Spectris NDC PREHEATER MCS120 Manual

PREHEATER MCS120 /190 /280

OPERATOR GUIDE

- daily operation and routine maintenance -

Making Light Work

www.ndc.com/betalasermike

Manual Part Number: 1053-1594EN

English • Revision 4 • © Copyright April 2020

Preheater MCS120/190/280 Operator guide

Part Number: 1053-1594EN Page 2 of 15 Revision 4 (April 2020)

Contents

Proprietary Statement.................................................................................................3

European Commission Requirements ...................................................................4

Safety Information .......................................................................................................5

Workstation....................................................................................................................6

Controls..........................................................................................................................7

State Indicator Icons ................................................................................................8

Preset Control Panel................................................................................................8

Threading the Wire ......................................................................................................9

Range Switch..............................................................................................................10

Range Switch Setting.............................................................................................10

Operation procedure.................................................................................................11

Operator Maintenance ..............................................................................................11

Troubleshooting.........................................................................................................12

Servicing and Returning Your Equipment...........................................................14

Contact Information ..................................................................................................15

Preheater MCS120/190/280 Operator guide

Proprietary Statement

Part Number: 1053-1594EN Page 3 of 15 Revision 4 (April 2020)

Proprietary Statement

Manufacturer/Distributor

NDC Technologies Inc., 8001 Technology Blvd., Dayton, OH 45424, USA

About This Manual

This manual contains descriptions, drawings, and specifications for a NDC Technologies product.

Equipment or products made prior to or subsequent to the publication date of this manual may have parts,

features, options, or configurations that are not covered by this manual. Specifications contained herein are

subject to change by NDC Technologies without prior notice. NDC Technologies is not responsible for

errors or omissions that may be contained herein or for incidental or consequential damages in connection

with the furnishing or use of this information.

The information contained in this manual is the property of NDC Technologies. The information disclosed in

this document is furnished in confidence and upon the condition that individual and corporate intellectual

rights, whether patented or not, will be respected. If this document is supplied on removable media (e.g.

CD), an electronic copy (stored on-site) and one printout is permitted. If this document is supplied in printed

form, no part of this document may be reproduced or scanned without the prior written consent of NDC

Technologies. This document may not be distributed or circulated to third parties.

Limited Warranty

NDC Technologies will correct by repair, or at NDC Technologies’ option, by replacement, F.O.B NDC

Technologies’ plant, any defect in workmanship or material in any equipment manufactured by NDC

Technologies which appears under normal and proper use within twelve months from the date of shipment

(eighteen months for OEM’s), provided NDC Technologies is given reasonable opportunity to inspect the

alleged defective equipment at the place of its use and under conditions of its use.

EXCLUSIONS: This warranty does not cover products which have been modified, altered, or repaired by

any other party than NDC Technologies or its authorized agents. Furthermore, any product which has been,

or is suspected of being damaged as a result of negligence, misuse, incorrect handling, servicing, or

maintenance; or has been damaged as a result of excessive current/voltage or temperature; or has had its

serial number(s), any other markings, or parts thereof altered, defaced, or removed will also be excluded

from this warranty.

WARRANTY SERVICE AT CUSTOMER SITE: Warranty service performed at the customer’s facility will be

free of charge for parts and labor; however, the customer will be liable for transportation and living expenses

of personnel dispatched to effect such repair. A purchase order or other written confirmation of the

acceptance of these charges, signed by an authorized individual, will be required prior to commencement of

repairs. Additional charges may be assessed the customer if: 1) The equipment is not made available on a

timely basis, 2) The equipment is found to be without fault, and/or 3) It is determined the equipment is not

under warranty, whether by expiration of the warranty or any act which voids the warranty.

OTHER THAN AS SET FORTH HEREIN, NDC TECHNOLOGIES MAKES NO WARRANTIES,

EXPRESSED OR IMPLIED, OF MERCHANTABILITY AS TO THE EQUIPMENT MANUFACTURED BY IT,

AND THERE ARE NO EXPRESSED OR IMPLIED WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE THEREOF. NDC Technologies’ obligation to correct defects in such

equipment by repair or replacement in accordance with the foregoing provisions is in lieu of any other

warranties, expressed or implied, and in no event shall NDC Technologies be liable for incidental or

consequential damages. No service of NDC Technologies’ equipment is permitted during the warranty

period without the specific written consent of NDC Technologies.

Note:

For information

about servicing

and returning

your equipment,

see the section at

the end of this

manual.

Preheater MCS120/190/280 Operator guide

European Commission Requirements

Part Number: 1053-1594EN Page 4 of 15 Revision 4 (April 2020)

European Commission Requirements

This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to other

equipment. There is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to other equipment, the user is encouraged to

try to correct the interference by one or more of the following measures:

- Re-orientate or relocate the equipment.

- Increase the separation between the pieces of equipment.

- Connect the pieces of equipment on separate mains circuits.

- Ensure that the relevant items of equipment are properly and securely earthed to a common

earth point using adequately sized cable or other means of connection.

- Where supplied or specified, shielded interconnection cables must be employed with this

equipment to ensure compliance with the pertinent RF limits.

This product has been rigorously tested to comply with the European EMC (Electromagnetic

Compatibility) Directive. With regard to this, NDC Technologies recommends that any non-

NDC Technologies peripheral equipment is CE marked. NDC Technologies also recommends

that any cables not supplied by NDC Technologies, but used for powering NDC Technologies

equipment, be built using good EMC practices (i.e. cables with braided shield, and connectors

with 360termination of the braid to a metal/metalised shell connector at both ends). If you

have any questions regarding this, contact the NDC Technologies Service Department.

Declaration of Conformity for this product is available upon request.

Preheater MCS120/190/280 Operator guide

Safety Information

Part Number: 1053-1594EN Page 5 of 15 Revision 4 (April 2020)

!

Safety Information

Electrical connections should be performed by a suitably qualified

person for the country of installation.

High Leakage Current. This equipment must be earthed.

Relays and associated wiring are rated for SELV levels i.e. 60vdc &

30vac rms. These levels must not be exceeded.

Fatal voltages are present within this equipment. The equipment

must be isolated before any internal access is attempted. The

residual voltages will take at least 5 MINUTES to discharge after

disconnection from the main electrical supply.

Operators need to read the relevant manuals, be trained in basic usage/safety and are

advised to wear gloves when handling the wire as the wire can become hot and the

pulleys also sharp after sustained use. Beware also of finger entrapment between the

pulley and the wire and the possibility of a wire break.

Ear protection is recommended for prolonged periods next to the preheater.

Warnings on Equipment

HOT SURFACES SYMBOL

This label is affixed to the pulley guard-door to warn of hot surfaces.The

pulleys and the wire under production will be running at high

temperature. The wire can remain at high temperature for considerable

distance after

exiting the preheater.

HIGH VOLTAGE SYMBOL

This label is affixed to the rear door of the electronics cabinet to warnthat

high voltages are present within thecabinet and the danger of electric

shock or electrocution exists if thecabinet is opened.

CAUTION SYMBOL

This label is affixed to front and rear doors to warn that safety interlocks

are in operation that can either electrically lock the doors or switch off the

preheater and stop the production line as appropriate.

READ THE MANUAL SYMBOL

This label is affixed to the access panel to the filter.

CHECK AND CLEAN/CHANGE FILTER REGULARLY

Preheater MCS120/190/280 Operator guide

Workstation

Part Number: 1053-1594EN Page 6 of 15 Revision 4 (April 2020)

Intended Use

The preheater is for use on production lines manufacturing communicationcables. The

unit is installed immediately ahead of the extruder and is used to heat the metalliccore of

the cable, thereby improving the adhesion of the insulation to thecore and, in the case of

foam insulation, improving the bubble structure.

Ifyou use the equipment in a manner not specified by the manufacturer *or if an out-of-

specification product is introduced, the protection provided by the equipment may be

impaired. In this case, the customer is responsible for taking the necessary precautions to

ensure operator safety.

* For example, minimum cut on speed most be set greaterthan the operator can pull the

product through the preheater during normal string up. This is to prevent the preheater

from turning on during the stringing up the process.

See also section ‘Materials to be Processed’ in the Specification.

Workstation

* wire input/output side can also be on other side depending on what was ordered.

control

panel

range

switch

door

handle for

accessing

pulleys

wire

input/exit

(on side of

unit*)

Preheater MCS120/190/280 Operator guide

Controls

Part Number: 1053-1594EN Page 7 of 15 Revision 4 (April 2020)

Controls

Display Shows the value of the preheating temperature set, or the actual voltage being applied to

the product in the shorted loop.

°C, °F, V Illuminated icons associated with the display.

When the C or F icon is illuminated, the value displayed (in C or F respectively) is

that set via the panel controls in the local mode or that set through the preset

temperature input in the remote mode.

When the V icon is illuminated, the display shows the loop voltage.

Alternates the display between reading voltage or set temperature.

and Sets the preheating temperature when in local mode. These buttons are disabled in

remote mode and when the display is showing voltage.

Setting range is 1 to approximately 500C (or 932F). In practice the maximum safe

setting is determined by the pulley material and is normally less than 500C.

and Sets the preheater ON or OFF. The button which is illuminated indicates the operating

state. For power to be supplied to the wire, the button must be illuminated and the

line speed must exceed the cut-on point. When the ON / OFF state is being remotely

controlled, the buttons are disabled but the currently illuminated button continues to

indicate the state correctly. The button is also used to reset an overcurrent or

wire break fault condition whether under local or remote control.

Preheater MCS120/190/280 Operator guide

Controls

Part Number: 1053-1594EN Page 8 of 15 Revision 4 (April 2020)

State Indicator Icons

Three illuminated icons to show the preheater operating state as follows:

Remote Icon

Illuminates when the set temperature is being remotely controlled.

It does NOT indicate remote control of the ON/OFF state.

Run Icon

Illuminates when power is being supplied to the wire.

Fault Icon

Illuminates if an inverter fault, current overload, or wirebreak occurs or if the temperature

in the lower part of the cabinet exceeds 43C (109F). No power is supplied to the wire in this state.

Preset Control Panel

A number of presets are located beneath this panel as follows:

Calib

Two rotary decade switches used to set a calibration factor to match the actual wire temperature to

the value set. The scaling is 0 to 99%, in 1% increments. The setting depends on the preheater

type and whether copper or aluminium is being processed. The switches are set to the nominal

value unless a means of measuring the actual wire temperature is available.

Bias

Two rotary decade switches used where the unit is required to give an accurate temperature over a

wide speed range. Its effect is to increase the temperature at the low speeds. The scaling is 0 to

99%, in 1% increments. The switches are set to 0% unless a means of measuring the actual wire

temperature is available.

Cut-On Speed

Rotary decade switch used to set the speed above which power is supplied to the wire. The scaling

is 0 to 90m/min (295.28feet/min), in 10m/min (32.81feet/min) increments. A high setting reduces

the chance of an accident if the operator attempts to thread the production line whilst the unit is in

the ON state. However, the value set must be lower than the intended running speed.

Wire Break Threshold

Rotary decade switch used to set the change in load current required to trip the wire break detector.

The scaling is 0 to 90% of the rated output current, in 10% increments. This function is particularly

useful when a ring marker is in use since should the wire snap immediately after the extruder a fire

can occur. In this event, the wire break circuit cuts the power instantly even though the preheater

pulleys are still rotating. The threshold is set at the nominal load current. It will then reliably detect

a change down to half and up to double the current. Do not use a low setting with a high current

since this may result in nuisance tripping. Set to 90% if this function is not required. DO NOT set to

0.

Preheater MCS120/190/280 Operator guide

Threading the Wire

Part Number: 1053-1594EN Page 9 of 15 Revision 4 (April 2020)

°C / °F Switch

Sets the units of measurement for the set temperature. It also sets the scaling of the remote set

temperature input and the connections to the Rotatemp. The C and F icons reflect

the switch setting.

Rotatemp 1 / 0 Switch

When a Rotatemp is fitted it can be used purely as an indicator of the true wire

temperature or in a feedback mode - where the power supplied to the wire is automatically trimmed

to eliminate any error. Set this switch to "1" to enable the feedback loop. Set the switch to "0" if a

Rotatemp is not fitted, otherwise a large temperature error will occur.

RUN / TEST Switch

Changes the display function and overrides the button. Set the switch to RUN for normal

operation. Set the switch to TEST to display the Inverter percentage set point or current, as

determined by the SP% /I% Switch described below. The switch does not affect the operation of

the

preheater and therefore it can be operated whilst heating wire.

SP% /I% Switch

Only active when the RUN / TEST Switch is in the TEST position. Set the switch to SP% to display

the percentage of the Inverter set point being used. The loop voltage and hence power delivered to

the wire is at its maximum with a set point of 100. The reading can rise to approximately 140 but in

this case the preheater has lost control and the actual wire temperature will be below the value set.

Set the switch to I% to display the percentage of available current being used. The current

overload trips at approximately 110%.

Threading the Wire

Gloves must be worn for this procedure and eye protection is recommended.

MCS120

Starting at the inlet hole, pass the wire over the top pulley back groove and down through the core

tube. Pass under the lower pulley and up through the second core tube. Pass over the upper pulley

front groove and horizontally to the exit hole.

MCS190

Starting at the inlet hole, pass the wire over the 200mm (7.87in) top pulley back groove and around

the 120mm (4.72in) pulley just below. Pass over the 200mm top pulley front groove and down

through the core tube. Pass under the 200mm lower pulley, over the second 120mm pulley and

again over the upper pulley front groove, where it touches the wire laying in the groove over a

20arc before exiting horizontally.

MCS280

The MCS280 is similar to the MCS120, except there is only one core tube.

Preheater MCS120/190/280 Operator guide

Range Switch

Part Number: 1053-1594EN Page 10 of 15 Revision 4 (April 2020)

Range Switch

The Range Switch maximises the transfer of power to the wire being processed. It alters the

effective number of turns on the induction transformer primary winding. Choosing the correct range

becomes important when the power required from the preheater is close to its rating. A low setting

will match a large wire but will limit the maximum preheating speed. A high setting will match a

small wire and enable a high preheating speed to be achieved.

The switch has to be pushed before it can be rotated. This operates an interlock, which stops

preheating whilst changing the range.

The Range Switch provision varies according to the preheater type as follows:

MCS120

No Range Switch. The units are individually wound to suit requirements. Only one wire size can be

perfectly matched but a range of wires can still be processed if the power requirements are low.

MCS190

A three-position Range Switch. This preheater is also individually wound to suit requirements,

which, together with the relatively small range of wires sizes used on this unit, enables excellent

matching to be achieved.

MCS280

A three-position Range Switch. Individually wound.

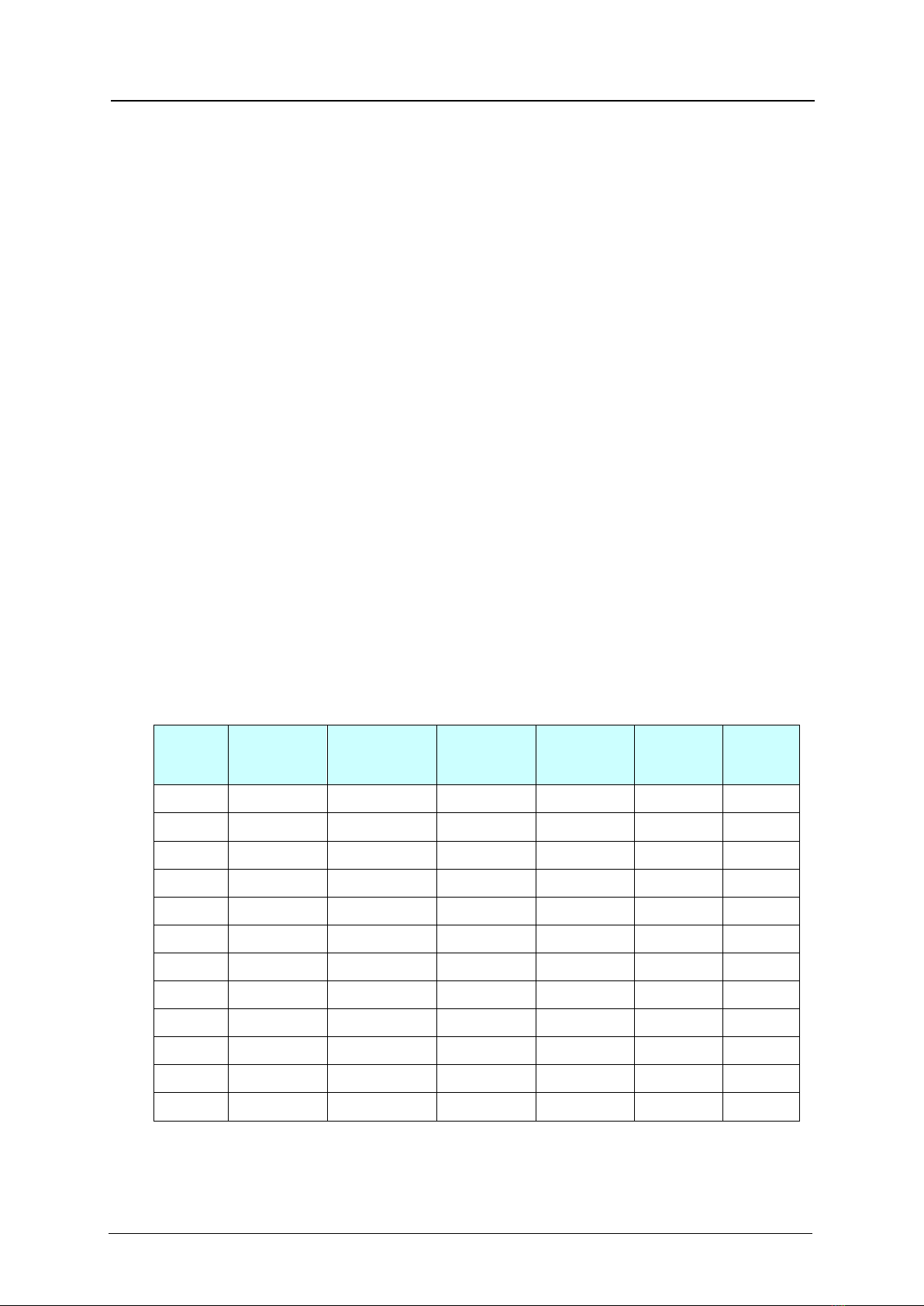

Range Switch Setting

Unit: MCS …………

Serial number:

Product

Number

Wire Dia.

Wire Area

Range

Switch

Position

Wire

Material

Speed

m/min

Temp

C

1

2

3

4

5

6

7

8

9

10

11

12

Preheater MCS120/190/280 Operator guide

Operation procedure

Part Number: 1053-1594EN Page 11 of 15 Revision 4 (April 2020)

Operation procedure

•Ensure Threading the Wire has been carried out.

•Set the Range Switch [if fitted] to suit the wire size (see Range Switch heading).

•Check the display and use the button, if necessary, so that Set Temperature is displayed.

•Set the required preheating temperature using the and buttons.

•When the production line is ready press the button. It should illuminate to indicate the

preheater is ready to supply power when the line starts. Note that the door bolt must be released

to allow the unit to enter the ON state.

•Start the production line, the RUN icon will be illuminated when the line speed exceeds

the Cut-On Speed.

Operator Maintenance

Fatal voltages are present within this equipment. The equipment must be

isolated before any cleaning or maintenance is attempted. The residual

voltages will take at least 5 minutes to discharge after disconnection from

the main electrical supply.

It is recommended to use gloves and eye protection when inspecting/cleaning pulleys, as

they can become sharp due to wear and tear and metal dust can accumulate.

The preheater pulley bearings are sealed and hence need no attention. The bearing for the

Rotatemp needs occasional re-greasing. There are no brushes to change.

After sustained periods of use the pulleys can become sharp at their edges and can also show

signs of wear in the pulley groove itself. Inspect the pulleys regularly for wear (especially in the

case of the shorting rim units) and replace if necessary. A monthly inspection is recommended to

help catch line tension and alignment problems before excessive damage occurs.

Once a month check interior of machine for hazardous build up of copper dust / flakes.

At the same time inspect the core tube or tubes and check that filter fan is working.

When pulleys needs cleaning use a soft wire brush, wipe with a clean cloth/rag and finally vacuum

up the loose copper dust in the unit.

Preheater MCS120/190/280 Operator guide

Troubleshooting

Part Number: 1053-1594EN Page 12 of 15 Revision 4 (April 2020)

Troubleshooting

Description

Possible Cause

Action

Preheater does not

start

(fault contact open, but

fault icon not illuminated)

No power

Check Isolator switch and mains supply.

Both the remote start and stop

contacts were closed while the

door solenoid is energized

De-energize the door solenoid or open

the remote stop contact.

Both remote start and stop

contacts were closed while the

door is open.

Close the door or open the remote stop

contact.

Preheater power is cut

off.

(fault contact open, but

fault icon not illuminated)

Door solenoid is operated while

the Preheater is running.

De-energize the door solenoid or open

the remote stop contact.

Preheater power is cut

off (fault contact open &

fault icon is illuminated:

Temperature of the lower part

of the cabinet has exceeded

43C (109F).

Operate the local stop button or open the

remote stop contact. Then try a lower

range switch setting (see heading below).

Wirebreak.

Rethread cable and restart Preheater.

See heading on Wirebreak below.

Current overload.

Check range switch setting.

Check whether cable diameter exceeds

maximum limit.

Blown fuse.

Contact Beta LaserMike Support.

Inverter fault.

Accuracy

One source of temperature error is heat loss into the metal rim shorting pulley and this alters with

wire size, speed and pulley diameter. The worst case is with a small wire at low speed with a large

pulley. The MCS190 has low losses due to its ceramic pulleys.

A second source of error is due to the inlet wire temperature. This is assumed to be at ambient

temperature but if the wire has been stored outside it may be at a considerably lower temperature.

Alternatively, the preheater may be sited after an inline annealer, in which case the wire may be

hot.

In general, an error of less than 10% occurs under typical conditions and the repeatability is far

better. The accuracy can be improved for one wire size if a means of measuring the true

temperature is available. Set as follows:

•Remove the preset panel cover.

•Run the line at the highest intended line speed.

•Adjust the Gain.

•Run the line at the lowest intended line speed.

•Adjust the Bias.

•Refit the cover.

Preheater MCS120/190/280 Operator guide

Troubleshooting

Part Number: 1053-1594EN Page 13 of 15 Revision 4 (April 2020)

Wirebreak Function

To automatically cut the heating power when a wirebreak occurs the sensitivity must be set to suit

the running conditions. This will minimise the possibility of nuisance tripping while ensuring a break

is detected. Set as follows:

•Run the line under typical conditions.

•Remove the preset panel cover.

•Move the RUN / TEST Switch to the TEST position.

•Put the SP% /I% Switch to the I% position.

•Note the meter reading and set the Wire Break threshold to approximately this value. For

example, if the meter reads 40% then set the sensitivity to 40%, i.e. position 4. Note that each

step is 10%.

•Replace the cover.

Range Switch Setting

If the fault icon illuminates whilst running up the line and there has not been a wirebreak

then try a lower Range Switch setting.

If the temperature is too low with the line running at the production speed and increasing the set

point has no effect, then the unit is voltage limiting. This can be confirmed by checking the SP% as

described Operator Guide. In this case try a higher range switch setting.

Line tension

The following problems will result if the line tension is too low:

- The shorting pulley will erode rapidly.

- The wire surface will be lightly pitted due to sparking.

- The wire temperature will fluctuate.

- The wire may touch and wear the induction transformer core tube.

- The wirebreak detector may operate.

Wire Sizes

Whilst some flexibility is allowed, do not grossly exceed the upper wire size limit since this will

rapidly wear the pulleys and may overheat them. The bearings could also suffer since a large wire

will need high tension.

Preheater MCS120/190/280 Operator guide

Servicing and Returning Your Equipment

Part Number: 1053-1594EN Page 14 of 15 Revision 4 (April 2020)

Servicing and Returning Your Equipment

Your instrument was carefully inspected electrically and mechanically prior to

shipment. It should be free of surface mars and scratches, and it should be in

perfect working order upon receipt. If any indication of damage is found, file a

claim with the carrier immediately, prior to using the instrument. If no damage is

apparent, proceed by using this manual to install and setup this instrument.

Save the shipping carton and packing material for future storing or shipment of

the instrument. If, at some future time, the instrument must be returned to the

factory for service, include a full description of the instrument failure and the

mode of operation the instrument was in at the time of failure. Also include a

contact person to discuss the instrument failure.

When returning equipment for service, it is important to first obtain a Return

Material Authorization (RMA) number. The RMA number is needed for proper

handling of returned equipment. To obtain an RMA go to https://ndc.custhelp.com/

and click on link ‘RMA Request’.

Ship the instrument in the original carton, or, if the original carton is unavailable,

ship in a carton providing sufficient protection. Send the instrument to the Asia,

Europe, or USA office, whichever is closest to you or to the office indicated by

your sales engineer. Place the RMA number on the outside of the carton, and

include a purchase order number and any other information specific to your

instrument.

Field warranty service is available, if the customer pays travel expenses by

advance purchase order. All service operations should be performed by skilled

electronics technicians, who have been trained by NDC Technologies. For more

information, see the Proprietary Statement at the beginning of this manual.

Preheater MCS120/190/280 Operator guide

Contact Information

Part Number: 1053-1594EN Page 15 of 15 Revision 4 (April 2020)

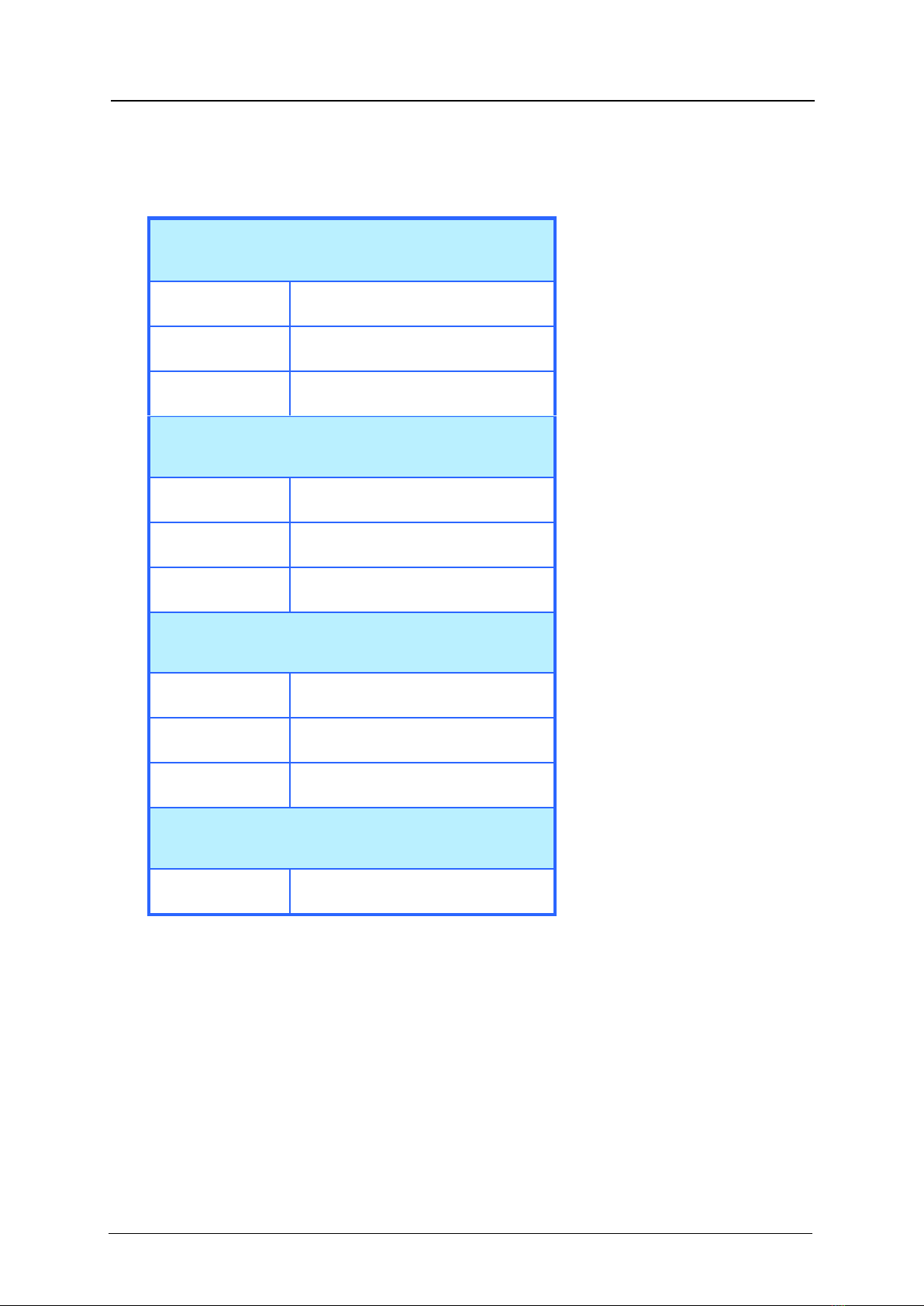

Contact Information

U.S.A. Support Desk

Tel

+1-937-233-9936

Fax

+1-937-233-7284

Website

https://ndc.custhelp.com/

EMEA Support Desk

Tel

+44-(0)1621-852244

Fax

+44-(0)1621-856180

Website

https://ndc.custhelp.com/

China Support Desk

Tel

+86-21-6113-3617

Fax

+86-21-6113-3616

Website

https://ndc.custhelp.com/

APAC Support Desk

Website

https://ndc.custhelp.com/

This manual suits for next models

2

Table of contents

Other Spectris Industrial Equipment manuals