Speedway 910-84112 User manual

DISCLAIMER In an effort to offer our ustomers the low pri es, qui k servi e and

great value, Speedway Motors reserves the right to hange suppliers, spe ifi ations,

olors, pri es, materials. Ea h of the previous items is subje t to hange without

noti e. Speedway is not responsible for any typographi al errors or

misinterpretations. Quantities are limited on some items.

WARRANTY DISCLAIMER The pur haser understands and re ognizes that ra ing

parts, spe ialized street rod equipment, and all parts and servi es sold by Speedway

Motors, In . are exposed to many and varied onditions due to the manner in whi h

they are installed and used. Speedway Motors, In . makes no warranties, either

express or implied, in luding any warranty of mer hantability or fitness for a

parti ular purpose other than those ontained in its urrent atalog with respe t to

the goods identified on the fa e of the invoi e. There is no warranty expressed or

implied as to whether the goods sold hereby will prote t pur haser or ultimate user

of su h goods from injury or death. Speedway Motors assumes no liability after this

period.

DAMAGE CLAIMS Always inspe t your pa kage upon delivery. Inspe t all pa kages

in the presen e of the delivery driver. The driver must note any damage. Ask the

driver the Carrier’s pro edures for handling damage laims. You must hold the

original box, pa king material and damaged mer handise for inspe tion or the

arrier will not honor the laim. Notify Speedway Motors ustomer servi e

department for instru tions on returning damaged goods. Speedway is not

responsible if no notifi ation is given within 5 days of re eipt.

SHORTAGES Always he k the ontents of your delivery to insure all the parts that

you ordered were re eived. Please read the invoi e. Double he k all pa king

materials, small items may be wrapped inside with these produ ts. Shortages may

o ur from damage to the box, so save all pa king materials. Inspe t the box for

holes that would allow parts to fall out. If you are missing any item(s) be sure to

he k your invoi e for ba k orders or an eled items before alling the ustomer

servi e department. If Speedway has to split a shipment into multiple boxes,

pa kages may be delivered on different days. You need to onta t the ustomer

servi e department within 5 days of delivery to assure the prompt repla ement.

Speedway Motors assumes no liability after this period.

REFUSALS All refused COD ustomers will be billed a 15% resto king harge plus

freight to and from the destination! If you have questions please onta t Speedway’s

ustomer servi e department.

WARRANTY CLAIMS If an item has a manufa turer’s warranty as being free from

defe ts we will ex hange only. If the item has been used and you are requesting

warranty work, this may take up to 30 days as warranty work is done by the

manufa turer NOT Speedway Motors. If you have any questions please onta t

ustomer servi e.

RETURNS Speedway wants you to be satisfied with your pur hase. If within 30 days

after you re eive your shipment you are not satisfied, you may return the item for

refund or ex hange. All ex hanged or returned mer handise must be in original

fa tory ondition with no modifi ations or alterations. Returned mer handise must

in lude all pa kaging materials, warranty ards, manuals, and a essories. If the

items being returned need to be repa kaged there will be a re-pa king harge. Re-

pa k the item in a sturdy box and in lude a opy of your invoi e and omplete the

form on the ba k of the invoi e. You must ship orders ba k PRE-PAID. WE DO NOT

ACCEPT COD SHIPMENTS. All ex hanges need to have reshipping harges

in luded. Items that are returned after 30 days are subje t to 15% resto king

harges. All fiberglass returned will have 15% resto king harge. No returns on

ele tri al parts, video tapes, and books. Absolutely no returns on spe ial order or

lose out mer handise.

FREE CATALOGS Speedway Motors offers FREE atalogs for Ra e, Street, Sprint

and Midget, Sport Compa t and Pedal Car restoration.

**Some items are not legal for sale or use in California on pollution ontrolled

motor vehi les. These items are legal in California for ra ing vehi les only whi h

may never be used upon a highway.

Before assembly, please read the assembly

instructions carefully. Refer to the parts list to

ensure all components are included.

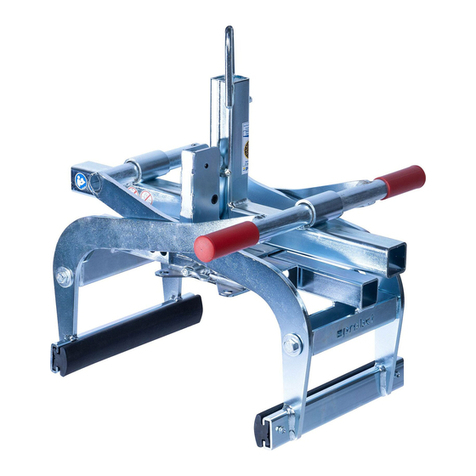

Tube Bender Assembly

910-84112 (Rev. #2)

Figure 1.0

Jack addle

& Bending

Die Assembly

In order to bend a smooth, galding free tube, “ peedy” Bill has the

following recommendations:

1) Pour a small amount of clean, No.10 weight oil into a shallow pan.

2) Put in several 3” to 5” wide strips of newspaper, (rag style, not color

printed advertising paper) in the pan and allow the oil to soak the

newspaper.

3) Remove the newspaper from the pan. Squeeze off excess oil. The

newspaper should not be over saturated with oil.

4) Place the oiled newspaper between the Bending die and the tube.

Start bending the tube with the newspaper in place. The lubrication

will help to prevent any galding or wrinkling of the tube.

5) Before bending the actual tube, it is best to try this method on a

shorter, scrap tube to perfect the bending motion. One may decide to

use multiple layers of oiled newspaper to provide a better cushion

between the die the tube.

6) ounting holes are provided on the base of the bender to allow the

customer to bolt the bender to a heavy duty workbench. If only a few

bends are needed, CLA P the bender to a heavy duty work bench.

Tube Bending Tip from " peedy" Bill mith

N TE: The Tube Bender can be mounted on the work

bench or a stand. 4 Mounting holes are provided at the

base of the Tube Bender for mounting the Tube Bender.

GE ERAL III TUBI G BE DER

BILL OF MATERIALS-910-84112

ITEM O. PART O. DESCRIPTIO QTY.

1 910-84108 8-TO BOTTLE JACK 1

2 910-84112-2-1 1⁄2”-13X31⁄4”LG. GR. 8 HEX CAP SCREW 1

3 910-84112-2-2 1⁄2”-13 GR C HEX LOCK UT 1

4 910-84112-2-3 1/4”-20 X 1/2” LG. GR. 5 HEX CAP SCREW 2

5 910-84112-2-4 #10-32 X 1/2” STAI LESS BUTTO HEAD ALLE SCREW 2

6 910-84112-2-5 1/2” RUE CLIP - (REF P/ : 940-1002) 2

7 910-84112-2-6 1” RUE CLIP - (REF P/ : 910-84102-10) 4

8 910-84112-3 3RD. GE . TUBE BE DER FRAME ASSEMBLY 1

9 910-84112-3-2 JACK SADDLE ASSEMBLY 1

10 910-84112-3-3 JACK RAM RETAI ER CUP 1

11 910-84112-3-4 DIA. 1.00” DIE PIVOT SHAFT 2

12 910-84112-3-5 DIA. 0.50” JACK PIVOT SHAFT 1

13 910-84112-3-6 11⁄8” O.D. X 10” LG. FORMI G DIE RETUR SPRI G 1

14 910-84112-3-7 DIA. 1/8” SPRI G SAFETY CABLE 1

15 910-84112-3-8 JACK PUMP HA DLE 1

16 910-84114 BE DI G DIE ASSEMBLY 1

17 910-84115 FOLLOWER DIE 1

ASSEMBLY INSTRUCTI N

The Tube Bender Assembly is the

latest design by Speedway Motors.

It consists of a Tube Bender Frame;

an 8 Ton Hydraulic Jack and a

Bending Die.

INSTRUCTI NS

1

11/4”

11/2”

15/8”

13/4”

tep 1

Jack addle/Bending Die Assembly

a) Locate the Bending Die Assembly (Item # 16), the Jack Saddle

Assembly (Item #9), the 1⁄2”-13 Hex Bolt (Item #2), and the 1⁄2”-13

Nyloc Nut (Item #3).

b) Position the Jack Saddle to the Bending Die Assembly as shown in

Figure 1.0. Note that the large radius cutout in the Jack Saddle

Assembly should be facing the back side of the Bending Die

Assembly. Align the mounting holes and fasten the two pieces with

the Hex Bolt and Nyloc Hex Nut. Do not over-tighten the assembly,

as it may prevent the Bending Die Assembly from rotating freely.

IMP RTANT

Speedway Motors Inc., P. . Box 81906

Lincoln, NE 68501 (402) 323-3200

www.speedwaymotors.com

©Speedway otors, Inc. ay, 2007

Tube Bending Operation

Figure 6.0 — Figure 6.0 shows the back view of the Tube Bender Assembly.

Figure 7.0 — Figure 7.0 shows the Front View of the Tube Bender Assembly.

Figure 8.0 —Tube Bending Operation

Note: One end of the jack handle will be used to lock the valve on the base of the jack. The other end is used as a jack

handle.

a)Place the steel tube between the Follower Die and the Bending Die. Slide the tube through the U-shape tube guide at one

end of the Bending Die. If the U-shape guide is too tight, loosen the nut to slide the tube into the tube guide.

b) Place the Jack Handle into the side holder of the jack. Apply pressure to compensate any slack from the assembly.

c) Start bending the tube by applying bending pressure to the jack. The Bending Die will rotate and begin to bend the tube.

Use the angle mark on the forming die to determine the bend angle.

d) After the tube is bent, use the flattened end of the Jack Handle to release the pressure of the jack. The Forming Die will

return to its original position and the bent tube can be removed from the Forming Die.

tep 5

8-Ton Bottle Jack & Retaining Cup Installation

a)Locate the 1/2” Jack

Pivot Shaft (Item #12),

and the two (2) 1/2”

Rue Clips (Item #6).

b)Position the Bottle

Jack & Retaining Cup

Assembly from tep #2

into the Tube Bender

Frame as shown in

Figure 5.0 with the

Retaining Cup between

the two mounting ears

on the top side of the

Tube Bender Frame.

Note orientation of the

Bottle Jack with respect

to the Tube Bender.

c) Apply a small amount of lightweight oil to the 1/2” Jack Pivot Shaft.

d) Insert the Jack Pivot Shaft through one of the outside holes in the

Tube Bender Frame. Then through the first mounting ear and finally

through the Jack Ram Retaining Cup and last mounting ear.

e) Insert the 1/2” Rue Clips into both ends of the Jack Pivot Shaft.

f) Position the Bottle Jack onto the Jack Saddle Assembly as shown

in Figure 5.0.

g. Speedway otors recommends match drilling a hole through the

Bottle Jack base into the Jack Saddle assembly. This will allow for

the installation of a 1/4” bolt and nut (not included) to secure the

Bottle Jack to the Jack Saddle(*).

NOTE: Customer may use a small C-Clamp or Vice Grip to clamp

the Bottle Jack to the Jack Saddle Assembly. This is only required if it

is not possible to install the 1/4" bolt and nut after match drilling the

Bottle Jack and Jack Saddle Assembly as indicated in 5-g.

tep 6

pring & afety Cable Installation

a) Locate the Forming Die Return Spring (Item #13), the Spring Safety

Cable (Item #14), two (2) 1/4”-20 Hex Bolts, (Item #7) and the Jack

Pump Handle (Item #15).

b) Feed the Spring Safety Cable through the Forming Die Return Spring.

c) Attach one end of the Forming Die Return Spring through the spring

mounting hole in the Jack Saddle Assembly as shown in Figure 6.0.

d) Pull the opposite end of the spring up and slide it over the Spring

Hook on the Tube Bender Frame as shown in Figure 6.0.

(Be certain the Forming Die Return Spring is hooked into the groove

on the Spring Hook.)

e) Fasten the upper end of the Spring Safety Cable to the threaded

hole on the Spring Hook using one (1) of the 1/4”-20 Hex Bolts.

Fasten the lower end of the Spring Safety Cable to the threaded

hole in the Tube Bender Frame with the remaining 1/4”-20 Hex Bolt

as shown in Figure 6.0.

f) Place the Jack Pump Handle into the Handle Retaining Rings on

the side of the Tube Bender Frame as shown.

Figure 6.0

pring & afety Cable Installation

tep 4

Follower Die Installation

a) Locate the Follower Die (Item #17), the remaining 1” Die Pivot

Shaft (Item #11), and the remaining two (2) 1” Rue Clips (Item #7).

b) Apply a small amount of lightweight oil to the Die Pivot Shaft.

c) Insert the Follower Die inside of the Tube Bender Frame. Insert

the 1” Die Pivot Shaft through the appropriate (*) mounting hole in

the Tube Bender Frame, through the Follower Die, and through

the corresponding hole in the other side of the Tube Bender

Frame as shown in Figure 4.0.

NOTE:(*) Use the hole marked “A” for the 1.00” and the 1.25”

Follower Dies. Use the hole marked “B” for the 1.50”, 1.625” and

the 1.75” Follower Dies.

d) Insert the Rue Clips into both ends of the Die Pivot Shaft.

tep 2

8-Ton Jack & Jack Ram Retainer Cup Assembly

a) Locate the 8-Ton Bottle Jack (Item #1), the Jack Ram Retainer Cup

(Item #10), and the two (2) #10-32 Button Head Allen Screws (Item

#5).

b) On the 8-Ton Bottle Jack, extend the Jack Ram up by screwing the

Jack Ram out. The Jack Ram should be approx. 11/16” to 3/4” above

the flat surface on top of the large hex of the Bottle Jack.

c) Place the Jack Ram Retainer Cup on top of the Jack Ram and align

the hole in the Retainer Cup as shown in Figure 2.0. The bottom

surface of the Retainer Cup should just touch the flat surface on top

of the large hex of the Bottle Jack. If it does not touch, remove the

Retainer Cup and screw in the Jack Ram until the Retainer Cup

touches. This insures the Bottle Jack will achieve maximum stroke.

d. Using the two (2) #10-32 Button Head Allen Screws, secure the

Retainer Cup to the Jack Ram. The screws may not completely

bottom out on the Retainer Cup, this is normal, as long as they are

secured tightly.

tep 3

Bending Die Assembly Installation

a) Locate the Tube Bender Frame Assembly (Item #8), one of the 1”

Die Pivot Shafts (Item #11), and two (2) of the 1” Rue Clips (Item #7).

b) Carefully locate the Bending Die Assembly/Jack Saddle Assembly

from tep #1 into the Tube Bender Frame Assembly as shown in

Figure 3.0.

c) Apply a small amount of lightweight oil to the 1” Die Pivot Shaft.

d) Align the pivot mounting hole of the Bending Die Assembly with the

mounting holes in the Tube Bender Frame. Insert the Die Pivot Shaft

into the mounting holes to fasten the Bending Die Assembly to the

Tube Bender Frame.

e) Insert the Rue Clips into both ends of the Die Pivot Shaft.

Figure 3.0

Bending Die

Assembly

Installation

Figure 2.0

8-Ton

Jack & Jack

Retainer Cup

Assembly

Figure 4.0

Follower Die

Installation

Jack Handle

Tube

Figure 8.0

Rear View of Finished Tubing Bender Assembly

Figure 7.0

Front View of Finished Tube Bender Assembly

Figure 5.0

8-Ton Bottle

Jack &

Retaining Cup