0901154 Rev: A (04/10) Page 3 of 12

INTRODUCTION

Foam cleaning is recognized as an effective method for removing oil and heavy soils from all types of surfaces. It is

used for cleaning throughout the food processing, dairy, transportation, industrial and agricultural industry. Due to it’s

characteristics, cleaning with foam is safe and cost effective. Foam can adhere to irregular surfaces and provide

better coverage than liquid cleaning chemicals. Foam stays in place longer to actively lift dirt and oil from surfaces

until it is rinsed off.

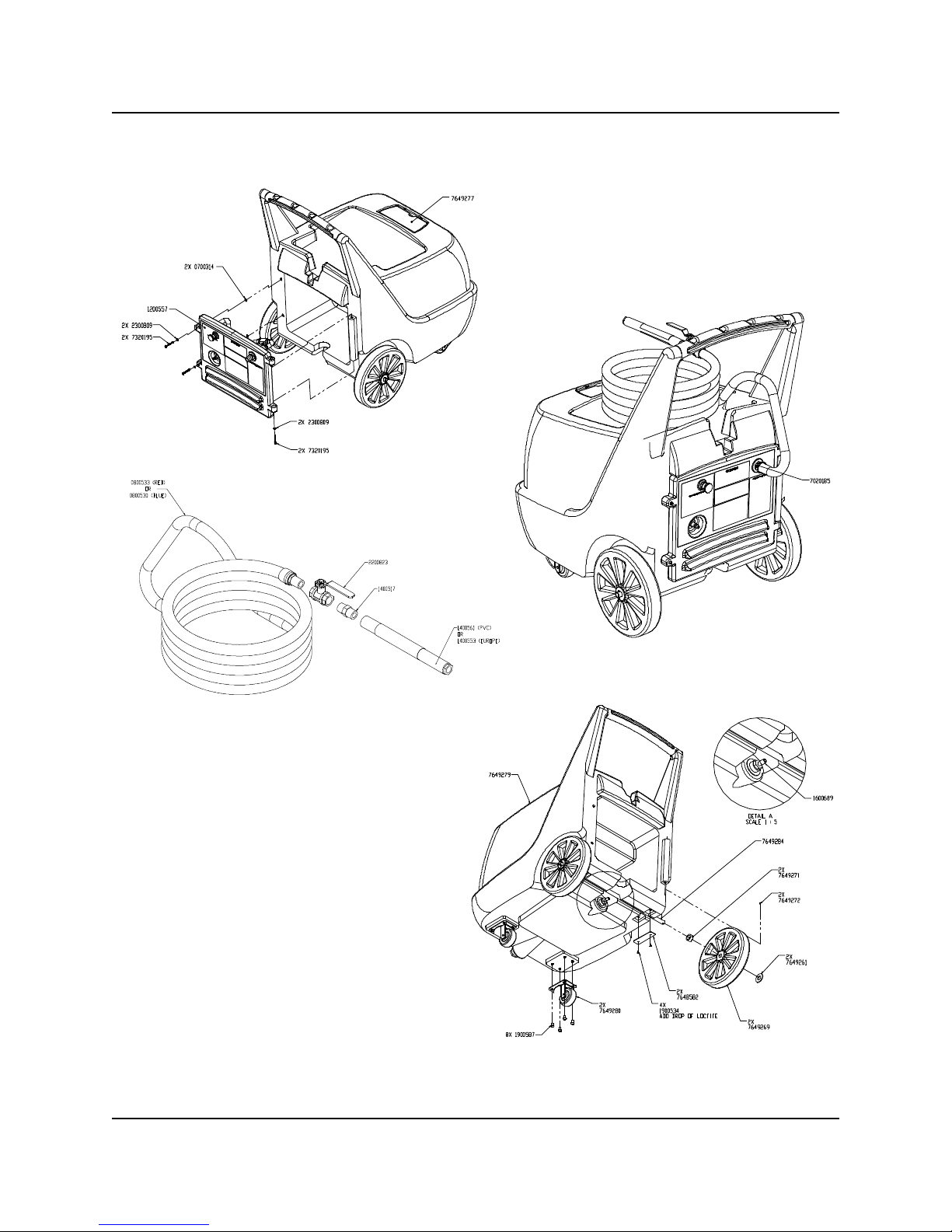

Knight’s Foam Clean system dispenses a rich lather of foam up to 65 GPM with a distance of up to 30 feet. With a

built-in 4 GPM (15 ltr/min) air operated pump, you’ll get consistent foaming quality for clean results. Simply turn a

knob and you can adjust the dryness or wetness of the foam for different cleaning applications.

APPLICATIONS

Food Processing Plants: Process Food, Beverage, Dairy, Baking, Poultry, Smoke Houses, Seafood.

Transportation: Trucking, Aviation, Transit, Automotive, Military, Ships, Construction Equipment.

Industrial: General Cleaning, Machinery Degreasing, Paint Manufacturers, Paper Mills.

Agricultural: Dairy, Poultry, Farm Equipment, Hog.

REQUIREMENTS

Minimum 60 PSI clean, dry air at 5 –10 CFM during operation of the foamer.

Chemical requirement: Most foam cleaning dilution rates operate at 3 to 5 oz/gal (24 to 39 ml/ltr) —consult your

chemical supplier for the proper foaming product and mixing ratio to use.

SPECIFICATIONS

Foam Output 65 gal/min (246 ltr/min)

Foaming Distance 25—30 feet (7.5—9 meters)

Chemical Compatibility Santoprene: All acids, corrosives, and petroleum products

Viton: Alkalines, soaps, mild acids, sodium hypochlorite

Air Operated Pump Materials Polypropylene Body w/ Santoprene Seals and Diaphragm

Polypropylene Body w/ Viton Seals and Diaphragm

Air Consumption 60-80 psi, 5-10 scfm

Hose Portable: 25 feet (7.6 meters) reinforced hose, 3/4‖ ID with wand