Spellman SPX Series User manual

118176-001 REV. A

Copyright 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

CAUTION: THIS EQUIPMENT PRODUCES

X-RAYS WHEN ENERGIZED!

DO NOT OPERATE THIS EQUIPMENT WITHOUT

FORMAL HARDWARE TRAINING FROM

SPELLMAN HIGH VOLTAGE ELECTRONICS.

ASNT LEVEL 3 RADIOGRAPHIC CERTIFICATION

IS HIGHLY RECOMMENDED.

WWW.SPELLMANHV.COM

SPX X-ray

Industrial Imaging System

Page 1 of 44 SPX Series System Manual

118173-001 Rev. D

TABLE OF CONTENTS

Chapter 1:..........................................................3

Introduction and General Information............3

Introduction...............................................3

SYSTEM OVERVIEW...............................3

The Control Unit.......................................4

The Tube Head..........................................4

The Cooling Unit (liquid cooled units

only).............................................................4

Legend –SPX X-ray System.................5

Manual Outline..........................................6

Safety Summary.......................................7

Radiation Hazard......................................8

Lethal Voltages.........................................8

Badges........................................................8

Radiation Protection ...............................8

Radiation Monitoring...............................8

Warm-Up Procedures..............................8

Operation ...................................................8

Cooling Unit Operation...........................8

Care in Handling.......................................8

Chapter 2:..........................................................9

Preparation for Use and Shipment...........9

UNPACKING INSTRUCTIONS................9

Reshipment Guidelines..........................9

Transporting the Unit........................... 10

EQUIPMENT CHECKLISTS................. 11

Checklist –Tube Head......................... 11

Checklist - Standard Equipment....... 11

Checklist - Optional Equipment........ 12

WARNINGS LABELS & CONTROL

NUMBERS............................................... 12

Specifications - General System ...... 13

Specifications - General Tube Head 14

Specifications - Optional Tube Head14

Specifications - Control Unit.............. 15

Specifications - Cooling Unit............. 16

Chapter 3:........................................................ 17

Installing the SPX-X-ray System........... 17

PRE-OPERATIONAL................................. 17

CHECKS & INSPECTION......................... 17

SYSTEM SET UP PROCEDURES...... 18

System Interconnections - Liquid

Cooled...................................................... 18

System Interconnections - Air Cooled

................................................................... 19

External Interlock Connections......... 20

Chapter 4:........................................................ 23

SPX Series Controls and Indicators .... 23

SPX Series Control Connections...... 24

Chapter 5:........................................................ 29

SPX Series Pre-operation....................... 29

Pre-Operational Safety Precautions 29

X-Ray Tube Warm Up........................... 29

Chapter 6:........................................................ 32

SPX Series System Operation............... 32

FAULT MESSAGES............................... 33

GUI Display.............................................. 34

Fault Descriptions................................. 35

Chapter 7:........................................................ 36

SPX Series Routine Care and

Maintenance............................................... 36

Introduction............................................ 36

Inspection Checklist............................. 36

Care and Maintenance......................... 37

Control Unit Maintenance................... 37

SPX X-ray

Industrial Imaging System

Page 2 of 44 SPX Series System Manual

118173-001 Rev. D

Tube Head Maintenance ..................... 37

Re-Pressurizing the Tube Head........ 38

Legend –Tube Head Pressurization

Set Up

...................................................... 39

Temperature Compensation.............. 39

Re-Filling the Tube Head .................... 40

COOLING UNIT UPKEEP..................... 43

Mixing & Adding Coolant Solution... 43

Cleaning - Cooling Unit Air Filter...... 43

Cleaning - Coolant Filter..................... 44

SPX X-ray

Industrial Imaging System

Page 3 of 44 SPX Series System Manual

118173-001 Rev. D

Chapter 1:

Introduction and General Information

Introduction

This manual describes the SPX series portable

Industrial X-ray Unit and explains the procedures

To properly set up, inspect operate and maintain

Intended Use

The SPX series is designed to meet the needs of the

commercial NDT user. The system is intended for, but

not limited to, the inspection of

materials for:

Defects

Inclusions

Cracks

Corrosion

Porosity

SYSTEM OVERVIEW

The SPX series can generate x-ray potential up to 160,

200 and 300 kilovolts (kV) and tube current up to 10

milliampers (mA). The maximum allowable dissipation

is 800 watts for the SPX-160 and 900W for the SPX-

200 and SPX-300. Maximum tube current is limited

automatically by the Control unit to 10mA, or to a value

that does not cause dissipation greater than rated

power (watts) at a set kV level.

The system offers 100% duty cycle and consists of the

following assemblies:

The Control Unit

The Tube Head

The Cooling Unit, liquid cooled units only)

The Electric Cooling Fan (air cooled units only)

These assemblies are described in detail next.

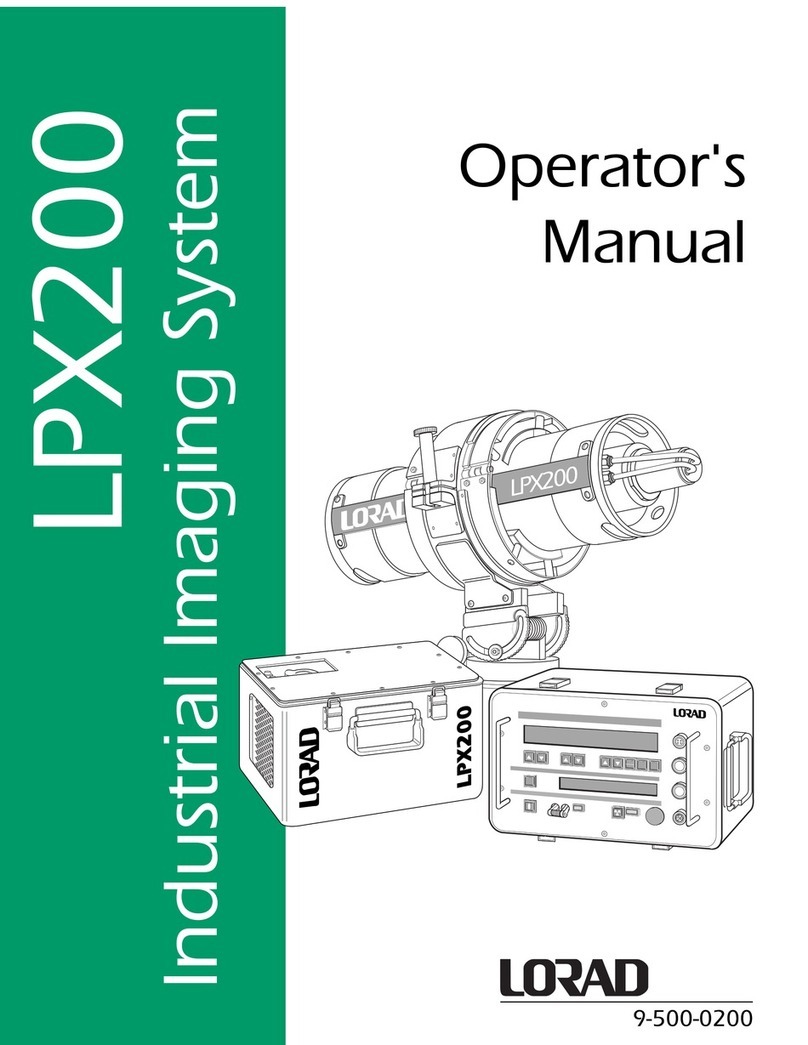

The SPX X-ray System

Figure 1-1

SPX X-ray

Industrial Imaging System

Page 4 of 44 SPX Series System Manual

118173-001 Rev. D

The Control Unit

The radiographer uses the Control Unit to set the

radiographic exposure parameters, and to

activate/deactivate x-ray emissions from the Tube

Head. One hundred feet of cable is supplied with the

system, which enables the Control Unit and operator to

maintain a safe distance from the X-ray Tube Head

during use.

The digital-based, micro-processor-regulated Control

Unit houses all the system pushbutton operating

controls, and exposure factor Vacuum Fluorescent

Display (for display of exposure factors, a Message

Vacuum Fluorescent Screen (for display of operating

mode and system messages), and the circuitry required

to provide power to the Tube Head and Cooling Unit.

The Control Unit is enclosed in a metal chassis and a

handle is provided as a means of transporting it.

The Tube Head

The Tube Head is a cylindrical aluminum shell

assembly housing the x-ray tube, the high voltage

power supply and the filament supply. It is insulated

with sulfur hexafluoride gas that is pressurized to 50 psi

@ 70˚F. Power to operate the x-ray tube is supplied

through a shielded cable that connects the Tube Head

to the Control Unit. The x-ray tube is end-grounded,

with an exposed anode that contains a beryllium

window approximately 2 inches from the anode end.

Built-in carrying handles are at each end of the Tube

Head.

There are two Tube Head models available:

Liquid-cooled

Air-cooled

The liquid cooled Tube Head uses a separate Cooling

Unit to dissipate anode heat. These models have a

length of twin hoses attaching the Tube Head to the

Cooling Unit. Air-cooled models have an electric cooling

fan mounted at the end of Tube head. The fan is

powered by an inter-connecting cable from the Control

Unit.

The Cooling Unit (liquid cooled units only)

The Cooling Unit dissipates heat generated at the

anode of the x-ray tube. Liquid coolant from a self-

contained reservoir is pumped through one side of a

twin hose assembly into the Tube Head. Coolant flows

through a manifold in the Tube Head into the anode

and returned to the Cooling Unit through the second

half of the twin assembly.

Once in the Cooling Unit, coolant passes through a flow

switch that is electrically interlocked with the Control

Unit, and then through a filter to screen out

contaminants. The coolant exits the filter and flows

through a forced air radiator where the conducted heat

is dissipated and then back into the reservoir.

An electric motor-driven fan and pump assembly

circulates coolant and creates airflow through the

radiator. Power is supplied via an interconnecting cable

from the Control Unit. When properly connected to the

system, the Cooling Unit is automatically activated by a

switch circuit within the Control Unit.

SPX X-ray

Industrial Imaging System

Page 5 of 44 SPX Series System Manual

118173-001 Rev. D

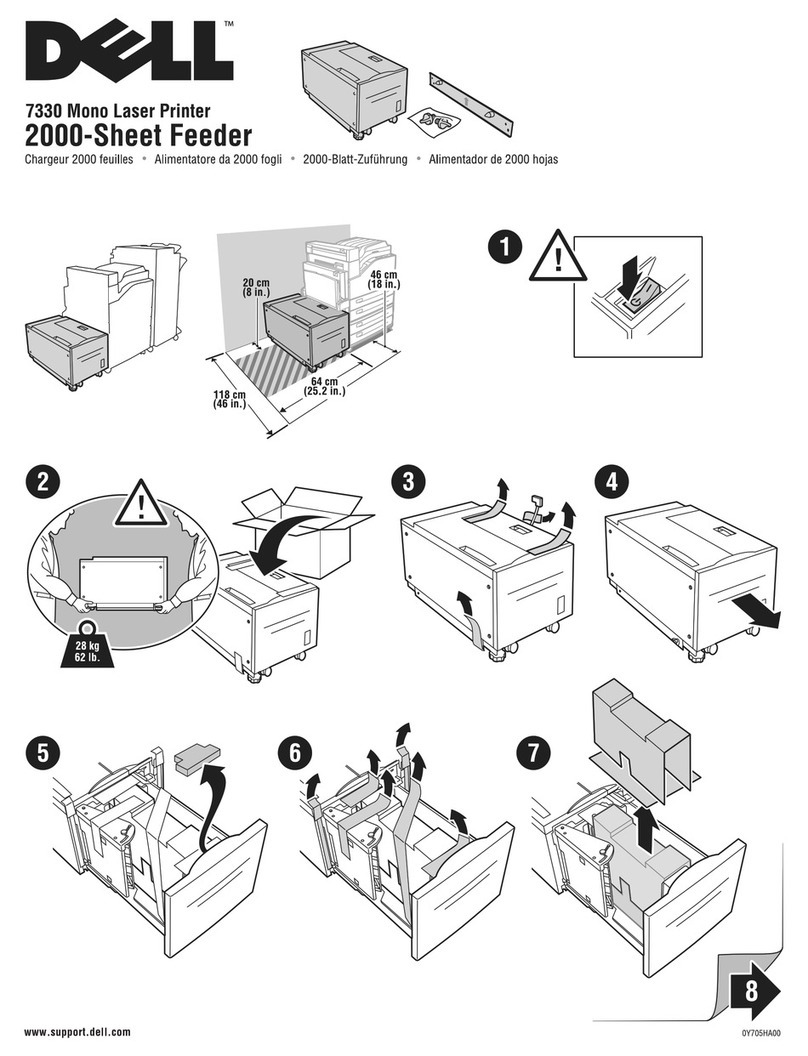

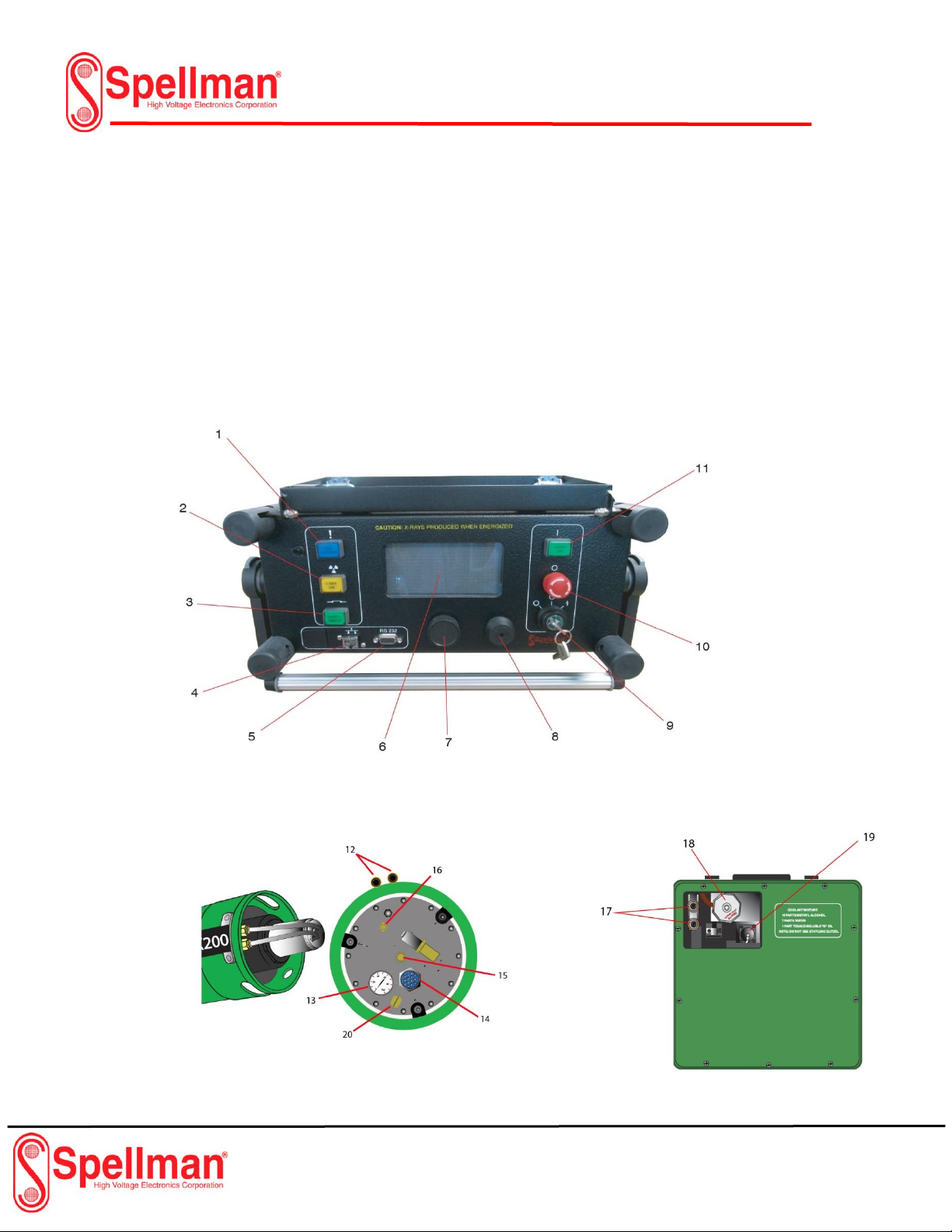

Legend –SPX X-ray System

Use the following legend as a reference for parts

identification.

1. Pre-Warning Indicator

2. X-ray Indicator

3. Interlock Indicator

4. Ethernet Port

5. RS-232 Port

6. VFD Display

7. Rotary Dial

8. Buzzer

9. Key Control

10. E-Stop

11. X-ray On Button

12. Tube Head Coolant Hose Fittings

13. Tube Head Gas Pressure Gage

14. Tube Head Cable Connector

15. Tube Head Pressure Relief Valve

16. Tube Head Gas Fill Valve

17. Cooling Unit Coolant Hose Fittings

18. Cooling Unit Reservoir Cap

19. Cooling Power Connector

20. Nut Safety

Cooling Unit

Control Unit

Tube Head Assembly

Figure 1-2

Figure 1-3

Figure 1-4

SPX X-ray

Industrial Imaging System

Page 6 of 44 SPX Series System Manual

118173-001 Rev. D

Manual Outline

This manual provides qualified radiographers and

technicians with a means to logically inspect, operate

and maintain the SPX series portable x-ray unit. The

following paragraphs describe the arrangement of this

manual and the information contained in each section.

Chapter 1:

Introduction and General Information

This section provides general information about the

SPX series units. Included in this section is a safety

summary.

Chapter 2:

Preparation for Use and Shipment

In this chapter, the user is provided instructions for

unpacking and reshipment, along with equipment

checklists and the basic specifications for assembly.

Also included in chapter 2 are the locations of warning

labels and I.D. tags.

Chapter 3:

Installing the SPX X-ray System

This chapter provides instructions making

interconnections for both liquid cooled and air cooled

units. It also includes a description of the various

interlock connections.

Chapter 4:

SPX X-ray Controls and Indicators

Chapter 4 details the controls and indicators on the

SPX Control Unit. Refer to this chapter during use for

operational details.

Chapter 5:

SPX X-ray System Operation

The warm up and operating instructions for the SPX X-

ray Unit is detailed in chapter 5. Included are

descriptions of error messages.

Chapter 6:

Routine Upkeep and Care

This chapter covers preventative maintenance and care

schedules for each assembly of the system. Included

are procedures for pressurizing and refilling the Tube

Head, cleaning the apparatus and various general care

practices.

SPX X-ray

Industrial Imaging System

Page 7 of 44 SPX Series System Manual

118173-001 Rev. D

Safety Summary

When properly installed, maintained and operated,

x-ray equipment can be used effectively and safely. If

any component of the unit is incorrectly installed,

operated by unqualified personnel, or the maintenance

schedule has been neglected, it is a potentially

dangerous apparatus.

Before operating or performing any maintenance on the

SPX series, the user MUST have a thorough

understanding of x-ray machinery, generation, high

voltage potential and x-ray control. The user MUST

understand all hazards associated with x-ray

generation.

Read this “Safety Summary” completely and thoroughly

to understand the contents. Read all of the safety

warnings, cautions and notes throughout the manual

prior to commencing any operating or maintenance

procedures.

All operators and technicians MUST adhere to the

following safety practices.

Read and understand the x-ray protection

warning published in the beginning of this

manual.

Read this manual in its entirety before

operation or maintenance is performed.

Understand all the procedures before

operating the unit.

Read thoroughly and understand completely

all NOTE, CAUTION and WARNING

statements before beginning operation or

maintenance procedures.

Use the following summary as a checklist to assure

comprehension of the safety indicators.

NOTE:

An essential operating procedure, condition or

statement, must be observed to ensure proper

understanding and operating of the system.

! CAUTION !

An operating ormaintenance

procedure, practice,condition,or

statement, which, if not strictly

observed,could result in damage to,

or destruction of equipment.

!

WARNING!

An operating or maintenance

procedure, practice, condition,

or statement, which, if not

strictly observed, could result in

injury to or death of personnel.

SPX X-ray

Industrial Imaging System

Page 8 of 44 SPX Series System Manual

118173-001 Rev. D

Radiation Hazard

This equipment generates X-radiation at levels that

can be lethal. This unit must only be operated by

personnel that are certified and experienced in

industrial x-ray generation. All operators must also

understand the characteristics of radiation and the

associated dangers of exposure to primary,

secondary, and residual sources of radiation.

Lethal Voltages

High power radiation sources depend upon the

generation of extremely high, yet well-protected

voltages. Under no circumstances should the

operator access the interior of the Tube Head.

Under no circumstances should the operator

access the interior of the Control Unit or the Cooling

Unit except for the procedures outlined in Section 5

of this manual.

Badges

All personnel who work around X-ray equipment

must wear a functional exposure dosage indicator.

Radiation Protection

X-ray equipment must be operated within properly

designated protective barriers. Otherwise,

personnel must not approach closer than 100 feet

from the Tube head, and in no cases cross the

direct path of the primary beam.

Radiation Monitoring

After installation, re-installation, transporting,

performing maintenance, and during all

radiographic operations not within a radiation

enclosure, a radiation survey should be

performed.

Warm-Up Procedures

Explicit procedures are outlined for “running-up”

high voltage with new equipment, equipment with a

new tube, equipment that has been inactive for a

period of time, and for daily use. These procedures

must be strictly followed at all times.

Operation

Equipment must be operated at correct

source voltage and frequency, and must

never be left running unattended. The gas

pressure in the Tube head must be checked

to ensure it is within allowable limits before

operating the unit. Never operate this

apparatus if output voltage/current is unstable.

Cooling Unit Operation

Regularly check the coolant solution in the Cooling

Unit to ensure:

◆

the coolant level is within specification

◆

the pump circulates the coolant properly

◆

the fittings, hoses, and coolant reservoir does

not leak

Always allow the Cooling Unit, or the fan on air-

cooled units, to run approximately 5 minutes after

completion of x-ray generation.

Caution:

Cooling unit shipped without

coolant. Cooling unit must be

filled to the appropriate level

prior to operation.

Care in Handling

Extreme care must be taken when handling

this x-ray apparatus. Exercise caution when

packing, unpacking, shipping, and while

performing maintenance. Remember, the X-

ray tube is durable but breakable: be sure to

store and ship it in the upright position.

SPX X-ray

Industrial Imaging System

Page 9 of 44 SPX Series System Manual

118173-001 Rev. D

Chapter 2:

Preparation for Use and Shipment

UNPACKING INSTRUCTIONS

The SPX X-ray Unit is shipped in a single wooden

container. To gain access to the unit, perform the

following:

◆

Remove the top cover from the crate.

◆

Carefully lift each component from the

container.

◆

Perform a thorough visual

inspection on each component.

If damage to any component has occurred,

immediately contact the carrier. Keep all damaged

containers until the carrier completes an inspection

by the carrier. If it is necessary to re-package and

ship the unit, follow the instructions outlined under

“Reshipment Guidelines”.

Reshipment Guidelines

In the event that the SPX X-ray Unit must be

transported or shipped, use the original wooden

container and packaging material whenever

possible. If the original shipping material is not

available, comply with the following re-packing

guidelines.

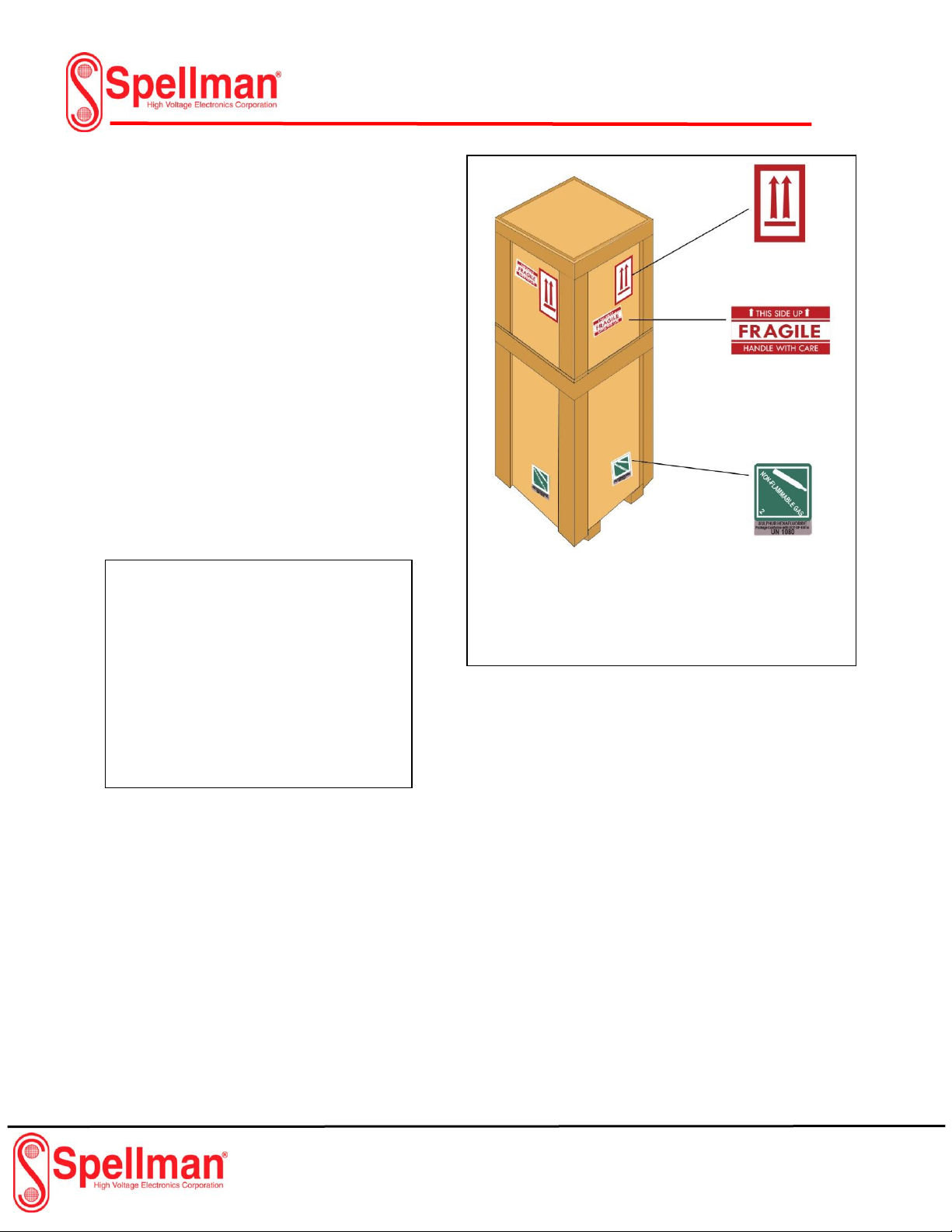

1. Construct a wooden shipping carton for

the Tube headAssembly similar to the

one in Figure 2-1. Build the carton so that

the top can be completely removed to

facilitate packing and unpacking.

2. Cushion the Tube head with 3" of

shock absorbent, foam type, packing

material (MINIMUM). This material

MUST surround the assembly on all

sides, including above and below the

Tube head.

3. Affix supporting blocks to the bottom

of the carton. Make sure the legs are

positioned to accommodate a pallet

jack as shown in Figure 2-1.

4. Pack the Control Unit in a

container rated for 60 lbs.

surround the Control Unit with a

MINIMUM of “2" of shock

absorbent packing material (sheet

or loose type), including the top

and bottom.

5. Pack the Cooling Unit in the

same manner as the Control Unit.

! WARNING!

The coolant solution is a flammable

substance and must be drained from

the Cooling Unit’s reservoir before it

can be shipped.

SPX X-ray

Industrial Imaging System

Page 10 of 44 SPX Series System Manual

118173-001 Rev. D

Transporting the Unit

When transporting by commercial carrier (i.e., truck,

rail, etc.), select the shipping method and carrier on the

basis of safe shipment, especially when shipping the

fragile Tube head Assembly. Distinctly mark the Tube

head carton on all sides with labeling which provides

the carrier the following information:

◆

Contents contains fragile glass

instrumentation.

◆

Container is to be shipped in upright

container only.

Customarily, the Tube Head is shipped via air,

generally avoiding ground transportation if possible.

When shipping via air, affix an additional label to the

carton stating the following:

Figure 2-1

Tube Head Shipping Container

“Sulfur hexafluoride, non-flammable

gas is present in limited quantities in

one or more packages of this

shipment. This is to certify that the

above mentioned materials are

properly classified, described,

packaged, marked, and labeled, and

are in proper condition for

transportation according to the

applicable regulations of the U.S.

Department of Transportation.”

SPX X-ray

Industrial Imaging System

Page 11 of 44 SPX Series System Manual

118173-001 Rev. D

EQUIPMENT CHECKLISTS

The following checklists outline the standard and

optional equipment of the SPX X-ray Unit. After

unpacking the unit, and completing a thorough visual

inspection, compare each item with this list to assure

completeness.

Note that several Tube Head models are available.

Verify that the Tube head shipped with your unit

matches the model that was originally ordered.

Checklist –Tube Head

SPX-160

Assembly, Tube Head* 3-000-0768-1

Air Cooled Unit; 40° cone,

Glass Insert

Beryllium Window

Assembly, Tube Head 3-000-0736-1

Liquid Cooled; 40° cone,

Glass Insert

Beryllium Window

Assembly, Tube Head 3-000-0772-1

Liquid Cooled; 360°

Panoramic, Glass Insert

Beryllium Window

SPX-200

Assembly, Tube Head* 3-000-3071-1

Air Cooled Unit; 40° x 60°

cone, Metal Ceramic Insert

Assembly, Tube Head 3-000-3072-1

Liquid Cooled; 40° x 60°

cone, Metal Ceramic Insert

Assembly, Tube Head 3-000-3073-1

Liquid Cooled; 360° Panoramic

Assembly, Tube Head 3-000-3258-1

Air Cooled; 40° Cone

Glass Insert

Beryllium Window

Assembly, Tube Head 3-000-3224-1

Liquid Cooled; 40° Cone

Glass Insert

Beryllium Window

SPX-300

Assembly, Tube head* 3-000-3192-1

Air Cooled Unit;

40° x 60° cone,

1.5mm Focal Spot,

1mm Beryllium

Window

Assembly, Tube head 3-000-3191-1

Liquid Cooled; 40° x 60°

cone, 1.5mm Focal Spot,

1mm Beryllium Window

* All Air Cooled Units are equipped with Fan Power

Cable (p/n: 1-040A-0355). The liquid Cooling Unit is

not equipped with this cable.

Checklist - Standard Equipment

Control Unit, Digital (1) 408574-001 (SPX160)

408574-002 (SPX200)

408574-003 (SPX300)

Cooling Unit Assembly (1) 3-000A-0737

(Liquid Cooled Units Only)

Power Cable Assembly (1) 1-040-0341

(3 Pin Connector, 25ft.) (SPX160,200,300)

Control Cable Assembly (1)

(14 Pin Connector, 100ft.) 1-040-0824 (SPX200,300)

(10 Pin Connector, 100ft.) 1-040-0342 (SPX160)

Cooler Power Cable (1)

(Liquid Cooled Units Only)

(8 Pin Connector, 50ft.) 1-040-0823

(8 Pin Connector, 100ft.) 1-040-0342 (SPX160)

Power Cable, Fan (1) 1-040-0355

(Air Cooled Units Only, 100ft.)

Interlock Jumper (1)

(Dummy Plug) 305531-001

SPX X-ray

Industrial Imaging System

Page 12 of 44 SPX Series System Manual

118173-001 Rev. D

Checklist - Optional Equipment

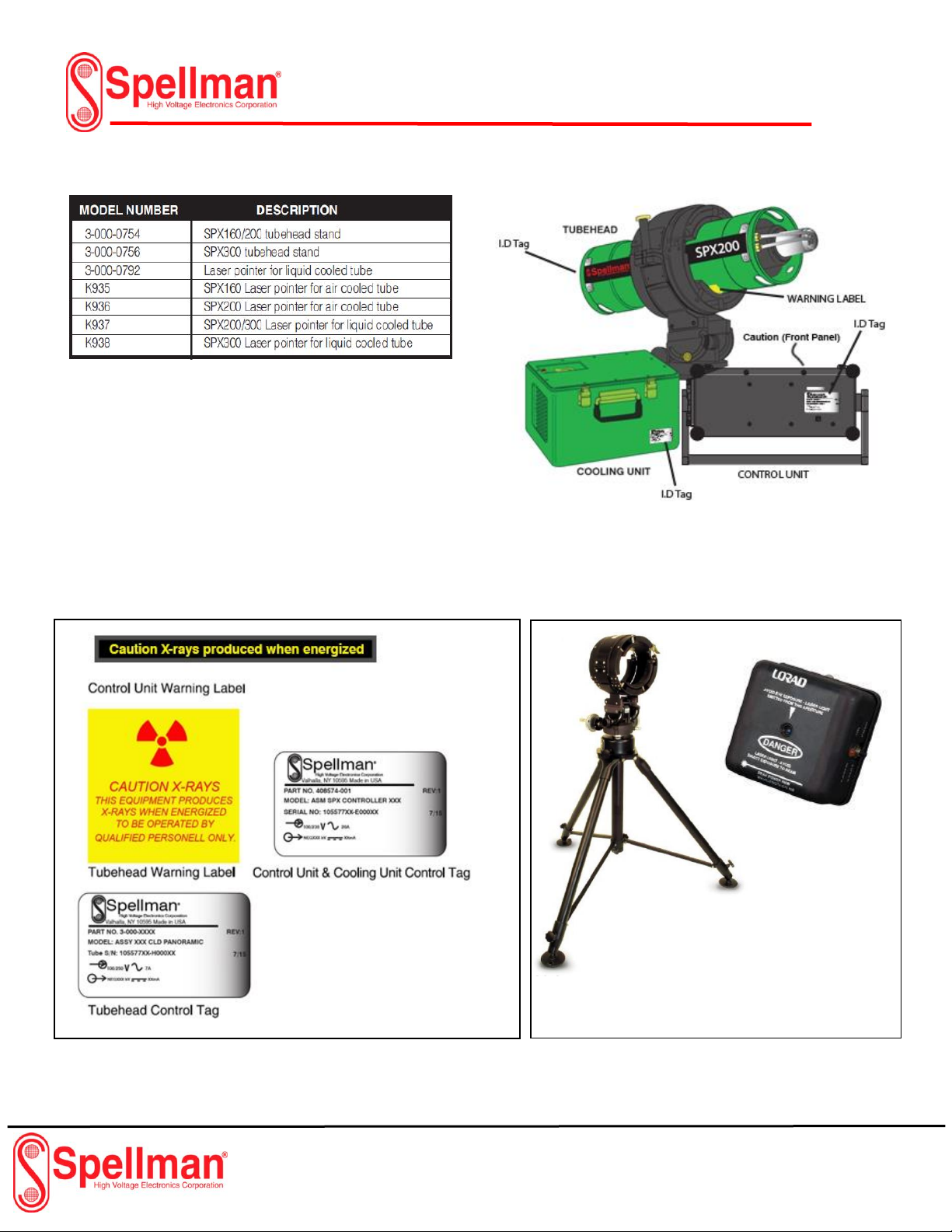

WARNINGS LABELS & CONTROL NUMBERS

Each assembly of the SPX X-ray System is equipped with an

I.D. tag (Control Tag) providing the serial number,

description, and part number. This data is used for

identification, if warranty or service information is needed,

and will be requested when contacting Spellman regarding

the apparatus.

Attached to the Control Unit and Tube head are warning

labels. Fig 2-3 illustrates the location of the I.D. tags and

warning labels for each assembly of the SPX-systems.

Figure 2-3

Figure 2-2

Tube Head Stand

Laser Pointer

Figure 2-4

SPX X-ray

Industrial Imaging System

Page 13 of 44 SPX Series System Manual

118173-001 Rev. D

Specifications - General System

The following outlines the general operating and

environmental limits of the SPX- system.

Line Voltage: 100 to 130 VAC - 50/60 Hz,

20amps (max.); or 200 to 250VAC - 50/60 Hz,

10 amps (max.).

Line voltage selection is automatic.

The system is operable from either line

voltage range without any switch or

jumper configuration.

Operating Potential:

SPX-160: 10kV to 160kV @ 0.5 to 5.0 mA,

800 Watts maximum

SPX-200: 10kV to 200kV @ 0.5 to 10.0 mA,

900 Watts maximum

SPX-300: 10kV to 300kV @ 0.5 to 10.0 mA,

900 Watts maximum

Operating Temperature Range: -30°F to

120°F (Ambient), or -34°C to 49°C (Ambient)

Humidity: 0 to 100% relative humidity

Stabilization: kV and mA remain within 1% of

set levels. Line voltage varied from 100-

130/200-250 VAC.

Storage Temperature Range _ -65°F to 160°F

(-54°C to 71°C)

Figure 2-5

SPX X-ray

Industrial Imaging System

Page 14 of 44 SPX Series System Manual

118173-001 Rev. D

Specifications - General Tube Head

See Datasheet regarding the specifications of

the Tube Head Assembly.

Tube Pressure Sense : Monitors pressure of the

SF6 gas within the Tube Head. Shuts unit down if

pressure falls below 25 psi.

Anode Thermal Sense: Monitors temperature of

the X-ray Tube Anode. Shuts down unit if Anode

temperature rises above 220°F.

Pressure Relief Valve: Automatically releases SF6

gas from Tube Head if pressure rises between 75 -

80 psi.

Pressure Gauge: Displays SF6 gas pressure within

Tube Head. Used in conjunction with Temperature

Compensation chart to visually inspect Tube Head

pressure.

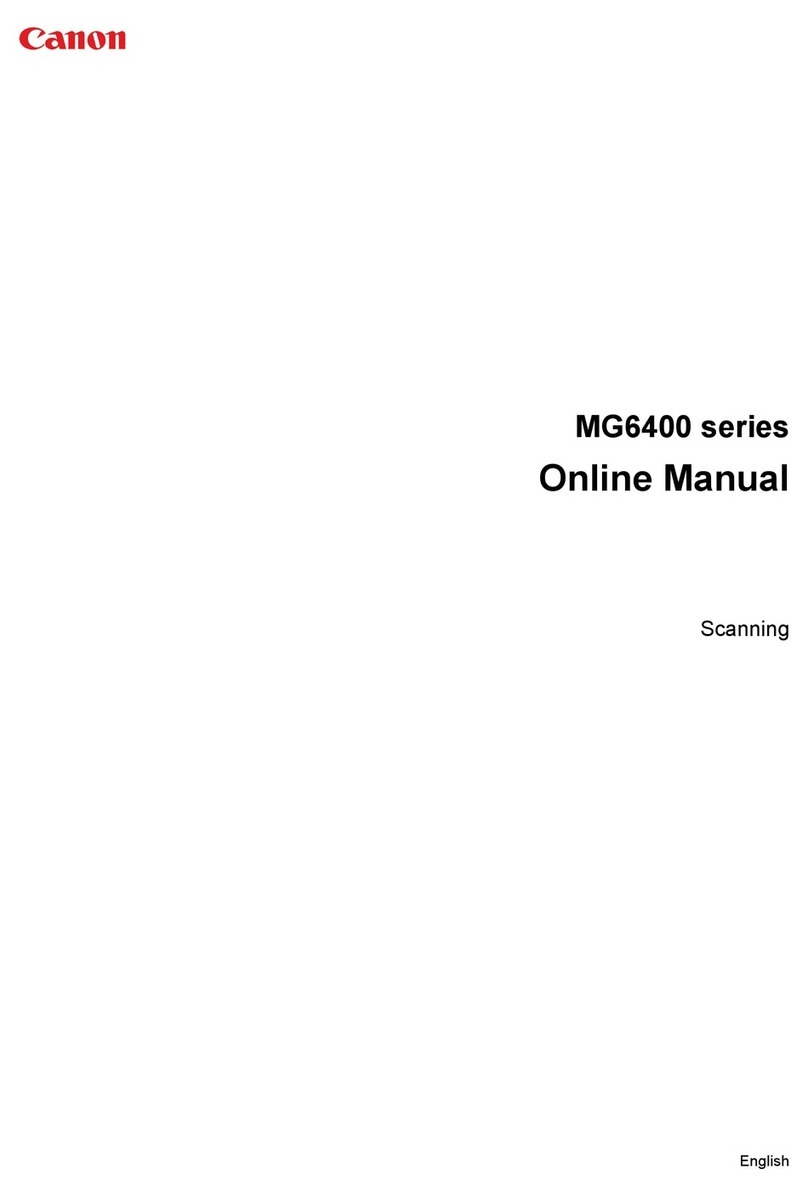

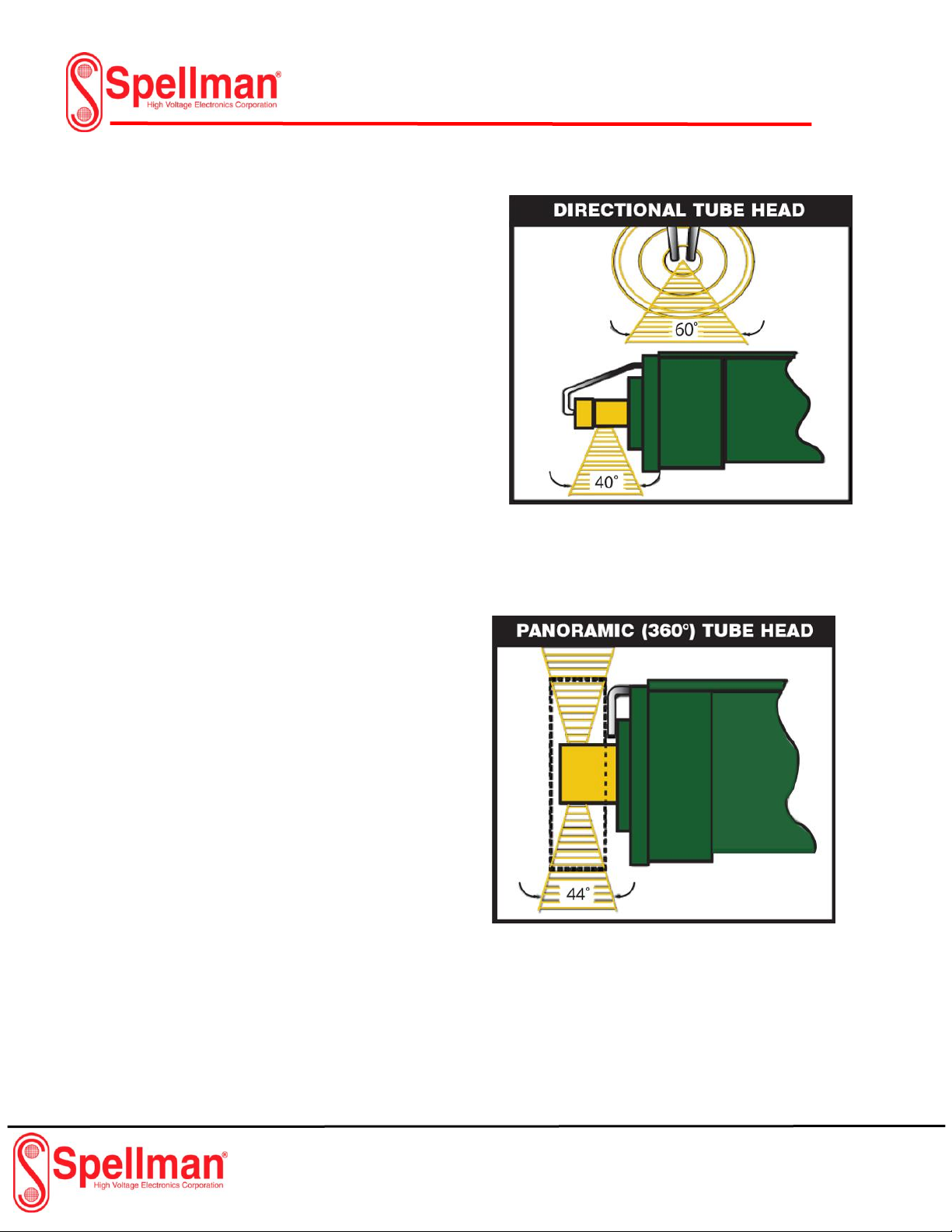

Specifications - Optional Tube Head

The information that follows furnishes the

specifications for several available Tube Head

assemblies. Figure 2-6 and 2-7 illustrate the

direction of the X-ray beam for both the 40° x 60°

cone and the 360° panoramic models.

Figure 2-6

Figure 2-7

SPX X-ray

Industrial Imaging System

Page 15 of 44 SPX Series System Manual

118173-001 Rev. D

Specifications - Control Unit

Below are the physical and operating

specifications of the Control Unit. Included are

the physical dimensions, and the operating

indicators and controls. The controls are

explained in detail in other section of this manual.

Fluorescent Screen: Display the set KV, mA level

and show the feedback reading.

Decoder: Used to navigate through the screens

and to set KV, mA levels and time.

Control Key: Turns on the unit in warm-up position

and enables Cooler and high voltage circuit.

Buzzer: Sounds alarm when X-ray activates.

Communication Ports: Serial RS-232 and Ethernet.

X-Ray ON Switch: Green Pushbutton switch with

radiation symbol. Enables x-ray generation.

X-Ray OFF Switch: Red Pushbutton E-Stop

terminates x-ray generation. May be depressed any

time x-rays are in use.

Pre-Warning Light: Illuminates for 20 seconds max.

to indicate that X-ray will be generated.

X-Ray ON Light: Illuminates when x-ray ramps to

the pre-set level. Remains on during normal

operation until X-ray is turned off.

Safety Circuit Light: Illuminates after all interlock

circuits are closed. If light is off the controller will not

allow x-ray generation.

Figure 2-8

SPX X-ray

Industrial Imaging System

Page 16 of 44 SPX Series System Manual

118173-001 Rev. D

Specifications - Cooling Unit

Below are the operating and physical

specifications of the Cooling Unit.

Dimensions: 12" H x 15" W x 14" L

Weight: 55 lbs. (approximate)

Coolant Solution : 14 parts methyl alcohol, 7

parts distilled water, 1 part soluble oil

(Chevron Soluble “B” )

Coolant Flow: 0.5 gallons per minute @ 50

foot-head.

Cooling Unit Connections: Self-sealing quick

disconnects.

Caution:

Cooling unit shipped

without coolant. Cooling

unit must be filled to the

appropriate level prior

to connecting the

system.

Figure 2-9

SPX X-ray

Industrial Imaging System

Page 17 of 44 SPX Series System Manual

118173-001 Rev. D

Chapter 3:

Installing the SPX-X-ray System

PRE-OPERATIONAL

CHECKS & INSPECTION

The following paragraphs outline the steps to

properly check and inspect the SPX- X-ray unit.

Perform these

procedures before setting up the system to

ensure integrity.

Check –Tube Head Gas Pressure

This check verifies that the gas pressure inside

the Tube head assembly is within limits. Note that

Tube head gas pressure normally varies 1 psi for

every 7°F increase or decrease in ambient air

temperature.

! CAUTION !

DO NOT operate this unit if

theTube Head Pressure is below

50 psi at 70°F or damage to the

Tube Head may occur.

1. Check the Tube Head gas pressure gauge and

verify that the gas pressure is within acceptable

limits for the ambient temperature

(see Figure 1-3).

2. If the gauge indicates Tube Head gas pressure

below the acceptable limit, but greater than 5 psi,

perform the procedures for “Pressurizing the Tube

Head” (refer to section 7).

3. If Tube Head gas pressure is below 5 psi at

70°F, purge the Tube Head of all remaining gas,

then perform the procedures for “Refilling the

Tube Head” (see section 7-3).

Check - Cooling Unit

This check verifies the integrity of the Cooling Unit

(liquid cooled Tube Heads only).

1. Inspect the twin hose assembly and hose

connections for damage. The connector couplings

must be firmly attached to the hose, and the hose

must be free of punctures, frays, or dry rot.

2. Remove the Radiator cap on the Cooling Unit

and check that the coolant level is within 1/2" from

the top of the reservoir. Add coolant solution at

this time if necessary (refer to figure 4-16).

Check - Control Unit

This check verifies the integrity of the Control

Unit.

1. Perform a thorough visual inspection

for damage.

2. Check the four connectors along the

right side of the unit for foreign

material and signs of corrosion.

3. Inspect the front panel controls for

missing or broken switches and

displays.

SPX X-ray

Industrial Imaging System

Page 18 of 44 SPX Series System Manual

118173-001 Rev. D

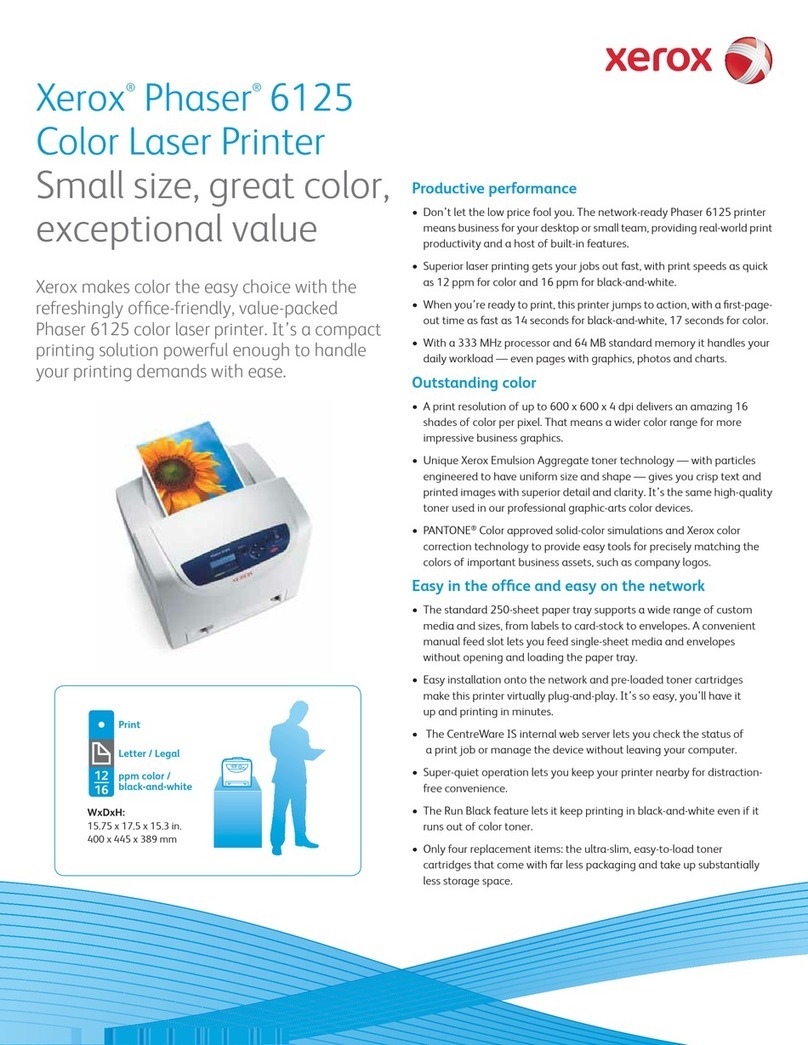

SYSTEM SET UP PROCEDURES

The procedures below describe the set up

procedures for both SPX Unit configurations;

liquid-cooled units, and air-cooled units. Use

Figure 3-1 (liquid-cooled), or Figure 3-2 (air-

cooled) as a reference while making the

necessary system connections.

System Interconnections - Liquid

Cooled

The following details the connections for setting

up a liquid cooled SPX X-ray System.

! WARNING !

All cables MUST be connected

to their appropriate connectors

on the Control Unit, Cooling

Unit, and Tube Head before

applying power to the system.

1. Connect the twin hose assembly between the

Tube Head and the Cooling Unit:

_ Attach the two angled couplings to the fittings

on the back of the Tube Head.

_ Attach the couplings on the opposite end to

the female fittings on the Cooling Unit.

NOTE:

There is no designated left or right side to the

twin hose assembly. If each coupling is

properly seated, coolant flow through the

Tube Head will be achieved.

2. Install the Cooling Unit power cable:

Connect the male end of the power cable to the

connector labeled “Cooler” on the Control Unit.

Connect the female end of the power cable to the

connector on the Cooling Unit.

3. Install the Tube Head Control cable:

Connect the male end of the Control cable to the

connector labeled “Tube Head” on the Control

Unit.

Connect the female end of the Control cable to

the connector on the Tube Head base plate.

4. Install the line power cable:

Connect the female end of the line power cable to

the connector labeled “Power” on the Control Unit.

Connect the “plug” end of the line power cable to

the AC voltage source (see Connecting to Power

instructions later in this section).

5. Make the External Interlock connection:

If available, connect the Interlock cable to the

connector labeled “Interlock” on the Control Unit

(see External Interlock instructions later in this

section).

Connect the “jumper” (supplied) to the connector

labeled “Interlock” on the Control Unit for units

that do not employ an external interlock system.

Figure 3-1

SPX-System Setup (Liquid Cooled)

This manual suits for next models

3

Table of contents

Other Spellman All In One Printer manuals