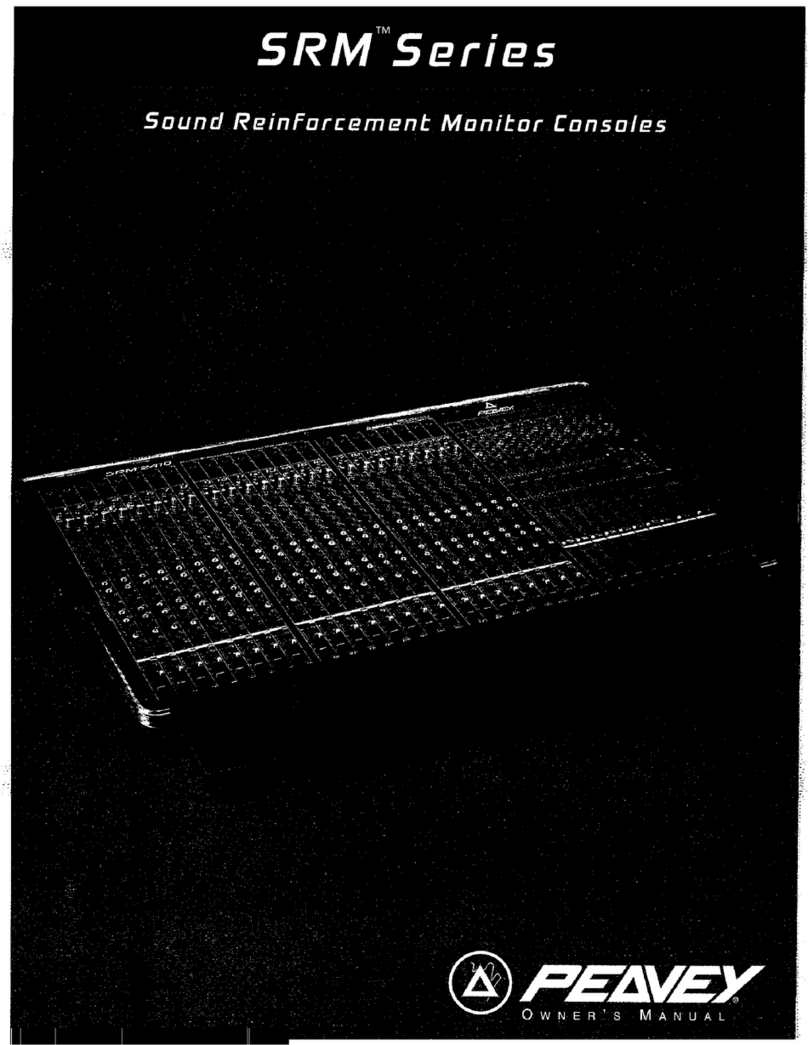

SPEC MIX PA1000 Use and care manual

KEEP GOING. KEEP MOVING. KEEP WORKING.TM

PA1000 · PA4000

POWER AUGER MIXING SYSTEMS

OPERATIONS & SAFETY MANUAL

ENGLISH EDITION

TABLE OF CONTENTS

Page

Introduction ................................................................................................. 3

PA Systems Specifications ......................................................................... 4

Transporting PA Systems ............................................................................ 5

Assembling PA Systems .......................................................................... 6-7

Starting Up & Inspecting PA Systems ...................................................... 8-9

Loading PA Systems ............................................................................ 10-11

Operating PA Systems ............................................................................... 12

Relocating PA Systems ........................................................................ 13-14

Maintenance for PA Systems ..................................................................... 15

© SPEC MIX®Inc. 2013

3

KEEP MOVING. KEEP WORKING. KEEP SAFE.

The PA (Power Auger) systems are a low profile, gas or electric powered hydraulic auger dispensing

material delivery system specifically engineered to increase a contractor’s efficiency, flexibility and

above all, safety. To ensure that a safe working environment is provided to all individuals who are

operating or have contact with SPEC MIX equipment, please abide by the following safety and

operation procedures for working with SPEC MIX PA systems and bulk bags.

Since safety is everyone’s responsibility, we ask that you become familiar with these procedures

yourself, and make sure that everyone operating or having any contact with SPEC MIX PA systems

and bulk bags be familiar with and implement, the following procedures as well.

It is everyone’s responsibility to be aware of the necessary precautions that must be taken to ensure

that laborers are provided with a safe working environment; and that they implement safe handling

and operating procedures for their own safety as well as others.

NOTE: These warnings do not constitute all possible safety hazards encountered in the use of

such products on a construction site. All applicable OHSA regulations must be followed in the

setup, relocation, cleaning, or use of the silo and product.

4

PA SYSTEMS SPECIFICATIONS

PA1000

PA4000

FOOTPRINT 4 ft X 5 ft HYDRAULIC POWER PACK 2.8K7V

CAPACITY 40 cubic feet MOTOR OPTIONS 14 hp GAS MOTOR

WEIGHT EMPTY 1,100 lb 7.5 hp ELECTRIC MOTOR (220V, 30AMP, SINGLE PHASE)

WEIGHT FULL UP TO 4,100 lb

SHIPPING SIZE 5 ft X 7 ft 6 in HYDRAULIC OIL TANK 6 gallon CAPACITY

SHIPPING HEIGHTS 4 ft 2 in COLLAPSED OIL OUTPUT 14 hp - 2,500 psi, 6 GPM

HOPPER HEIGHTS LOW SETTING: 4 ft 2 in

HIGH SETTING: 5 ft 2 in MIX OUTPUT 14 hp - 3,000 lb PER 7 MINUTES

AUGER DISPENSING HEIGHTS LOW SETTING: 5 ft

HIGH SETTING: 6 ft FORKLIFT REQUIREMENTS 4,500 lb

FOOTPRINT 7 ft 3 in X 6 ft 3 in HYDRAULIC POWER PACK 2.8K7V

CAPACITY 150 cubic feet MOTOR OPTIONS 14 hp GAS MOTOR

WEIGHT EMPTY 2,000 lb 7.5 hp ELECTRIC MOTOR (220V, 30AMP, SINGLE PHASE)

WEIGHT FULL UP TO 17,000 lb

SHIPPING SIZE 7 ft 8 in X 8 ft 6 in HYDRAULIC OIL TANK 6 gallon CAPACITY

SHIPPING HEIGHTS 6 ft 3 in COLLAPSED OIL OUTPUT 14 hp - 2,500 psi 6 GPM

HOPPER HEIGHTS LOW SETTING: 6 ft 3 in

HIGH SETTING: 7 ft 7 in MIX OUTPUT 14 hp - 3,000 lb PER 7 MINUTES

AUGER DISPENSING HEIGHTS LOW SETTING: 5 ft

HIGH SETTING: 6 ft 4 in FORKLIFT REQUIREMENTS 4,500 lb

5

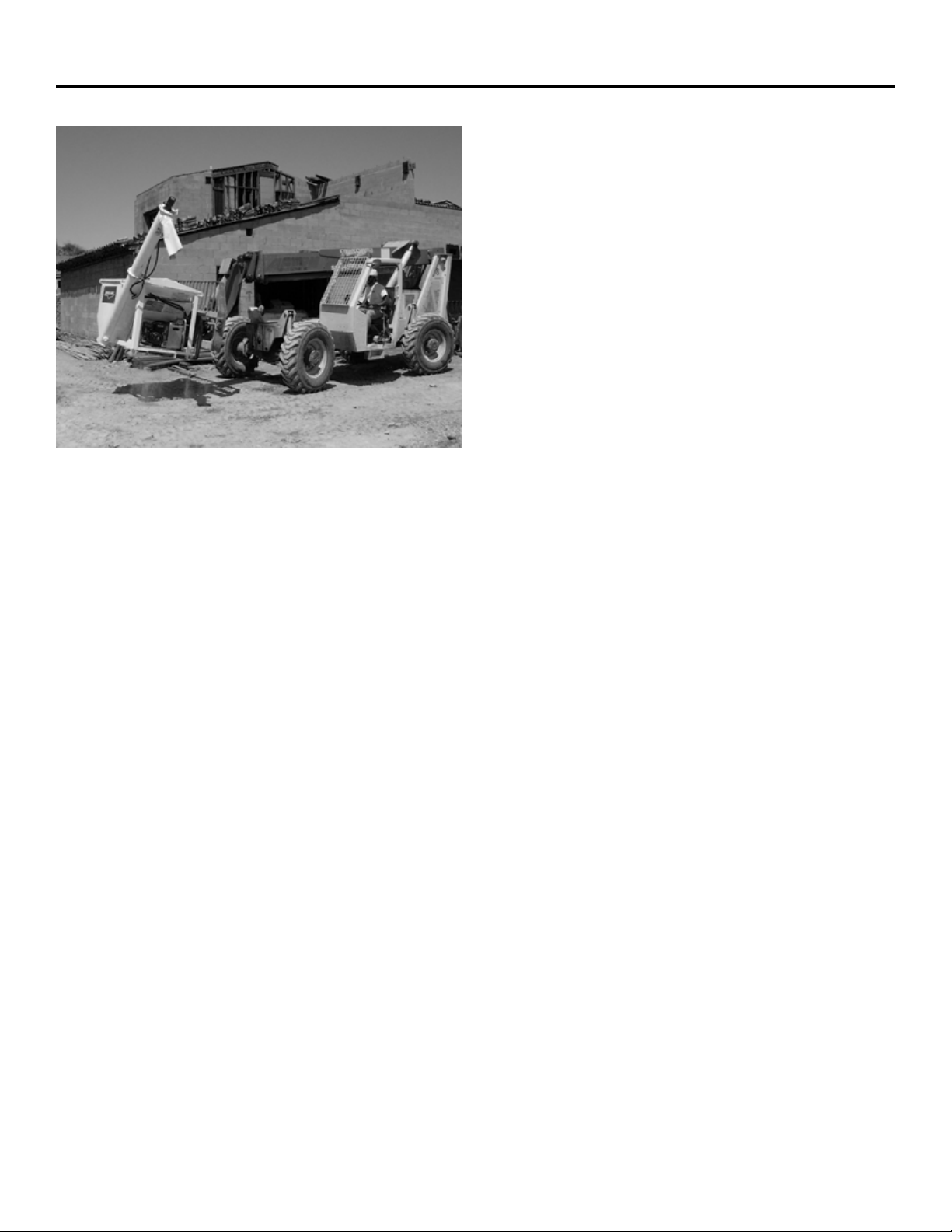

TRANSPORTING SPEC MIX®PA SYSTEMS ON ROADWAYS

1. Inspect SPEC MIX PA system to make sure that it

has been emptied.

WARNING: Do not enter the interior of the PA system

hopper for any inspection or maintenance. If

absolutely necessary, turn off the PA system and

perform lockout procedures. All personnel must

follow confined space entry procedures (OSHA).

2. Make sure the gas or electric power pack is

securely locked or bolted into its place.

3. Secure top hatch handle with bolt and nut or lock-

pin.

4. To lower the PA system (PA4000), slightly raise the

system and remove leg pins & hitch pins from legs.

Lower PA system then secure legs in collapsed

position with leg pins.

5. Once lowered to the transportation mode, re-install

leg pins and hitch pins to their original position to

secure PA system’s legs.

6. If the terrain the PA system is being

transferred over is rough and uneven, secure a third

contact point between PA unit and forklift using

chain or strap with minimum tensile strength of

5,000 pounds live working load.

7. Slowly and carefully load the PA system onto the

trailer following accepted U.S. DOT procedures.

8. Secure PA system to the trailer using DOT

approved chains or straps and ratchets with a

minimum of 5,000 pounds tensile strength per

ratchet.

9. Remove any debris or material from PA system or

trailer bed before traveling.

6

ASSEMBLING SPEC MIX®PA SYSTEMS

1. Select a position on the jobsite where the ground

is dry, compacted, level and stable.

NOTE: To ensure the stability of the PA system, dry,

compacted, level ground MUST be available

for set up, or the unit should NOT be erected or

used.

2. Softer soil will require the use of either footings or

concrete pads of 24 x 24 x 6 inches of reinforced

concrete with a minimum compressive strength

of 3,500 psi.

3. Foot pads should be constructed of three

separate pieces of 24 x 24 inch treated plywood

that are ¾ inch thick and laminated together with

screws or of 24 x 24 x 1 inch steel pads. Discard

footpads when punctured. Each PA system

requires four footpads.

NOTE: A proper capacity forklift must be utilized to

lift the standard weights of the PA system and

material being used. (See PA specifications on

Page 3).

4. If the terrain the PA system is being transferred

over is rough and uneven, secure a third contact

point between PA unit and forklift using chain

or strap with minimum tensile strength of 5,000

pounds live working load.

5. Slowly lift and recline forklift position while

making sure no objects or people are in the way.

6. Place the PA system on the best suited location

on the project site.

7. By slightly raising the PA system, remove all four

leg pins allowing silo legs to telescope to full

adjustment.

WARNING: Keep legs, feet and hands clear of PA

system legs as they are lowered.

7

ASSEMBLING SPEC MIX®PA SYSTEMS

8. Raise tower to desired height until holes in

PA system leg match holes in receiver tube

assembly.

9. Secure PA system by inserting all four leg pins

at the desired height, then insert the safety hitch

pins in the holes of the four leg pins to lock the

leg pins in place.

10. Re-insert leg pin through receiver tube and leg

assembly while standing outside of the perimeter

of PA system.

8

STARTING UP & INSPECTING SPEC MIX®PA SYSTEMS

NOTE: It is very important to follow the proper

start-up and inspection procedures for the

SPEC MIX PA systems to ensure safe, reliable

and efficient operation.

1. With the PA system turned off and locked out,

check material flow basket and both augers for

positioning, obstructions or defects.

2. Connect Hydraulic Hoses: Verify that the

hydraulic hoses are coupled into position and

connected properly to the valves on the power

pack.

3. Filling the Hydraulic Oil Reservoir Tank: Open

the cap on the hydraulic oil tank and ensure

the tank is filled with 5 gallons of standard

hydraulic oil. If not, add the appropriate

amount of hydraulic oil. Close the cap on the

tank, run the unit and check the oil level again.

Top off hydraulic oil until a full reading is taken

on the dipstick. Use heavy weight hydraulic

oil in the summer (hot weather conditions) and

light weight hydraulic oil in the winter (cold

weather conditions). Change hydraulic oil

every 500 hours of use or with the change in

seasons. Always change the hydraulic oil filter

when changing hydraulic oil.

4. Filling & Checking Engine Oil: Fill the motor

oil reservoir with 5W-30 motor oil until a full

reading is achieved on the motor oil dipstick.

Change the motor oil after the first 20 hours of

operation and then after every hundred hours

of operation. The run time on the motor can be

located in the run time timer.

5. Filling Gas Engine: Fill the gas reservoir on the

motor with UNLEADED gasoline only.

9

STARTING UP & INSPECTING SPEC MIX®PA SYSTEMS

6. Greasing Auger Zerts: There are two grease

zerts on each PA unit. One is at the lower

bearing of the discharge auger opposite the

hydraulic motor and the other is on the end

of the bottom auger opposite the hydraulic

motor. Grease before use and then grease on a

weekly basis.

7. Connecting Battery: Connect the red wire to

the positive connection and the black wire to

the negative connection on the battery. If the

unit does not turn over when turning the key,

replace the battery.

8. Adjusting the Hydraulic Pressure: The hydraulic

pressure comes preset; however, the pressure

may be adjusted up or down on the unit. To

adjust the pressure, locate the valve mounted

on the hydraulic oil tank of the power pack.

Using an Allen wrench, remove the cap at the

rear of the valve. Then insert an Allen wrench

into the cap and turn clockwise to increase

pressure or counterclockwise to decrease

pressure.

IMPORTANT NOTE: The hydraulic pressure

should rarely, if ever, need adjustment. Contact

your local representative prior to adjustment.

Adjustment should be done by a qualified

mechanic only. If the PA System is not

dispensing material or appears to be jammed

up, contact your local supplier.

9. Prior to loading the PA system, turn it on to

ensure proper function while it is empty. Make

sure the fuel switch is in the “On” position.

Open the choke, if necessary. Position the

throttle to a low/medium position. Turn the

electric ignition key to start the motor. Close

the choke upon ignition. Slowly increase the

throttle to an operating level.

10. Use the corded auger switch to engage the

augers. Make sure the augers are turning the

appropriate direction to dispense material.

Turn off the motor by turning the key to the off

position prior to loading the PA system.

10

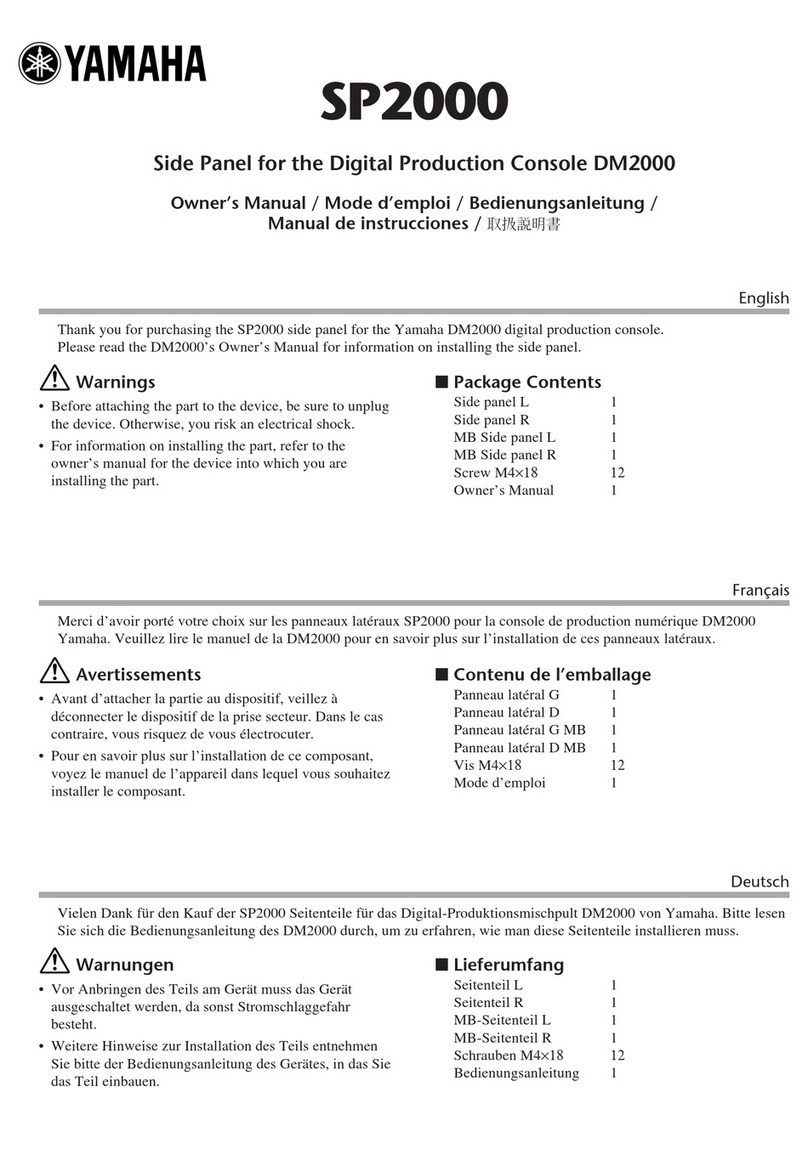

LOADING SPEC MIX®PA SYSTEMS

1. While standing on the ground, slide the outer

plastic cover down to the pallet level of the

material bulk bag. At this time, inspect the overall

condition of the bulk bag giving special attention

to the bag’s lifting loops. Check for fraying on

both sides. If the strap appears stressed, set the

bag and pallet aside for replacement and recover

to protect the material inside.

2. Save the product identification card or batch

ticket located inside the plastic cover. This

will verify the product delivered matches the

product ordered, which may be useful during the

construction process.

3. Once the bag has passed the visual inspection,

insert the forklift forks through the four lifting

loops. The forks should easily slide to a position

where all four loops are on the forks as far as

possible. It is important the loops do not leave

this position before lift tension is applied.

4. To improve flow, open the top spout of bag.

5. From an area opposite the side of the silo safety

rail platform or wherever the silo loading operator

is stationed, carefully raise the bag to the silo

hatch. At no time should personnel be under

the suspended bulk bag. The forks should be

at a reclined position while raising the bag to a

distance of 3-4 feet above the loading hatch. The

bag can now be slowly lowered to a point where

the bottom of the drop spout is 4-6 inches above

the PA flow basket. Hand communication signals

should be used to indicate when the bag has

been lowered the appropriate distance.

WARNING: Do not allow the bag to rest on the top

of the PA system.

6. The laborer/operator can now climb the ladder to

the safety railed platform once the bag is in this

position.

WARNING: The person on the platform must

securely attach both safety chains across the

entry point when on the safety railed platform.

11

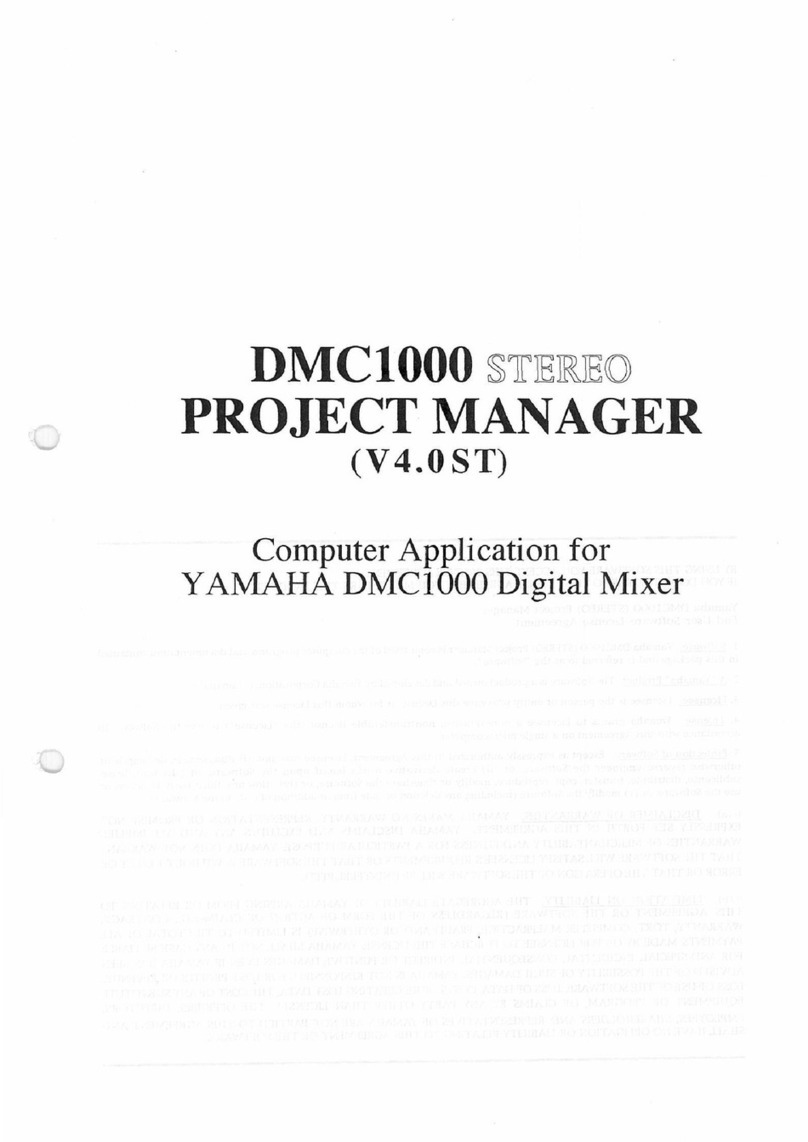

LOADING SPEC MIX®PA SYSTEMS

7. The design of the PA system and bags is such

that the material charging of the silo can be done

without accessing the PA system top.

WARNING: Stay off the top of the PA system. All

PA system loading is to be done from the safety

platform or ground only.

8. After the bag is positioned over the hatch, slide

the silo hatch open.

9. Using the SPEC MIX Safety Hook grasp and

pull the hitch pin closure or plastic closure pin

located on the outer tie on the bottom of the

bag. This will open the protective outer flap

encompassing the bag’s discharge chute.

10. With the same SPEC MIX hook, pull the tagline

on the inner chute tie downward allowing it to

unravel into the open PA hatch and dispense

material down into the unit. There will be two

separate bag ties to unlock with the safety hook.

WARNING: Product dust may be hazardous. SPEC

MIX contains Portland cement and lime, masonry

cement, mortar cement, additives, sand and/or

color pigment that may cause eye and/or skin

irritation. We advise anyone using our product to

wear a NIOSH-approved dust protection mask,

eye protection, gloves, and appropriate clothing

to help protect from possible injury. Wash hands

thoroughly after handling. In case of eye contact,

immediately flush with plenty of water for at least

15 minutes. Contact a physician immediately.

Keep out of the reach of children.

11. Repeat these exact procedures for each bag

emptied into the silo for charging.

REQUIRED EQUIPMENT

Hard Hat

Gloves

Safety Harness

Safety Goggles

Dust Mask Recommended

12

OPERATING SPEC MIX®PA SYSTEMS

1. Position mixer under the flexible boot on the end of

the discharge auger to facilitate dumping of mixed

product into mud box or tub.

2. Place discharge chute as close as possible to mixer

protective grate or orifice. The height of the PA system

can be raised or lowered to accommodate most any

mixer. See instructions “Assembling PA systems”.

3. Start the mechanical mixer or mixer-pump.

4. Introduce 2/3 of needed mixing water into mixer. Start

the PA system (see starting instructions in “Starting

up” section. Next, locate the corded auger switch

that controls the flow of SPEC MIX preblended

material into the mixer. This is on a cord that extends

from the power pack.

5. To start the flow of material, push the switch forward

or backward to allow a steady stream of material to

flow into the mixer.

NOTE: Do not leave the switch unattended while

charging the mixer.

6. Adjust mix as needed by adding either more water or

SPEC MIX in order to obtain a workable or optimal

consistency.

7. Mixing times are 4-5 minutes per batch unless

otherwise specified in the Product Data Sheet’s

mixing instruction section. Mix each batch fully

according to standards.

WARNING: Injurious to eyes, lungs. Causes skin

irritation. SPEC MIX contains portland cement and

lime, masonry cement, mortar cement, additives, sand

and/or color pigment.

8. Avoid eye contact, prolonged breathing of dust or

contact with skin. Recommended are appropriate eye

protection, gloves and the proper clothing to protect

from prolonged exposure.

9. Wash hands thoroughly after handling. In case of eye

contact, immediately flush with plenty of water for at

least 15 minutes and consult a physician. Protect from

prolonged exposure.

10. When finished using the PA system on the project or

before relocation, follow clean-out procedures. See

“Cleaning out the SPEC MIX PA system” in Relocating

PA system.

13

RELOCATING SPEC MIX®PA SYSTEMS

1. One of the many advantages of the SPEC

MIX PA system is the easy relocation of the

equipment. The ability to move the PA system

around the jobsite enables the forklift operator

to deliver mortar quickly and efficiently.

2. Select a position on the jobsite where ground

is dry, compacted, level and stable. (See

additional requirements in “ASSEMBLING SPEC

MIX PA systems.”)

3. Empty PA system as much as feasible or as

much as possible. (Material may be re-loaded

into an empty bag if necessary.)

4. Cleaning Out the SPEC MIX PA systems:

Run the PA system until material stops flowing

from the discharge auger and the interior of

the PA system appears to be reasonably free

of material. To completely clean the PA system

out, remove the threaded cap at the lower

end of the discharge auger. Allow the material

to drain until it stops, then engage the motor

and run the augers keeping hands out of the

cleanout hole. Place a container underneath the

cleanout to catch the material as it flows out.

Use or discard appropriately.

WARNING: Do not enter interior of the PA system

hopper for any inspection or maintenance. If

absolutely necessary, turn of the PA system and

perform lockout procedures. All personnel must

follow confined space entry procedures (OSHA).

NOTE: The PA1000 and PA4000 weigh

approximately 1,200 to 2,200 pounds,

respectively. See PA System specifications on

page 3 above for more specifics.

5. Remove mixer and any obstructions that may

hinder the freedom of movement, including any

hardened material around base of silo legs and

foot pads.

6. With the PA system empty and turned off, insert

the forklift forks into the PA unit’s fork tubes to

their full depth.

14

RELOCATING SPEC MIX®PA SYSTEMS

NOTE: A proper capacity forklift must be utilized

to lift the standard weights of the PA system

and material being used. See PA system

specifications above.

7. Slightly raise PA system and remove hitch pins

and leg pins from legs. Lower PA system while

manually raising ladder to avoid damage, if the

model is equipped with a ladder.

8. Once lowered to the transportation mode re-

install leg pins and hitch pins to their original

position.

9. If the terrain the PA system is being transferred

over is rough and uneven, secure a third contact

point between PA unit and forklift using chain

or strap with minimum tensile strength of 5,000

pounds live working load.

NOTE: The third contact point is necessary for

preventing the PA system from sliding off the

forklift forks during any jobsite transportation.

10. Slowly transport PA system to new location.

11. Follow same guidelines for initial erection of PA

system paying note to soil conditions as before.

12. Re-charge PA system following the instructions

for Loading SPEC MIX Power Auger Systems.

15

MAINTENANCE OF SPEC MIX®PA SYSTEMS

1. Maintenance begins on the day the silo is delivered.

a. PA system should be coated with release agent as supplied by Arrow/Mag-nolin, ZEP, or other

manufacturer.

b. Make sure all warning signs and decals are in appropriate locations on PA system and work platform. If not,

contact your local rep.

c. Check power pack, ladders, legs, augers, discharge boots for all parts, alignment, and ease of operation.

d. Check all leg pins, hitch pins, cables, stabilizer nuts and bolts, hatches, and safety chains for ease of

operation and proper locations.

e. Upon silo erection at jobsite, cover legs with poly, form release agent or utilize another method to protect

leg assemblies, and foot pads from material collection.

2. Daily maintenance to be performed by contractor:

a. Keep top hatch free of excess material in order to facilitate ease of opening and closing.

b. Check safety chains for stress.

c. Check discharge chute for proper height rips or tears. Replace as needed.

d. Check to make sure all warning signs are visible and in their proper location.

e. Check to ensure that all non-skid tapes are in place.

f. Check to make sure that all handles, chains, leg pins, hitch pins, and cables are in place and not bent, cut

or damaged. If so, replace immediately.

g. Inspect PA legs for alignment, dents or bending. Replace PA system immediately if necessary.

h. Check PA system for plumb and level.

i. Check position of all four 24 x 24 inch foot pads.

3. Power Pack Daily/Weekly Maintenance:

a. Inspect and Clean air filter on motor after every day of use. Install new air filter if it is excessively dirty or

damaged.

b. Check hydraulic oil for proper level. Adjust as needed.

c. Check Motor oil on gas power pack for proper level. Adjust as needed.

d. Check grease zerts weekly and add grease as necessary.

4. Upon return to Distributor or SPEC MIX Licensee, check the following and correct or replace as needed.

a. All signs are clean and visible.

b. All safety chains and clasp are operational.

c. PA unit is clean and empty.

d. Discharge chute is not cut, torn or weathered.

e. Material flow basket is intact, clean and operational.

f. Legs are free of mortar build-up.

g. Top of PA unit is free of excessive mortar build-up.

h. Top hatch integrity is sound and free of defects, broken welds or supports and free of mortar build up.

NOTE: Damaged PA legs affecting the integrity of the PA system must be replaced immediately before PA set up or

any continued use.

NOTE: There is no replacement schedule for the hitch pins unless a manufacture defect is evident.

WARNING: Do not enter the interior of the PA system hopper for any inspection or maintenance. If absolutely

necessary, personnel must follow confined space entry procedures as outlined by OSHA.

SPEC MIX PA systems have undergone constant improvement since their inception. Some retrofit actions are

necessary to maintain the highest safety standards.

1-888-SPECMIX

PHONE

1230 EAGAN INDUSTRIAL RD., STE 160, EAGAN, MN 55121

FAX 651-454-5315 WWW.SPECMIX.COM

© 2021 SPEC MIX, INC.

This manual suits for next models

1

Other SPEC MIX Music Mixer manuals