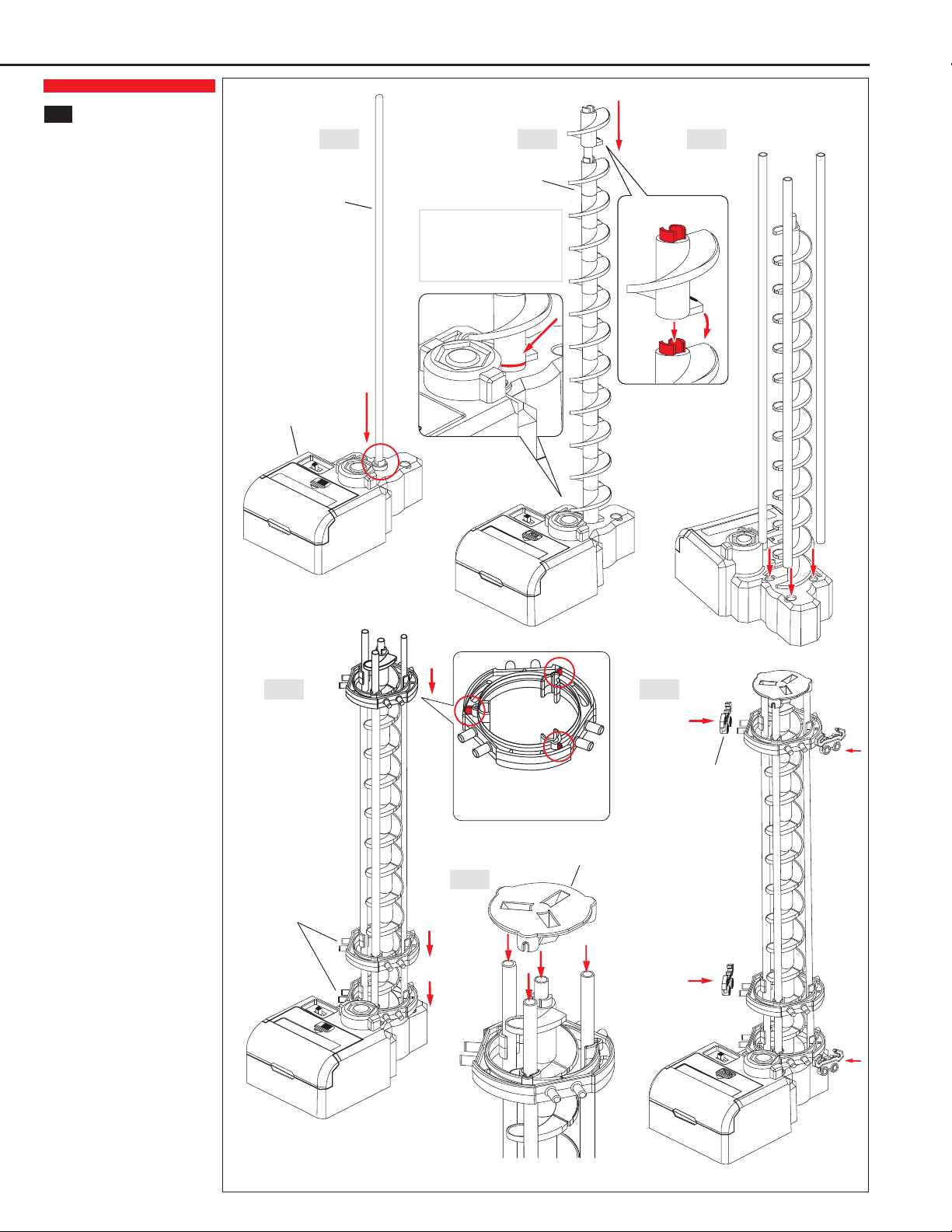

Assemblyoftheelevator

1. Insert the300mmshaftintothe

gearbox(fg. 06-1)

2. Slidetheelevator(12pcs) onto

the300mmshaft(fg. 06-2

Pleasenotethecorrectdirection

of rotation

3. Insert 3 further300mmshafts

intotheexact pre-defned

positionsonthegearbox(fg. 06-3)

4. Allowthe3 shafts tosnap into

place(pic. 06-4). Takecarethat

theelevator rings areproperly

located

Seepages 6+7 fortheproper

locations of theelevatorrings

5. Insert the4 shafts into the

elevatorcover (fg. 06-5). Take

carethat theshafts are properly

located

6. Nowattach3 rail stands [A6] to

theelevatorring(fg. 06-6)

06-1 06-2 06-3

06-4

06-5

06-6

4

[S1] Shaft 300mm

[E1] Elevator helix

[S1] Shaft 300mm

Pleasenotethecorrectdirection

ofrotation

Makesureconvexred parts point up

and everythingis correctlyseated

Assembly of the elevator

[G1] Gearbox

[E2] Elevator ring

[E3] Elevator cover

[A6] Rail stand

[A6] Rail stand

Avoidthat there is a gap between

gearboxandelevator helix. Otherwise

theelevatorwill not operateproperly

6

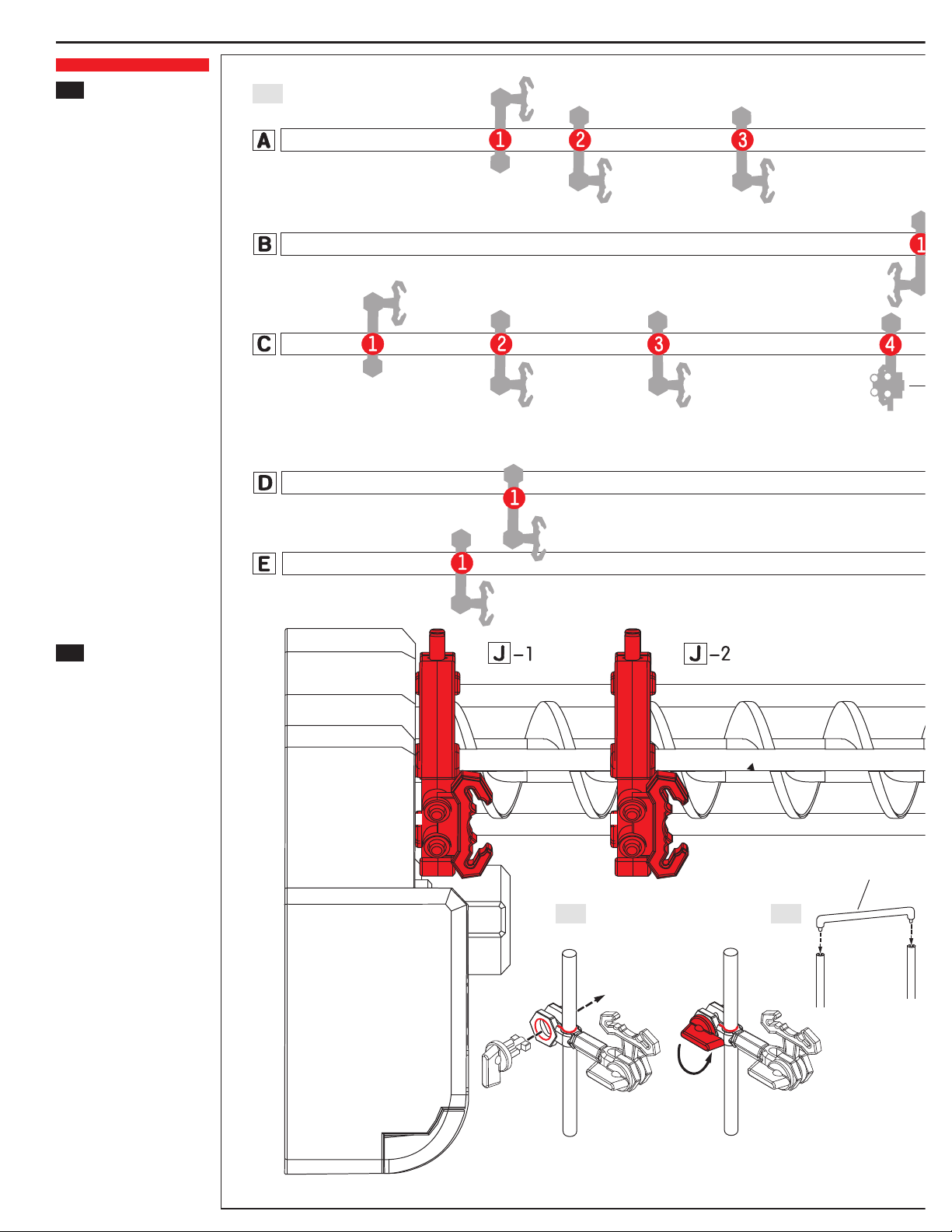

Installationofbaseplate,

shaftsandgearbox

Inserttheshafts(fg.07)intothe

baseplate(fg. 11, A-E)

Pleasenotethecorrectdirections

ofshafts

Attachthe3clipsatthebottom

ofthegearbox(seeredmarkings

infg.10)totheexactpre-defned

positionsofthebaseplate(fg.11)

Installationofshaftsand

arms

Attachthearmstotheshaft

(fg.07showsascaleof1:1)

Positionsofarms(fg.07):

Shaftsareshowninascale

of1:1.Attachthearmstothe

exactpre-defnedredpositions.

Pleasenotethecorrectorderand

directionsofarms

Inserttheshaftintoarmholder

B.Insertthearmwrenchintothe

armholderBandturnitby90

degreestofxthearm(fg.08)

Note: Tomodifytheangleofthe

arm, releasethefxationfrst

Attachtheconnectingpieces

[S3]totheshafts(fg. 09)

Pleasenotetheexactpre-defned

positionsoftheshaftsonthe

baseplate(fg. 11)

5

6

[S3] Connectingpiece

Note: Whenturningthearmwrench, makesurenot tochangetheright

positionof thearm

07

08 09

7

[G1] Gearbox

Back

Front

[G2] Gearboxsocket

Elevator

Positionforconnectingpiece[S3]

[S1] Shaft 300mm

[S1] Shaft 300mm

[S1] Shaft 300mm

[S2] Shaft 200mm

[S2] Shaft 200mm

Pleasenotethecorrect positions anddirections of arms (seeabove)

Seesaw(mountlefthandside) Seesaw(mountlefthandside)

Seesaw(mountrighthandside)

Back

Armposition Seesawposition

Down Up

Front

Connect withholes onbase

plate

Assembly of shafts, arms, gearbox and base plate

10 11

8

Rail connectionmarks

Releasearmtube[A3]beforemountingtherails

Lettersandnumbers(e.g. D-2)showthecorrect

positionsofshaftsandarmsdescribedonpage6-7

Loop(enlargedpicture)

Fromseesawexit(start) toelevatorentry:

Install 2x26cmrails (fg. 13-1)

Insert rail standattheendof

therail toensurebestseesaw

stability

Simplycut therails tothedesiredlength(seepage9: Rail joining)

Rail assemblysteps

Thisballrollercoasterprovides2elevatorexits(start)

and2elevatorentries(end).Pleasenotefg.12+13

andthepicturesonpage2+3duringassembly

Installrailstandstogetherwiththerails(page9)

Duetothelongdistance, theinstallationof this

sectionis dividedinto2 assemblysteps(please

refertofg. 12-1+12-2)

Fig.12-1and12-2showtheupperandlowertracklayout

Fig. 12-1: Fromelevator exit (start) totheloopentry

Fig. 12-2: Fromloopentrytolower elevator entry

Install 2 x245cmrails forthecompletedistance

infg. 12-1+12-2

Theenlargedpictureprovides furtherinformation

regardingloopinstallation

Fromelevatorexit (start) toseesawentry: Install 2x

105cmrails (fg. 13-2)

Fig.13-1and13-2showtheupperandlowertracklayout

Note:Fig.27onpage11providesfurtherassistanceif

thesteelballsdonotrunsmoothlyintotheelevator

7

12-1

12-2

13-1

14

13-2

Seesaw(enlargedview)

Correctseesawinstallation

Assembly of the rails

Don´tcut

Don´tcut

9

[R1] Rail

[R1] Rail

[R1] Rail

[A1] Arm

[R2] Rail joining

Insert rails intoarm

Userail stands likerailwayties

Install thearms inaninclinedpositiontoeachother tocreatesteepsections

Thedistancebetweenthearms should bebetween8 to 10cm.

Whenthedistanceis larger, rail stands [A6] havetobeinstalled

815

17

18

19

16

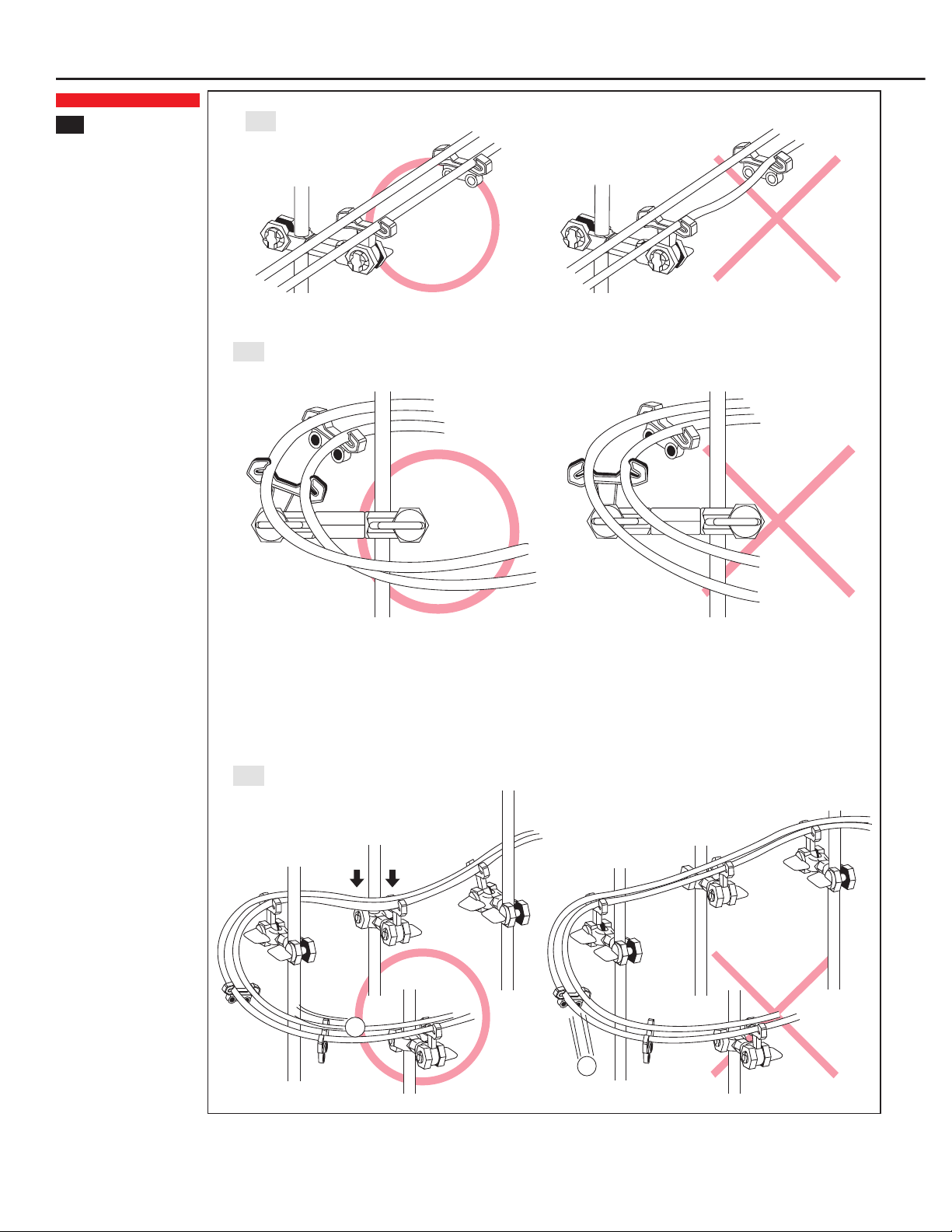

Installationoftherails

Inserttherails intothearms

(fg. 15+16)

Rail joining(fg. 17)

Adjust andconnecttherails.

Inserttherail joinings [R2] into

theholes atthecenterof the

rails (fg. 17)

Informationabout rail stands

(fg.18)

Thedistancebetweenthe

arms shouldbebetween8 to

10cmtoensurebeststability.

Whenthedistanceis larger,

rail stands [A6] havetobe

installed

Attachrail stands insteep

sections and elevatorentry/

exit points to ensurebest

stabilityof therails

Steepsections (fg.19)

Install thearms inaninclined

positiontoeachotherto

createsteepsections,so

that thesteel balls canrun

smoothly(fg.19)

Assembly of the rails

10

Assembly of the rails

Keeprails parallel

Curves need to beassembled ina certainangle

Adjust rails toreducespeed

20

21

22

8

Installationoftherails

Distancebetweenrails

(fg. 20)

Install therail standtokeep

rails parallel

Curves(fg. 21+22)

Curvesneedtobeassembled

inacertainangletoprevent

steel ballsfrommissingthe

turn(fg.21). Ifsteel balls

miss theturn,speedhastobe

reducedrightbeforethecurve

Adjust rails toreducespeed

of thesteel balls (f g. 22)

11

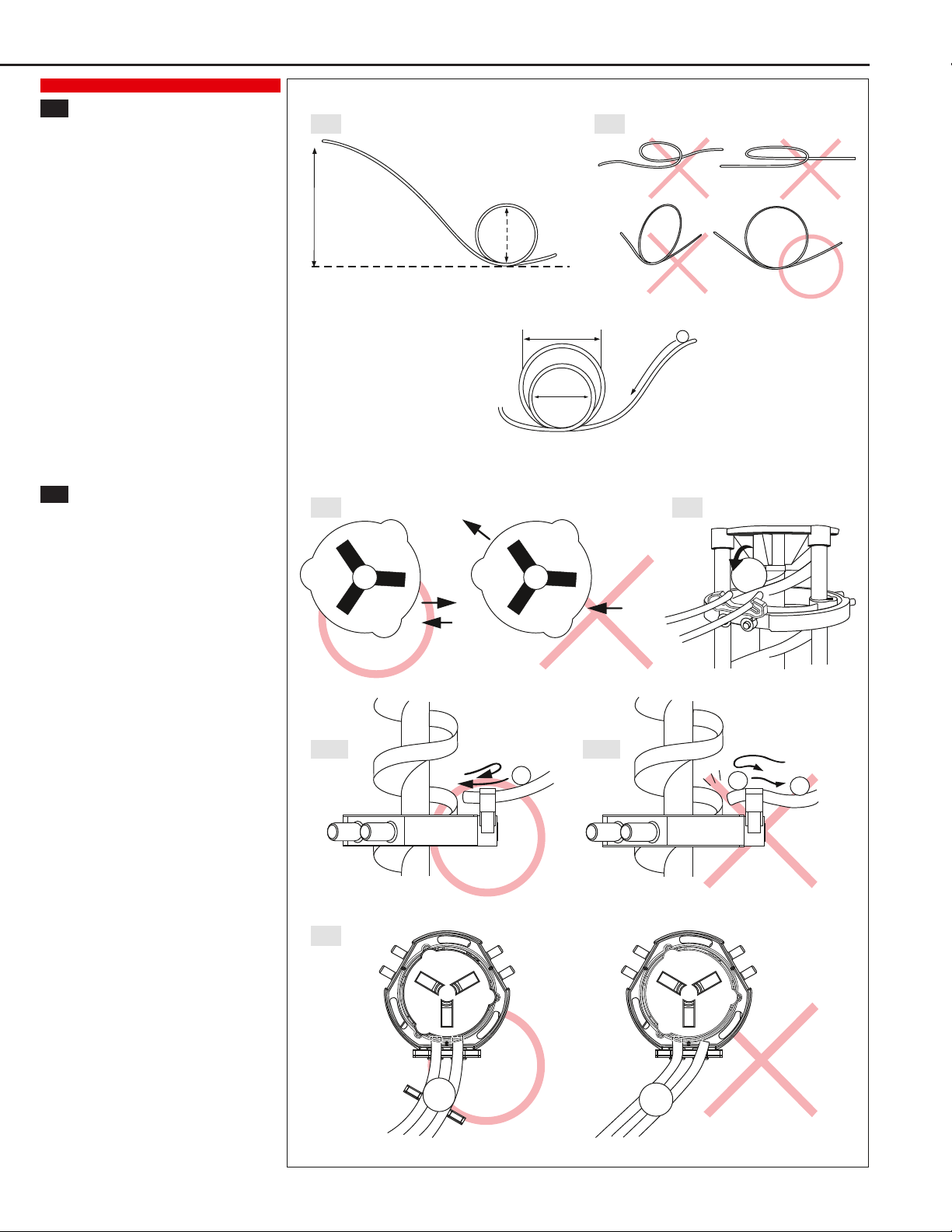

Installationofaloop

Ensurethesteelballsrunningsmoothly(fg. 23)

Thediameter of theouter loop shouldhavetwice

thediameter of theinner loop

Important informationfortheassemblyof loops

(fg. 24)

Rails haveto formacircle that remains inan

upright positionto ensurethesteel balls running

smoothly(fg. 24)

Whenmountingloops, thesecond loop has tobe

smaller thanthefrstlooptoensurethesteel balls

runningsmoothly

Installationofelevator(entry&exit)

Important information fortheassemblyof elevator

entryandexit (fg. 25)

Steel balls will not run correctlyif entryand exit

point inthesamedirection

Payattentionto aproperinstallationof theentry

andexit(fg. 26)

Install rails as closelyas possibletotheentryand

exit of theelevatorto ensurethesteel balls running

smoothly(fg. 26)

Payattentiontoacorrect angleoftherails whenthe

steel balls entertheelevator(fg. 27-1, 27-2, 28)

Makesurethesteel balls enter theelevatorslowly.

Otherwisetheywill rebound andfall off therails

(fg. 27-1)

Steel balls that enter theelevatormayrebound and

thownbackonto therails after hittingthehelix.

Payparticularattentionheretothecorrect seating

of therails. Otherwisethesteel balls will stopand

cannot re-enter theelevator(fg. 27-2)

At the entryall rails must beat right angles tothe

elevator(fg. 28)

Assembly of the rails

Loopdiameter

Height

Entry

Entry

Exit

Exit

Pleaserefer tothepictureabovefor thecorrect diameter of theinner loop

All rails must beat right angles to theelevator

23

25

28

26

27-1 27-2

24

9

10

12

Safety Instructions – Keep After Reading

General SafetyInstructions

This ball rollercoaster is NOTATOYandonlysuitablefor persons 14 years and older!

Warning: Readthemanual carefullybeforeusingtheball rollercoaster. Keepthe manual afterreading.

Always followexactlytherecommendations given in the instructions.

Errors and negligences inoperatingyour ball roller coaster can result ininjuries and damageto

property. As manufacturers andvendors haveno infuence onthe operation andmaintenance of your

ball roller coaster, webringthesehazards expresslyto your attention but denyall further liability.

Keepawayfromchildren. Theball rollercoastercontains small parts. Chokinghazard.

Warning: Sharp edges - watchyour fngers.

Warning: Do not drapetherail around your neck, as this couldresult insuffocation or injury.

Strangulationhazard.

Keep thepackagingfor futurereferenceas it contains important information.

SafetyInstructionsDuringOperation

Movingparts are aconstant sourceof injury. Never touch movingparts.

Keep hands, hair, loose clothingandfurther objects awayfrommovingparts.

Persons (includingchildren) with reducedphysical, sensoryor mental capabilities or lackof

experience arenot allowedto usethis ball roller coaster, unless theyaresupervisedbya person

responsiblefortheirsafetyandabletogiveprofessional advicehowtheproduct shouldbeused.

Do not bend the shafts and other parts to avoidinjuryand ensuresafe operation.

Keep fngers awayfromthemovingelevator to avoidinjury.

Onlyuseoriginal steel balls topreventdamageof theball roller coaster.

Caution: Violent jamming(stopping) duringoperationmaydamagethemotor. Do not cumber the

elevator.

Always storeandoperatetheball roller coaster at a safeplace.

Besure to checkbatteryregularlyto ensure aproper operationof theelevator.

Checkrails regularlyfor af rmseatingandadjust if necessary!

Protect theball roller coaster fromheatandsun.

Caution: Toprotect motorfromdamageandoverheating, do not operatethe ball rollercoasterformore

than 5hours at atime.

SafetyInstructionsForBatteries

Onlybatteries of thesameor equivalent typeas recommendedareto beused.

Exhausted batteries shouldbe removed fromtheball roller coaster.

Do not disposebatteries inf re – batteries will explodeor leak.

Batteryis to beinsertedwiththecorrect polarity.

Non-rechargeablebatteries arenot toberecharged.

Removebatteryif theball roller coaster is not to beusedfor anextended period of time.

Besure to checkbatteryregularlyto ensure aproper operationof theelevator.

Disposal Restrictions(WEEE)

Electrical and electronic equipment shouldbedisposedseparatelyfromthe householdwaste. Takeyour unwanted equipment to your local communitycollectionpoint. This requirement applies tomember

countries of theEuropeanUnionas well as other non-Europeancountries witha separatewastecollectionsystem. Never throwbatteries into normal householdwaste, but disposeof dischargedbatteries at the

collectionpointsprovidedforthat purpose(e.g. yourlocal toxicwastedisposal centre).

RecommendedAccessories: 1 xC/LR14 battery1.5V

Insertingthebattery: Usea Phillips screwdriverto openthe batterycompartment cover. Insert 1 xC/ LR14 batterywiththecorrect polarityandreplace the batterycompartment cover.

Distributedby:

SpaceRails LLC, 1910 West 1040 South, Salt Lake City, UT, 84104 - 801.486.6837 - www.spacerails.com

Table of contents

Other SpaceraiL Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price M9972 instruction sheet

Eduard

Eduard Stryker Blast panels quick start guide

Rapido Trains

Rapido Trains british rail APT-E user manual

LEGO

LEGO 31034 CREATOR Assembly guide

REVELL

REVELL MESSERSCHMITT Me 410 B-6 / R-2 manual

Accucraft trains

Accucraft trains UNION PACIFIC 4-8-8-4 BIG BOY instruction manual