Spectronics Corporation Marksman II SPI-MDT User manual

Table of contents

Languages:

Other Spectronics Corporation Security Sensor manuals

Popular Security Sensor manuals by other brands

BEINAT

BEINAT SGM595/A-H2CH Installation and user guide

ADT

ADT Visonic PowerMax Plus quick guide

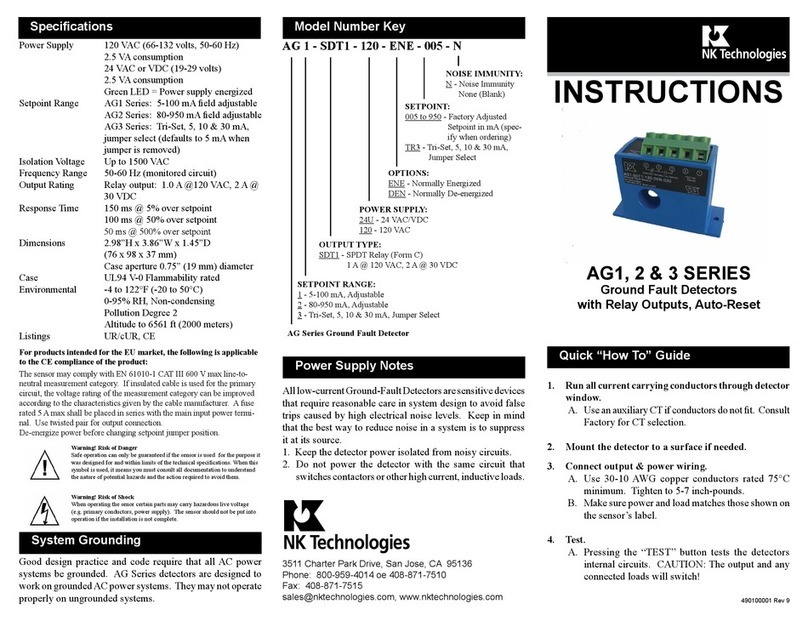

NK TECHNOLOGIES

NK TECHNOLOGIES AG1 Series instructions

System Sensor

System Sensor 885WP-B Installation and maintenance instructions

AMC

AMC SS800 Installer manual

GST

GST D-9107RExd Installation and operation manual

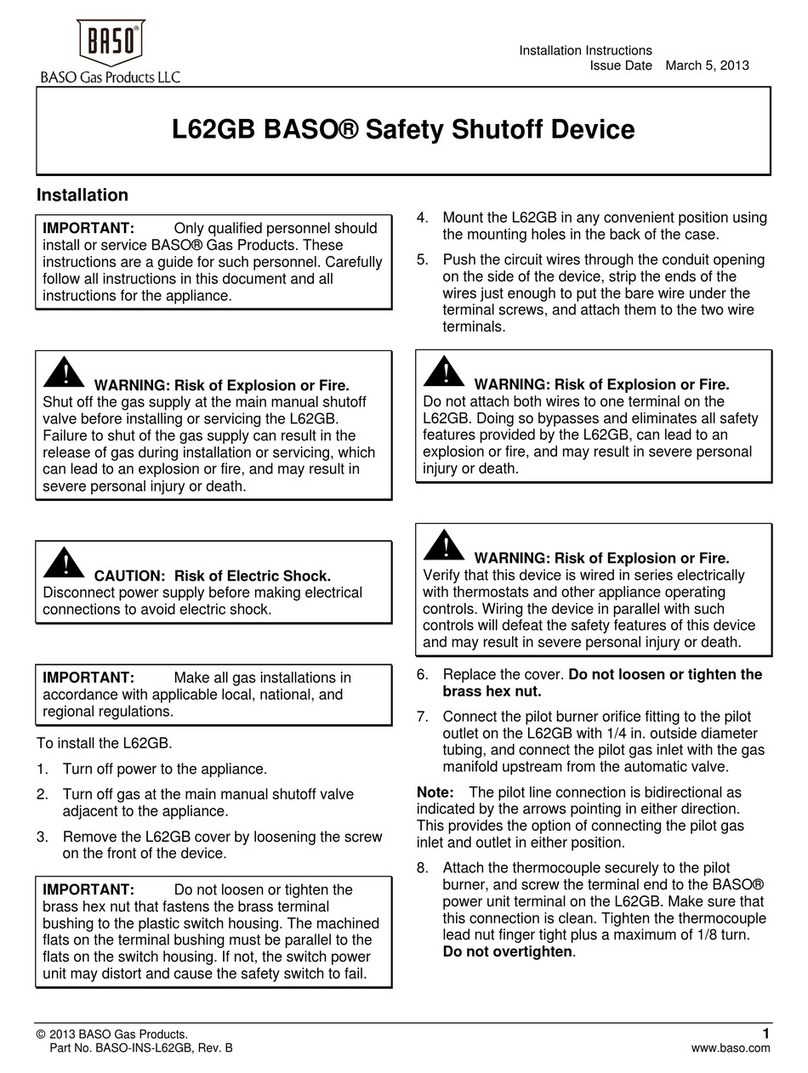

Baso

Baso L62GB installation instructions

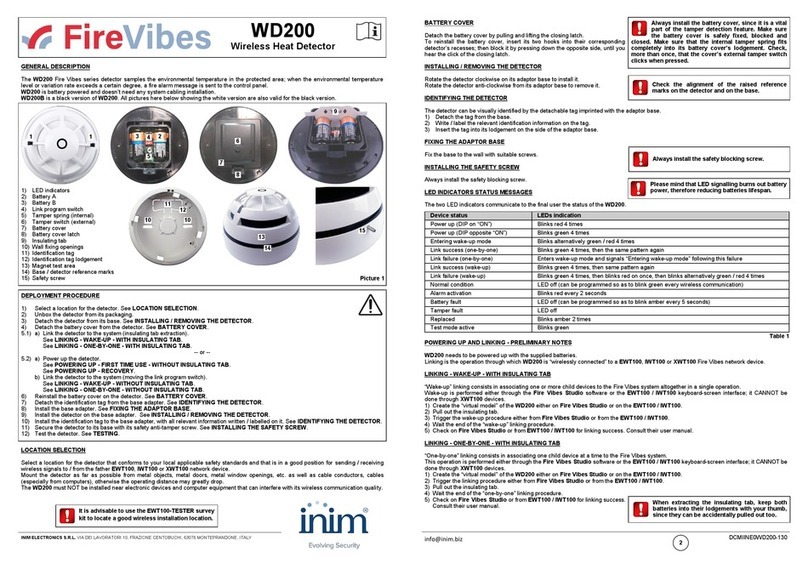

INIM

INIM FireVibes WD200 manual

Conrad

Conrad 552445 operating instructions

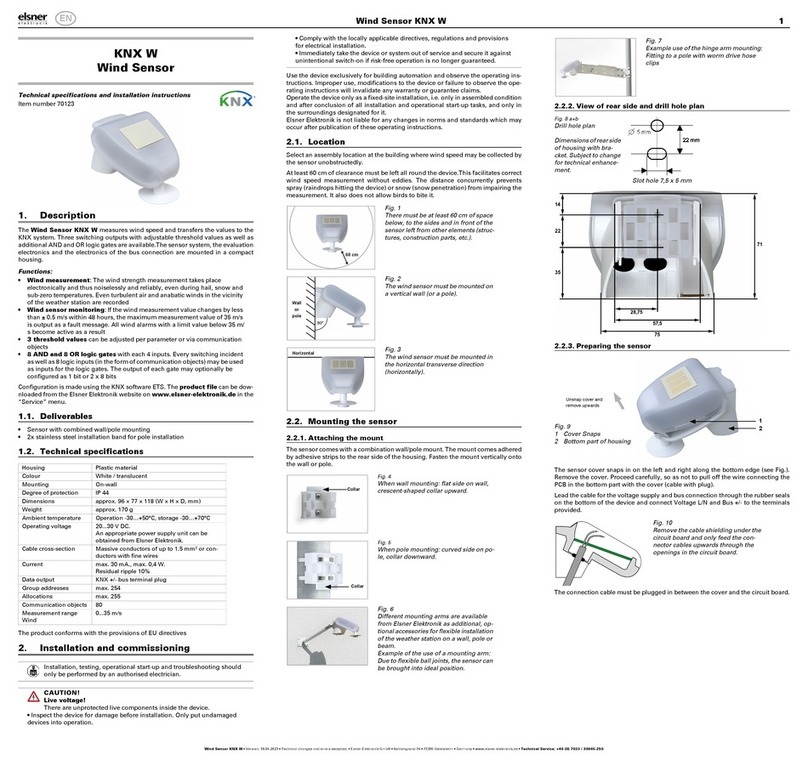

elsner elektronik

elsner elektronik KNX W Technical specifications and installation instructions

Net Safety

Net Safety Net Safety AD-ST1400-25 user manual

Datalogic

Datalogic SG2 BASE Series instruction manual

TLV

TLV SonicMan SN1 instruction manual

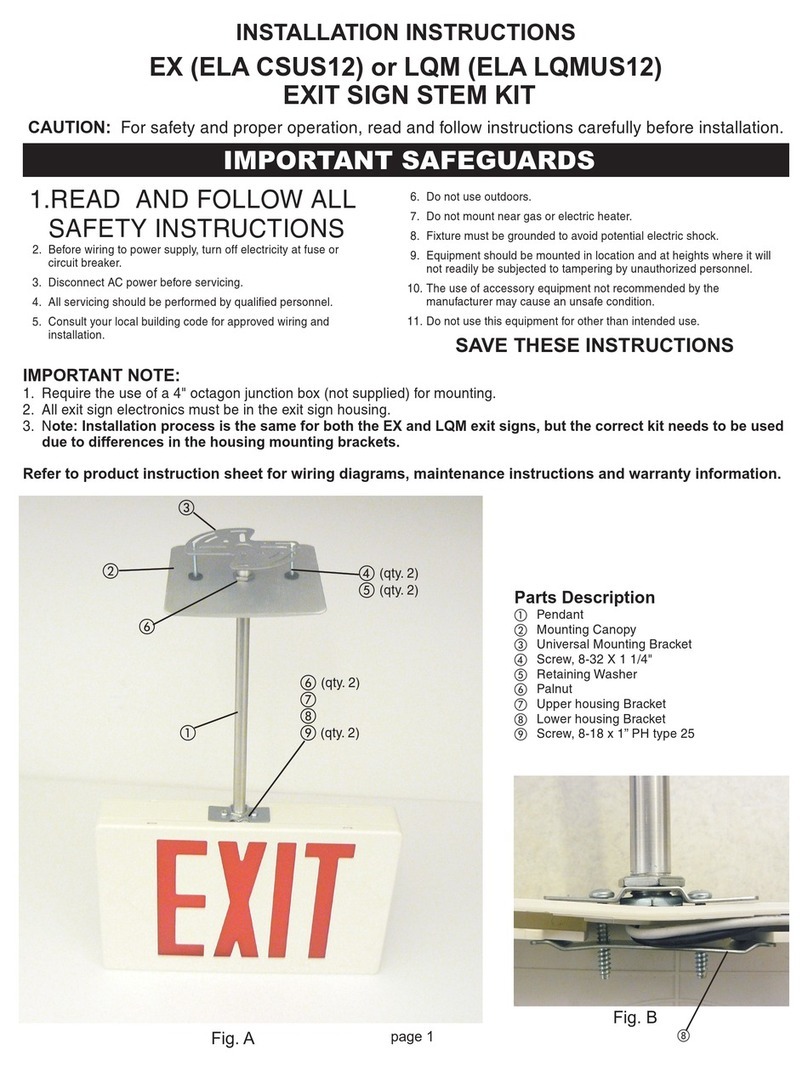

Lithonia Lighting

Lithonia Lighting EX installation instructions

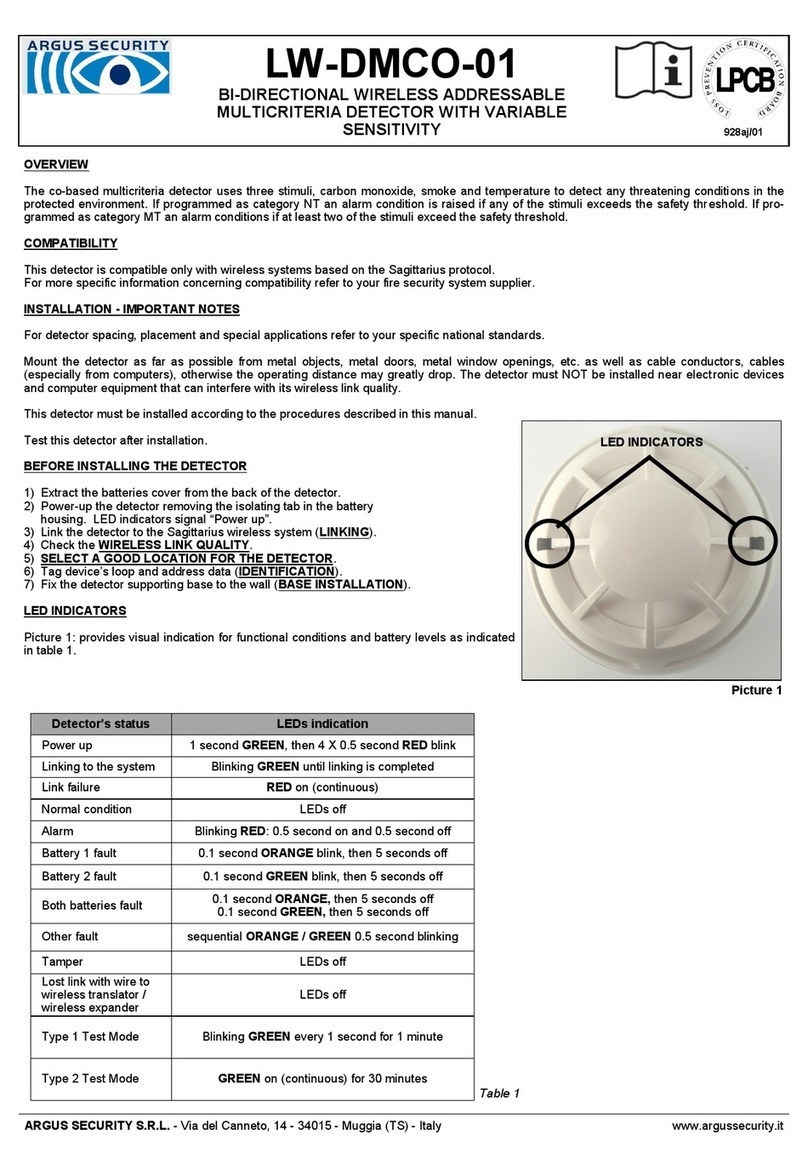

Argus Security

Argus Security LW-DMCO-01 manual

Respirex

Respirex Simplair Instructions for use

Sekotech

Sekotech GCU-OSD10 operating manual

Pepperl+Fuchs

Pepperl+Fuchs VAS/M-2A8L-KE4-6SE-EV operating instructions