Speedwolf FS20E User manual

USER MANUAL

Optical Fiber Fusion Splicer

PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY BEFORE

OPERATING THE EQUIPMENT.

ADHERE TO ALL SAFETY INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

KEEP THIS MANUAL IN A SAFE PLACE.

FS20E

Shenzhen SPEEDWOLF Technology Co., Ltd.

About This Manual

Thank you for purchasing our company product. Please read this manual

carefully before using any of our company products. Always observe the

warnings and cautions appearing throughout this manual.

This manual contains the information necessary for proper operation and

maintenance of Optical Fiber Fusion Splicer, troubleshooting instructions as well

as information regarding obtaining services.

Optical Fiber Fusion Splicer is carefully assembled and undergoes a rigorous

mechanical, electrical, and optical inspection prior to shipment. For detailed

packing information, please refer to the packing list. Upon receiving the

instrument, please check for any obvious signs of physical damage that may

have occurred during shipment. Report any damage to the shipping agent .

immediately. Retain the original packing materials in case reshipment becomes

necessary.

If you have any question,Please contact us directly for help.

Website: www.speedwolf.net

Shenzhen SPEEDWOLF Technology co.,Ltd.

Email: after-sale@ speedwolf.net speedwolf@ speedwolf.net

Warning and Caution

A

The splicer has been designed for splicing Silica-based optical fibers for

telecommunications. Do not attempt to use this machine for other applications.

Our company gives much consideration and regard to personal injury. Misuse of

the machine may result in electric shock, fire and/or serious personal injury.

Follow all safety instructions

Read and understand all safety instructions

Stop using it when it malfunctions

Ask our service centers for repair as soon as possible.

Instruction Manual

Read this instruction manual carefully before operating this machine. Store this

instruction manual in a safe place

Notices

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval or translation into a foreign language)

without prior agreement and written consent from our company as governed by

international copyright laws.

Warranty

The material contained in this document is subject to change without notice.

Our company makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Our company shall not be liable for errors

contained herein or for incidental or consequential damages in connection with

furnishing, performance, or use of this material.

The battery is a consumable part and is not subject to the warranty.

ISO9001 Certification

The product exactly conforms to ISO9001 International Quality System

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

Safety Instructions

During each stage of operation of this instrument, please always observe the

following safety instructions. Not taking any safety precautions or following the

instructions will violate the safety standards of design, manufacturing and

application of these instruments. In no case will our company bear the

responsibilities for consequences incurred by violation of the following

instructions.

General

This product is a Safety Class 3 instrument. The protective features of this

product may be impaired if it is used in a manner not specified in the operation

instrument.

Environmental Conditions

It is designed to operate at a maximum relative humidity of 95% and at altitudes

of up to 5000 meters. For more details, please refer to the specifications tables.

Before Applying Power

Verify that the product is set to match the available line voltage, the correct fuse

is installed, and all safety precautions are taken. Note the instrument’s external

markings described under Symbols.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Do Not Remove the Instrument Cover

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made only by qualified service

personnel.

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

Safety Terms Used in This Manual

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personnel injury. Do

not proceed beyond a WARNING sign until the indicated

conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an

operating procedure, or the like, which, if not correctly

performed or adhered to, could result in damage to or

destruction of part or the entire product. Do not precede

beyond a CAUTION sign until the indicated conditions are

fully understood and met.

The NOTE sign information that may be beneficial during the

use and maintenance of the instrument.

The splicer has been designed for splicing Silica-based optical fibers for

telecommunications. Do not attempt to use this machine for other applications.

Our company gives much consideration and regard to personal injury. Misuse of

the machine may result in electric shock, fire and/or serious personal injury.

a) Follow all safety instructions.

b) Stop using it when it malfunctions and ask our service centers for repair

as soon as possible.

c) Read this instruction manual carefully before operating this machine.

Disconnect the AC power cord from the AC adapter inlet or the wall socket

(outlet) immediately if user observes the following or if the splicer receives the

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

following faults:

a) Fumes, bad smell, noise, or over-heat occurs.

b) Liquid or foreign matter falls into cabinet.

c) Splicer is damaged or dropped.

If this occurs, ask our service center for repair. Leaving the splicer in a damaged

state may cause equipment failure, electric shock or fire and may result in

personal injury, death or fire.

Use only the AC adapter / battery charger designed for this splicer. Using an

improper AC power source may cause fuming, electric shock or equipment

damage and may result in personal injury, death or fire.

Do not disassemble or modify the splicer, AC adapter or battery. In particular, do

not remove or bypass any electrical or mechanical device (e.g. a fuse or safety

switch) incorporated into the design and manufacturing of this equipment.

Modification could cause damage that may result in personal injury, death,

electric shock or fire.

Never operate the splicer in an environment where flammable liquids or vapors

exist. Risk of dangerous fire or explosion could result from the splicer’s

electrical arc in such an environment.

Do not use compressed gas or canned air to clean the splicer. They may contain

flammable materials that could ignite during the electrical discharge.

Do not touch the electrodes when the splicer is on and power is supplied to the

unit. The electrodes generate high voltage and high temperatures that may cause

a severe shock or burn.

NOTE: Arc discharge stops when wind protector is opened.

Turn the splicer off and disconnect the AC power cord before replacing

electrodes.

Safety glasses should always be worn during fiber preparation and splicing

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

operation. Fiber fragments can be extremely dangerous if it comes into contact

with the eye, skin, or is ingested.

Use only proper power source.

a) Check theAC power source before use: Proper AC power source is

AC100-240V, 50-60Hz. Proper DC power source is DC10-12V.

Improper AC or DC power source may cause fuming, electric shock or

equipment damage and may result in personal injury, death or fire;

b) AC generators commonly produce abnormally high AC output voltage

or irregular frequencies. Measure the output AC voltage with a circuit

tester before connecting the AC power cord. Such abnormally high

voltage or frequency from a generator may cause fuming, electric shock

or equipment damage and may result in personal injury, death or fire.

Make sure the generator is regularly checked and serviced.

Do not modify, abuse, heat or excessively pull on the supplied AC cord. The use

of a damaged cord may cause fuming, electric shock or equipment damage and

may result in personal injury, death or fire.

The splicer uses a three-prong (core) AC cord that contains an earthed ground

safety mechanism. The splicer MUST be grounded. Use only the supplied

three-prong (core) AC power cord. NEVER use a two-prong (core) power cord,

extension cable or plug.

Connect AC power cord properly to the splicer (inlet) and wall socket (outlet).

When inserting the AC plug, make sure there is no dust or dirt on the terminals.

Engage by pressing the female plug into the splicer (inlet) and the male plug into

the wall socket (outlet) until both plugs are fully seated. Incomplete engagement

may cause fuming, electric shock or equipment damage and may result in

personal injury, death or fire.

Do not short-circuit the terminals of AC adapter and optional battery. Excessive

electrical current may cause personal injury due to fumes, electric shock and

equipment damage.

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

Do not touch the splicer, AC power cord and AC plugs with wet hands. This

may result in electric shock.

Do not operate splicer near hot objects, in hot temperature environments, in

dusty/humid atmospheres or when water-condensation is present on the splicer.

This may result in electric shock, splicer malfunction or poor splicing

performance.

When using Li-ion battery, follow the instructions below. Failure to follow these

may result in explosion or personal injury.

a) Do not charge battery with other methods than instructed.

b) Do not discard battery into an incinerator or fire.

c) Do not charge or discharge battery near a flame or under direct sunlight.

d) Do not excessively shake or jar the battery.

e) If battery leaks of liquid residue, be careful handling the battery so the

liquid does not get in skin or eye contact. If it reaches contact,

immediately wash skin or eyes thoroughly and see the doctor. Dispose

of the battery and call the service center for replacement.

f) If charge did not complete in four hours or the "CHARGE" LED is

constantly on, immediately stop charging and call the service center for

repair.

Do not store splicer in any area where temperature and humidity are extremely

high. Possible equipment failure may result.

Do not touch protection sleeve or tube-heater during heating or immediately

after completion of heating. Their surfaces are very hot and touching these may

result in skin burn.

Do not place the splicer in an unstable or unbalanced position. The splicer may

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Warning and Caution

shift or lose balance, causing the unit to fall. Possible personal injury or

equipment damage may result.

The splicer is precision adjusted and aligned. Do not allow the unit to receive a

strong shock or impact. Possible equipment failure may result. Use supplied

carrying case for transportation and storage. The carrying case protects the

splicer from damage, moisture, vibration and shock during storage and

transportation.

Follow the below listed instructions for handling electrodes.

a) Use only specified electrodes.

b) Set the new electrodes in the correct position.

c) Replace the electrodes as a pair.

Failure to follow the above instructions may cause abnormal arc discharge. It can

result in equipment damage or degradation in splicing performance.

Do not use any chemical other than pure alcohol (99% or greater) to clean the

objective lens, V-groove, mirror, LCD monitor, etc., of the splicer. Otherwise

blurring, discoloration, damage or deterioration may result.

The splicer requires no lubrication. Oil or grease may degrade the splicing

performance and damage the splicer.

The equipment must be repaired or adjusted by a qualified technician or

engineer. Incorrect repair may cause fire or electric shock. Should any problems

arise, please contact your nearest sales agency.

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Table of Contents

Table of Contents

Description of Products....................................................................................................- 4 -

1. Components of Splicer.............................................................................................- 4 -

Our Splicer................................................................................................................- 4 -

Options ......................................................................................................................- 4 -

2. Other Necessary Items for Splicing Operation......................................................- 5 -

3. Description and Function of Splicer .......................................................................- 6 -

Front Side of the splicer.........................................................................................- 6 -

Back Side of the splicer..........................................................................................- 6 -

Top Side of the splicer............................................................................................- 7 -

Keypad of the splicer.............................................................................................- 8 -

Point of the Splice Procedure...........................................................................................- 9 -

1. To Get a Stable Low Splice Loss..............................................................................- 9 -

Daily Cleaning Before Splicing Operation.............................................................- 9 -

Select / Use the Suitable Splice Mode....................................................................- 10 -

Clean the Equipment before Every Splicing........................................................- 10 -

Splicing Procedure.................................................................................................. - 11 -

Heating ....................................................................................................................- 13 -

2. Power Supply..........................................................................................................- 13 -

Battery.....................................................................................................................- 13 -

Basic Operation..............................................................................................................- 14 -

1. About Power ...........................................................................................................- 14 -

Inserting Power Supply into Splicer.....................................................................- 14 -

Battery operation....................................................................................................- 14 -

2. Turning Splicer "ON"............................................................................................- 15 -

LCD BrightnessAdjustment .................................................................................- 15 -

3. Fiber Preparation...................................................................................................- 16 -

A. Placing Protection Sleeve over Fiber ....................................................................- 16 -

B. Stripping and Cleaning Fiber................................................................................- 17 -

Sheath Clamp..........................................................................................................- 17 -

C. Fiber Cleaving.........................................................................................................- 17 -

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Table of Contents

Fiber holder System................................................................................................- 18 -

4. Loading Fiber to Splicer........................................................................................- 19 -

Sheath Clamp..........................................................................................................- 19 -

5. Splicing Procedure..................................................................................................- 21 -

Splice loss increase: Cause and remedy................................................................- 23 -

6. Removing spliced fiber...........................................................................................- 25 -

7. Heating protection sleeve.......................................................................................- 25 -

Maintenance of Splicing Quality...................................................................................- 26 -

1. Cleaning and Checking before Splicing................................................................- 26 -

2. Periodical Checking and Cleaning........................................................................- 29 -

Menu Operation .............................................................................................................- 31 -

1. Splice Mode Menu..................................................................................................- 31 -

How to select the “Splice Mode” ...........................................................................- 32 -

Database..................................................................................................................- 33 -

2. Heater Mode............................................................................................................- 38 -

3. Splice Set .................................................................................................................- 40 -

4. Data Save.................................................................................................................- 41 -

5. Set Menu..................................................................................................................- 41 -

6. Maintenance Menu.................................................................................................- 46 -

Common Problems and Troubleshooting.....................................................................- 48 -

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Introduction

- 1 -

Introduction

Optical Fiber Fusion Splicer is for fiber fusion with low splice loss and ensures

splice long-time stabilization. Splice loss depends on certain conditions like fiber

preparation, splicing parameters, fiber condition, variation after splicing and etc.

The standard principle of splicing is not complicated, firstly the splicer finds the

fiber core and aligns it correctly, and then it splices the fiber with the arc

generated by the electrodes. There are two major technologies to ensure

high-quality splice, LID (Local Injection and Detection) and CDS (Core

Detection System), which is also widely known as PAS (Profile Alignment

System).

The splicer with PAS technology is designed for splicing many types of optical

fibers. It is small in size and light in weight, making it suitable for any operating

environment. It is easy to operate and it splices fast while maintaining low splice

loss. In order to achieve the splicer's full capabilities, read the following

important information.

Splice mod

Use [SM] splice mode for standard SM fiber (ITU-TG.652) splicing. It

completes in 9 seconds and is the quickest mode for SM fiber splicing.

Use [AUTO] splice mode if fiber type is not identified. Splice takes longer but it

covers most conventional fibers splicing for following reasons.

a) [AUTO] mode first identifies fiber type by analyzing fiber profile, and then

unique splicing condition is chosen for the type of fiber. The types of fibers

covered by [AUTO] are all the conventional fibers, such as SMF (G652),

NZDSF (G655), MMF (G651), etc. The [AUTO] modes takes longer for the

above processes but is recommended in fiber type is not sure.

b) [AUTO] mode comes with automatic arc calibration function, which

observes the splicing process and feedback adequate heat power information

to the next splice (See next chapter for detail).

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Introduction

- 2 -

Automatic arc calibration function

This function calibrates the arc power at every splice. When the automatic arc

calibration function is enabled, performing the [Arc calibration] function before

a splice operation is not necessary. The automatic arc calibration function works

in AUTO modes only. It doesn’t work in the standard splice modes. When using

those modes, performing [Arc calibration] before splicing is strongly

recommended.

Environment Performance

To operate by the bad environment, the splicer has improved the performance.

Dropping

Water-Proof

Dust

Our company does not guarantee that the splicer will not be damaged under

these conditions.

Unique function

a) Operating display can be changed

The splicer can be operated with monitor in front or at back. The fiber/display

image on the monitor can be changed.

b) Sheathe clamping method

Either conventional sheathe clamping system or “fiber holder system (optional)”

can be selected.

c) Carrying Case with worktable.

The top cover of caring case can be used as a work table.

d) Upgrade the software

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Introduction

- 3 -

The splicer’s software can be upgraded via internet by using “Software

Download Tool” software. Refer to the instruction manual of “Software

Download Tool.

The splicer is equipped with a LCD monitor, manufactured in a high

quality-controlled factory environment. However, some black dots may

appear, or red/blue/green dots may remain on the screen. The screen

brightness may not appear uniformly depending on viewing angle. Note

that these symptoms are not defects, but are nature of LCD.

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Description of Products

- 4 -

Description of Products

1. Components of Splicer

Our Splicer

Options

1) 4-in-1 Holder

2) Fiber Holder (Option)

Fiber Holder [FH-250] is for the 250um coating fiber.

Fiber Holder [FH-900] is for the 900um coating fiber.

Fiber Holder [FH-IN] is for the bow-type coating fiber.

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Description of Products

- 5 -

3) SOC Holder (Option)

Fiber Holder [FH-SC/FC] is for the SC/FC connecter.

2. Other Necessary Items for Splicing Operation

Fiber Cleaver [OFC-15]

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Description of Products

- 6 -

3. Description and Function of Splicer

Front Side of the splicer

Back Side of the splicer

USB port InputOutput

Wind Protector

LED

Power Unit Dock

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Description of Products

- 7 -

Top Side of the splicer

Electrode Cover

V-grooves

Electrode

Fiber Clapms

Ocular

Tube Heater

Wind Protector Mirror

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Description of Products

- 8 -

Keypad of the splicer

Left keypad Right keypad

Screen keypad

Shenzhen SPEEDWOLF Technology Co., Ltd.

Email: speedwolf@ speedwolf.net

Table of contents

Other Speedwolf Welding System manuals

Popular Welding System manuals by other brands

Migatronic

Migatronic automation CoWelder UR10E PI350 AC/DC Instruction handbook

MANDREL welder

MANDREL welder RSX01 instruction manual

Razorweld

Razorweld KUMJRRW110DC operating manual

ESAB

ESAB EPP-200 instruction manual

iWeld

iWeld MIG 5200 DOUBLE PULSE user manual

Stel

Stel MAX dp 171C Instructions for use and maintenance

Lincoln Electric

Lincoln Electric RANGER 225 GXT Service manual

ESAB

ESAB Multimaster 300 instruction manual

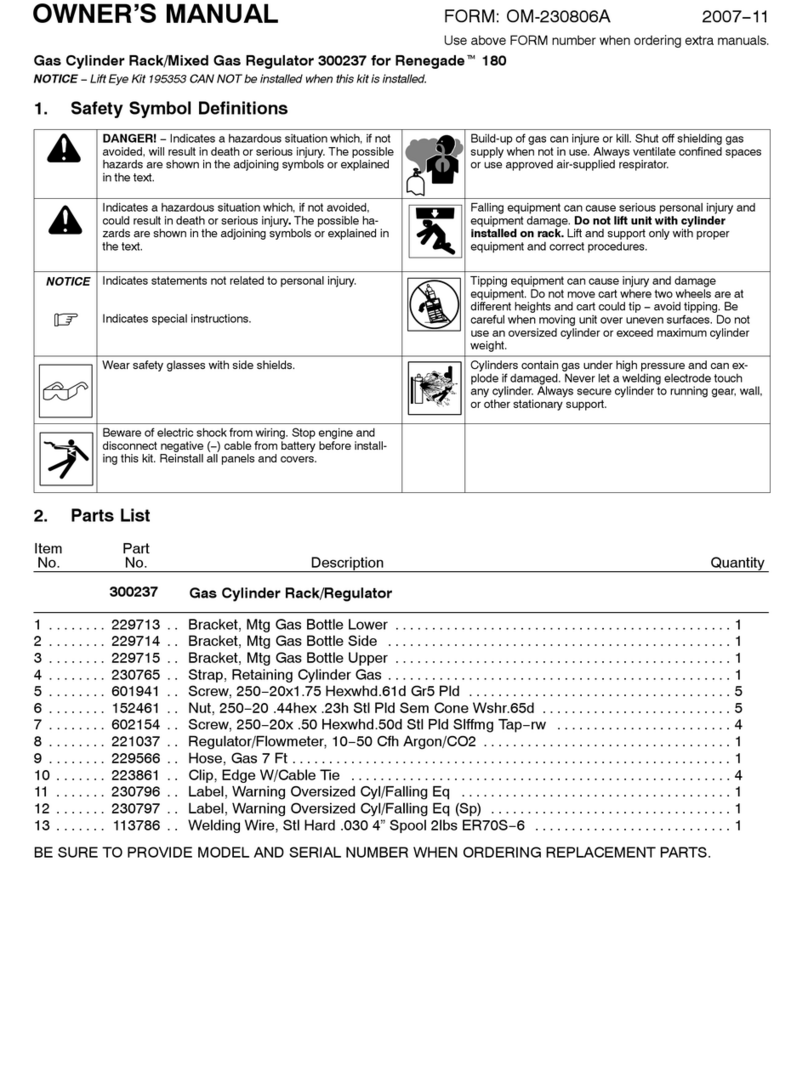

Miller Electric

Miller Electric Gas Cylinder Rack owner's manual

Migatronic

Migatronic FOCUS TIG 161 DC PFC user guide

Migatronic

Migatronic MTE DIALOG instruction manual

Kemppi

Kemppi KEMPOWELD 3200 Operation instructions