Speed Clean SC-TC-60 Installation and operation manual

SpeedClean®

Innovative Maintenance Tools.

OPERATING & MAINTENANCE INSTRUCTIONS

MODEL

SC-TC-60

Tube Cleaner

SC-TC-60

2Model SC-TC-60 Operating and Maintenance Manual

Table of Contents

SC-TC-60

Important Safety Instructions .............................................................................................. 3

Work Area ..........................................................................................................................3

Personal Safety .................................................................................................................3

Operational Safety ...........................................................................................................3

Service ...............................................................................................................................4

Safety Checklist ................................................................................................................4

Grounding/Electrical Safety ............................................................................................... 5

Overview ...............................................................................................................................6

Operation ............................................................................................................................. 6

Pre-Operation Checklist ...................................................................................................6

Connecting Flexible Shaft ................................................................................................6

Operating Procedure .......................................................................................................7

Forward/Reverse Foot Pedal............................................................................................7

Maintenance and Storage ..................................................................................................7

Maintenance.....................................................................................................................7

Storage ..............................................................................................................................7

Troubleshooting ............................................................................................................... 8

Specifications .................................................................................................................. 8

Parts List ................................................................................................................................ 9

Plumbing Diagram .............................................................................................................10

Accessories .................................................................................................................... 10

Wiring Diagram .................................................................................................................. 11

Warranty Information......................................................................................................... 12

Thank you for purchasing SpeedClean’s SC-TC-60 tube cleaning machine. We appreciate

your business and look forward to serving you in the future. As with all SpeedClean products,

you can be assured that the finest quality components and workmanship have gone into

this machine.

Please take a few minutes to read the following Operating and Maintenance Instructions.

Please pay particular attention to the safety instructions and exercise caution when using

this machine.

© 2018 All Rights Reserved. 3

Table of Contents

WARNING! Read and understand all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious personal injury.

Save these Instructions!!

1. Work Area

• Keep your work area clean and well lit. Cluttered benches and dark areas

invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

2. Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

• Do no overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard

hat, and hearing protection are recommended.

3. Operational Safety

• This unit is to be used only by trained operators.

• Keep clear of moving shaft. Make sure the shaft will not catch on anything while in use.

• Be sure to select the proper size flexible shaft and tool for the job. Do not force the tool.

Use the correct tool for the application.

• Check flexible shaft for weak or worn condition before each use. Make certain that all

connections are tight and secure.

• Do not use with flammable or explosive fluids such as gasoline, fuel oil, kerosene, etc. Do

not use in explosive atmospheres.

• Disconnect the plug from the power source and turn off water supply before

disconnecting hoses, fittings, or flexible shaft and before making any adjustments or

changing accessories. Such preventive safety measures reduce the risk of starting the

unit accidentally.

• Do not use tool if foot switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Store idle tools out of reach from children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

Important Safety Instructions

SC-TC-60

SC-TC-60

4Model SC-TC-60 Operating and Maintenance Manual

Important Safety Instructions

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced

before using.

• If the machine does not operate properly or is damaged, contact Speedclean

Customer Service.

4. Service

• Unplug the power cord when servicing the unit or leaving the machine unattended.

• Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

• DANGER!! DO NOT OPERATE THE UNIT WITH COVER(S) REMOVED WITH MOVING PARTS AND

ELECTRICAL CONNECTIONS EXPOSED!!!

Safety Checklist

Do’s

• Keep this manual with the unit at all times.

• Always grasp the plug - not the cord - when unplugging from AC power.

• Always run clean water through the unit.

• Always secure the unit while transporting to prevent it from damage.

• Store unit indoors in a cool, dry area and protect from freezing. If the unit is stored in an

unheated location and temperatures reach freezing, damage to the internal components

may occur.

• Always be extra careful when not on level, secure ground.

• Keep operational area clear of all persons.

• Use only SPEEDCLEAN recommended attachments.

Don’ts

• Don’t use the SC-TC-60 if it is not in good operating condition, is not completely assembled,

or is damaged. Always inspect the unit to ensure there are no leaks.

• Don’t operate without eye protection.

• Don’t spray the SC-TC-60 with high-pressure water. Wipe it down with a damp rag.

• Don’t point flexible shafts at people or animals as the end of the shaft rotates at high

speeds which may cause serious injury.

• Don’t use the unit with combustible fluids.

SC-TC-60

© 2018 All Rights Reserved. 5

Grounding/Electrical Safety

SC-TC-60

• Make certain that the power source conforms to the requirements of the equipment.

• This product must be grounded. If it should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away from the user. Grounded

tools must be plugged into an outlet properly installed and grounded in accordance with

all codes and ordinances. Never remove the grounding prong or modify the plug in any

way. DANGER!! Improper connection of the equipment-grounding conductor can result in

risk of electrocution. Check with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. DO NOT USE ANY TYPE OF ADAPTER PLUG WITH THIS PRODUCT.

• This unit is equipped with a Ground Fault Circuit Interrupter (GFCI) at the plug end of the

cord for electrocution protection. DO NOT REMOVE THIS DEVICE. If replacement of the

plug or cord becomes necessary, use only identical replacement parts that include

GFCI protection.

• Use only 3-wire extension cords that have 3-prong grounding type plugs and 3-pole cord

connectors that accept the plug from the product. Use only extension cords that are

rated for outdoor use. These extension cords are identified by a marking, “Acceptable for

outdoor use; store indoors while not in use”. Do not use damaged extension cords. Examine

extension cord before using and replace if damaged. When using an extension cord, be

sure to use one large enough to carry the current the product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and overheating. If in doubt,

use the next heavier gage. The smaller the gage number, the larger the cord.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock. Store unit indoors in a cool, dry area.

• Don’t roll the unit over the power cord, pull the cord, close the door on the cord or pull the

cord around sharp corners. Keep the cord away from HOT surfaces.

• Don’t expose unit to rain.

• Don’t allow water to freeze in unit.

• Don’t use the machine if it has a damaged cord or plug.

• Don’t use the unit in an environment or on objects that are above 175° F (79° C).

• Don’t use unit with children in the immediate area.

SC-TC-60

6Model SC-TC-60 Operating and Maintenance Manual

The SC-TC-60 tube cleaner uses a brush on the end of a rotating, polymer-encased flexible

steel shaft. As the operator feeds the rotating brush/shaft assembly through the tube, the brush

or tool loosens any deposits (mud, sand, etc.) and water flows through the casing to flush them

out. A solenoid operated ball-valve controls

the water flow.

The SC-TC-60 with a ½ HP (0.4 kW)

motor is designed for cleaning

tubes and pipes ¼”-1” (6.4-25.4mm)

I.D. It is a compact, self-contained,

carry-anywhere unit which permits

operation in tight quarters.

Overview

1

1. Quick Connect Latch

2. Latch Lock

3. Carry Handle

4. GFCI Power Cord

5. Garden Hose Connector

6. Foot Pedal

2

34

5

6

Operating Instructions

SC-TC-60

Pre-Operation Checklist

✓Check for adequate water supply. Use no smaller than a 5/8” garden hose for

water supply.

✓Check ground fault circuit interrupter (GFCI). Test & reset.

✓Check all connections.

Connecting Flexible Shaft

1. Select the proper size flexible shaft (SC-TC-S02, SC-TC-S03) for

tube diameter and length to be cleaned.

2. Insert square end of flexible shaft into the square in the drive

shaft of the machine. The shaft may have to be turned up to

90 degrees for alignment.

3. Push flexible shaft strain relief into quick connect latches and

turn locking peg to lock shaft in place. Latch Lock moves to the UP

position to lock and DOWN to

unlock.

Latch Lock

© 2018 All Rights Reserved. 7

Operating Procedure

CAUTION: Do not operate this machine without eye protection.

1. Connect water hose to water inlet of no more than 100 psi. Water supply should be clean.

Make sure screen washer is in place.

2. Plug electric cord into an outlet in accordance with the power requirements on the

nameplate and push the “Reset” button on the GFCI.

3. Ensure that the two hoses in the footswitch assembly are plugged into the two pneumatic

switches in the foot pedal compartment. Each side of the footswitch corresponds to a

different drive direction of the shaft.

4. Select proper size cleaning tool and fasten onto end of flexible shaft. Never use a tool

larger than I.D. of tube. NOTE: Most tubes are rolled at tube sheet. Always measure I.D.

beyond roll or consult manufacturer’s manual for tube O.D. and gauge.

5. Position shaft locator on the outside of the flexible shaft so that when the shaft is fully

inserted in the tube, the entire cleaning tool extends outside the other end of the tube.

6. Uncoil flexible shaft completely and feed it into the tube. DO NOT FORCE SHAFT DOWN

TUBE. Allow machine to do the work. If resistance is felt, back off 2”-3” (50-75mm) and feed

shaft again until it goes easily. If resistance is too great, use a smaller cleaning tool.

7. For easiest operation, if possible, insert shaft into tube and keep there for several hours

before starting in order to remove loops from flexible shaft. CAUTION: Minimum operating

radius of flexible shaft is eighteen inches. However, it is recommended that the shaft be

kept as free from loops as possible. This is especially critical nearest the drive unit.

8. After completing the job, always unplug machine before disconnecting water supply.

Running a shaft “dry” may damage the seals. CAUTION: The SC-TC-60 is designed to be

used wet or dry — NOT BOTH. It is equipped with a water seal. If used dry, the water seal will

no longer prevent water leakage.

Forward/Reverse Foot Pedal

• The direction the shaft rotates is controlled by the two-way foot pedal.

• Clockwise rotation is considered the “Forward” direction

• Position the foot pedal like the gas pedal of a car and rock your foot back and forth

to control direction.

Maintenance & Storage

SC-TC-60

Maintenance

Keep machine clean and dry to maximize performance and longevity. Follow maintenance

outlined in this manual, such as checking for weak spots, leaks, slices or cuts in hose, replace

shafts when worn. Additional maintenance details follow in this manual. If the machine

does not operate properly or has been damaged or exposed to water, call the factory for

assistance — do not try to service the unit yourself.

Storage

Disconnect water supply line. Disconnect the flexible shaft and drain water to prevent rusting of

shaft. Do not store machine where residual water in machine may freeze. Refer to Flexible Shaft

manual for flexible shaft storage.

SC-TC-60

8Model SC-TC-60 Operating and Maintenance Manual

General Maintenance & Storage

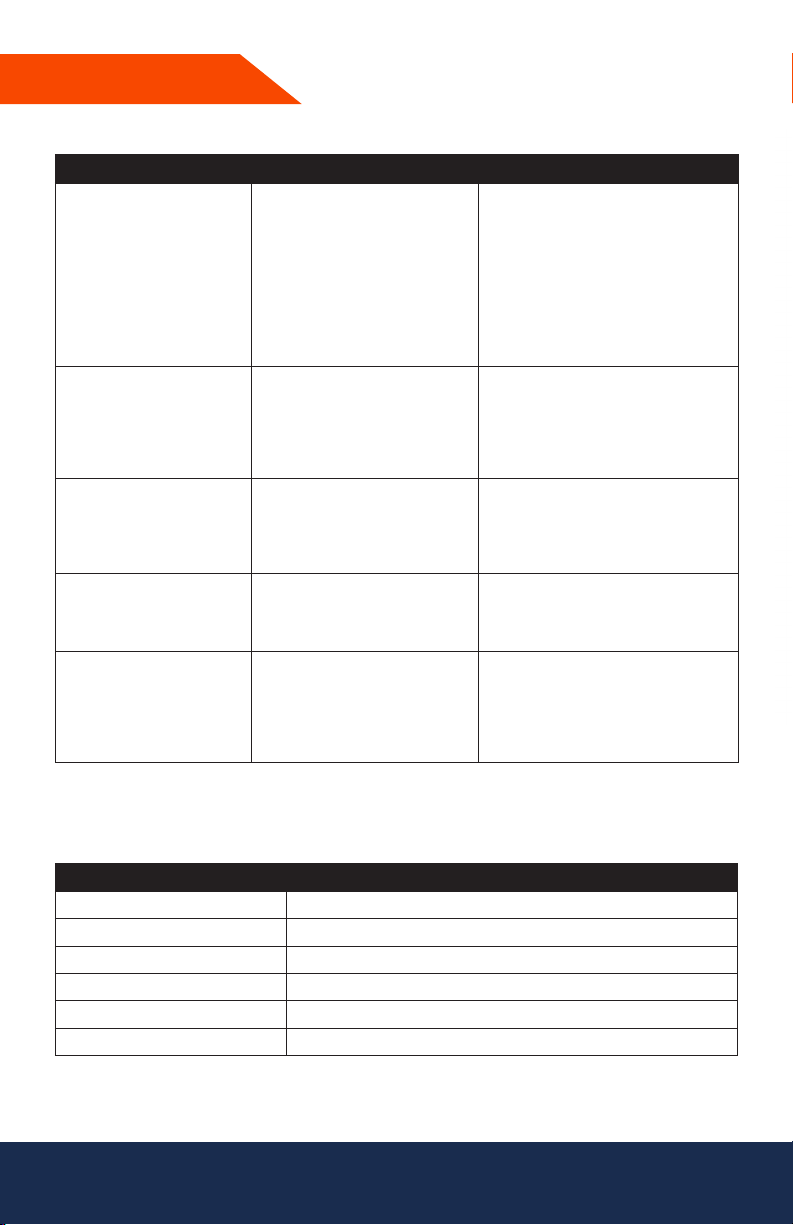

Trouble Shooting

PROBLEM PROBABLE CAUSE SOLUTION

Runs in one direction only • Leak in air control circuit

• Faulty wire connection(s)

• Leak in footswitch air

bellows or air hoses

• Faulty air switch

• Disconnect power. Disconnect

air hoses from air switches to

allow foot pedal bellows to

inflate to full height. Reconnect

and tighten all connections

• Disconnect power.

• Check wiring.

• Switch air hoses to isolate

problem (machine or footswitch)

• Check/replace air switches

Water leaking from base • Leak in water

circuit plumbing

• Leak at shaft manifold seal

• Disconnect power. Check hoses

and fittings for leaks. Tighten

loose connections.

• Check for leak where drive shaft

enters shaft manifold. Replace

manifold seal.

Runs for short period of

time and/or stops, GFCI

trips/won’t reset

• Electrical short to ground

• Overheated, disconnect

from power. Unit will

automatically turn on

when cool.

• If GFCI trips often call

SpeedClean. There may be an

unsafe electrical condition.

• Allow unit to cool.

Motor runs but shaft/brush

does not turn

• Problem drive coupler

• Broken flexible shaft

• Disconnect power. Check drive

coupler for damage.

• Replace shaft fittings and/

or core.

No water through

flexible shaft

• Problem with water supply

• Inlet screen clogged

• Solenoid valve

not functioning

• Water supply not on, restrictions

in hose or hose too small, water

supply pressure insufficient.

• Remove hose and clean screen.

• Replace solenoid valve,

call Speedclean.

Problem Not Listed, Call Speedclean Customer Service: 1-888-700-3540.

SC-TC-60

Motor ½ HP, 230/115 VAC motor

Power Requirements 230 V 50/60 Hz @ 4.5 A | 115 V 50/60 Hz @ 9.0 A

Rotational speed 860 RPM

Input water connection ¾” standard garden hose

Maximum water pressure 100 psi (7 bar)

Maximum water temperature 140 °F (60 °C)

Specifications

© 2018 All Rights Reserved. 9

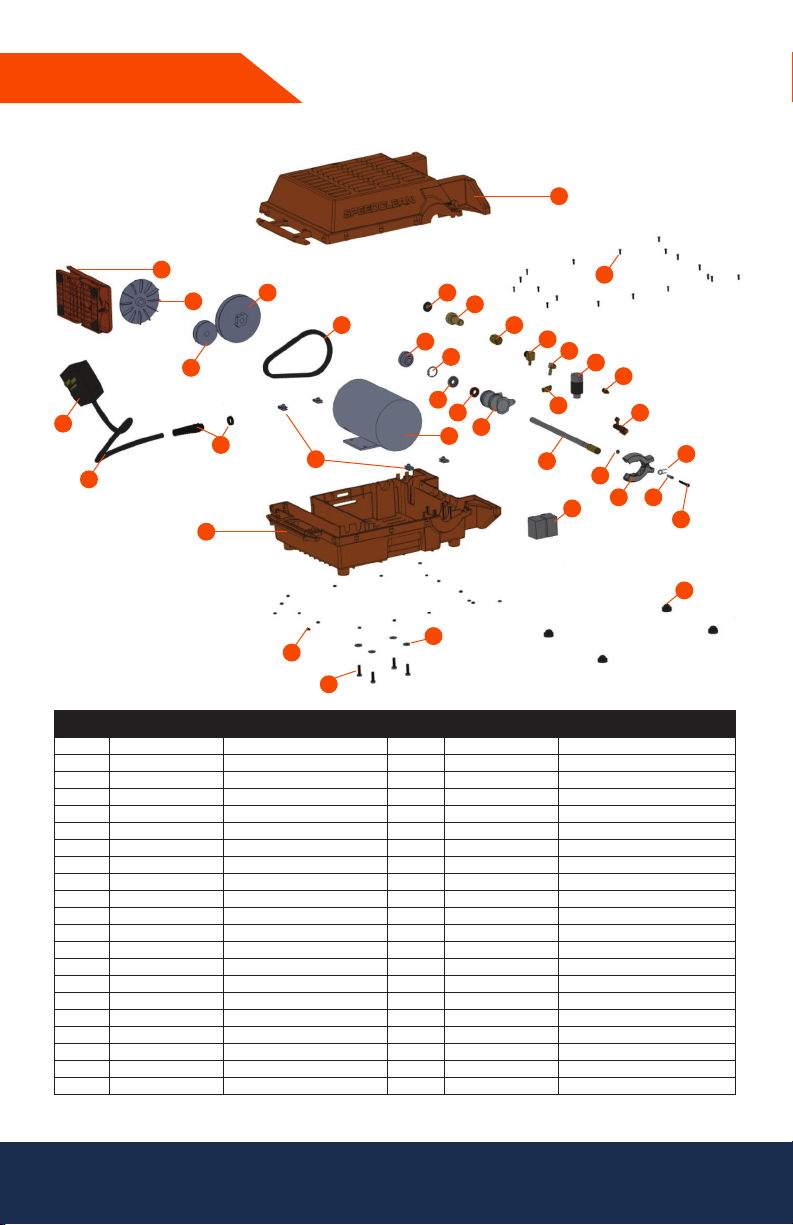

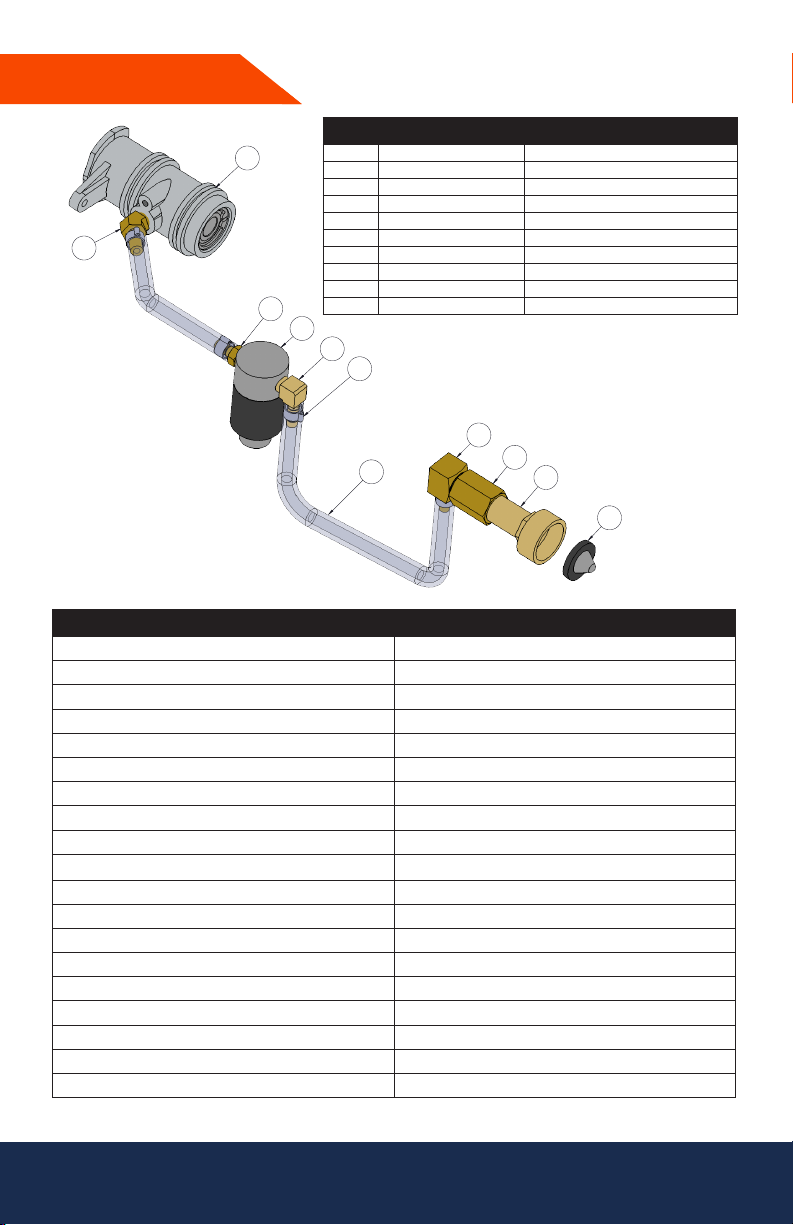

General Maintenance & Storage Parts List

SC-TC-60

ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION

1SC-TC-BH Bottom Housing 22 HWP-45E125M25F Elbow, 1/8” NPT

2SC-TC-TH Top Housing 23 820 Solenoid Valve

3829 Motor, ½ HP 24 936 Barbed Hose Fitting

4SC-TC-FPR Foot Pedal 25 1718 Elbow, ¼” Barb x 1/8” MPT

5EX-005 Manifold 26 930-1 Garden Hose Connector

6824 Lip Seal 27 1057 Coupling, 3/8” NPT

7825 Bearing 28 CJ2-20 Elbow, ¼” Barb

8826 Snap Ring 29 803 Screen Washer

9SQC-07 Latch 30 879 Motor Clip

10 SQC-08 Spacer 31 HWW-252 Washer, ¼”

11 SQC-10 Torsion Spring 32 HWS-0632S-50 Screw, #6-32 x ½”

12 EX-007 Rubber Foot 33 HWN-0632 Nut, #6-32

13 834R-1 Air Switch 34 HWN-1024 Nut, #10-24

14 SC-TC-LL Latch Lock 35 HWS-1024-163-SC Screw, #10-24 x 1-5/8”

15 530-122 Strain Relief 36 1234-1 Screw, ¼”-20 x 1”

16 873 Shaft Driver Assembly 37 CV-CFCI-A GFCI Adapter

17 831 Pulley, 2-1/2” 38 809-E Power Cord

18 830 Pulley, 5” NS SC-TC.517-HRNS Wiring Harness

19 829-60-1 Cooling Fan NS 9648 Hose Clamp

20 833-1 Bearing NS 935 Hose, ¼”

21 832 V-Belt

1

2

3

4

5

6

7

8

20

9 10

11

12

13

14

15

16

17

18

19

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

SC-TC-60

10 Model SC-TC-60 Operating and Maintenance Manual

1

4

10

7

8

11

6

5

3

9

2

ITEM PART NO. DESCRIPTION

1EX-005 Manifold

2820 Solenoid Valve

3930-1 GH Connector

4HWP-45E125M25F 1/8” MPT x ¼” Barb Elbow

51057 3/8” MPT Coupling

6CJ2-20 3/8” MPT x ¼” Barb Elbow

71718 1/8” MPT x ¼” Barb Elbow

8936 1/8” MPT x ¼” Barb Hose Fitting

9803 Garden Hose Screen

10 9648 Hose Clamp

Plumbing Diagram

DESCRIPTION PART NO.

702 Flexible Shaft 15’ SC-TC-S02-15R

702 Flexible Shaft 25’ SC-TC-S02-25R

702 Flexible Shaft 35’ SC-TC-S02-35R

703 Flexible Shaft 15’ SC-TC-S03-15R

703 Flexible Shaft 25’ SC-TC-S03-25R

703 Flexible Shaft 35’ SC-TC-S03-35R

Grit Brush 7/16” - 5/8” ID SC-TC-BGB-075

Grit Brush 11/16” – 3/4” ID SC-TC-BGB-100

Grit Brush 13/16” – 1” ID SC-TC-BGB-125

Brush for 1” ID SC-TC-BN-1

Brush for 1/2” ID SC-TC-BN-1/2

Brush for 11/16” ID SC-TC-BN-11/16

Brush for 13/16” ID SC-TC-BN-13/16

Brush for 15/16” ID SC-TC-BN-15/16

Brush for 3/4” ID SC-TC-BN-3/4

Brush for 5/8” ID SC-TC-BN-5/8

Brush for 7/16” ID SC-TC-BN-7/16

Brush for 7/8” ID SC-TC-BN-7/8

Brush for 9/16” ID SC-TC-BN-9/16

SC-TC-60

© 2018 All Rights Reserved. 11

Plumbing Diagram

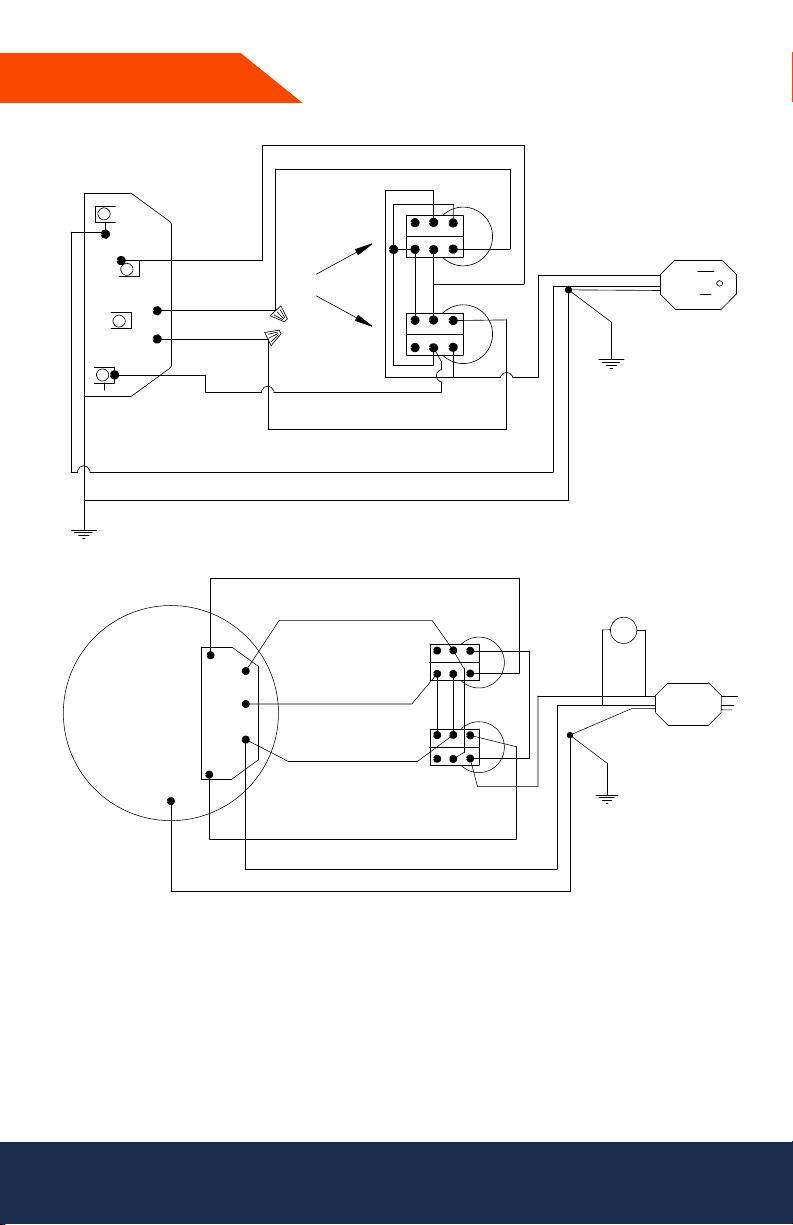

Air Switches

NO

NO

GFI

L1

White

T3

115Volt

Blue

A

C

Red

4

Reverse

Orange

B

NC

NC

L2

Black

C

C

white

3

T2

Forward

L2

Black

2

Motor

1

2

1

NC

NC

NO

NO 2

C1

115 Volt

Ground

Ground

T8

T5

Wiring Diagram, 115V, 50/60Hz

Wiring Diagram

Wiring Diagram, 240V, 50/60Hz

Wiring Diagram, SC-TC-60 50Hz

SC-TC-60

DESCRIPTION PART NO.

702 Flexible Shaft 15’ SC-TC-S02-15R

702 Flexible Shaft 25’ SC-TC-S02-25R

702 Flexible Shaft 35’ SC-TC-S02-35R

703 Flexible Shaft 15’ SC-TC-S03-15R

703 Flexible Shaft 25’ SC-TC-S03-25R

703 Flexible Shaft 35’ SC-TC-S03-35R

Grit Brush 7/16” - 5/8” ID SC-TC-BGB-075

Grit Brush 11/16” – 3/4” ID SC-TC-BGB-100

Grit Brush 13/16” – 1” ID SC-TC-BGB-125

Brush for 1” ID SC-TC-BN-1

Brush for 1/2” ID SC-TC-BN-1/2

Brush for 11/16” ID SC-TC-BN-11/16

Brush for 13/16” ID SC-TC-BN-13/16

Brush for 15/16” ID SC-TC-BN-15/16

Brush for 3/4” ID SC-TC-BN-3/4

Brush for 5/8” ID SC-TC-BN-5/8

Brush for 7/16” ID SC-TC-BN-7/16

Brush for 7/8” ID SC-TC-BN-7/8

Brush for 9/16” ID SC-TC-BN-9/16

L1

NO

Red

Light

Brown

Blue

230 Volt

Blue

White

Yellow

C

C

NC

NC NO

REVERSE

L2

CV-GFCI

240 VOLT

Blue

FORWARD

WIRING DIAGRAM, IRAM 240V 50Hz

MOTOR

Orange

Ground

Ground

T5

T4

T1

T8

P1

Warranty Information

SC-TC-60

SpeedyFoam®CoilJet®Mini-Split

Bib®Kit

PO Box 110301

Stamford, CT 06911-0301

(888) 700-3540

www.speedclean.com

This unit has been carefully tested and inspected and is warranted to be free from defects in

material or workmanship. The company will, under this warranty, repair or replace any parts

which prove, upon examination, to be defective. This warranty is valid for one year from date of

purchase by original purchaser.

This warranty excludes accessories, unusual wear, abuse, damage resulting from an

accident, or unreasonable use of this machine. It is recommended that any repairs be done

by SpeedClean as improperly performed repairs will void the warranty.

For repairs or warranty information DO NOT contact the place of purchase. Call SpeedClean

Customer Service at (888) 700-3540.

To obtain warranty service a proof of purchase is required and the unit must be returned freight

prepaid. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state. SpeedClean reserves the right to improve products. Contact

the factory for the latest configuration and uses.

SpeedClean is a registered trademark of Crossford International Speedclean reserves the right to improve

products — contact the factory for the latest configuration and uses

P/ N : M NL- S C TC 60 1118

Table of contents

Other Speed Clean Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

Pro-Ject Audio Systems

Pro-Ject Audio Systems VC-E Instructions for use

Tower Hobbies

Tower Hobbies CW20 Safety and instruction manual

Makita

Makita DCL284F instruction manual

Ultrawave

Ultrawave Q Series quick guide

Mosmatic

Mosmatic FL-CR 750 Assembly & instruction manual

GemOro

GemOro SparkleSpa Pro user guide