Speed Merchant Speed Spec Pan Sedan User manual

Congratulations on your purchase of a Speed Merchant

SpeedSpec 2 competition chassis.

This instruction manual will detail the specific steps involved to

build your new car. Make sure to take your time when building,

since even though there are very few parts in this kit, it is

important to make sure that everything is smooth (metal parts

such as kingpins, pivot balls, etc are polished, and that nothing

binds) and working the way they should. This will make

noticeable difference in the handling of the car out on the track.

Required tools and supplies:

.050” Hex driver

1/16” Hex driver

3/32” Hex driver

5/64” Hex driver

3/16” Nut driver

¼” Nut driver

3/32” Nut driver

File

Cyanoacrylate Glue

(CA or super glue)

35 Wt. Shock Oil (recommended)

Tube Spooge (damper tube lube)

1/8” and 3/32” Drill bits

82° countersink

Metal polish

Double sided tape (servo tape)

Ruler

Pen or pencil

Additional required parts:

540 sized electric motor

Electronic Speed Controller

Radio Transmitter

Radio Receiver

Servo (standard sized)

Servo saver

(to match servo brand)

4 Cell Sub-C size

NiMh or Ni Cad Battery

Tires and Wheels

Body shell

Paint for body shell

Speedspec2 - 0.0.2

2

Chassis prep:

Shown here is the chassis top and

chassis bottom. Note that the chassis

bottom has countersunk holes. To

prep this chassis you will need to file

the battery slots to keep from cutting

the insulation labels on the batteries.

This will also allow the battery pack to

sit lower in the chassis, lowering the

center of gravity.

top

bottom

When filing the slots, file from the top

side of the chassis with the file at a 45°

angle. Have an assembled 4-cell battery

pack handy to check depth as the

chassis is filed. Removing too much

material will allow the battery pack to sit

too low and could rub on the ground in

high speed corners.

After filing, the slots should look something like

the illustration to the right. If you filed the slots

too low and the battery sits lower than the

bottom of the chassis, they can be built back up

slowly using multiple layers of thick

cyanoacrylate (CA) glue.

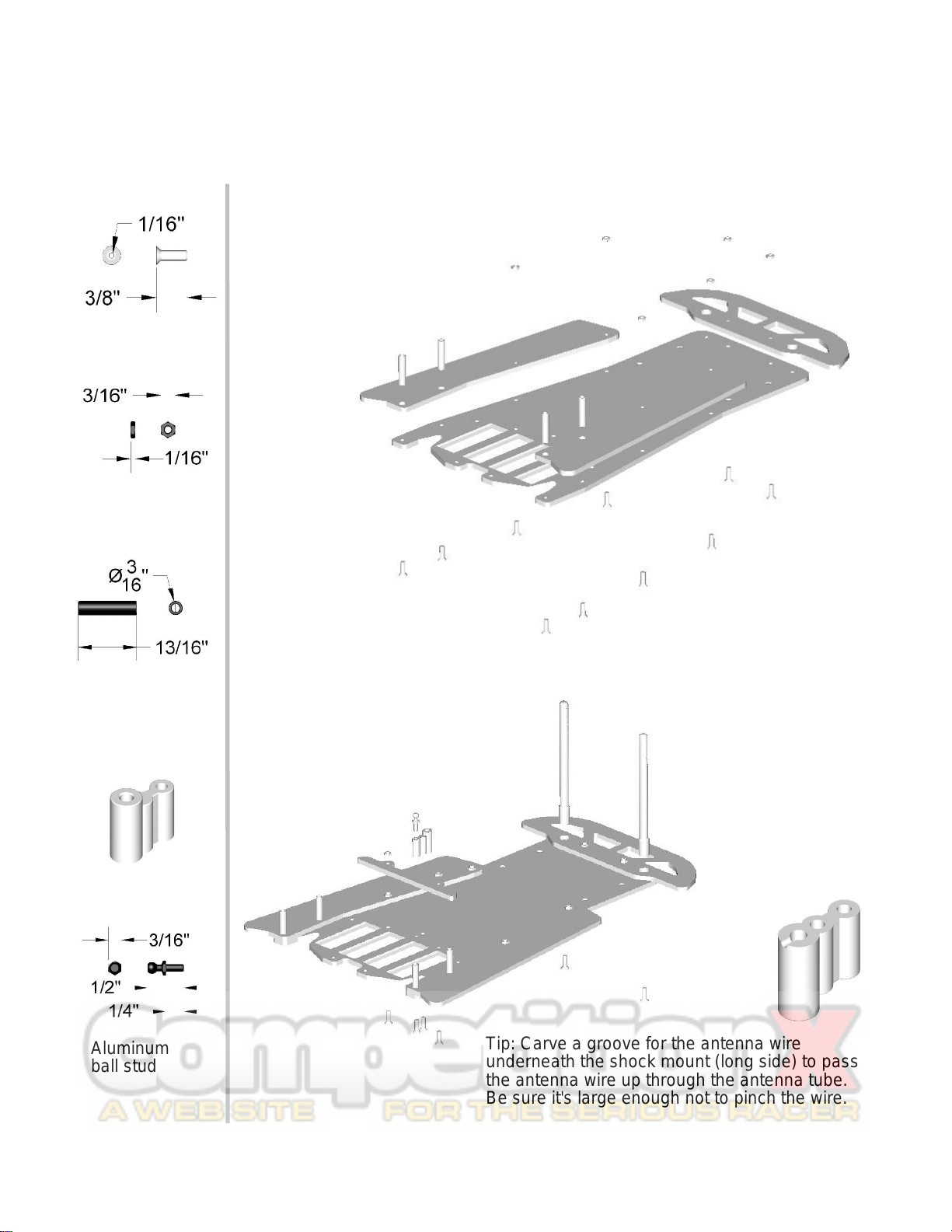

Next assemble the chassis

components, using 4-40 x 3/8” flat

head screws (x10) (smr2012),

4-40 thin hex nuts (x6) (smr2077),

4-40 threaded stand-offs (x4).

Tip: use a little blue thread lock on

all metal to metal fasteners.

Continue assembly adding

battery positioning plate

using 4-40 x 3/8” flat head

screws (x2) (smr2012) and

4-40 small hex nuts (x2)

(smr2076). Attach the

antenna mount (smr1432)

and front body mounts

(smr1551) to the chassis

using 4-40 x 3/8” flat head

screws (x2). Install 4-40

aluminum ball stud into rear

of the antenna mount using

a little CA glue to secure it.

4-40 x 3/8”

flat head

4-40 hex nut

small

Tip: Carve a groove for the antenna wire

underneath the shock mount (long side) to pass

the antenna wire up through the antenna tube.

Be sure it's large enough not to pinch the wire.

Antenna/shock

mount

Tweak plate

and battery

strap stand-off

Aluminum

ball stud

4

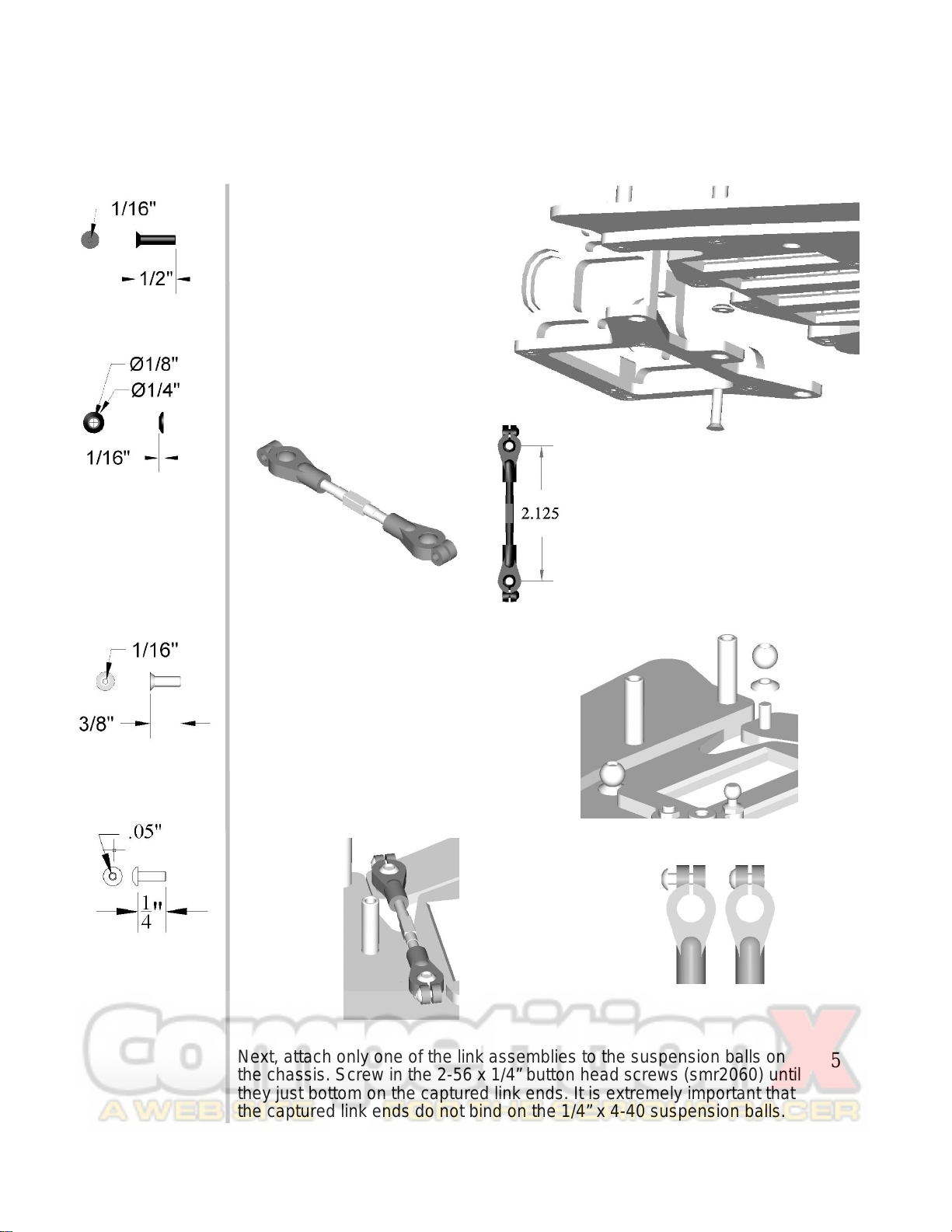

Assemble the center pivot plate

with the pivot socket set

(smr1268), in the configuration

shown, fastening with 2-56 x 1/4”

button head screws (x2).

Attach to the chassis 4-40 x 1/2” flat head screws (x2) (smr2014) with 4-40 hex

nuts (x2) (smr2078). Slide center pivot assembly onto the 4-40 screws and

secure with 4-40 lock nuts (x2) (smr2082).

Attach the left and right bulkheads to the lower pod plate with 4-40 x 1/4”

flat head screws (x5) (smr2010).

2-56 x 1/4”

button head Pivot plate (smr1514)

2-56 x 1//4” (smr2060)

Suspension ball

Pivot socket - lower

(smr1269)

Pivot socket - upper

(smr1269)

4-40 x 1/2”

flat head

4-40 large

locknut

4-40 large

hexnut

4-40 x 1/4”

flat head

5

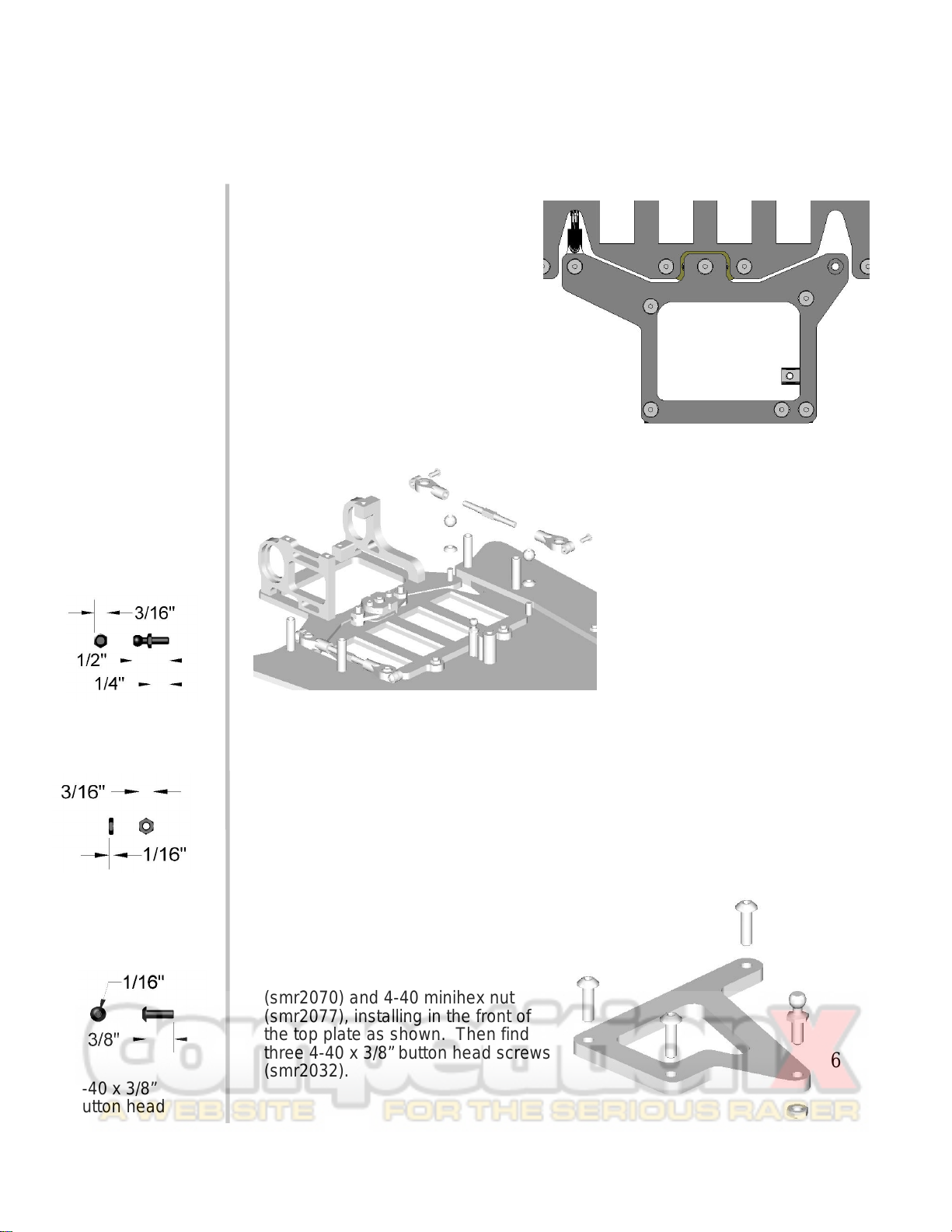

Attach rear pod to the main

chassis using a 4-40 x 1/2” flat

head screw (smr2014). Use a low

roll center cone (SMR5008) on

top of the lower pod plate,

screwing through the 1/4” x 4-40

suspension ball in the center

pivot. Secure with 4-40 mini-

locknut (SMR2080).

Assemble the side links from the

Link Set (smr1264), screw onto

each end of the turnbuckles one

of the captured link ends

(smr1265-s). Space the plastic

captured link ends equally 2-1/8”

apart from center to center. This

will get the link close, and will be

fine-tuned later.

Next, place two 4-40 x 3/8” flat

head screws (smr2012) through

the chassis and lower pod plate.

From the top of the chassis, place

one low roll center cone

(smr5008) on each of the screws,

followed finally by a 1/4” x 4-40

suspension ball screwed down

tightly using a small amount of

blue thread lock.

Next, attach only one of the link assemblies to the suspension balls on

the chassis. Screw in the 2-56 x 1/4” button head screws (smr2060) until

they just bottom on the captured link ends. It is extremely important that

the captured link ends do not bind on the 1/4” x 4-40 suspension balls.

4-40 x 1/2”

flat head

Low roll

center cone

4-40 x 3/8”

flat head

2-56 x 1/4”

button head

6

Holding the chassis and lower

pod plate level, examine the

gap between the main chassis

and the lower pod plate from

the bottom. The gap should be

even all the way across. Make

adjustments to the single

attached link until the gap is

even.

Next, place two 4-40 x 3/8” flat

head screws through the

chassis and lower pod plate on

the opposite side. From the

top of the chassis, place one

low roll center cone on each of

the screws, followed finally by

a 4-40 threaded ball screwed

down tight. Next attach the

second link to the opposite

side using the same method

as before.

Articulate the rear pod, twisting it left and right, noting the feeling of the

motion. The method for fine adjustment for the different actions are as

follows:

- If the motion on one side feels 'clicky', then the link on that side of the

pod is too long.

- If the motion on one side of the pod feels 'tight', then that side link is too

short.

The twisting motion from side to side of the rear pod is really important to

get correct. If not adjusted correctly, it will lead to an ill-handling car.

Locate a 4-40 aluminum ball stud

(smr2070) and 4-40 minihex nut

(smr2077), installing in the front of

the top plate as shown. Then find

three 4-40 x 3/8” button head screws

(smr2032).

Aluminum

ball stud

4-40 hex nut

small

4-40 x 3/8”

button head

7

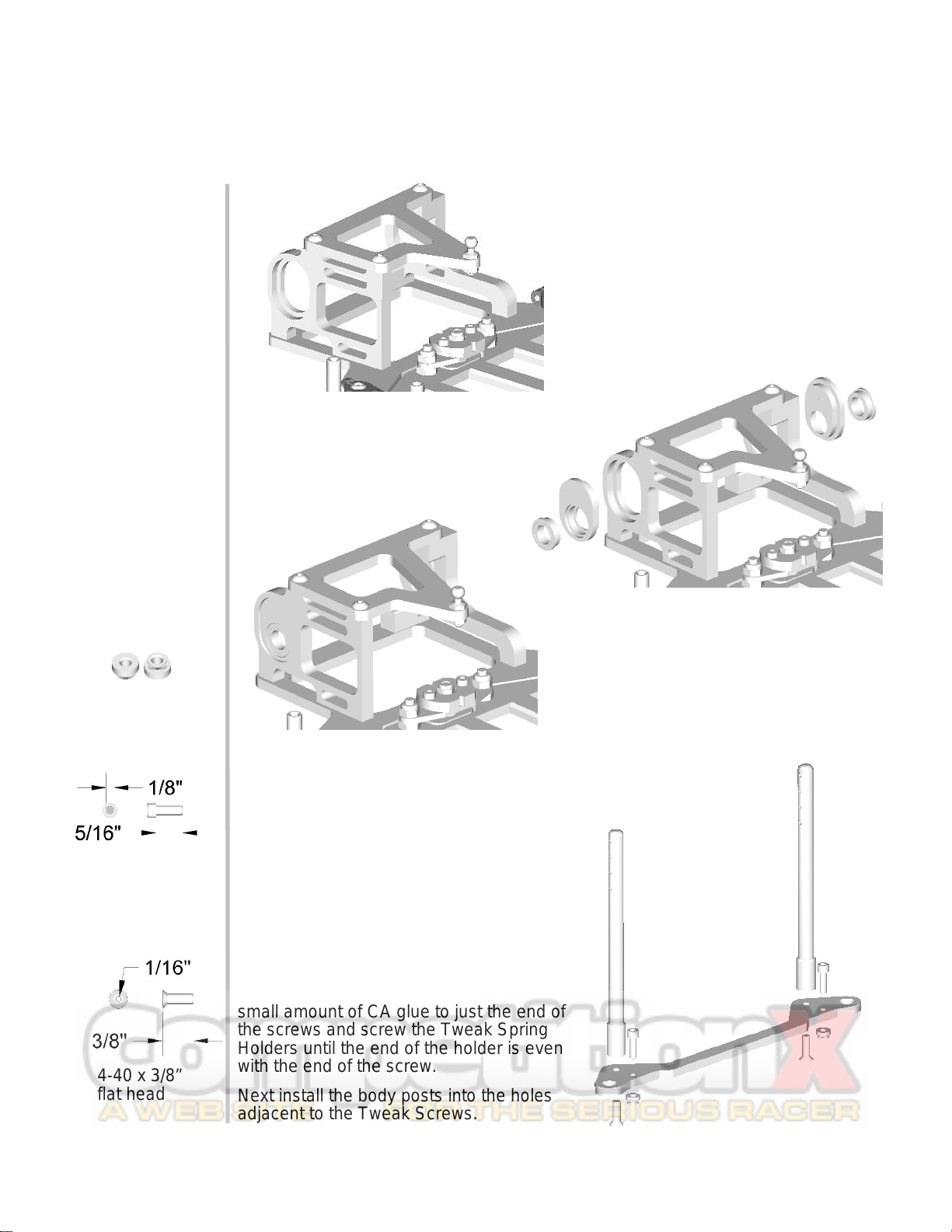

Attach the upper pod plate to the

bulkheads already attached to the

lower pod, do not use thread lock

on these screws. To install a

motor (not included) into the rear

pod, the top plate will need to be

removed, and the motor installed

with the pinion shaft side first,

pivoting the rear of the motor into

place.

Locate two No. 4 axle ride height

adjusters (smr1293), and two 3/8” x

1/4” bearings (smr5001) and install

them into the rear pod. Orientate

the axle ride height adjuster so that

the bearing in the low position.

Tip: Sometimes the axle ride height

adjusters have flashing around the

edges that will need to be trimmed.

This is left on from the molding

process, and can ensure that a good fit

is possible. Trim the gate off with a

hobby knife and test fit in the milled

opening. Only sand enough material off

till the parts just slide in.

Locate the following items:

Body posts (smr1551)(x2), 4-40 x 3/8” flat

head screws (smr2012)(x2). The Tweak

spring carriers (smr1279): 4-40 x 3/8”

socket head cap screws (x2), and Tweak

Spring Holders (x2). Also the Tweak

Springs (x2) (smr5062). And the Tweak

Plate.

The top side of the Tweak Plate has the

counter sunk holes on the outside edges

facing up. Install the socket head cap

screws from the top side, threading into

the non-countersunk holes. Next, apply a

small amount of CA glue to just the end of

the screws and screw the Tweak Spring

Holders until the end of the holder is even

with the end of the screw.

Next install the body posts into the holes

adjacent to the Tweak Screws.

4-40 x 3/8”

flat head

4-40 x 3/8”

socket head

Tweak spring

holder

(top/bottom)

Install the tweak springs, only after the CA glue has

fully cured, by pushing and twisting the spring in a

clock-wise motion until it ‘clicks’ into position.

Assemble the tweak plate to the

chassis using 4-40 x 3/8” flat head

screws (smr2012)(x2) and a little

drop of blue thread lock.

Next locate the battery hold down

plate and install with 4-40 x 3/8”

flat head screws (smr2012)(x2).

Note: no thread lock here!

Find the parts bag containing the rear axle and differential (diff) parts.

From left to right shown above is; the rear axle, diff ring, 3/8” x ¼” un-flanged

bearing, 100 tooth spur gear, 1/8” diff balls (x12), diff ring, 3/8” x ¼” flanged

bearing, right hub, 3/8” x ¼” flanged bearing, thrust cone, nylon diff nut.

These components will be installed in that order. Silicone diff grease should be

used on the balls after installation into the spur gear (both sides).

Tip: to aid in the assembly, put 3 to 4 dots of grease on the axle flange, and on

the right hub before mounting the diff rings. This will hold the rings in place until

the assembly is completed.

When tightening the diff nut, tighten it down slowly until it just starts to tighten the

diff. From this point on, only tighten ¼ turn increments, spinning the axle while

holding the spur from turning. This will allow the diff to break in slowly. Keep

tightening the diff nut until it’s difficult to spin the spur while holding the axle and

right hub firmly.

4-40 x 3/8”

flat head

9

After assembling and breaking in

the differential, install the axle into

the rear pod through the right side

bulkhead. Slide all the way

through until the hub on the diff

flange is touching the bearing.

Install 4-40 x 3/8” socket head cap

screws (x2) into the left rear axle

hub, and do not tighten.

Slide three ¼” axle shims

(smr2090), and the stepped

spacer onto the axle to the

bearing, followed by the left hub

assembly completed in the step

above. Leave a hair gap between

the axle spacer and then tighten

the two socket head cap screws

located on the left hub.

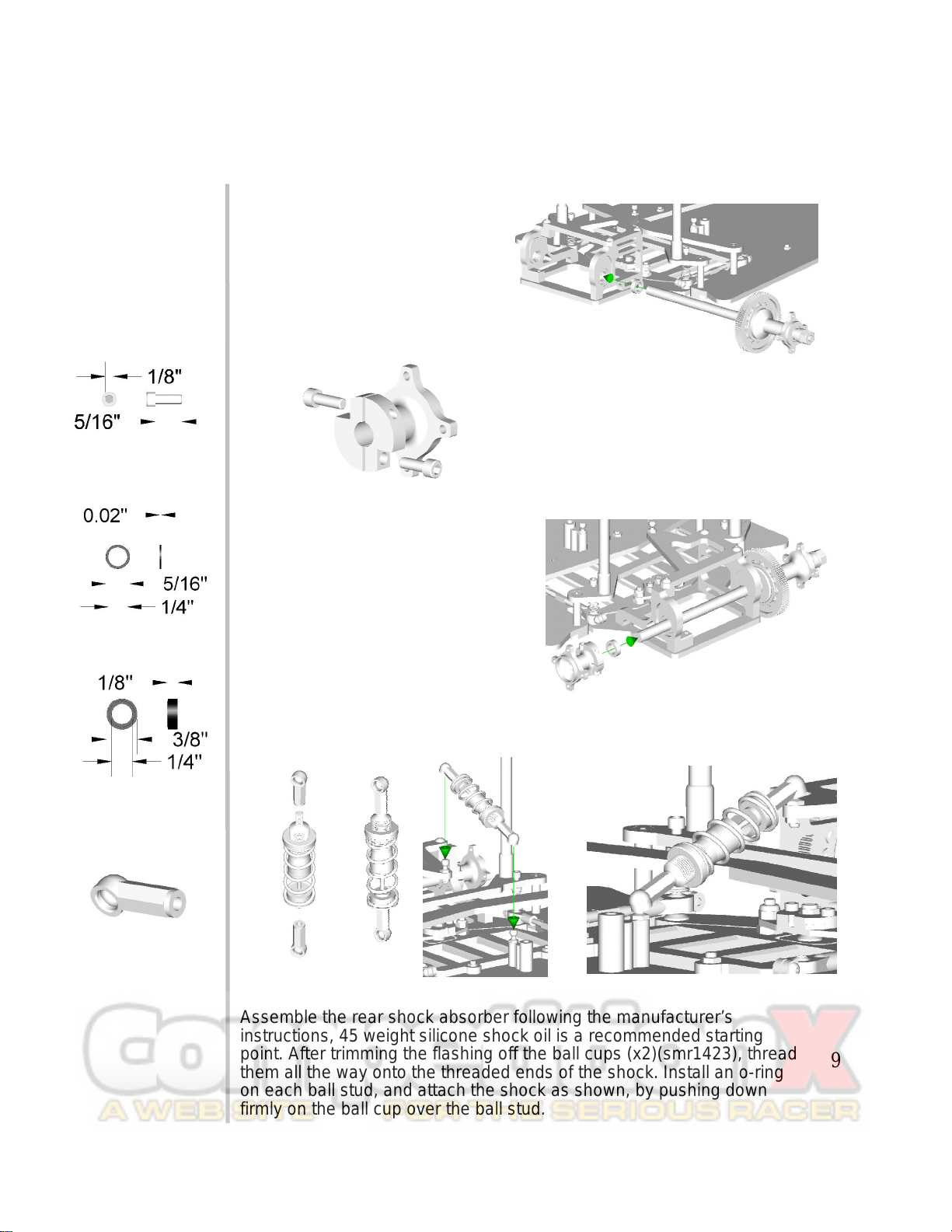

Assemble the rear shock absorber following the manufacturer’s

instructions, 45 weight silicone shock oil is a recommended starting

point. After trimming the flashing off the ball cups (x2)(smr1423), thread

them all the way onto the threaded ends of the shock. Install an o-ring

on each ball stud, and attach the shock as shown, by pushing down

firmly on the ball cup over the ball stud.

4-40 x 3/8”

socket head

1/4” axle shim

1/4” stepped

axle shim

Ball cup

10

Find the steering knuckles (smr1281)(x2), front

axles (smr1289)(x2) and E-clips (smr2092)(x2).

Install an E-clip into the groove on the axle, then

press fit the axle into the steering block threaded

end first. Press the axle all the way through the

steering block till the E-clip bottoms on the steering

block. Using a 3/32” drill, open the indicated hole on

the tabs of both steering blocks. Thread in the short

neck ball studs (smr2069), secured by 4-40 mini-

hex nuts (smr2076), use thread lock on the stud.

Noting the bump on the front of the suspension

arm (smr1289)(x2), install the steering knuckle

with the ball stud located toward the rear.

Start by installing the kingpin (smr1282)(x2)

through the top of the suspension arm, just

enough to slide the .022” spring (smr1286)

onto. Next position the steering knuckle as

mentioned above. Slide the kingpin down

carefully, taking care not to catch the spring in

the E-clip grooves.

Tip: Polish the kingpins before installing using

some metal polish for smooth operation.

When installing E-clips (smr2092),

ensure the groove in the kingpin is

aligned with the top of the steering

knuckle. Slide the first E-clip between the

knuckle and spring, firmly snapping it

into the groove.

With the top E-clip installed, installing the

bottom E-clip is as simple as sliding it

between the steering block and lower

part of the suspension arm with the clip

started on the groove. Now, let the

suspension relax. Holding the knuckle in

place, use the back side of a hobby knife

blade to snap the E-clip into place.

Drill 3/32”

hole

Note: it is recommended to wear safety glasses when installing E-clips.

E-clip

Axle

Short Neck

Ballstud

Nut

Kingpin

Front Spring

11

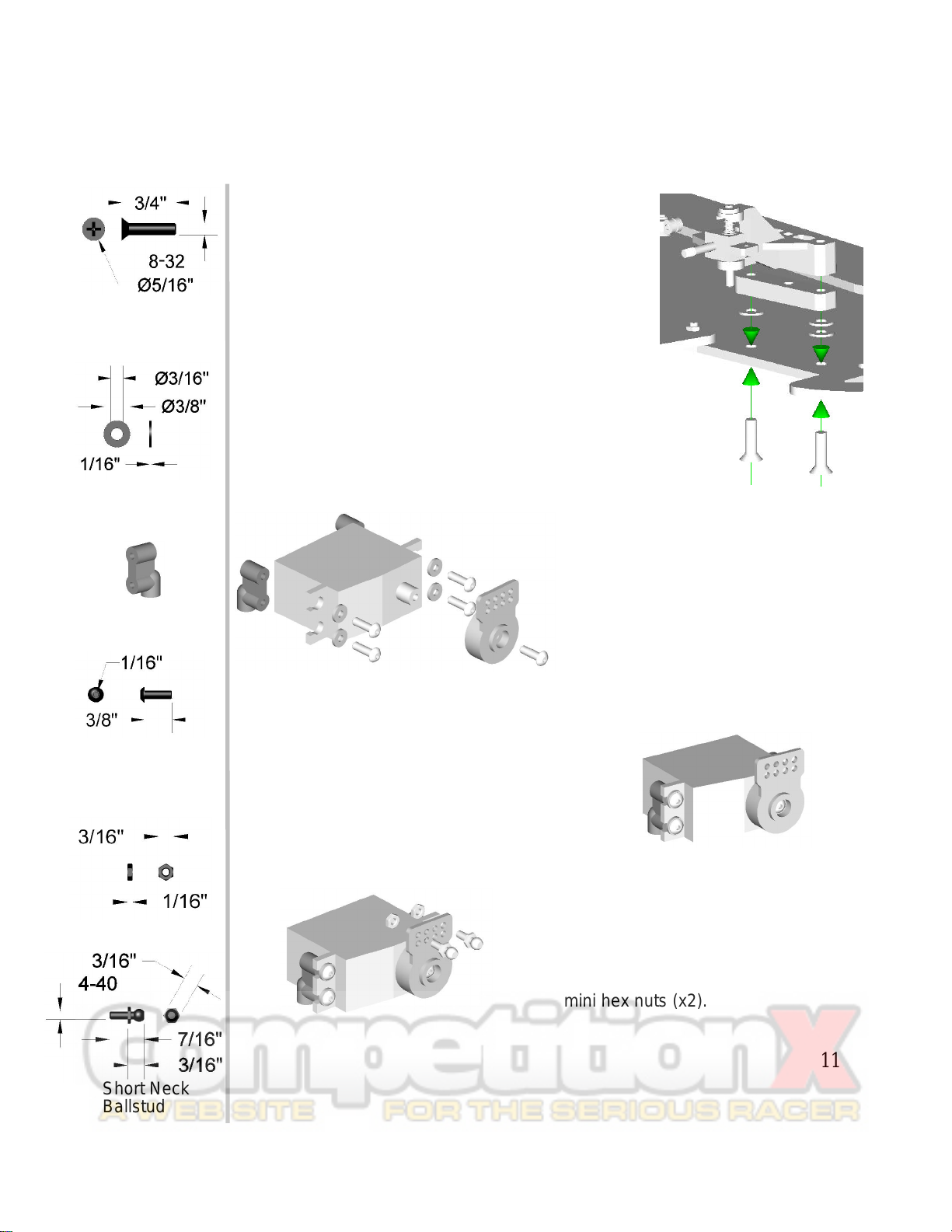

With two 8-32 x 3/4” flat-head cross-point

(phillips-head) stainless steel screws (smr2045),

mount one ride height/caster shim (smr2089)

toward the rear-most hole, and two ride

height/caster shim on the screw in the front. Pass

these screws through the plastic suspension arm

spacer, and firmly screw down the front

suspension arm.

Tip: the bump on the suspension arm faces the

front of the chassis.

Repeat the process for the opposite side.

To install your steering servo (not

included), find the servo mounts

(smr1430)(x2), 4-40 x 3/8” button

head screws (smr2032)(x4), #4

flat washers (smr2088)(x4), and a

servo saver that matches your

servo (not included). Make sure to

retain the screw that came on the

splined output shaft of the servo

to attach the servo saver.

8-32 Flat

Head Screw

Caster/ride

height shim

Servo mount

With the servo orientated in the direction

shown, assemble by passing the 4-40

button head screws through the #4

washers, screwing firmly into the servo

mounts through the mounting ears on

the servo case. Be sure to not over

tighten these screws. The bottom of the

servo mounts should be even with the

bottom side of the servo.

Install two short neck ball studs

(black) in the upper-outer most holes

on the servo saver. After putting a

drop of thread locker on the threaded

end of the ball stud, thread on 4-40

mini hex nuts (x2).

4-40 x 3/8”

button head

Nut

Short Neck

Ballstud

12

Because every servo is slightly

different in size, drilling mounting holes

for the servo is left to the builder. To

locate the holes to mount the servo,

place a piece of masking tape just

behind the suspension arms as shown.

Locate the center of the chassis on the

tape, and draw a line from front to back

as shown.

Place the servo assembly on the

chassis. Use the line drawn to

center the servo saver on the

chassis, as far forward as possible.

Be sure to have the servo as

square to the chassis as possible,

too. Locate on the tape, the holes

to mount the servo.

The line drawn across the chassis

should be the same line for both holes,

as the servo should be mounted

square to the chassis.

Drill two 1/8” holes, and countersink

the holes from the bottom side of the

chassis with an 82°countersink until the

4-40 x 3/8” flat head screws (x2) sit

flush with the bottom of the chassis.

Tip: pilot drill the holes slowly with a smaller drill bit to help locate the holes

more precisely, this will keep the larger drill bit from 'walking' away from the

intended location.

After removing the tape, use the

countersink tool to slightly chamfer the

top sides of the newly located holes. This

will remove any burrs and give the holes

a finished look. Install the servo

assembly with 4-40 x 3/8” flat head

screws (smr2012)(x2). Be sure not to

over-tighten them.

4-40 x 3/8”

flat head

13

Using the remaining plastic ball cups (x2)(smr1423) and 4-40 turnbuckles

(x2)(smr1297), assemble them into the steering linkage as shown below,

paying attention to keeping the turnbuckle equally threaded into the ball cups.

This will allow adjustment without the danger of bottoming the turnbuckle

inside the ball cup. The dimension shown is to get the length roughly the

correct length. Shown is the left hand turnbuckle, the right hand will have the

ball cup on the right facing away from you. Fine tuning of the linkage will have

to be completed when it is assembled on the model.

After installing the linkage onto the chassis, it should appear as shown below.

The remaining hardware is for mounting the front wheels: 1/8” x 5/16” flanged

bearings (x4)(smr5003) to be mounted into the front tires of your choice, 4-40

mini lock-nuts (x2)(smr2080) used to secure the front wheels to the front axles.

Tip: be sure when tightening the front wheel nuts not to crush the bearings.

The nuts should just touch the inner bearing race with the wheel seated flush

against the steering block. To test for over tightened nuts, spin the wheel while

tightening the wheel nut. When the nut causes the wheel to slow, back the nut

off until there isn't any more compression and the wheel spins freely.

More remaining hardware is as follows: 4-40x 1/2” socket head cap

screws (x8)(smr2024). These are used for mounting the rear tires of your

choice. Tighten these till the screws are firmly secured. Over tightening

will cause the rims to deform and not run true. It could also lead to

premature rim failure.

Installing the electronics using the layout shown has proven to be the

most efficient layout. This allows the positive wires to go to the battery on

the left side, then straight back to the motor (non-reversing ESC). The

negative battery lead to the right, while the motor negative goes straight

back. Tip: route the motor wires down the centerline of the car, following

the shock. This will keep from imposing tweak between the motor pod

and main chassis.

Other Speed Merchant Motorized Toy Car manuals