General Safet Rules.

1) Always wear ear and e e protection when you use this product, or are in the vicinity of the

product when it is use.

2) Do not use the compressor in areas near combustible materials, combustible fumes or dust.

3) Always use a respirator or mask when spray paintin or whenever there is a possibility vapors

may be inhaled. Read all instructions provided with the mask to ensure it provides adequate

protection a ainst inhalin harmful vapors.

4) DO NOT ALLOW CHILDREN TO OPERATE THE COMPRESSOR AT ANY TIME.

5) DO NOT MAKE ANY MODIFICATIONS TO THE UNIT OR ANY OF ITS COMPONENTS.

6) UNITS WITH BROKEN OR MISSING PARTS OR WITHOUT THE PROTECTIVE

HOUSING OR COVERS SHOULD NEVER BE OPERATED.

7) Do not leave the compressor unattended while the pressure switch is in the “I” (On) position.

8) Do not add or chan e oil while the compressor is in operation.

9) Use only the supplied or recommended lubricatin oil for the compressor

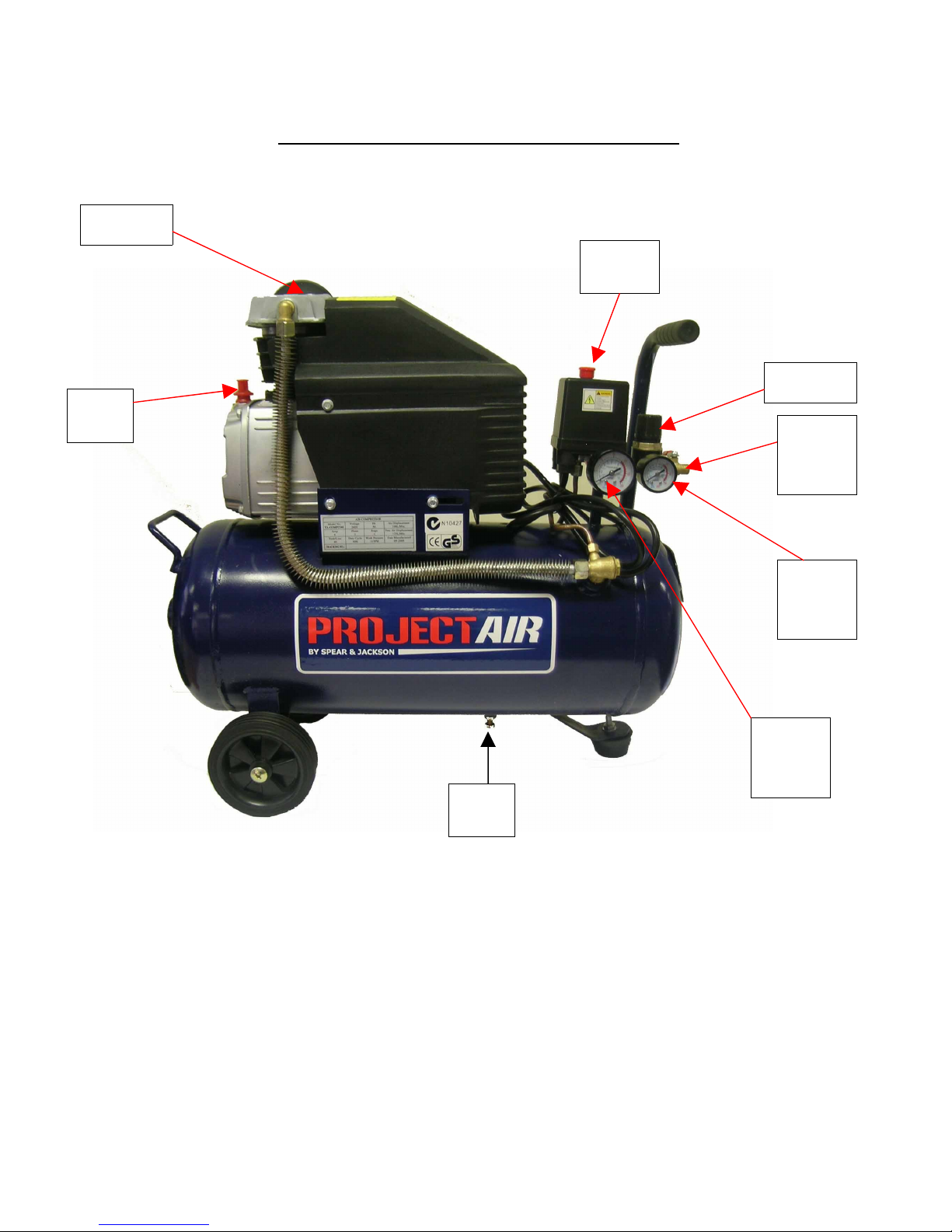

10) This compressor is fitted with an automatic “On/Off” switch. When the switch is in the “on” position,

the compressor may start operatin at any time when the pressure in the tank falls below the preset

level of the pressure switch.

11) Disconnect all tools, fittin s, etc and drain tank of remainin air if leavin unattended for prolon ed

periods of time.

12) To reduce the risk of fire or explosion, never spray flammable liquids in a confined area.

13) Never directly inhale the compressed air produced by a compressor.

14) Do not use the air from the compressor for char in breathin /scuba tanks.

15) Do not use weldin equipment in close proximity to the compressor. Do not weld anythin to the air

tank of the compressor: this could dan erously weaken the tank and will void the warranty.

16) To avoid the risk of burns and injury from movin parts, do not operate the compressor with the

safety shield removed. Allow hot parts to cool before handlin or servicin .

17) Before transportin the compressor make sure that the pressurised air is bled from the tank and that

the compressor is firmly secured.

18) Protect the air hose and cord set from dama e. Inspect for weak or worn spots re ularly and replace if

necessary.

19) Never apply the outlet air of this compressor directly on to any part of a person’s body. Do not

attempt to block the air outlet with your fin er or any part of your body.

20) The tool must be used only for its prescribed purpose. Any use other than those mentioned in this

Manual will be considered a case of misuse. The user and not the manufacturer shall be liable for any

dama e or injury resultin from such cases of misuse.

21) The manufacturer shall not be liable for any chan es made to the tool nor for any dama e resultin

from such chan es.

Warning !

In the event that an air line is cut or broken, the air suppl must be turned

off at the compressor.

3