Spartan Equipment SKID-PAC 1000 User manual

TECHNICAL MANUAL

SKID-PACTM

1000

&

1000B

Technical

Manual

573936

Rev

09nov

READ THIS MANUAL BEFORE OPERATING

Read, understand and follow carefully the operating and safety instructions in

this manual to ensure safe and efficient operation of the Spartan Equipment.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

i

SAFETY

MESSAGES

Be Alert to Safety Messages

Safety messages appear throughout this

manual and on decals affixed to the Spartan

Equipment. Read and understand the

information contained in the safety message

before attempting to install, operate, service

or transport the Spartan Equipment.

All safety messages affixed to the

Spartan Equipment must be legible.

Replace damaged or missing decals.

Purpose of Safety Messages

The information provided in the safety

message is important for your safety. These

messages provide instructions on how to

avoid injury from potential hazards

associated with improper use, operation or

handling of the Spartan Equipment. Read

and follow the instructions of each safety

message and be aware the consequence if

these instructions are not followed.

Safety messages are arranged to provide

the following information:

Alert personnel to potential hazards

Describe the severity of the hazard, if

encountered

Identify the nature of the hazard

Instruct how to avoid the hazard

Safety Alert Symbol

ATTENTION, BECOMEALERT, YOUR

SAFETY IS INVOLVED.

The exclamation point within an equilateral

triangle is the safety alert symbol. The

symbol is used to draw attention to the

presence of potential hazards.

Signal Words

“DANGER”, “WARNING” and “CAUTION”

are signal words used to express the

different degrees of hazard seriousness.

Learn to recognize and understand the

severity and consequence associated with

each of these signal words should a

potentially hazardous condition be

encountered.

“DANGER”identifies the highest degree of

hazard seriousness. Its use is limited to the

most extreme situations.

DANGER - Indicates an imminent hazard,

which, if not avoided, will result in death or

serious injury.

WARNING - Indicates an imminent hazard,

which, if not avoided, can result in death or

serious injury.

CAUTION - Indicates hazards which, if not

avoided, could result in serious injury or

damage to the equipment.

Additional Precautionary Messages and

Instructions

Additional precautionary messages and

instructions found in this manual are

preceded with –“IMPORTANT” and

“NOTE”.

IMPORTANT - indicates instructions that if

not followed, may cause damage to the

equipment.

NOTE –Indicates instructions that highlight

suggestions, which will result in enhanced

installation, reliability, or operation.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

ii

Safety Message Overview

In this manual, safety messages will

precede any task that may involve a

potentially hazardous condition. The

following is a sampling of potential hazards

that can arise during installation, operation,

maintenance and transport of the Spartan

Equipment attachment. It is not intended to

be all- inclusive.

CAUTION

Read, understand and

follow the instructions

provided by the

manufacturer of the

associated equipment

used to power this

Spartan Equipment for

any additional safety

precautions.

CAUTION

Keep personnel away from

the equipment while in

operation. Never operate

the Skid-Pac with workers

in close proximity to the

compactor.

CAUTION

Noise Hazard. Exposure to

high noise levels may

cause hearing loss. Wear

hearing protection when

operating the Skid-Pac.

CAUTION

Risk of eye injury from

flying debris. Wear eye

protection when operating

or servicing the Skid-Pac.

CAUTION

Burn hazard. Hydraulic

components,

including

the motor, hoses and

valve become hot during

operation Avoid contact

with hot parts.

CAUTION

To avoid the risk of

injury, wear protective

equipment, including

appropriate clothing,

gloves, safety eyewear

and shoes when

handling the Skid-Pac.

CAUTION

Fluid penetration hazard.

Pressurized oil can

penetrate skin. Never use

hands to locate leaks.

Use cardboard. Regularly

inspect hoses for cuts

and other signs of

damage. Replacement

hoses must be the same

type and pressure rating.

CAUTION

Falls into open

excavations can cause

serious injury.

Establish pedestrian

barriers. Ground

vibrations may

collapse trench walls.

Excavations must be

shored to meet federal,

state and local

guidelines.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

3

CAUTION

Crush hazard. Instruct

machine operator to

move controls only when

directed by

the

equipment installer.

Keep hands and fingers

clear of moving parts and

pinch points while

equipment is being

positioned.

WARNING

Shock or explosion

hazard. Cutting a utility

line could

cause

serious

injury. Use

extreme caution when

working around electric

and gas lines. Locate

existing underground

service and utility lines,

before starting

operation.

WARNING

Crush hazard. Injury may

result if the Skid-Pac

shifts or falls. Do not lift

the Skid-Pac by the

mounting pins or whip

hose. The LIFT POINT

decal identifies the

recommendedlifting

points. Lifting devices

must safely carry the

loads to which they will

be subjected. Lift away

from people. Do not

enter the danger zone

while compactor is being

lifted.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

4

SAFETY and RESPONSIBILITY

Before Operating Any Equipment

Read the Manual

This manual contains important

information for the safe and proper use of

the Spartan Equipment attachment. Read

and understand thoroughly all instructions

and safety precautions described in this

manual before installing, operating or

servicing the Spartan Equipment.

AND

Read and follow the instructions provided

by the manufacturer of the associated

equipment used to power this Spartan

Equipment attachment for any additional

safety precautions.

Qualified Person

For the purposes of this manual and product

labels, a qualified person is one who:

Has read, understands and adheres to

the safety messages in this manual.

Is able to recognize the

possible

dangers

of potential hazards and take

appropriatemeasures to safeguard

against personal injury and property

damage.

Has received adequate training in safe

and proper installation, maintenance

and operation for this Spartan

Equipment.

Is authorized to operate, service and

transport the Spartan Equipment.

Spartan Equipment cannot anticipate every

possible circumstance that might involve a

potential hazard. The warnings in this

manual and labels affixed to the Spartan

Equipment attachment are therefore not all

inclusive.

Owner’s Responsibilities

The equipment owner is responsible to

ensure that only qualified personnel operate

and service the Spartan Equipment

attachment.

Qualified personnel must adhere to the

procedures explained in this manual,

especially regarding personnel safety.

If necessary, the owner or safety/training

personnel must expand upon these general

instructions and adapt them to particular

applications.

General Construction Safety

Always follow procedures that promote safe

conditions for workers and bystanders. The

standard safety precautions expected and

required of those working in construction

shall include, but not limited to: locating

existing underground service and

utility

lines,

establishing pedestrian barriers and

using personnel protection equipment, etc.

Federal, State, Local and OSHA

Construction Guidelines and

Regulations

Use the Spartan Equipment in accordance

with all federal, state and local regulations

regarding construction practices and public

safety. Identification of, and compliance to,

governing regulations are the responsibility

of the owner and operator.

In the United States, comply with the

recommendationsof the Occupational

Safety and Health Administration standards

of the U.S. Department of Labor. For OSHA

construction guidelines contact your local

federal government office or write:

U.S. Government Printing Office

Superintendent of Documents P.O. Box

371954 Pittsburgh, Pa. 15250-7954

www.osha.gov

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

5

Ask for Construction Industry OSHA

Standards Stock #869-034-00107-6.

Operational Safety Program

The safe and effective use of the Spartan

Equipment attachment depends upon

proper installation, operation, maintenance

and repair. Operational safety must

encompass all of these factors.

Accident prevention through operational

safety programs must be further developed

by the equipment owner and tailored to

meet specific site conditions and

applications.

Developing such programs will result in

improved equipment life, performance and

reduced downtime. Most importantly, it will

minimize the risk of personal injuries and

equipment damage.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

6

TABLE OF CONTENTS

SECTION Pg.

SAFETY MESSAGES…..………… i

Be Alert to Safety Messages……….… i

Purpose of Safety Messages……….… i

Safety Alert Symbol ..…………..……… i

Signal Words –“DANGER”,

“WARNING” and “CAUTION”………… i

Additional Precautionary Messages…. i

SAFETY MESSAGE OVERVIEW ii

SAFETY and RESPONSIBILITY iv

Before Operating Any Equipment…..... iv

Qualified Person…………….…..……… iv

Owner’s Responsibilities……….….…… iv

General Construction Safety……….…. iv

Federal, State, Local and OSHA

Construction Guidelines and

Regulations……………….……….……. iv

Operational Safety Program………….. v

TABLE of CONTENTS……..…….. vi

LIST of FIGURES…………..…...… vii

DOCUMENT REVISIONS………… ix

1.0 INTRODUCTION..……..……… 1

1.1 About This Manual………….……… 1

1.2 Additional Publications….……….... 1

2.0 EQUIPMENT

IDENTIFICATION…………….. 2

2.1 Serial Number Location.………..…. 2

2.2 Equipment Identification Plate….… 2

2.3 Record the Serial Number……..….. 2

3.0 WARRANTY PROTECTION

SUMMARY…………..….….…..

3

3.1 Overview…….……………….…….. 3

SECTION Pg.

3.2 Owner’s Responsibilities……..…... 3

3.3 Spartan Equipment Product

Policies……………... 4

4.0 EQUIPMENT OVERVIEW……. 5

4.1 Product Description and

Application……………………..……

5

4.2 Major Subassemblies………..……. 5

5.0 Principle of Operation………. 6

5.1 Skid-Pac…………………………… 6

5.2 Definition of Hydraulic Installation

Terms…………………………….…

6

6.0 Technical Information…. 8

6.1 Specifications……….…………….. 8

6.2 Dimension Diagrams……….…….. 9

6.3 Identification and Safety Labels….. 13

7.0 Mounting Information……….. 16

7.1 Skid-Pac Mounting…………..….…. 16

8.0 Installation & Removal……… 18

8.1 Carrier Compatibility……….….…… 18

8.2 Testing and Adjusting……….…….. 18

8.3 Installation on to Carrier…….…….. 18

8.4 Removal from Carrier……..…..…… 20

9.0 Operation..…………..………… 21

9.1 Pre-operation Checks…………..… 21

9.2 Operation…………………………... 21

10.0 Troubleshooting……..……... 24

11.0 Service and Maintenance…. 25

11.1 General Guidelines………….…… 25

11.2 Daily Maintenance…………...…… 25

11.3 Preventative Maintenance……..…26

11.4 Threaded Fasteners………....…… 26

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

vii

SECTION

11.5 Conditional Maintenance…………

Pg.

26

11.6 Pressure Relief Plug………………

26

11.7 Lubrication (1000B)..…………...…

25

11.7.1 Lubrication (1000 Only)...………

25

11.7.2 How to Check & Add Oil…….….

27

11.7.3 How to Drain Oil…………………

27

11.8 How to Check Bearings…..…...….

27

11.8.1 Bearing Replacement.………….

27

11.8.2 Bearing Removal………….…...

28

11.8.3 Bearing Installation…………..…

28

11.9 Spring Mount Replacement……...

28

11.10 Hydraulic Motor…….…………….

29

11.10.1 Hydraulic Motor Service……....

29

11.10.2 Motor Rotation.………………...

29

11.11 Flow Regulator Valve……….…..

29

11.11.1 Flow Regulator Valve Service

29

11.11.2 Valve Port Identification……...

29

11.12 Tightening Torque…………..…..

30

12.0 Lifting, Transport & Storage

31

12.1 Lifting & Transport…………..……

12.1.1 Transported Independently of

31

TABLE OF CONTENTS (cont’d)

SECTION Pg.

Motor and Valve Package………..……. 27

Mounting Frame & Hydraulic

Components –1000………..………….. 28

Dynamic Assembly –1000…………... 30

Mounting Frame & Hydraulic

Components –1000B……..…………... 32

Dynamic Assembly & Suspension

Components –1000B…………....…….. 34

Carrier…………………….….…31

12.1.2 Transported Attached to Carrier 31

12.2 Storage…….……….…….……….. 31

13.0 Parts Information……….…… 26

13.1 General…………………..………… 26

13.2 Motor and Valve…………...……… 27

13.3.1 Motor Identification.…………..…27

13.3.2 Valve Identification………….…. 27

List of figures Pg.

2-1 Equipment Identification Plate……. 2

2-2 Location of ID Plate………….….…. 2

4-1 Major Subassemblies……….….…. 5

5-1 Flow-Pressure Diagram…….….….. 7

6-1 Dimension Diagram………………... 9

6-2 Decal Locations………………….…. 11

8-1 Proper Hose Connection..….…..…. 19

11-1 Oil Level Check & Fill Decals….... 26

11-2 Oil Level Check & Fill Locations 26

11-3 Proper Oil Level…..…….….…….. 27

11-4 Bearing/Eccentric installation Tool 22

11-5 Spring Mount Installation………… 23

11-6 Proper Motor Rotation..………….. 23

11-7 Valve Port Identification…..…….... 24

11-8 Special Assembly Instructions…... 24

13-1 Motor Identification…………..…… 33

13-2 Valve Identification……………….. 33

13-3 Frame & Hydraulic Components –

1000……………………….……… 28

13-4 Dynamic Assembly & Suspension

Components –1000……..…....… 30

13-5 Frame & Hydraulic Components –

1000B……………………..…….... 32

13-6 Dynamic Assembly & Suspension

Components –1000B…...…....…34

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

viii

Document Change Notice

for

Spartan Equipment Skid-

PacTM Model 1000

Date

Nov. 30, 2005

Page

---

Change

Original Issue of Technical Manual 571834

Jan. 4, 2006

3

Revise text

May 1, 2006

Throughout

Revise parts list & figures

May 10, 2006

27 & 28

Revise Fig 14.1 & Table 14.2

Sep. 29, 2006

20

Revise oil capacity

Jun. 27, 2007

Cover, 7,9,27,29 & 30

Revise parts list & figures

May 1, 2008

27 & 29

Revise figures

Feb 3, 2009

Page 26

Table 14.1 revise Part No. 102651 now 102516

Document Change Notice

for

Skid-PacTM Model 1000B

Date Page Change

Nov. 2009 --- Original Issue of Technical Manual 573936. This

Manual supersedes Technical Manual 571834.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

1

Table 1.2

Related Publications

Manual

Model

Part No.

Technical

Manual

Skid-PacTM

1000 &

1000B

573936

The Technical Manual provides safety

precautions, specifications, service,

maintenance, warranty information,

product policies, troubleshooting,

installation / removal, storage, lifting and

transporting information. A section for

replacement parts is also included.

Skid-Pac

Swivels

All Models

(Except

Skid-Pac)

103467

This manual provides information about

the Allied Skid-Pac Swivel. The optional

swivel allows the Skid-Pac to turn at

either a 45° or a 90° angle to the boom.

Compaction

Handbook

All Models

103392

The Compaction Handbook contains

background information about soil, soil

compaction and basic soil compaction

equipment. It also contains general

information about the operation of

boom-mountedvibratory

compactors/drivers,as well as

performance data for Skid-Pac models

derived from field tests.

Notice: Material presented in these

manuals, including descriptions,

illustrations, specifications and designs,

are subject to change without prior

notice.

SECTION

1.0

INTRODUCTION

1.1 About this Manual

This publication is an integral part of this

product. Keep it in a convenient location so

that it is easily accessible for future

reference.

1.2 Additional Publications

Further information about the Spartan

Equipment Skid- Pac and optional

accessories can be found in the following

manuals:

Table 1.1

Technical Manual No. 573936

This Technical Manual is applicable to

the following Spartan Equipment

product(s):

Product

Name: Ho-Pac

Model(s): Skid-Pac 1000 &

Skid-Pac 1000B

Serial

Numbers:

Years of

Manufacture:

1000: 1014 thru 1058

1000B: 1059 & above

2005 –2009

2009 and above

Prior to performing any adjustments or

repairs and before ordering parts, confirm

that the information contained on your

equipment’s ID Plate corresponds with the

above information. For the location of the

I.D. Plate, refer to Section 2.0.

The Technical Manual provides safety

precautions, specifications, service,

maintenance, warranty information, product

policies, troubleshooting,installation /

removal, storage, lifting and transporting

information. A section for replacement parts

is also included.

The illustrations and parts descriptions

contained in this manual are typical of the

model identified above. Note that this

manual covers two models and parts such

as the dynamic assembly are different. Also

note that for both models, the motor is

available in various sizes. Be sure to match

your equipment to the proper configuration.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

2

SECTION

2.0

EQUIPMENT

IDENTIFICATION

2.1 Serial Number Location

The equipment serial number can be found

in two locations. The serial number is

stamped into the eccentric housing, near

the motor, as shown in Figure 2-2. The

serial number is also located on the metal

ID Plate affixed to the mounting frame.

Check that the information on your

equipment’s ID Plate correspond to the

information given in Table 1.1 of this

manual.

2.2 Equipment Identification Plate

The equipment identification plate contains

the following useful information:

Manufacturer’s name

Address

Product name

Model number

Serial number

Year of manufacture

Mass

Figure 2-2

Locations of Equipment Identification

2.3 Record Equipment I.D.

Information for Future Reference

Copy the Model and Serial Number from

the equipment identification plate to the

space provided below.

Indicate the date in which the

Spartan Equipment was placed into

service.

Return the completed warranty

registration form to Spartan

Equipment.

Model:

Serial

Number:

In

service

date:

Figure 2-1

Equipment Identification Plate

Provide this information when contacting

your local dealer about this Spartan

Equipment. The dealer requires this

information to better assist you with

questions regarding parts, warranty,

operation, maintenance, or repair service.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

3

SECTION

3.0

WARRANTY PROTECTION

SUMMARY

3.1 Overview

The Spartan Equipment attachment is

delivered assembled, lubricated, and

factory tested. Upon receipt of the

equipment, inspect for possible shipping

damage.

Improper installation of the Spartan

Equipment attachment, including machine

set-up, operation, service or use of non-

Spartan Equipment parts may result in loss

of performance or subject the equipment to

conditions beyond their design. Unapproved

modifications to the attachment, or

installation, operation and maintenance, not

in accordance with the instructions outlined

in this manual may cause equipment failure

or personal injury. For details regarding

warranty terms and conditions, refer to form

A100668.

3.2 Owner’s Responsibilities

The following outlines the minimum

maintenance policies required for all

Spartan Equipment Skid-Pac models. The

equipment owner is strongly encouraged to

expand upon these general instructions to

adapt them to particular applications.

When properly installed, operated and

maintained by qualified personnel, the

Spartan Equipment attachment requires a

minimum of service.

Ensure that personnel entrusted with

installation, operation, maintenance and

transporting of the Spartan Equipment

adhere to the following:

Read and thoroughly understand the

information and procedures detailed

in this manual.

Understand proper operating

techniques for all recommended

applications.

Use the Spartan Equipment

attachment only if it is in sound

operating condition. Immediately

rectify any faults that, if left

uncorrected, could lead to personal

injury or further damage.

Use the Spartan Equipment

attachment only for the purpose for

which it is intended.

Adhere to the specifications listed in

this manual and operate the Spartan

Equipment within its performance

limits.

Appoint Who Does What. Ensure

that

all

personnel understand what

their specific responsibilities include.

1. Establish equipment

maintenance to be performed

by the OPERATOR.

2. Establish equipment

maintenance to be performed

by the SERVICE

TECHNICIAN.

Recognize problems and know how

to take corrective action as detailed

in Operator TroubleshootingSection

10.0.

Conduct regular checks

and

inspections

as scheduled in the Care

and Maintenance Section 11.0.

Allow only qualified operators and

Spartan Equipment trained service

technicians to perform maintenance

and repair as specified in the care

and maintenance schedule.

Use only genuine Spartan

Equipment replacement parts and

recommended lubricants

to protect total warranty coverage.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

4

Maintain written records of

equipment maintenance, service and

repair. These records are helpful if

warranty coverage is ever in

question.

Each record shall include at least:

1. The date of the service,

maintenance or repair.

2. A description of the service,

maintenance or repair performed.

Include part numbers if applicable.

3. Copies of purchase order(s) and

invoice(s) for repair parts and

service.

4. The name and signature of the

person performing the service,

maintenance or repair.

3.3 Spartan Equipment Product

Policies

In this manual, Spartan Equipment

recommends Skid-Pac applications,

maintenance and service consistent with

industry practices.

Spartan Equipment assumes no

responsibility for the results of actions not

recommended in this manual and

specifically the results of:

Improper Training

Improper Installation

Operation in non-recommended

applications

Incorrect operation

Improper maintenance

Use of non-genuine

Spartan Equipment

replacement parts

Non-approvedmodifications

These exclusions apply to damage to the

Spartan Equipment, associated equipment

and injury to personnel.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

5

SECTION

4.0

EQUIPMENT

OVERVIEW

4.1 Product Description and

Application

The Spartan Equipment Skid-Pac is a

skid-steer- mounted, hydraulic powered,

vibrating plate compactor. It is used for soil

compaction. Applications include backfill

compaction, base course preparation, finish

surface treatment and embankment buildup.

Specifically designed for skid-steers,

installation of the Skid-Pac requires no

additional mounting or hydraulic kits. It’s

attached to the skid-steer in the same

manner as mounting a bucket. Power to

operate the Skid-Pac is provided by the

skid-steer’s auxiliary hydraulic circuit.

Suitable Skid-steers must have adequate lift

and hydraulic capacities to properly and

safely operate the Skid-Pac. Refer to the

specifications in Section 4.1 for operating

specifications and carrier requirements.

Contact your dealer or Spartan Equipment if

you have any questions regarding the

installation of this equipment.

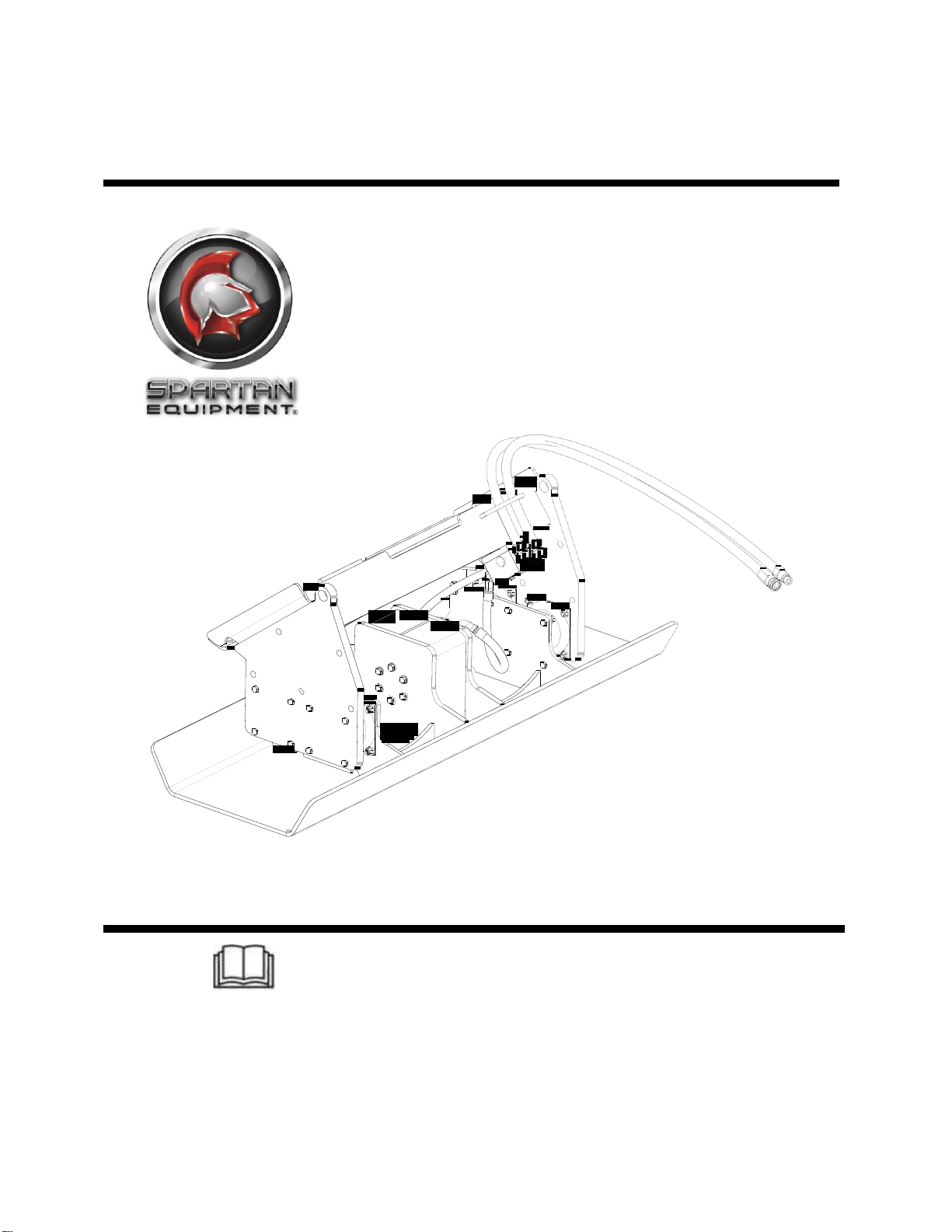

4.2 Major Subassemblies

Figure 4-1 Major Subassemblies

1-Dynamic Assembly, 2-Suspension System, 3-

Mounting Frame, 4-Control Valve

The Spartan Equipment Skid-Pac consists of

the following major subassemblies:

Dynamic Assembly - Generates and

transfers the vibratory energy to the soil.

The assembly includes the hydraulic motor,

eccentric mass, bearings, housing and

compaction plate.

Suspension System –Rubber Spring

Mounts suspend and isolate the Mounting

Frame from the Dynamic Assembly.

Mounting Frame –Connected to the

Suspension System, the Mounting Frame

provides hook up points for attaching the

Skid-Pac to the loader arms.

Control Valve –A standard feature on all

models is the multi-function, hydraulic

control valve. The valve is designed to

optimize operation and provide reliability of

critical components, such as the hydraulic

motor and bearings. NOTE: The valve is

factory pre-set and requires no further

adjustments.

The valve offers the following protection:

Flow regulator - Prevents over-

speeding the hydraulic motor by limiting

the flow.

Pressure control - Prevents over-

pressuring the motor and other hydraulic

components. This is factory pre-set at

the maximum operating pressure plus

200 psi (14 bar).

Anti-cavitation circuit - Controls

deceleration of the hydraulic motor and

eccentric mass. Also protects motor

from damage on circuits not set up with

an open return.

Return line check valve - Prevents

reverse flow to the hydraulic motor.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

6

SECTION

5.0

PRINCIPLE OF

OPERATION

5.1 Skid-Pac

The Spartan Equipment Skid-Pac is a

high-energy compaction tool utilizing three

compaction techniques:

The Impulse Force generated by the

rotating eccentric mass vibrates the soil

near the base plate to eliminate voids

between material particles.

The Vibration Frequency of 2000

r.p.m. provides maximum effectiveness

for the consolidation and compaction of

granular soil materials.

The Down Force of the carrier provides

a preload force to effectively transfer the

vibrating energy and to compress the

material.

Optimum compaction is usually obtained

with two passes. The duration of the initial

pass is dependent on depth and material.

The second pass may require additional fill

material and Skid-Pac repositioning to

achieve a finished surface. Refer to the

Compaction Manual for further details.

5.2 Definition of Hydraulic Installation

Terms

For the purposes of this manual, Hydraulic

Flow, Operating Pressure, Dynamic Relief

Pressure and Static Relief Pressure are

defined as follows:

Hydraulic Flow –The quantity of oil

flow (measured in GPM / LPM),

necessary for the safe and efficient

operation of the Spartan Equipment

attachment.

The hydraulic motor performs in a

narrow range of flow. While it is

permissible to supply the Skid-Pac with

a lesser flow of oil, it is important to

realize that the vibrations generated by

the dynamic assembly are developed by

the speed of the hydraulic motor.

Therefore, reduced compaction

performance can be expected due to a

drop in motor speed. Typically, optimal

compaction performance cannot be

achieved unless the oil flow is at, or

slightly above, the specified flow

requirement of the motor. It is important,

however, not to exceed the

specified

flow

beyond 10%, as this will

over-

speed

the motor and shorten

component life.

Hydraulic circuit designs can differ from

machine to machine. Damage to the

Skid-Pac or skid steer may result if

installed improperly. The motor must be

sized according to the hydraulic output

of the skid-steer. Using a flow meter,

measure the auxiliary hydraulic circuit.

Select the motor that best matches by

comparing the measured flow to the

available motor options listed in the

Specifications Table.

IMPORTANT

Never use a relief valve as a means to

reduce the hydraulic oil flow to the

Spartan Equipment attachment. Oil by-

passed over the relief valve will cause

significant heat generation and result in

damage to the attachment and/or carrier.

Operating Pressure –The average

hydraulic oil pressure measured in the

supply line during normal operation

(under a load). Compaction

performance is reduced when the

minimum operating pressure is not

reached. If, however, the compactor is

regularly operated at pressures that

exceed the design limits of critical

components, a decrease in service life

can be expected.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

7

IMPORTANT

The Operating Pressure is not to be used

as a relief valve pressure setting. Poor

performance and significant heat

generation will occur.

Dynamic Relief Pressure - The

pressure when the relief valve first

“cracks”open and allows a small

amount of oil to by-pass through the

valve.

IMPORTANT

The carrier's hydraulic system shall be

capable of providing the desired oil flow at

a pressure equal to at least the dynamic

relief pressure.

Static Relief Pressure - The pressure

when the relief valve is fully open and

the entire oil flow is by-passed through

the valve. At no time is it permissible to

subject the Spartan Equipment

attachment to Static Pressures that

exceed the values listed in Section 6.

IMPORTANT

The relief valve is a safety device, used to

protect the circuit against hydraulic

overload. It is a required component.

When selecting a relief valve for Spartan

Equipment attachments,the pilot controlled

relief

valve is

better suited for high flow

applications. Pilot controlled relief valves

generally exhibit shorter opening curves,

compared to direct acting relief valves.

Opening Curve –The range or stroke of

the

relief valve from the point that it first

cracks open (Dynamic) to when it has

reached the fully open position (Static).

Several factors influence the opening

curve, including spring rate, volume and

viscosity of the fluid passing through the

valve.

The cracking pressure (dynamic) is

always less than the static pressure. A

relief valve set to a dynamic pressure of

3000 psi (200 Bar) will crack open when

this pressure is reached, but fully opens

at a higher pressure.

Operating

Pres

su

re

Dynamic ReliefPressure

(Relief

valvecracks o

p

en)

FL

O

W

H

yd

ra

ulic

Flow Range

O

penin

g

Curve

Att

achment

O

per

at

ion

al

Ra

ng

e

O

per

ati

n

g

Pres

su

re

Ra

ng

e

Static ReliefPressure

(No flow to

atta

chment)

PR

ESS

U

RE

Figure 5-1

Flow-Pressure Diagram

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

8

SECTION

6.0

TECHNICAL

INFORMATION

6.1 SPECIFICATIONS

Table 6.1

General Specifications

1000

1000B

Impulse Force

8,000 [35,586]

Lbs [N]

Cycles Per Minute

2000

1/min

Sound Power Level

105 [Est’d]

DBA [LWA]

Hydraulic Flow (a)

Motor

Option

1

12 [45]

gpm

[lpm]

2

18 [68]

3

21 [79]

Max Operating

Pressure

Motor

Option

1

2800 [193]

psi

[bar]

2

2000 [138]

3

2000 [138]

Oil Pressure @ No Load

300-1000 [20-35]

Auxiliary Circuit

Relief Pressure

(b)

Dynamic

Max Operating + 400 [28]

Static

Max Operating + 650 [45]

Compaction Plate Dimensions

18 x 72

[457 x 1829]

Inch

[cm]

Compaction Area

9.0 [0.84]

Ft

2

[m

2

]

Hose Size

Pressure

3/4 [16]

Inch

[mm]

Return

3/4 [16]

Weight (c)

Standard

1110 [499]

Lbs

[kg]

With Optional

Weight Kit

1310 [90.7]

Carrier Weight (d)

Skid Steer

4000 [1800] Minimum

Lbs (1,000)

[kg] (1,000)

(a) For efficient machine operation, proper selection of the Motor & Valve Package is critical. The auxiliary circuit

must be capable of delivering the specified oil flow at a pressure equal to at least the dynamic relief pressure.

(b) Verify the carrier’s main relief is set to the manufacturer’s specifications and that this value is equal or greater

than the dynamic relief setting.

(c) Working weight with and without optional weight kit (part number 572366).

(d) Mount only to Skid Steers having adequate load-carrying capabilities. The Skid Steer should weigh a minimum

of 4000 lbs. If the Skid Steer cannot provide sufficient down force, install the optional weight kit, part number

572366, for added ballast.

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

9

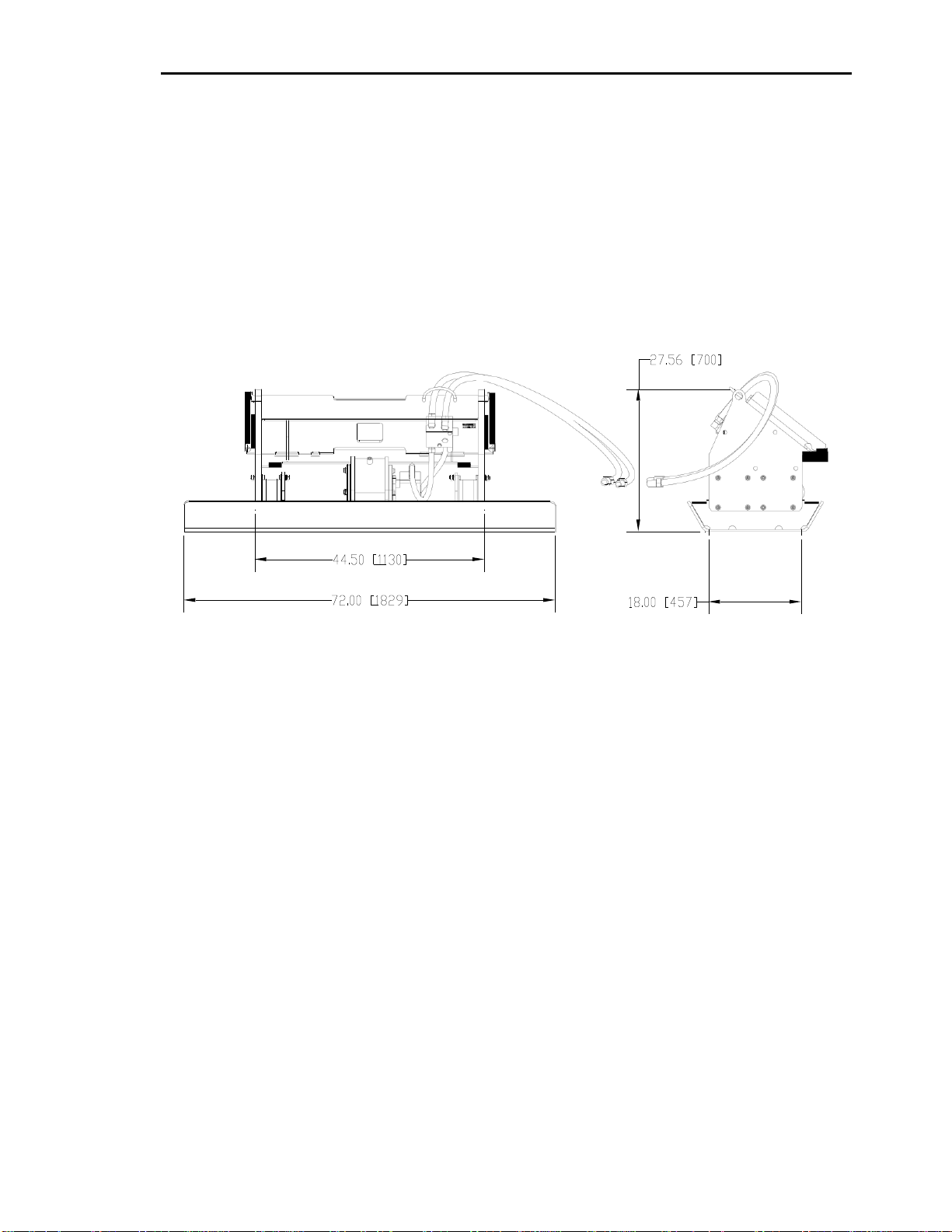

6.2 DIMENSION DIAGRAMS

Figure 6-1

Skid-Pac 1000 & 1000B

Spartan Equipment Technical Manual Skid-PacTM 1000, 1000B

10

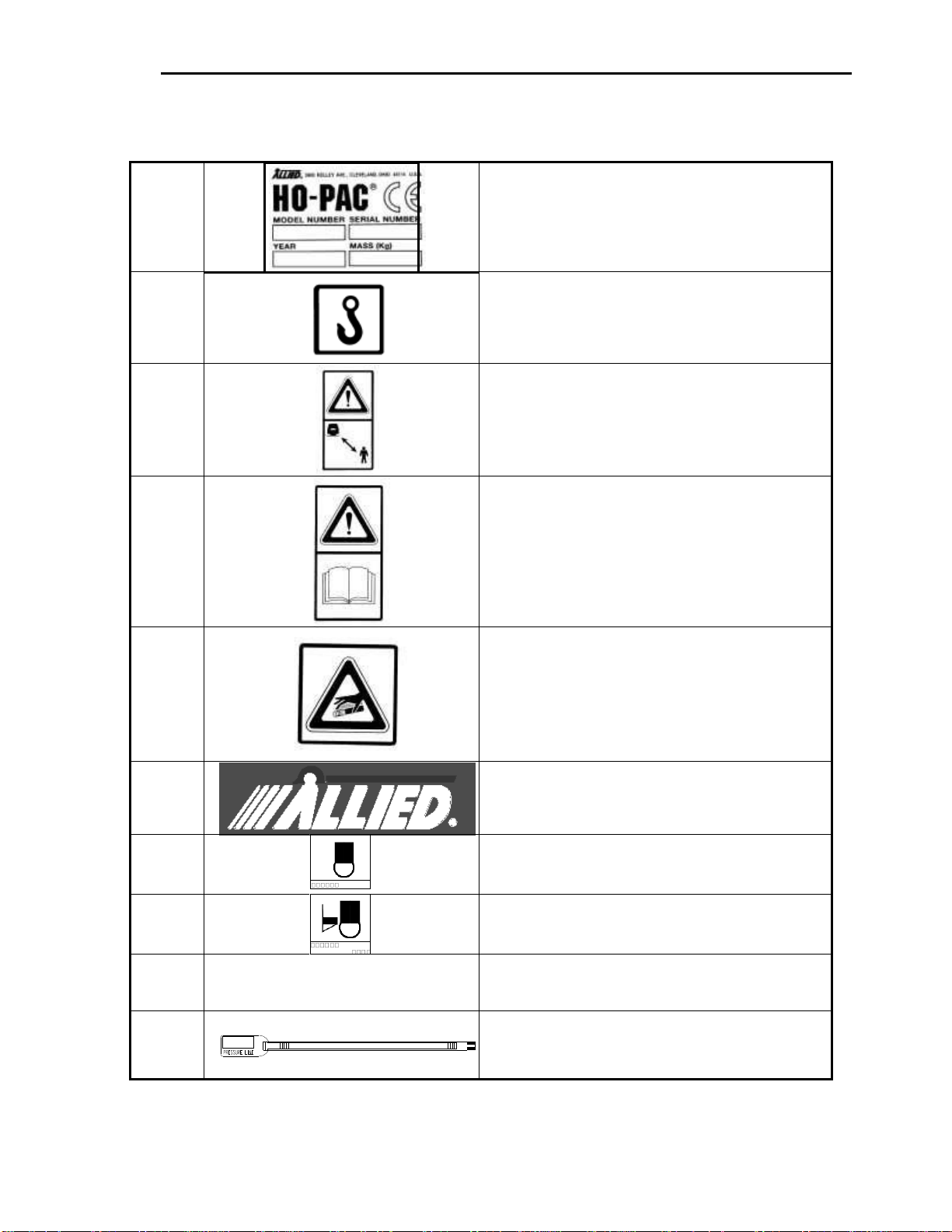

6.3 IDENTIFICATION and SAFETY LABELS

1

The ID PLATE (Identification Plate) contains

the following information: Manufacturer’s

name and address, Product Name, CE

compliance marking, Model Number, Serial

Number, Year of Manufacture, and Mass

2

The LIFT POINT decal identifies the

location of the recommended lifting points of

the Skid-Pac.

3

The STAY CLEAR decal indicates that

personnel and by-standers are to maintain a

safe distance from the Skid-Pac during

operation.

4

The READ INSTRUCTIONdecal indicates

that it is important to read the manual for

detailed explanations and instructions

5

The HOT SURFACE decal indicates

hydraulic components that become hot

during operation. These include the quick

disconnect couplings, hoses, hose fittings,

valve and motor. Avoid contact with hot

parts.

6

The SPARTAN EQUIPMENT LOGO decal is

the Spartan Equipment brand identifier and

is a registered trademark of Spartan

Equipment.

7

The OIL FILL decal identifies the location to

add oil to fill the oil reservoir. Refer to

Section 11.7 for more information.

8

The OIL LEVEL decal identifies the location

to check the oil level. Refer to Section 11.7

for more information.

9

1000, 1000B

The MODEL NUMBER decal indicates the

Skid-Pac model number.

10

The PRESSURE I.D. tag is attached to the

pressure hose for ease of identification

between hoses.

This manual suits for next models

1

Table of contents

Other Spartan Equipment Power Tools manuals