Spectris PARTICLE MEASURING SYSTEMS HPGP 101-C User manual

HPGP™ 101-C with PDS-E

Ultra High Purity Gas Particle Counter

and Particle Detection System

P/N 1000025203

OPERATIONS MANUAL

Without measurement there is no control

HEADQUARTERS

5475 Airport Blvd

Boulder, Colorado 80301 USA

T: +1 303 443 7100

Instrument Service & Support

T: +1 800 557 6363

Customer Response Center

T: +1 877 475 3317

E: Info@pmeasuring.com

GLOBAL OFFICES

AUSTRIA

T: +43 1 71 728 285

E: pmsaustria@pmeasuring.com

BENELUX

T: +32 10 23 71 56

E: pmsbelgium@pmeasuring.com

BRAZIL

T: +55 11 5188 8227

E: pmsbrazil@pmeasuring.com

CHINA

T: +86 21 6113 3600

E: pmschina@pmeasuring.com

FRANCE

T: +33 (0)1 60 10 32 96

E: pmsfranc[email protected]

GERMANY

T: +49 6151 6671 632

E: pmsgermany@pmeasuring.com

ITALY

T: +39 06 9053 0130

E: pmssrl@pmeasuring.com

JAPAN

T: +81 44 589 3498

E: pmsjapan@pmeasuring.com

KOREA

T: +82 31 286 5790

E: pmskorea@pmeasuring.com

MEXICO

T: +52 55 2271 5106

E: pmsmexic[email protected]om

NORDIC

T: +45 707 028 55

E: pmsnordic@pmeasuring.com

PUERTO RICO

T: +1 787 718 9096

E: pmspuertoric[email protected]om

SINGAPORE

T: +65 6496 0330

E: pmssingapore@pmeasuring.com

SWITZERLAND

T: +41 71 987 01 01

E: pmsswitzerland@pmeasuring.com

TAIWAN

T: +886-3-5525300 Ext: 301

E: pmstaiwan@pmeasuring.com

HPGP™ 101-C RoHS with PDS-E

Ultra High Purity Gas Particle Counter

and Particle Detection System

Operations Manual

P/N 1000025203 Rev D

ii HPGP™ 101-C RoHS with PDS-E Operations Manual

HPGPTM 101-C RoHS with PDS-E Operations Manual

P/N 1000025203 Rev D

© 2022 Particle Measuring Systems, Inc.

All rights reserved.

Cajon® and Swagelok® are registered trademarks of the Swagelok Company.

Viton® is a registered trademark of Dupont Dow Elastomers L.L.C.

All trademarks appearing in this manual are the property of their respective owners.

This confidential document contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this document may be reproduced,

distributed, or transmitted in any form without the prior written consent of Particle

Measuring Systems. The information contained in this document is subject to change

without notice.

Quality Statement

The Quality Policy of Particle Measuring Systems is to strive to meet or exceed the

needs and expectations of our customers, and to align the activities of all employees

with the common focus of customer satisfaction through continuous improvement in

the quality of our products and services.

Environmental Information

This equipment must be properly disposed of at end-of-life by means of an

authorized waste management system. Contact our Customer Response Center at

(877) 475-3317 or (303) 443-7100 (International Telephone +1 3034437100) for

dismantling and disposal information.

DO NOT REPRODUCE OR DISTRIBUTE CONFIDENTIAL DOCUMENT

HPGP™ 101-C RoHS with PDS-E Operations Manual iii

Manual Conventions

It is important that you observe cautions and warnings while performing the

procedures described in this manual. Caution and warning labels are located on and

inside the instrument to alert you to potentially hazardous conditions. Please

familiarize yourself with this information.

WARNING

A warning in the text is used to notify the user of the potential for bodily injury or death.

CAUTION

A caution in the text is used to highlight an item that if not done, or incorrectly done, could

damage the instrument and/or any materials or devices affected by the instrument.

– — NOTICE — –

A notice in the text is an instructional communication regarding requirements or policies

issued by Particle Measuring Systems.

NOTE: A note in the text is used to highlight an item that is of operational importance

to the user.

iv HPGP™ 101-C RoHS with PDS-E Operations Manual

and Declaration of Conformity

Application of Council Directive(s): CE 2014/30/EU, 2014/53/EU, 2014/35/EU, RoHS 2011/65/EU,

2015/863

UKCA Electromagnetic Compatibility Regulations 2016,

Electrical Equipment (Safety) Regulations 2016

The Restriction of the Use of Certain Hazardous Substances in

Electrical and Electronic Equipment Regulations 2012

Standard(s) to which Conformity is Declared: EMC EN 61326-1:2013

S.I. 2016 No. 1091

Safety EN61010-1: 2010, 3rd, Ed., S.I. 2016 No. 1101, EN60825-1:2014

RoHS BS EN 63000:2018

Manufacturer’s Name: Particle Measuring Systems, Inc.

Manufacturer’s Address: 5475 Airport Boulevard

Boulder, CO 80301 USA

Manufacturer’s Telephone/FAX: + 1 3034437100 / + 1 3034496870

Distributor’s Name: Particle Measuring Systems, S.R.L.

Distributor’s Address Via di Grotte Portella 34

00044 Frascati (Roma) ITALY

Distributor’s Telephone/FAX: + 39 06 90530130 / + 39 06 9051315

Type of Equipment: Particle Monitoring

Model No: HPGP 101-C RoHS with PDS-E

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive(s) and Standard(s).

Signature: Signature:

Full Name: Scott MacLaughlin Full Name: Frank Panofen

Position: Director of Engineering Position: Marketing Manager, Life Sciences

Place: Boulder Date: April 25, 2022 Place: Rome Date: April 25, 2022

CAUTION

All I/O cables and accessories must meet current factory specifications in order for this unit to

remain in compliance with CE marking requirements. Consult the factory for details.

If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

HPGP™ 101-C RoHS with PDS-E Operations Manual v

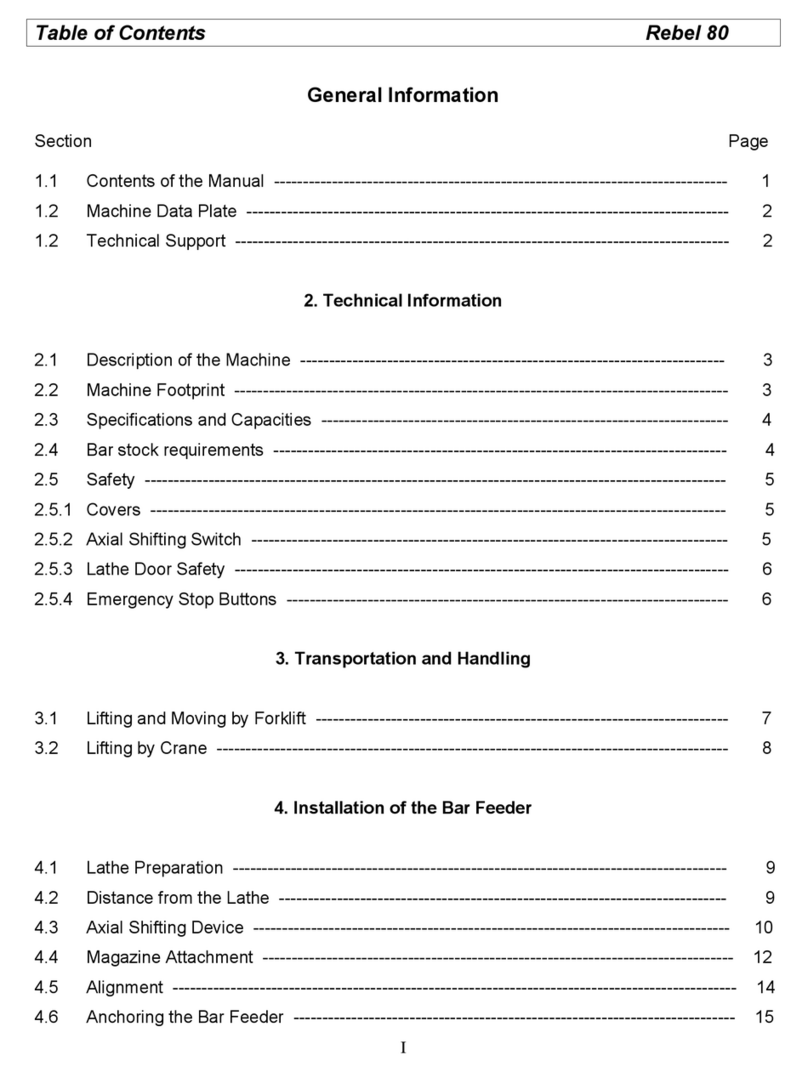

Table of Contents

List of Figures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

List of Tables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - xi

Chapter 1: Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

HPGP 101-C Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

HPGP 101-C Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

HPGP 101-C Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

PDS-E Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

PDS-E Side Panel Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

PDS-E Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

Chapter 2: HPGP 101-C Safety Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Safety Sheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Warning Labels- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Chapter 3: Unpacking and Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

HPGP 101-C Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

PDS-E Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Recycling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Installation of HPGP 101-C- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Installing the PDS-E Wall Mount - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Installing the PDS-E Rack Mount - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

Chapter 4: PDS-E Communications Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Serial Setup Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Serial Configuration Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Alphabetical List of Serial Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Telnet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

Ethernet Communication Set Up- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14

Set Ethernet Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14

Additional Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

Ethernet Settings Record- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

PMS Protocol (Facility Net) Configuration and Operation - - - - - - - - - - - 4-16

Modbus Configuration and Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - 4-16

OPC Configuration and Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17

vi HPGP™ 101-C RoHS with PDS-E Operations Manual

:

Retro Operational Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-18

Chapter 5: Performance Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Particle Size Calibration Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Reference Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Air Flowrate Calibration Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Zero Count Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Chapter 6: Maintenance and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Low Reference Voltage Background - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Checking for Leaks- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Transient Induced Counts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Nitrogen Purging and Backfilling the Probe Containment Vessel - - - - - 6-5

Pressure Method of Purging and Backfilling/Pressurizing - - - - - - - - 6-5

Vacuum Method of Purging and Backfilling - - - - - - - - - - - - - - - - - - - 6-7

Required items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

Appendix A: International Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

WARNING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

AVERTISSEMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

WARNUNG - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

ATTENZIONE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

ADVERTENCIA - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Hazard Symbols- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

Symboles de risque - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

Warnschilder - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Simboli di pericolo- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Simbolos de peligro- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Appendix B: Modbus Protocol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

Modbus Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

Input Registers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-2

Holding Registers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-6

Coils - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-7

Data Packet Processing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-8

Associated Values for Specific Registry Entries- - - - - - - - - - - - - - - - - - - - B-8

Appendix C: OPC Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

Connecting a PC to the PDS-E OPC Server - - - - - - - - - - - - - - - - - - - - - - - C-1

PDS-E OPC Data Access Tags- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-2

Appendix D: Ethernet Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - D-1

IT Department - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

Ethernet Addressing Basics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

:

HPGP™ 101-C RoHS with PDS-E Operations Manual vii

IP Address- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-2

Network Mask- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-2

Gateway Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-3

Multicast Address- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-3

MAC Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-3

Static IP Addresses versus DHCP Addresses - - - - - - - - - - - - - - - - - - - - - - D-4

Troubleshooting Ethernet Connectivity - - - - - - - - - - - - - - - - - - - - - - - - - D-5

Instrument to Laptop Ethernet Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - D-7

Method 1: Modifying the IP Settings on a PC - - - - - - - - - - - - - - - - - - - D-7

Method 2: Modifying the Settings on an Instrument - - - - - - - - - - - - - D-10

Appendix E: Serial Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - E-1

Adapters and Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-2

Useful Serial Adapters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-2

USB Serial Port Adapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

USB Driver for Windows - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

Serial Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

RJ-12 Cable and Adapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-4

Connector Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-5

Communication Software Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-6

HyperTerminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-6

PuTTY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-7

Tera Term- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-8

Communications Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-9

ENODE Specific Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-9

Troubleshooting Serial Communications - - - - - - - - - - - - - - - - - - - - - - - - E-9

No Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-9

Dropped Characters or Strange Characters- - - - - - - - - - - - - - - - - - - - E-9

Unexpected Characters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-9

Appendix F: 有毒或有害的物质和元素 PDS-E - - - - - - - - - - - - - - - - - - - - - - - - - - - - F-1

Appendix G: 有毒或有害的物质和元素 HPGP 101-C - - - - - - - - - - - - - - - - - - - - - - G-1

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Index-1

viii HPGP™ 101-C RoHS with PDS-E Operations Manual

:

This page is intentionally left blank.

HPGP™ 101-C RoHS with PDS-E Operations Manual ix

List of Figures

Chapter 1: Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Figure 1-1 The Particle Measuring Systems PDS-E and HPGP 101-C instruments - - - - - - - - - - - - - - 1-1

Figure 1-2 HPGP 101-C Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Figure 1-3 HPGP 101-C flow diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Figure 1-4 HPGP 101-C front panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

Figure 1-5 PDS-E side panel connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

Chapter 2: HPGP 101-C Safety Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Chapter 3: Unpacking and Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Figure 3-1 HPGP 101-C shipping kit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Figure 3-2 PDS-E shipping kitRecycling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Figure 3-3 Attaching the Fill Gauge- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Figure 3-4 PDS-E with wall mounting brackets- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Figure 3-5 Rack mount PDS-E (rear) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

Figure 3-6 19” Rack mount PDS-E (front) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

Chapter 4: PDS-E Communications Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Figure 4-1 Communication ports on side panel of the PDS-E. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Chapter 5: Performance Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Chapter 6: Maintenance and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Figure 6-1 HPGP 101-C Optical System diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Figure 6-2 HPGP 101-C cylinder assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Figure 6-3 Detail of HPGP 101-C cylinder assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Appendix A: International Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Appendix B: Modbus Protocol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

Appendix C: OPC Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

Appendix D: Ethernet Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

Figure D-1 Ethernet port connectivity LED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-5

Figure D-2 Example for ping test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-6

Figure D-3 Example for ipconfig command - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-6

Figure D-4 Local Area Connection Properties window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-8

Figure D-5 The IP address and subnet mask defined - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-9

x HPGP™ 101-C RoHS with PDS-E Operations Manual

:

Appendix E: Serial Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-1

Figure E-1 USB serial adapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

Figure E-2 Serial cable with DE-9 male and female connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

Figure E-3 RJ-12 adapter and cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-4

Figure E-4 HyperTerminal screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-6

Figure E-5 PuTTY Configuration screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-7

Figure E-6 PuTTY Main screen- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-7

Figure E-7 Tera Term Setup window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-8

Figure E-8 Tera Term Main window (colors reversed) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-8

Appendix F: 有毒或有害的物质和元素 PDS-E - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F-1

Appendix G: 有毒或有害的物质和元素 HPGP 101-C - - - - - - - - - - - - - - - - - - - - - - - - G-1

HPGP™ 101-C RoHS with PDS-E Operations Manual xi

List of Tables

Chapter 1: Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Table 1-1 HPGP 101-C Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

Table 1-2 HPGP 101-C Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

Table 1-3 PDS-E Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Table 1-4 PDS-E Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

Chapter 2: HPGP 101-C Safety Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Chapter 3: Unpacking and Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Table 3-1 Correction of Flowmeter for Different Gas Molecular Weight- - - - - - - - - - - - 3-8

Chapter 4: PDS-E Communications Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Table 4-1 Cable pin assignments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Table 4-2 Communication settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Chapter 5: Performance Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Table 5-1 Correction of Flowmeter for Different Gas Molecular Weight- - - - - - - - - - - - 5-2

Chapter 6: Maintenance and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Appendix A: International Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Appendix B: Modbus Protocol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

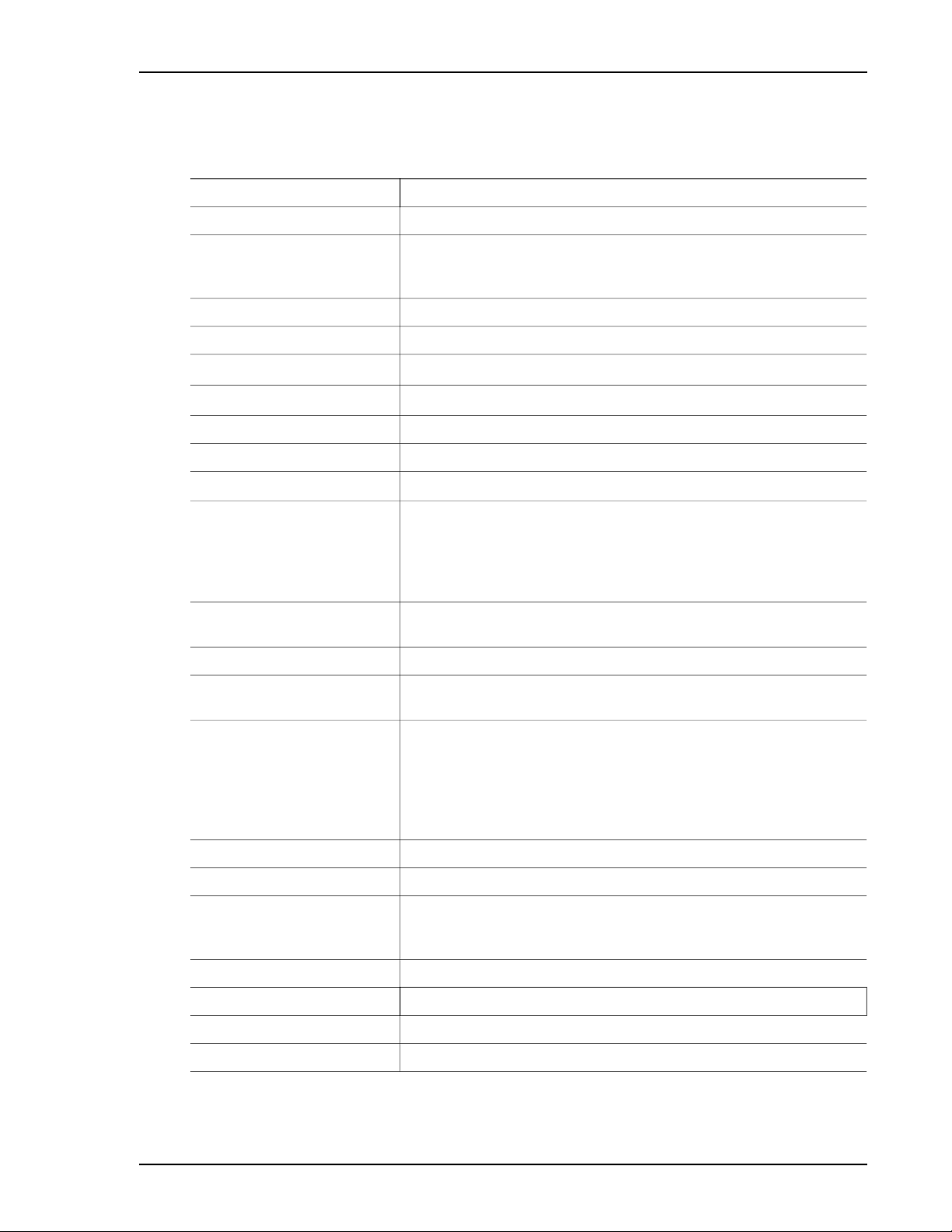

Table B-1 Input register – configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-3

Table B-2 Input register – data packet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-4

Table B-3 Holding registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-6

Table B-4 Coils- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-7

Table B-5 Associated values for specific registry entries - - - - - - - - - - - - - - - - - - - - - - - B-8

Appendix C: OPC Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

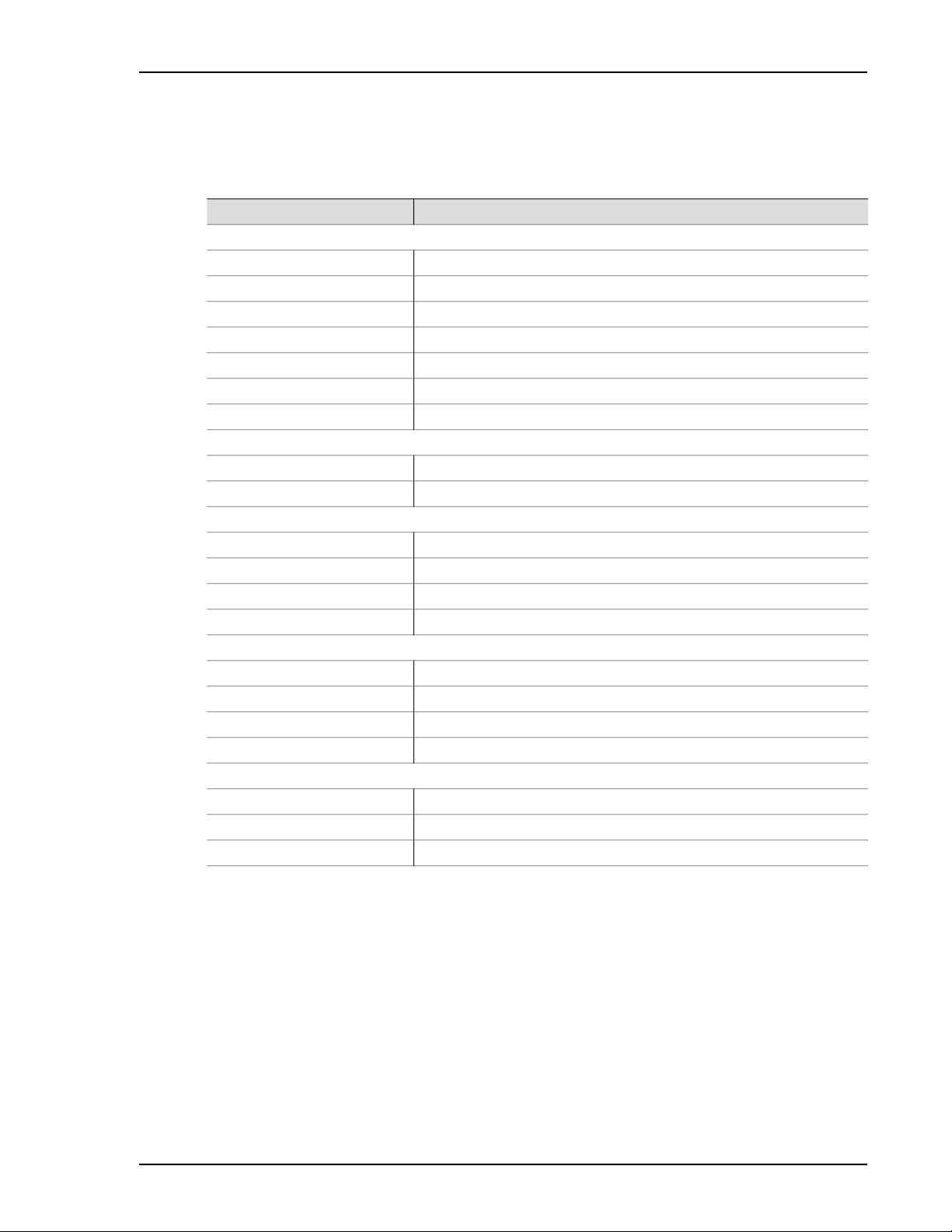

Table C-1 PDS-E OPC Data Access Tags - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-2

Appendix D: Ethernet Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

Table D-1 Private IPv4 Network Ranges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-2

Table D-2 Default Network Mask Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-2

Appendix E: Serial Communications Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-1

Table E-1 Recommended Serial Adapters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-2

Table E-2 Standard PC Serial Port (DE-9) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-5

xii HPGP™ 101-C RoHS with PDS-E Operations Manual

:

Table E-3 RJ-12 Instrument Connector- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-5

Table E-4 Communication parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-9

Appendix F: 有毒或有害的物质和元素 PDS-E - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F-1

Appendix G: 有毒或有害的物质和元素 HPGP 101-C - - - - - - - - - - - - - - - - - - - - - - - - G-1

HPGP™ 101-C RoHS with PDS-E Operations Manual 1-1

Chapter 1

Introduction

Overview

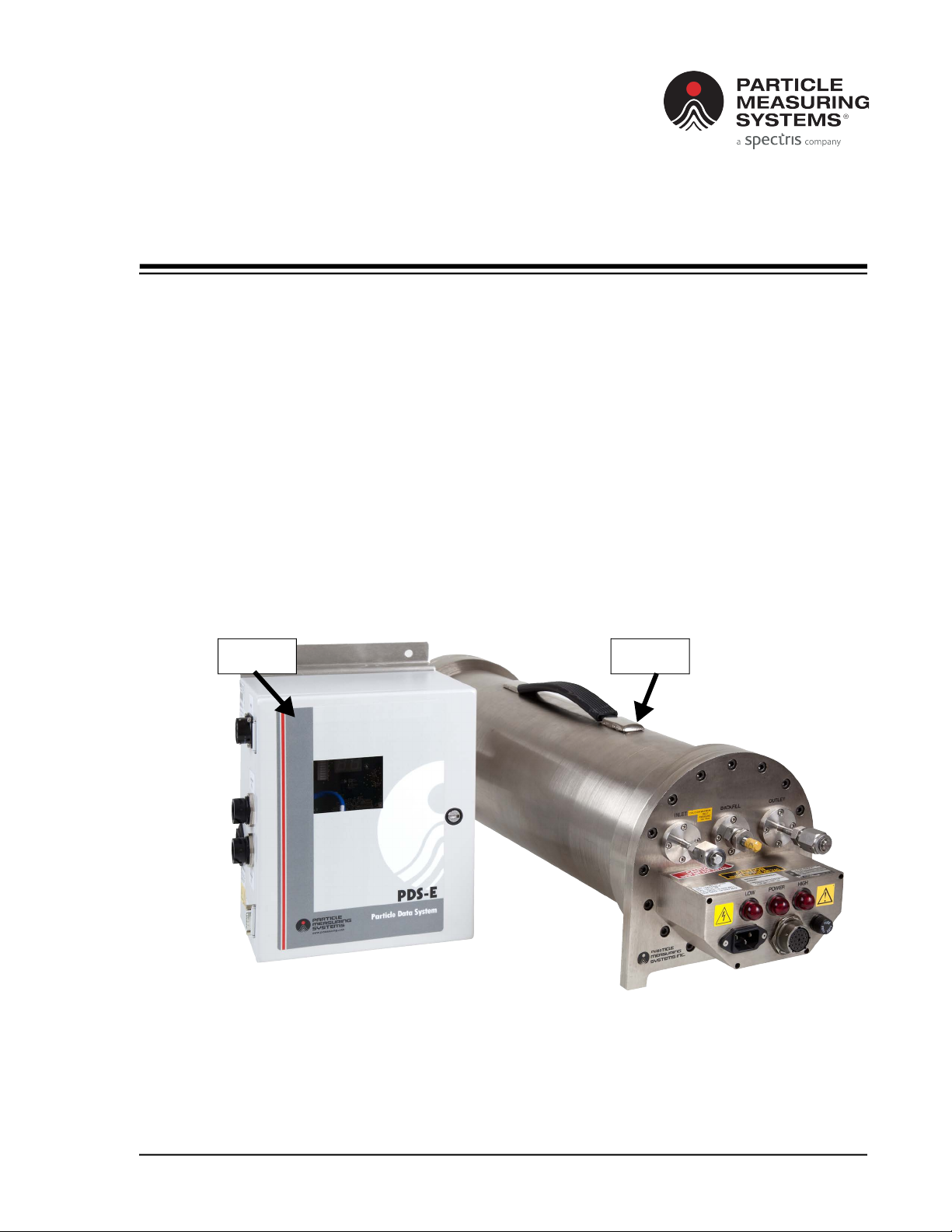

The HPGP™ 101-C monitors particles in gas lines operating at line pressures of 40 –150

PSIG to measure particle contamination with up to 8 size channels of: 0.1, 0.2, 0.3, 0.5,

1.0, 2.0, 3.0, and 5.0 µm. HPGP 101-C is compatible with Ar, CO2, He, H2, Ne, N2, O2, and

other bulk gases (contact PMS for specific applications).

The Particle Data System - Ethernet (PDS-E) aggregates data from the HPGP 101-C and

reports to a connected or networked PC. The PDS-E is designed to be the controller

and data interface between the HPGP 101-C and any external network (see Figure 1-1).

Figure 1-1 The Particle Measuring Systems PDS-E and HPGP 101-C instruments

HPGPPDS-E

1-2 HPGP™ 101-C RoHS with PDS-E Operations Manual

Chapter 1 : Introduction Overview

The PDS-E allows data communication for multiple data management options via:

• Ethernet (via PMS protocol) for communication to Facility Net (PMS data

management software)

• Modbus via Ethernet

• OPC via Ethernet

• RS-232 (bi-directional)

The volumetric sample flowrate of 0.1 SCFM (2.8 LPM) is regulated by an internal mass

flow controller. The HPGP 101-C delivers a counting efficiency of > 50% at 0.14 µm, zero

count level < 2/ft3 or < 0.2/min, and has a maximum concentration of 3,000 counts per

cubic foot. All other specifications can be found in Table 1-1, “HPGP 101-C

Specifications” on page 1-5.

The entire HPGP 101-C assembly, with dimensions and form factors, can be seen in

Figure 1-2. The probe is contained in a cylindrical containment vessel which serves as

a safety containment envelope and should be opened only by trained Particle

Measurement Systems representatives.

Figure 1-2 HPGP 101-C Dimensions

Overview Chapter 1 : Introduction

HPGP™ 101-C RoHS with PDS-E Operations Manual 1-3

All input and output interfaces are located on the front panel to provide easy

connection access. The optics, electronics, and other flow hardware are internally

located within the HPGP 101-C. All power supplies are modular units and the low

voltage supplies have short-circuit protection. The laser high-voltage supply is sealed

and shielded.

The HPGP 101-C uses a HeNe, 633-nm laser source which is Class I per EN60825-1 and,

internally, a Class III B laser per EN60825-1. The PDS-E accurately monitors the laser

reference voltage (input between 0 - 10 V). The laser reference voltage is a

measurement of the passive cavity laser power. A certain level must be maintained to

have an adequate signal-to-noise ratio for correct sizing accuracy. A minimum

reference level of 5.5 volts at operating pressure is considered adequate.

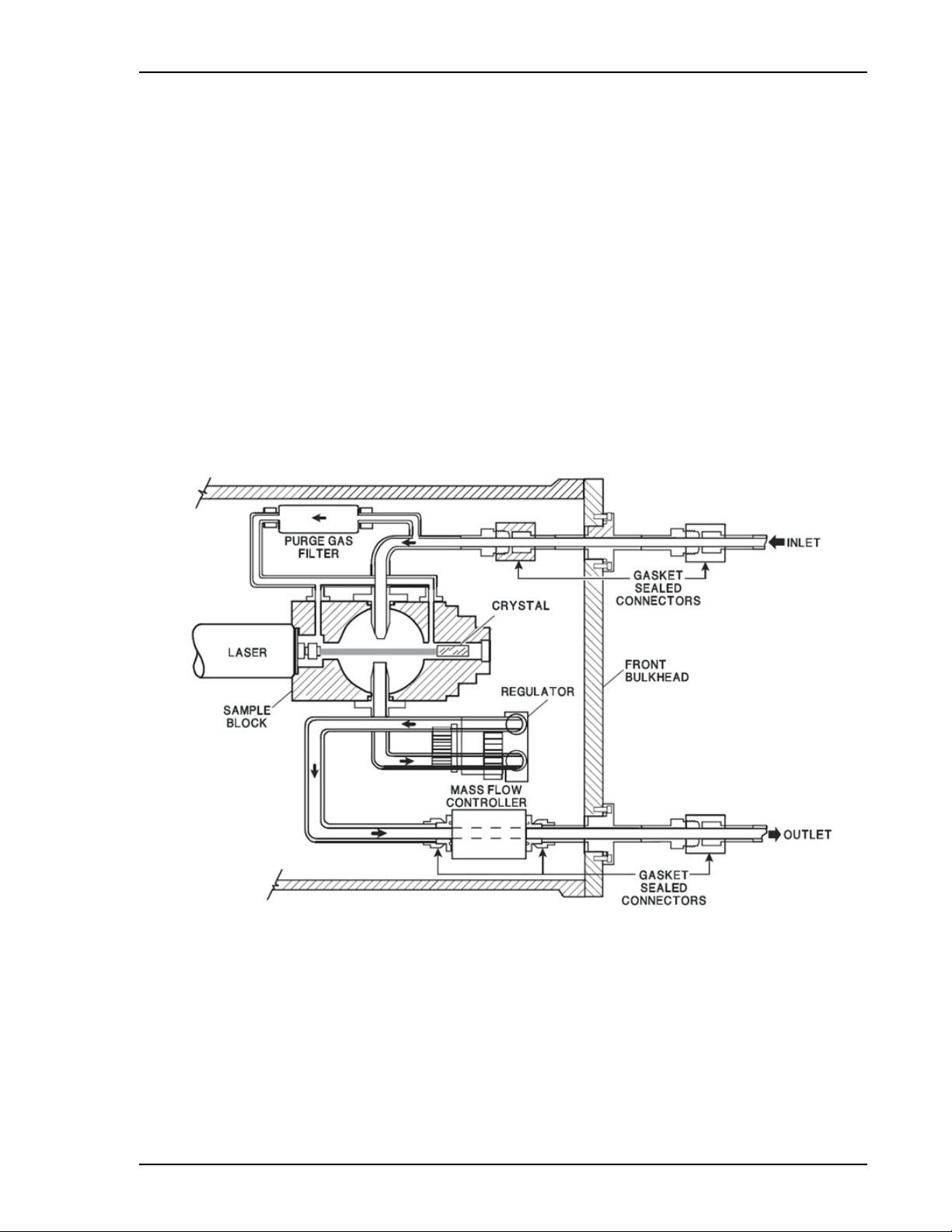

All wetted surfaces are either 316 L stainless steel, glass, or an inert polymer with VCR

fittings through the aerosol inlet, and Swagelok® fittings from the aerosol outlet back

to the front panel.The flow path for the high pressure gas probe is shown in Figure 1-3.

Figure 1-3 HPGP 101-C flow diagram

A mass flow controller in the sample outlet flow stream provides 0.1 CFM of gas flow at

standard temperature and pressure (STP). It controls the flow to within ± 2%

independent of the inlet line pressure for the 40 –150 PSIG working range. The mass

flow controller requires a specific control voltage for the particular gas being sampled.

If the PDS-E is used, it provides the control voltage for the mass flow controller.

1-4 HPGP™ 101-C RoHS with PDS-E Operations Manual

Chapter 1 : Introduction Overview

The laser reference voltage is a measurement of the passive cavity laser power. A

certain level must be maintained to have adequate signal-to-noise ratio for correct

sizing accuracy. A minimum reference level of 5.5 volts at operating pressure is

considered adequate. All other specifications can be found in Table 1-3, “PDS-E

Specifications” on page 1-8.

HPGP 101-C Specifications Chapter 1 : Introduction

HPGP™ 101-C RoHS with PDS-E Operations Manual 1-5

HPGP 101-C Specifications

Table 1-1 HPGP 101-C Specifications

Size range 0.1 – 5.0 µm

Size channels 8 with thresholds at 0.1, 0.2, 0.3, 0.5, 1.0, 2.0, 3.0, and 5.0 µm

Flow rate 0.1 SCFM (2.8 LPM)

Flow is regulated by mass flow controller located downstream of the

sampling cavity.

Sample volume 0.1 SCFM (2.8 LPM)

Counting efficiency > 50% at 0.14 µm

Zero count level < 2/ft3 or < 0.2/min

Maximum concentration 3,000/ft3

Operating pressure 40 – 150 PSIG

Concentration 3,000 per cubic foot

Compatible gases Air, Ar, CO2, He, H2, Ne, N2, O2, and other bulk gases.

Toxic gases Particle Measuring Systems, Inc. uses oxygen compatible procedures

when assembling the laser bench and plumbing (de-greasing

mechanical parts, inspection with black light, etc.); however, Particle

Measuring Systems, Inc. will not assume any liability relating to user or

product when sampling toxic gases.

Construction material All wetted surfaces are either 316 L stainless steel, glass, or inert

polymer.

Laser source HeNe, 633 nm

Laser classification Class I per EN60825-1

Internally, a Class III B laser is used, per EN60825-1

Installation requirements Indoor use only

Pollution degree 2

Over-voltage Category II

Ordinary protection (Not protected against harmful ingress of

moisture.)

Class I Equipment (Electrical grounding is required for safety.)

Data communications Differential line drivers

Data system compatibility PDS-E

Environment Temperature: 32 – 113 °F (0 – 45 °C)

Humidity: 0–95% non-condensing

Maximum altitude: 9,842 ft (3,000 m)

Power 240 V, 50 – 60 Hz, 0.5 A

Fuse 0.5A 5 x 20mm T

Dimensions (L,W,H) 26 8 9 in (66 20 22 cm)

Weight 45 lb (20.4 kg)

1-6 HPGP™ 101-C RoHS with PDS-E Operations Manual

Chapter 1 : Introduction HPGP 101-C Front Panel Features

HPGP 101-C Front Panel Features

Figure 1-4 HPGP 101-C front panel

Inlet and Outlet

The gas inlet is on the front left of the HPGP 101-C. Refer to Figure 1-4.

• The gas outlet is on the front right of the HPGP 101-C.

• The user needs to supply the following fittings to use as the mating connectors

for both the inlet and the outlet of the HPGP 101-C.

• PMS-F1163 Cajon (SS-4-VCR-1) (1 each)

• PMS-F1188 Cajon (SS-4-VCR-3-4MTW) (1 each)

• PMS-F1164 Cajon (SS-4-VCR-2-GR) (1 each)

Sensor Cable

The sensor cable for the HPGP 101-C is attached to the lower middle front of the

instrument along with the AC power. Refer to Figure 1-4 on page 1-6.

Fuses

The fuse for the HPGP 101-C is located next to the sensor cable.

Stand/Feet

The HPGP 101-C’s feet are mounted with 6-32 socket head screws. See Figure 1-2 on

page 1-2.

HPGP 101-C Materials Chapter 1 : Introduction

HPGP™ 101-C RoHS with PDS-E Operations Manual 1-7

HPGP 101-C Materials

Table 1-2 HPGP 101-C Materials

Part Material

Laser Optical Bench Assembly

Bench, block body 316 L SS

Screws Stainless steel

Collecting mirrors BK-7 glass

Laser mirrors Quartz

O-rings Viton 75

Fittings (VCR & Swagelok) 316 L SS

Bonding agent Bonding agent VTC-2 UV cured epoxy

Plumbing Assembly

Tubing 316 L SS Stainless Steel

Flow controller

Regulator Assembly

Diaphragm 316 L SS

Valve assembly 316 L SS

Valve seat FKM

Elastometers Fluorocarbon

Flow Controller Assembly

Meter Borosilicate glass

Wetted meter parts 316 SS

Valve assembly Corrosive protected magnetic steel

Seals Viton

Containment Vessel

Cylinder Nickel plated 6061 T6 aluminum

End plates Nickel plated 6061 T6 aluminum

Fasteners (end plate) 1/4-28 x 5/8 Steel alloy Allen head screws. Torque to 100 inch-pounds

Table of contents

Other Spectris Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Rupes

Rupes HTE 300 START-UP, OPERATING AND MAINTENANCE INSTRUCTIONS

ITOH DENKI

ITOH DENKI POWER MOLLER IB-P03 Technical documentation

Pepperl+Fuchs

Pepperl+Fuchs LS68 DA-F2 Series manual

Meler

Meler MICRON+ GEAR Series instruction manual

Afag

Afag aflex150 qc quick guide

Siemens

Siemens SIVACON 8PS BD2 Series installation instructions

CAB

CAB 5314 Service manual

Siemens

Siemens SIMATIC RTLS4084T operating instructions

Edge

Edge Rebel 80 General information

Tennsmith

Tennsmith PR16 Installation, operation, parts & maintenance manual

Siemens

Siemens Simcenter SCADAS RS user manual

Mars

Mars Comfort-aire Century Compact HBH Series Installation operation & maintenance