Spartan Equipment 010 User manual

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

Spartan Make Digital Torque Wrench

Overview

1.1Main purpose and applicable range

A ratchet-head digital display torque wrench and replaceable head digital display

torque wrench are different from normal torque wrench, wherein the AWJC replaceable

head wrench with its attached ratchet head can be replaced with an open head, a plum

blossom head, a movable opening head,etc at any time. Both have powerful operating

functions, including torque setting; unit setting; mode setting; value storage; value clearing;

value output and user correction function. With easy operation, the digital display is

installed to reduce the requirement on the operator. It is applicable to the fastening and

control of bolts in automobile industry, machinery industries.

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

1.2 Functions and features

1.2.1 Reading value of digital display torque

1.2.2 Accuracy of ±2% by clockwise, and ±2.5% by

counterclockwise (Max.operating range is within 20~100%)

1.2.3 It can be operated by both clockwise and counterclockwise

1.2.4 Peak hold and real time mode

1.2.5 Buzzer and LCD indication (when the torque value is pre-set)

1.2.6 Four kinds of engineering units (ft.lb、in.lb、N.m、kgf.cm)

1.2.7 99 groups of recorded values can be stored

1.2.8 Automatic shutdown in 5 minutes

1.3 Product model and selection

①:Max.accuracy

②:Is it with communication function?

Communication and transmission functions

None

None

Accuracy

±2% by clockwise/±2.5% by counterclockwise

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

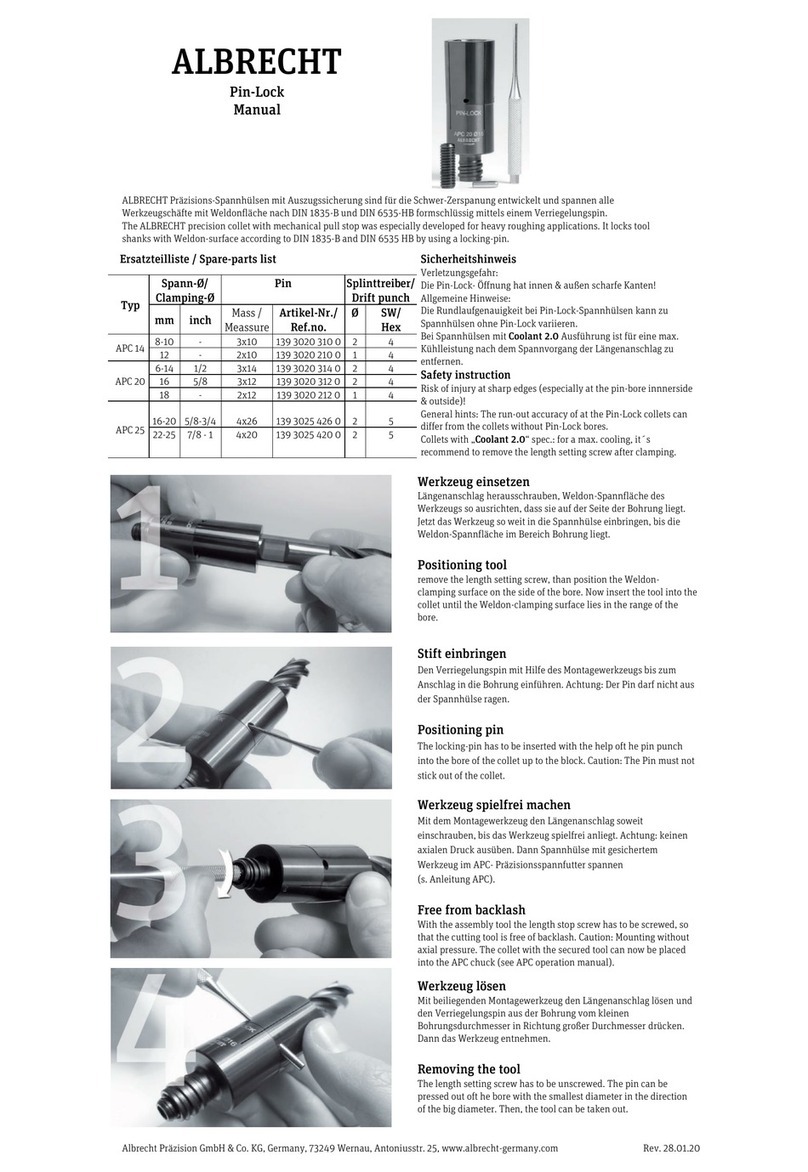

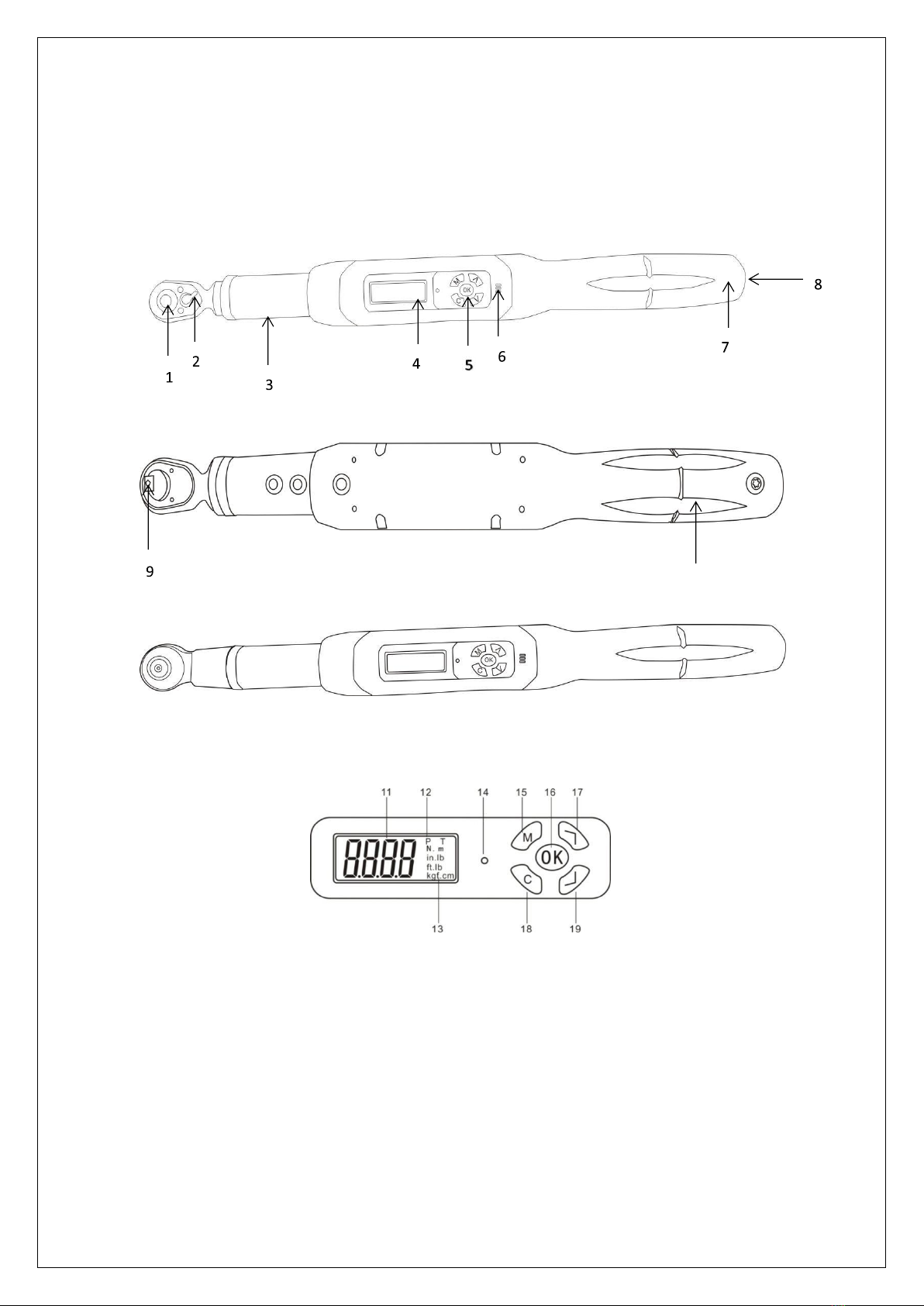

1.4 Functions and names of each component -

1.Two-way ratchet head

2. Steering paddle 3.

Main body

4.LCD screen

5. Key

6. Buzzer

7. Battery box

8. Batterycover

9.Ratchet torque square head

10.Handle

11. Torque value

12.P (peak mode), T (real time mode)

13. Unit (N.m、in.lb、ft.lb、kgf.cm)

14. LED indicator

15. Menu key

16.Confirm key

17.Upward key

18.Cancel key

19.Downward key

10

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

Technical Specification of Product -

Model

010

030

030

060

085

135

135

200

340

500

850

010

30A

30B

060

085

135

135

200

340

Min.scale

value

0.01

0.1

Max.

operating

range

(N.m)

10N.m/

7.37ft.lb

/88.50in

.lb/101.

97kgf.c

m

30N.m/

22.12ft.l

b/265.5i

n.lb/305

.91kgf.c

m

30N.m/

22.12ft.l

b/265.5i

n.lb/305

.91kgf.c

m

60N.m/

44.25ft.l

b/531.0

4in.lb/6

11.82kg

f.cm

85N.m/

62.69ft.l

b/752.3

1in.lb/8

66.75kg

f.cm

135N.m

/99.57ft.

lb/1195i

n.lb/137

6.61kgf.

cm

135N.m

/99.57ft.

lb/1195i

n.lb/137

6.61kgf.

cm

200N.m

/147.5ft.

lb/1770i

n.lb/203

9.43kgf.

cm

340N.m

/250ft.lb

/3009in.

lb/3467.

03kgf.c

m

500N.m

/4424in.

lb/368.7

ft.lb/509

8.58kgf.

cm

850N.m

/7521in.

lb/626.8

ft.ln/866

7.58kgf.

cm

Connectors

(inches)

1/4

3/8

1/2

3/4

Size of

replaceable

head

connection

9*12

14*18

Setting

range of

buzzer

(N.m)

0.5~10

1.5~30

1.5~30

3~60

4.25~

85

6.75~

135

6.75~1

35

10~

200

17~34

0

25~50

0

42.5~

850

Length

390

420

535

655

950

1220

Accuracy*1

Clockwise: ±2%

Counterclockwise:±2.5%

Clockwise: ±2.5%

Counterclockwise:±3.5%

Storage

capacity of

materials

100

Operating

mode

Peak hold (P)/real time mode (T)

Unit

N.m、in.lb、ft.lb、kgf.cm

Type of

ratchet head

Two-way ratchet head

Teeth

number of

ratchet head

36

48

Number of

key

5

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

Battery

2 sets of 1.5V#5 battery

Operating

temperature

-10℃~60℃

Storage

temperature

-20℃~70℃

Humidity

It can reach 90% under no condensation

Drop testing

height

1m

Vibration

testing

condition*2

10G

Life test*3

10000times

Use Method -

3.1 TurnON/FF by zero clearing: press C key to turn on, if the power value appears after the turn

on, press C key to clear, under no operation, enter the sleeping mode for 5 minutes, press C

key to start, and also press and hold C key to turn off.

3.2 Setting method of pre-set value: Under normal power-on state, shortly press M key on the

measurement interface, and switch UP/DN key to obtain your required pre-set value. After setting

the pre-set value, the system will automatically save the pre-set value, and continuously press M key

until returning back to the measurement interface.

3.3 Setting methods of real time and peak modes: This product starts by real time mode Tin

default. If you want to switch to the peak mode P, you need to press M key twice shortly on the

measurement interface, and pops up NODE, then you can select the T.Pswitching mode by UP/DN

keys. After the selection is completed, press M continuously until returning back to the measurement

interface.

3.4 Setting methods of unit mode: This product has totally four kinds of unit modes for

selection such as N.m、in.lb、ft.lb、kgf.cm, which can be switched according to actual use condition.

The modes are set up by press M key 3 times shortly on the measurement interface, and pops up UNLT,

then the required unit modes can be selected by UP/DN keys. After the selection is completed, press M

key continuously until returning back to the measurement interface.

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

3.5 Data save and checking method: The data save can be used under P peak mode, and the

measured data can be discarded by directly pressing C key, and press OK key to save. After save is

completed, you will automatically return back to the measurement interface for re-testing. By such

circulation, max. data can be saved to 99 groups (data number is 001.002 099 by sequence).

Data check. Press M key to check the saved data group on the measurement interface (display 0000

under no saved data) and data number can be checked by UP/DN keys, then if no operation lasts for

2 seconds, it will display the detailed force values saved by this number. After checking, press M

key continuously until returning back to the measurement interface.

3.6 Clearing data storage values: Shortly press M key for 5 times on the measurement interface to

pop up CLR, and press C key to pop up No?, then press C key again to confirm clear, which

display DEL for completion, then returning back to the measurement interface. (If in No? Press M

key on the interface to discard and delete, then returning back to the measurement interface. Note:

Data clearing is one-time clear which completely clears all the data without single operation)

Precautions -

4.1

In order to maintain good accuracy, it is recommended to re-calibrate one time approximately

every year.

4.2

Over-torque may cause damage or loss of accuracy (more than 105% of the maximum torque

range).

4.3

Do not shake the wrench vigorously or drop the wrench to the ground.

4.4

Do not use the wrench as a hammer.

4.5

Do not place the wrench in a place with high temperature, high humidity or direct

sunlight.

4.6

Do not use the wrench near water.

4.7

If you accidentally wet the wrench, dry it with a dry towel immediately. Salt in the

sea can damage the wrench.

4.8

Do not use organic solvents to clean the wrench, such as alcohol or paint thinner.

4.9 Do not place the wrench close to the magnetic object.

4.10 Do not place the wrench in a place with a lot of dust or sand, which will cause

serious damage to the wrench.

4.11 Do not heavily press LCD screen.

Battery treatment

5.1 If you do not use the torque wrench for a long time, please take out the battery.

5.2 When you need to travel long distances or in a cold area, please prepare a spare

battery.

Office No- 114, First Floor, Dhuri Commerce Plaza,

Vasai Station (E), Opposite Bus Depot,

Dist : PALGHAR- 401208

5.3 Do not mix batteries of different brands, and do not mix old and new batteries.

5.4 Sweat, oil and other factors will hinder the contact of the battery electrode, please

wipe the battery clean before putting the torque wrench.

5.5 Please discard the used battery at the designated recycling location. Do not put the

battery in a fire.

Detailed list of accessories attached with the unit

1

Drying agent

1 bag

2

5V battery

1 pair

3

Key for battery box

1 set

4

User’s manual

1 copy

5

Certificate Warranty card

1 copy

Note: Packaging accessories for ratchet head and replaceable head are unified

This manual suits for next models

10

Table of contents

Other Spartan Equipment Power Tools manuals