Spectra Watermakers Z-Ion Catalina 300 Mk II User manual

Popular Water Dispenser manuals by other brands

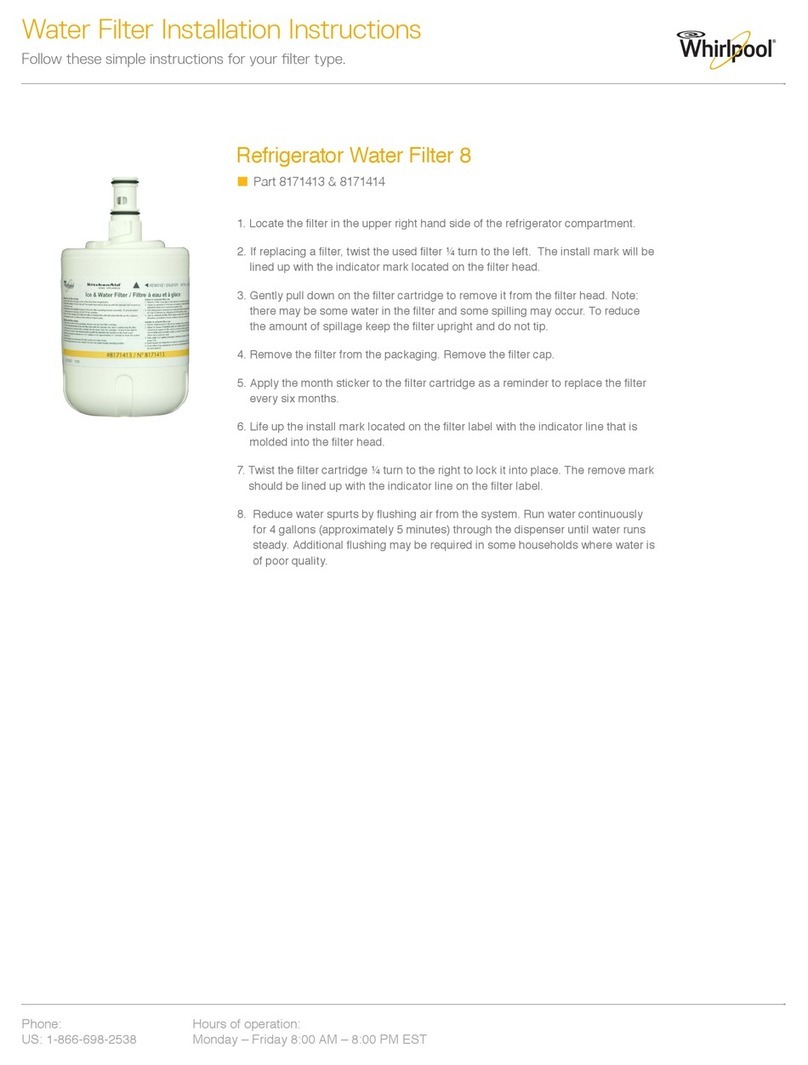

Whirlpool

Whirlpool 8171413 installation instructions

Kenmore

Kenmore 625.384480 owner's manual

CalMag

CalMag CalSoft Series manual

Cosmetal

Cosmetal UV Connect 28 A Installation, use and maintenance handbook

Aquaport

Aquaport AQP-SFS-IH Installation & operating instructions

Hague Quality Water

Hague Quality Water WaterMax ST Series Owner's manual and installation guide

Drija

Drija ACQUA user manual

GE

GE GXMH31H00 Owner's manual and installation instructions

Haier

Haier WDQS055 installation instructions

Follett

Follett L78614 Installation, operation and service manual

3M

3M Aqua-Pure CS Series Installation and operating instructions

Everpure

Everpure Water Filter and Cartridge QL2-OW200L Installation and operation guide

Grohe

Grohe Blue Chilled & Sparkling manual

Brita

Brita PURITY 600 Quell ST manual

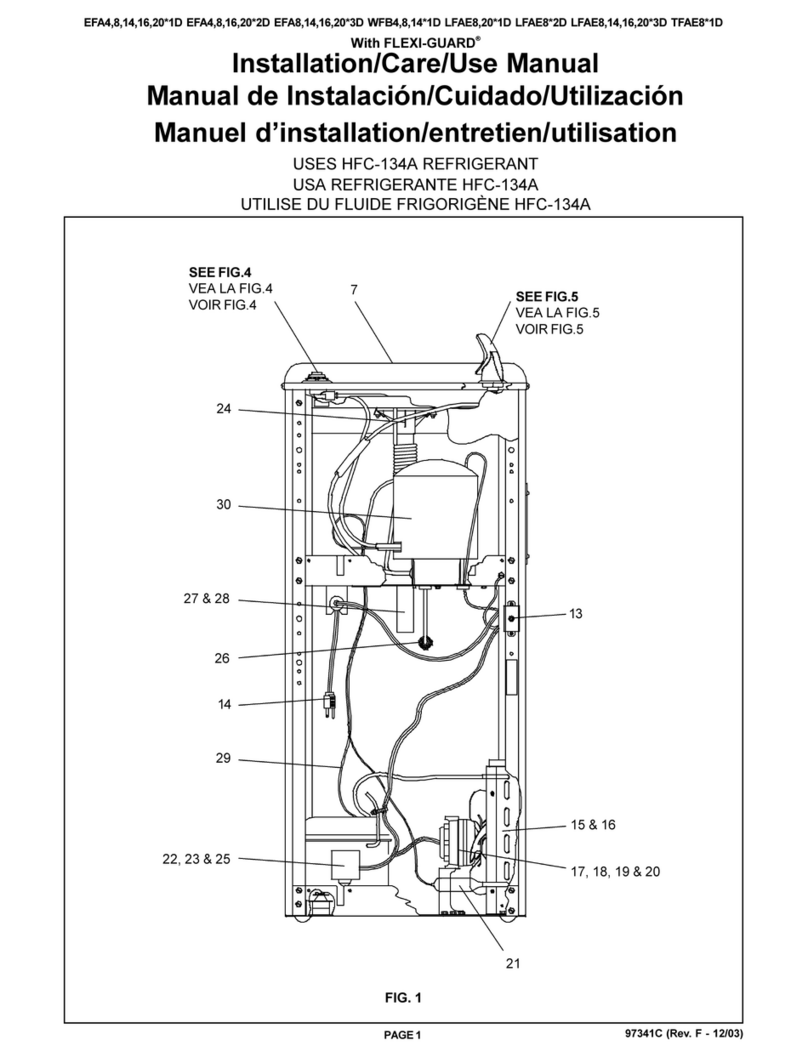

Elkay

Elkay EFA4 1D Series Installation, care & use manual

Scalemaster

Scalemaster SL TWIN E Installation & operation manual

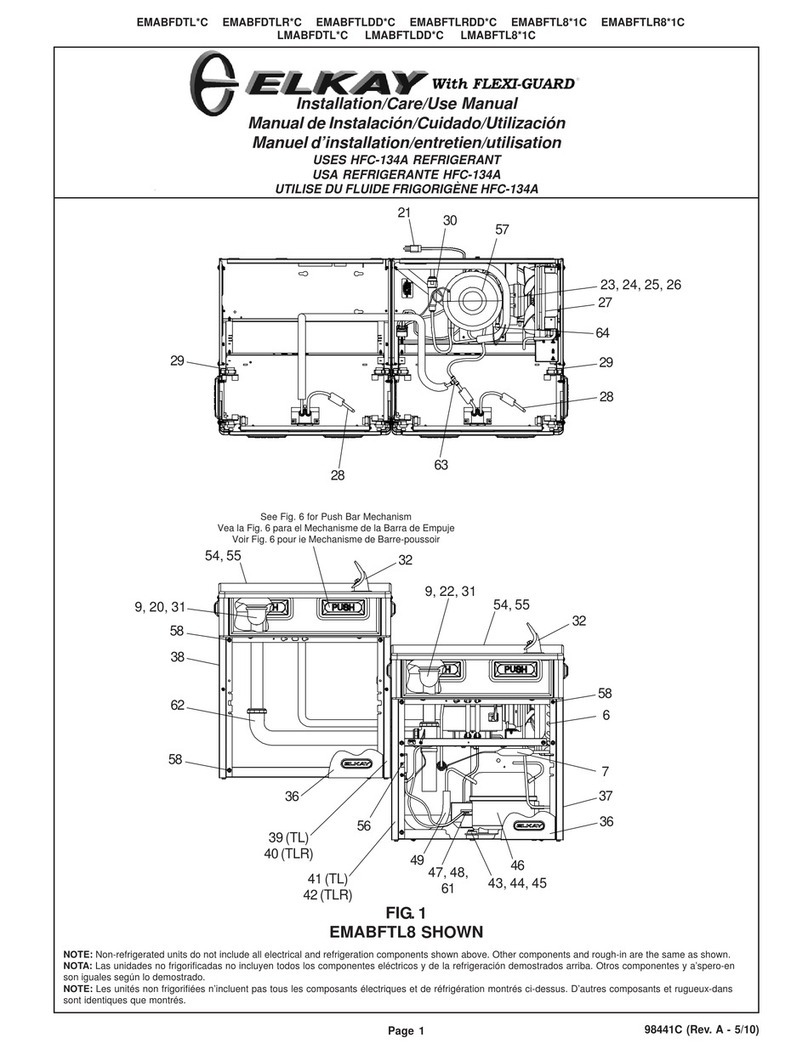

Elkay

Elkay EMABFDTL C Series Installation, care & use manual

blupura

blupura BLUSODA HOT Series Use & maintenance manual