Speeflo S-3 User manual

P/N 313-2440B © 2004 Titan Tool Inc. All rights reserved. 1

Owner’s Manual

For professional use only

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to an

area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard which may cause

serious injury or loss of life. Important safety information

will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

HAZARD: Injection injury — A high pressure fluid stream

produced by this equipment can pierce the skin

and underlying tissues, leading to serious injury

and possible amputation. See a physician

immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician immediately.

The maximum operating range of the gun is 3900 PSI / 27

MPa fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

•NEVER put hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut pump off, and release all

pressure before servicing, cleaning tip or guard, changing

tip, or leaving unattended. Pressure will not be released by

turning off the motor. The PRIME/SPRAY valve or pressure

bleed valve must be turned to their appropriate positions to

relieve system pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in the sprayer’s Owner’s Manual.

• ALWAYS keep tip guard in place while spraying. The tip guard

provides some protection but is mainly a warning device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect the

hose before each use.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

• All accessories must be rated at or above the maximum

operating pressure range of the airless sprayer. This

includes spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

WARNING

NOTE: Notes give important information which should

be given special attention.

CAUTION

WARNING

HAZARD: EXPLOSION AND FIRE - Solvent and paint fumes

can explode or ignite. Severe injury and/or

property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to keep

the air within the spray area free from accumulation of

flammable vapors.

• Avoid all ignition sources such as static electricity sparks,

electrical appliances, flames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working order.

• Place pump at least 25 feet (7.6 m) from the spray object in

a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area

must be extremely well ventilated. The pump contains

arcing parts that emit sparks and can ignite vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Use only conductive or grounded high-pressure fluid hose.

Gun must be grounded through hose connections.

• Power cord must be connected to a grounded circuit.

• Always flush unit into separate metal container, at low pump

pressure, with spray tip removed. Hold gun firmly against

side of container to ground container and prevent static

sparks.

• Follow material and solvent manufacturer's warnings and

instructions.

• Use extreme caution when using materials with a flashpoint

below 70° F (21° C). Flashpoint is the temperature at which

a fluid can produce enough vapors to ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose spray area. Do not use plastic drop cloths when

spraying flammable materials.

• Use lowest possible pressure to flush equipment.

GAS ENGINE (WHERE APPLICABLE)

Always place pump outside of structure in fresh air. Keep all

solvents away from engine exhaust. Never fill fuel tank with a

running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump to a grounded object.

Refer to engine owner’s manual for complete safety information.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS - Will cause severe injury or property

damage. Some pumps and accessories contain

aluminum and cannot be used with halogenated

hydrocarbon solvents. Follow the prevention

section if your pump or accessories are not

compatible with halogenated hydrocarbon

solvents. The S-3 Airless Spray Gun is

compatible with halogenated hydrocarbon

solvents.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

bleach, mildewcide, methylene chloride and 1,1,1 -

trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

S-3

Airless Spray Gun Model Number 550-250

3900 PSI Maximum Operating Pressure/Stainless Steel Fluid Passages

2 P/N 313-2440B © 2004 © Titan Tool Inc. All rights reserved.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials can be harmful if

inhaled or come in contact with body. Vapors can

cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide

the necessary protection.

• Wear protective eyewear.

•Wear protective clothing as required by coating

manufacturer.

HAZARD: GENERAL - Can cause severe injury or property

damage.

PREVENTION:

• Read all instructions and safety precautions before operating

equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the

General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specifications and safety devices of the pump

manufacturer.

•Before each use, check all hoses for cuts, leaks, abrasion or

bulging of cover. Check for damage or movement of

couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a

grounded high-pressure hose.

•All hoses, swivels, guns, and accessories must be pressure

rated at or above the maximum operating pressure range of

the airless sprayer.

•Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Always unplug cord from the outlet before working on

equipment.

Specifications

Maximum operating pressure.......3900 PSI (27 MPa)

Material inlet thread size...............NPSM 1/4”

Diffuser thread size.......................7/8 - 14 UNF-2A

Wetted parts material ...................High-grade stainless steel,

urethane, polyethylene, nylon,

hard metal

Operating temperature range .......40°F to 104°F (5°C to 40°C)

Maximum material temperature....109°F (43°C)

Maximum sound output ................81 dB(A)*

Weight...........................................1.3 lbs. (590 g)

*Measurement location: 1.5’ away from the coating surface, 1.5’

behind the spray gun, spray pressure 1700 PSI, tip size 0.021”

Using the Gun Trigger Lock

Always engage the gun’s trigger lock when the gun is not in use.

1. To lock the trigger, rotate the trigger lock forward until it

stops.

2. To unlock the trigger, rotate the trigger lock backward until it

is vertical.

Trigger locked

(gun will not spray)

Trigger unlocked

(gun will spray)

Setup

Never attempt to assemble, change, or clean the gun, tip, or

tip guard without first relieving pressure from the spray

system. Follow the “Pressure Relief Procedure” in the

sprayer’s Owner’s Manual.

Always use a tip safety guard for added protection against

injection. Beware that the guard alone will not prevent

injection. Never cut off tip guard! Always engage gun

trigger lock when the gun is not in use. Before servicing

equipment, consult Owner’s Manuals and follow all

warnings.

1. Set up the sprayer. Refer to the instructions in the sprayer’s

Owner’s Manual.

2. Attach a grounded, airless spray hose to the material inlet on

the gun. Using two wrenches (one on the gun and one on

the hose), tighten securely.

3. With the tip and tip guard off the

gun, start the sprayer. Flush and

prepare the spray system

according to the sprayer’s

Owner’s Manual. Inspect the

spray system to make sure that all

fittings are secure and that there

are no leaks.

4. Perform the “Pressure Relief

Procedure” described in the

sprayer’s Owner’s Manual.

5. Using the arrow head on the tip

handle, insert the tip seal and tip

seal retainer into the back of the tip guard. Press in for final

adjustment.

6. Insert the tip into the slot on the tip guard.

7. Thread the tip guard onto the gun. Position the tip guard in

the desired spraying position and tighten securely.

Operation

1. Make sure the arrow on the tip handle is pointing in the

forward direction for spraying.

2. Start the sprayer. Refer to the instructions in the sprayer’s

Owner’s Manual.

3. Adjust the fluid pressure on the sprayer until the spray is

completely atomized. Always spray at the lowest pressure

necessary to get the desired results.

4. To clear a clogged tip:

a. Rotate the tip 180° so that the arrow on the tip handle is

pointing opposite the spray direction.

b. Trigger the gun once so that the pressure can blow the

clog out.

Never pull the trigger more than once at time with the tip in

the reverse position.

c. Continue this procedure until the tip is clear of the clog.

CAUTION

NOTE: The spray tip determines the size of spray

pattern and coverage. When more coverage is

needed, use a larger tip instead of increasing

fluid pressure.

NOTE: The arrow on the tip handle should be pointing

in the forward direction for spraying.

Tip Seal

Retainer

Tip Seal

Tip

Tip

Handle

Tip

Guard

WARNING

WARNING

Changing a Tip

Tips can be removed and replaced easily without disassembling

the gun.

Never attempt to change or clean the tip or tip guard without

first performing the “Pressure Relief Procedure.”

1. Perform the “Pressure Relief Procedure” described in the

sprayer’s Owner’s Manual.

2. Remove the tip from the slot on the tip guard.

3. Insert the new tip into the slot on the tip guard. The arrow

on the tip handle should be pointing in the forward direction

for spraying.

Removing the Seal and Tip Seal

1. Remove the tip and tip guard from the spray gun.

2. Remove the seal and tip seal from the back of the tip guard.

Identifying Tip Sizes

To identify tip sizes, use the following formula. A “517” tip size

will be used in this example.

The first digit multiplied by two represents the size of the spray

pattern when spraying 12” away from the work surface:

5 x 2 = 10” spray pattern

The second two digits represent the diameter of the orifice on the

tip: 17 = .017” orifice

Cleanup

Maintaining a clean gun is important to ensure trouble-free

operation. Flush the gun after each use and store in a dry

location. Do not leave the gun or any of its parts in water or

solvents.

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting flushed solvents in a one gallon metal container,

place it into an empty five gallon container, then flush

solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

The sprayer, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to cake,

seriously affecting the performance of the unit.

Always spray at minimum pressure with the

tip and tip guard removed when using

mineral spirits or any other solvent to clean

the sprayer, hose, or gun. Static electricity

buildup may result in a fire or explosion in

the presence of flammable vapors. Hold the

gun firmly against a metal container while flushing.

WARNING

CAUTION

WARNING

NOTE: Worn spray tips will adversely affect the spray

pattern and result in reduced production, poor

finish, and wasted material. Replace worn tips

immediately.

WARNING

Maintenance

Follow all safety precautions as described in the Safety

Precautions section of this manual before proceeding.

Replacing/Servicing the Packing Seal

Assembly

If your spray gun leaks or spits at the tip when you release the

trigger, the needle or seat is worn, damaged, or dirty and must

be replaced or cleaned.

Never attempt to perform maintenance on the spray gun

without first performing the “Pressure Relief Procedure”

from the sprayer’s Owner’s Manual.

1. Perform the “Pressure Relief Procedure” and disconnect the

fluid hose from the gun.

2. Remove the end cap and the packing spring from the rear of

the gun head.

3. Using a 3/8” socket, remove the packing seal assembly from

the rear of the gun head.

4. Soak the removed parts in the appropriate solvent and wipe

clean.

5. Inspect the parts for wear or damage and use new parts

during reassembly of the gun, when necessary.

6. Make sure the two retractor pins inside the gun head are still

in the correct position.

7. Insert the packing seal assembly into the rear of the gun

head and thread it by hand until it stops.

8. Using a 3/8” socket, tighten the packing seal assembly.

Torque to 5 Nm (3.7 ft./lbs.).

9. Grease both ends of the packing spring and place it over the

packing seal assembly in the gun head.

10. Place the end cap over the packing spring so that the pilot

inside the end cap seats inside the packing spring.

11. Push the end cap toward the gun head while threading it

into the gun head. Using a wrench, tighten the end cap

securely.

12. Perform the “Adjusting the Packing Seal Assembly”

procedure described below.

Adjusting the Packing Seal Assembly

Proper adjustment of the packing seal assembly is essential

to ensure positive shut-off when the trigger is released.

1. Insert an 1/8” hex wrench through the hole in the center of

the end cap until it seats inside the packing seal adjustment

screw.

2. Turn the packing seal adjustment screw clockwise until the

ball on the packing seal assembly can be felt seating into

position. Then, turn the screw 1/4 turn more for proper

tension.

WARNING

NOTE: Lubricate all packings and moving parts before

reassembly with a lithium-based grease.

WARNING

NOTE: Refer to the Parts List section in this manual

for part identification.

WARNING

P/N 313-2440B © 2004 Titan Tool Inc. All rights reserved. 3

4 P/N 313-2440B © 2004 © Titan Tool Inc. All rights reserved.

Warranty

Titan Tool, Inc., (“Titan”) warrants that at the time of delivery to the original purchaser for use (“End User”), the equipment covered by this warranty is free from defects

in material and workmanship. With the exception of any special, limited, or extended warranty published by Titan, Titan’s obligation under this warranty is limited to

replacing or repairing without charge those parts which, to Titan’s reasonable satisfaction, are shown to be defective within twelve (12) months after sale to the End

User. This warranty applies only when the unit is installed and operated in accordance with the recommendations and instructions of Titan.

This warranty does not apply in the case of damage or wear caused by abrasion, corrosion or misuse, negligence, accident, faulty installation, substitution of non-

Titan component parts, or tampering with the unit in a manner to impair normal operation.

Defective parts are to be returned to an authorized Titan sales/service outlet. All transportation charges, including return to the factory, if necessary, are to be borne

and prepaid by the End User. Repaired or replaced equipment will be returned to the End User transportation prepaid.

THERE IS NO OTHER EXPRESS WARRANTY. TITAN HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES INCLUDING, BUT NOT LIMITED TO, THOSE

OF MERCHANTABILITY AND FITNESS FOR APARTICULAR PURPOSE, TO THE EXTENT PERMITTED BY LAW. THE DURATION OF ANY IMPLIED

WARRANTIES WHICH CANNOT BE DISCLAIMED IS LIMITED TO THE TIME PERIOD SPECIFIED IN THE EXPRESS WARRANTY. IN NO CASE SHALL TITAN

LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES UNDER ANY AND

ALL WARRANTIES IS EXCLUDED TO THE EXTENT PERMITTED BY LAW.

TITAN MAKES NO WARRANTY AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY TITAN. THOSE ITEMS SOLD, BUT NOT

MANUFACTURED BY TITAN (SUCH AS GAS ENGINES, SWITCHES, HOSES, ETC.) ARE SUBJECT TO THE WARRANTY, IF ANY, OF THEIR MANUFACTURER.

TITAN WILL PROVIDE THE PURCHASER WITH REASONABLE ASSISTANCE IN MAKING ANY CLAIM FOR BREACH OF THESE WARRANTIES.

United States Sales & Service

1-800-526-5362

Fax 1-800-528-4826

107 Bauer Drive

Oakland, NJ 07436

www.titantool.com

Canadian Branch

1-800-565-8665

Fax 1-905-856-8496

200 Trowers Road, Unit 7B

Woodbridge, Ontario L4L 5Z8

International

1-201-337-1240

Fax 1-201-405-7449

107 Bauer Drive

Oakland, NJ 07436 USA

Replacing/Removing the Filter

1. Pull the bottom of the trigger guard forward so that it comes

loose from the handle assembly.

2. Loosen and remove the handle assembly from the gun

head.

3. Pull the old filter out of the gun head.

4. Slide the new filter, tapered end first, into the gun head.

5. Make sure all the parts are clean and the handle seal is in

position inside the gun head.

6. Thread the handle assembly into the gun head until secure.

7. Snap the trigger guard back onto the handle assembly.

Filter Chart

Part

Number

Application Filter

Type

Color of

Filter

Body

550-274 Synthetic resin,

enamels, clean

varnishes, stains

azures

Extrafine red

550-273 Base coat enamels,

primer enamels,

fillers, marking paints,

textured enamels

Fine yellow

550-271 Emulsions,

latex paints,

acrylic paints

Medium white

550-272 Filler paints,

large area surfaces

Coarse green

Parts List

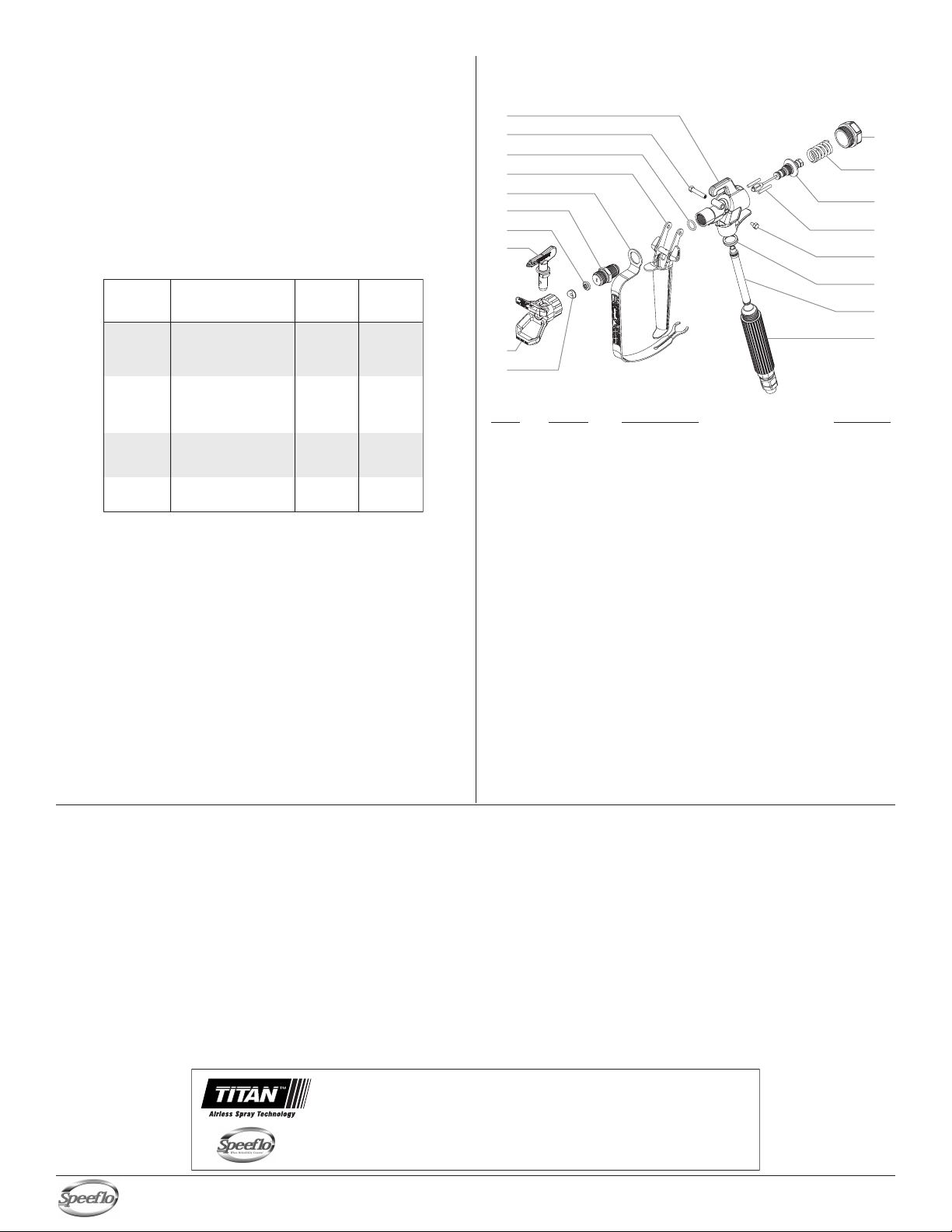

Item Part # Description Quantity

1 550-253 Gun head...................................................1

2 550-254 Trigger screw, long ....................................1

3550-255 Diffuser o-ring ............................................1

4 550-256 Trigger assembly, 4-finger gun..................1

5 580-532 Trigger guard .............................................1

6 550-257 Diffuser, 7/8” (includes item 3)

7 651-020 Tip seal ......................................................1

8 661-517 Tip assembly (see accessory

catalog for additional sizes).......................1

9 661-012 Tip guard, 7/8”

10 651-040 Tip seal retainer.........................................1

11 550-258 End cap......................................................1

12 550-259 Packing spring...........................................1

13 550-264 Packing seal assembly..............................1

14 550-265 Retractor pin..............................................2

15 580-513 Trigger screw, short ...................................1

16 560-038 Handle seal................................................1

17 550-271 Filter, medium............................................1

18 550-266 Handle/swivel assembly, 1/4 NPS.............1

19 550-251 S-3 label (not shown).................................1

550-275 Gun repair kit, 7/8” diffuser

(includes items 3, 6, and 13)

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

11

This manual suits for next models

1

Table of contents

Other Speeflo Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

BUFFALO TURBINE

BUFFALO TURBINE BT-CS4 Original instructions and parts manual

Sagola

Sagola 450A instruction manual

Norac

Norac Rogator 1286C installation manual

Defort

Defort DSG-400 user manual

KIRKLAND

KIRKLAND Orvin Mounted Single Sprayer Use and maintenance manual

Graco

Graco FinishPro II 395 PC Operation, parts