Speedline Models Y Class RIB User manual

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

Floor boards (in

two

h

alves

)

Sponge filled floor mat

Hull Underside

Hull Underside Hull Underside

Sponge floor mat

Small items

Floor boards

Rod/dowel

laser-cut sheet

Decals set

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

1

2

4

3

5

6

7

9

2 1

2 2

2 3

2 4

1 0

1 1

1 2

1 5

1 3

8

1 9

1 6

1 4

1 7

1 8

2 0

W h e r e t o c u t t h e 0 . 5 m m t h i c k v a c f o r m i n g s

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

The items are:

1. Rectangular backing pads.

2. Compass halves.

3. Oar holders (cut as shown).

4. Support for the spray shield hoop.

5. Inflation valve insert.

6. Rectangular backing pads.

7. Compass base.

8. Grab line support strip.

9. Forward storage bags.

10. Oval backing pads for the grab handles.

11. Aft storage bags.

12. Oval backing pads for the grab handles.

13. Grab line support strip.

14. Grab handles.

15. Rowlock supports.

16. Toolbox lower section.

17. Bottom of outboard motor.

18. Fuel tank bag.

19. Bases for the rope and grabs.

20. Toolbox lid.

21. Outboard motor engine cover.

22. Oar supports.

23. Oar retainers.

24. Outboard motor legs.

The kit comprises of vac-formed polystyrene parts, laser cut Perspex parts, cast resin

parts, cut vinyl lettering, rope and plastic rod.

Both plastics will glue well using Plastic Weld.

Wash the styrene parts in soapy water before starting work on them. The Perspex parts

are very clean so no need to wash them.

Make sure that any protective film which may be on the Perspex is removed.

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

The kit comprises of vac-formed High Impact Polystyrene parts and laser-cut Perspex

components, Vinyl pre-cut decals, rope and plastic rod.

Both plastics should be glued using ‘Plastic Weld’, a clear liquid glue which is ideal and

dries very quickly.

The components within the plastic bag easily fall out of their backing sheet and care

should be taken to avoid loosing them.

The vac formed sheets should be washed in soapy water to remove any residue and

then dried thoroughly. (The Perspex components are very clean and do not require

washing prior to assembly).

CAUTION:

When removing the laser cut components from the backing sheet (particularly the

thinner, complicates shapes, proceeded with great care as they are attached to

their backing sheet with double sided tape. Gently ease then out, DO NOT RUSH

THIS otherwise the components may break.

The hull tubes

Begin by marking out the cutting line on

the two hull tube halves.

Make up a scribing gauge out of scrap

material similar if possible to the one in

the photograph. The idea is to enable a

line to be draw parallel to the outermost

edge at a distance of 17.5mm, the

‘halfway’ line.

The illustration below shows how the

gauge works.

17mm

Hull tubes

Gauge

The picture below show the gauge in

action!

Then there is the inside to scribe in a

similar manner.

When you are satisfied with the line

position, apply narrow masking tape (or

similar) along the line to help you guide

the knife.

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

Cut very slowly and very lightly. DO

NOT try to cut all the way through in just

a couple of cuts. You wont do it and its

not necessary.

USE VERY LIGHT CUTS.

When the line is pretty well established,

try bending the plastic back and it will

probably break, just like in the photo

below. If not, try a couple more strokes.

When the parts have been cut, no

matter how hard you tried, they probably

wont fit. DON’T PANIC! Mine are

always miles out so, using a piece of

scrap wood, make up a sanding board.

Make a decent job of it, it will last for

ages and be very useful for the rest of

the kit too.

Naturally I have one I made earlier and

its still doing a good job. Use ‘150

grade’ wet and dry glued as flat as

possible.

Now sand the edges to the line keeping

as flat as possible. Do a test fit, sand a

little, test fit again. Look to see where

the proud bits are and give them a light

sanding. Test fit again. Keep doing this

until you have a good fit. Take your

time and remember, your supposed to

be enjoying this!

When you are happy with the fit (and

don’t forget what filler is for), build a

‘fence’ around the inside edges of the

lower moulding. It needs to be about

3mm wide that’s all. See the next

photo.

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

Looking good eh?

Fit the top and bottom halves together

and hold in place with a little tape.

Apply ‘Plastic Weld’ with a brush all the

way round doing a section at a time.

When its all dry use, remove all the tape

and use the sanding board to get a nice

even joint line. Finish off with 400 grade

wet and dry.

When its as good as it can be, use filler

to fill any holes or unevenness and sand

smooth.

The floor and rigid section of the hull.

Use the template supplied to mark out

the 1mm polystyrene sheet. Follow the

instructions on the template. With the

hull ‘bottom-up’ fit the floor into the

recess. When happy with the fit, glue

into place. Cut out and sanded to shape

the rigid hull section and fit over the floor

as shown below.

Hull tubes

Floor

Rigid hull section

The patches and fittings on the hull.

Most of the items that fit onto the hull

tubes are in reality, rubber sheet or

rubber moulding. The four storage bags

for example fit around the hull tubes and

you will see that they are moulded onto

a curved section. They need cutting out

and then the inside shape needs

sanding to fit the hull tubes. This is

really easy when you use the

‘Speedline Wonder Sander!

See the photo below.

The Wonder Sander consists of another

piece of wet and dry, this time 400

grade, taped to the outside of one of the

hull tubes. This guarantees that the

inner curve is the same as the tubes.

Simple and inexpensive.

Well I think you will get the idea. Use

the wonder sander to shape everything

that fits onto the tubes, including the

long moulding that the lifeline goes

through.

Study the drawings and the photos and

make up all the components one at a

time. Test fit them but don’t start fitting

them into place just yet.

There is an illustrated sheet at the end

of these instructions which shows all the

parts and what they are made up from.

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

The transom

The transom is made from four pieces of

Laser-Cut-Perspex (LCP) and two resin

castings.

On the largest of the LCP sheets are

two halves of the transom. Glue these

together with the engraved detail facing

outwards. The outer face of the

transom has the large ‘motor plate’ on it

and the inner face has the small strip

like spacer near the top edge.

Glue the two rings around the transom

flap holes on the inside.

Transom

Transom Flap

Ring

The two resin cast transom flaps should

be painted and then glued in place using

‘superglue’ or two part epoxy resin glue

the flaps onto the transom as shown

after the latter has been painted.

The Outboard

By now, this will be easy! The two

halves of the outboard leg simply join

along the vertical centerline, ‘but’ joining

them in a similar manner to the hull

tubes.

1

2

3

8

9

4

5

6

7

10

The drawing above shows what

everything is and where it goes. (VF is

Vac form and LCP is Laser Cut

Perspex)

1. Engine cover (VF)

2. Engine base plate (VF)

3. Handle (LCP)

4. Spacer (LCP)

5. Top hinge(LCP)

6. Pin (rod)

7. King post assembly (LCP)

8. Out side – plate (LCP)

9. Inner side – plate (LCP)

10. Bottom hinge (LCP)

Make up the engine mounting brackets

8 and 9, (the larger plate is on the

outside).

Now make up the engine mount

kingpost as follows.

The engine mount kingpost comprises

of a number of laser cut components.

Study the following drawing to see how

they all go together.

The vertical rod should be 4mm longer

than the kingpost so that it just fits into

the top and bottom hinges.

‘Y’ CLASS LIFEBOAT INSTRUCTIONS

Glue them all together to form a rigid

assembly.

Item 3, the handle can be added to give a

little more scale realism just by adding

scraps of plastic sheet and sanding to a

fuller 3D shape.

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price W5542 owner's manual

Circuit Cubes

Circuit Cubes Space Rovers XV-A1 manual

THUNDER TIGER

THUNDER TIGER mini Titan V2 Series instruction manual

Mattel

Mattel Hot Wheels Star Wars FLIGHT CONTROLLER instructions

Mattel

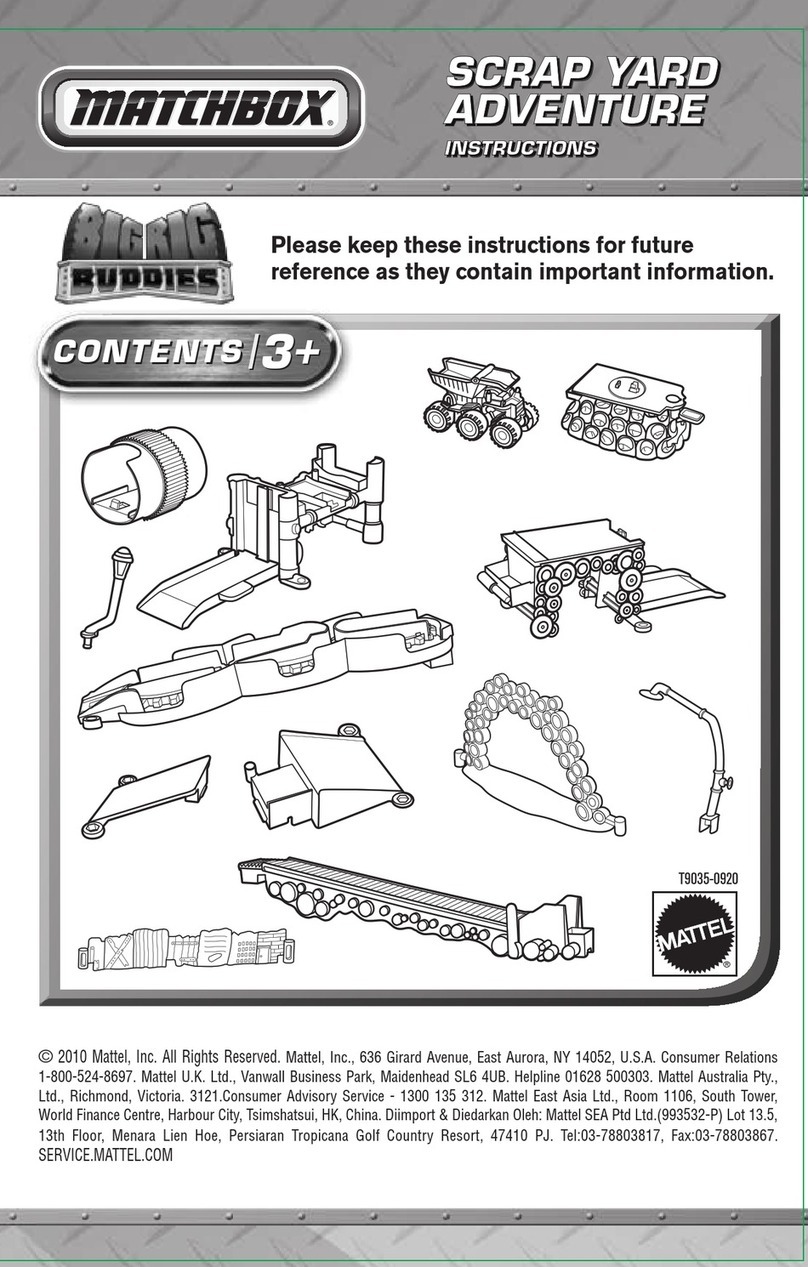

Mattel MATCHBOX BIG RIG BUDDIES SCRAP YARD... instructions

Eduard

Eduard EF-2000 Typhoon Single Seater quick start guide

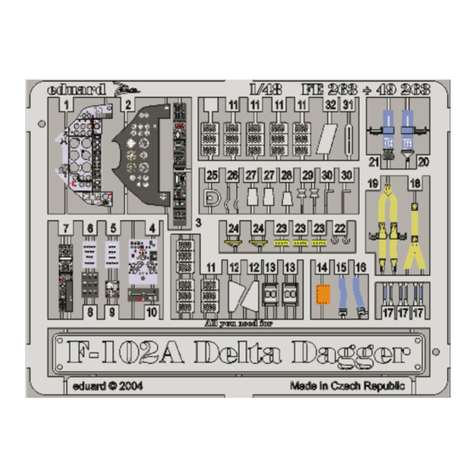

Eduard

Eduard Zoom F-102 Delta Dagger quick start guide

Kyosho

Kyosho spree sports m36 instruction manual

TeacherGeek

TeacherGeek Wiggle-Bot quick start

byox

byox Be Happy instruction manual

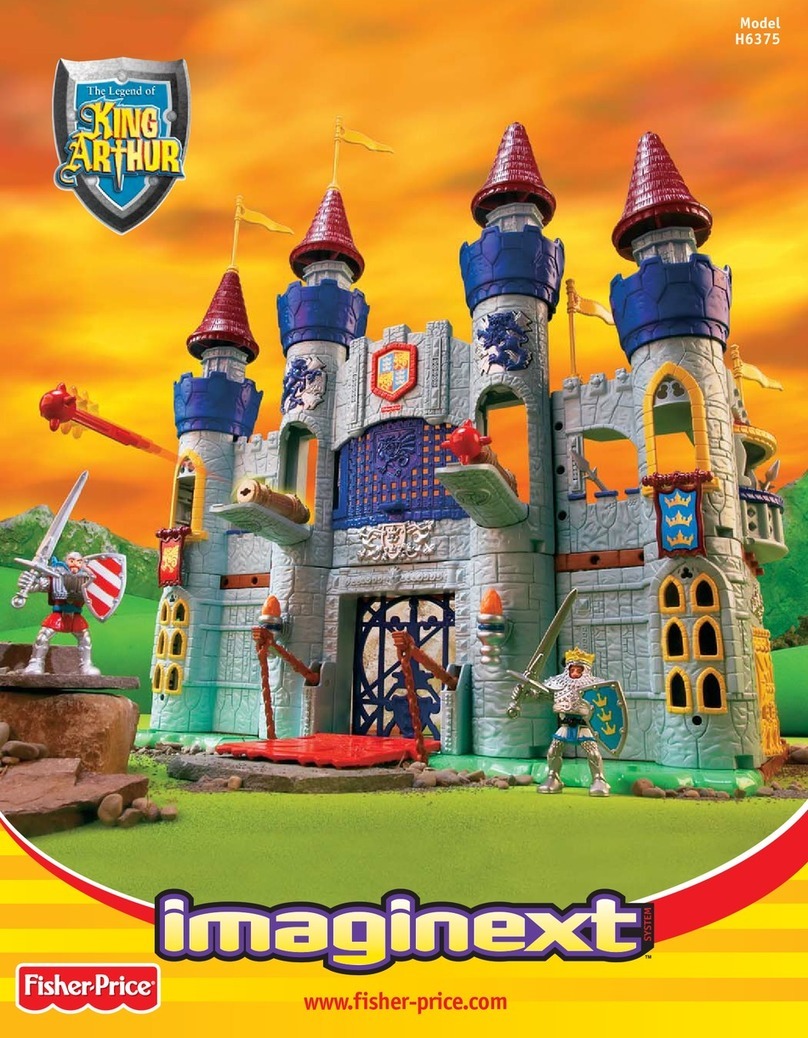

Fisher-Price

Fisher-Price Imaginext Legend Of King Arthur H6375 manual

Haute Decor

Haute Decor DCYD0009 quick start guide