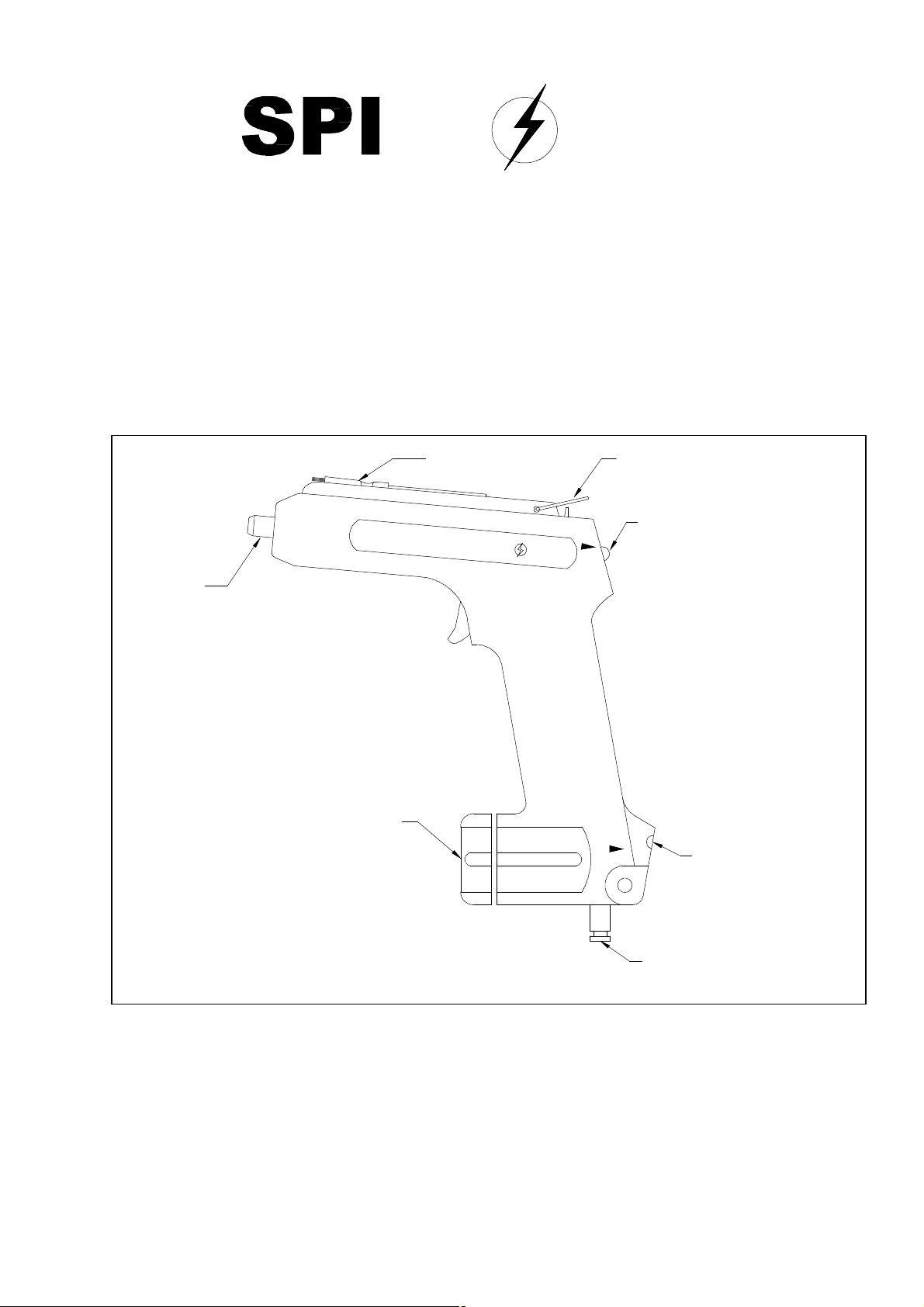

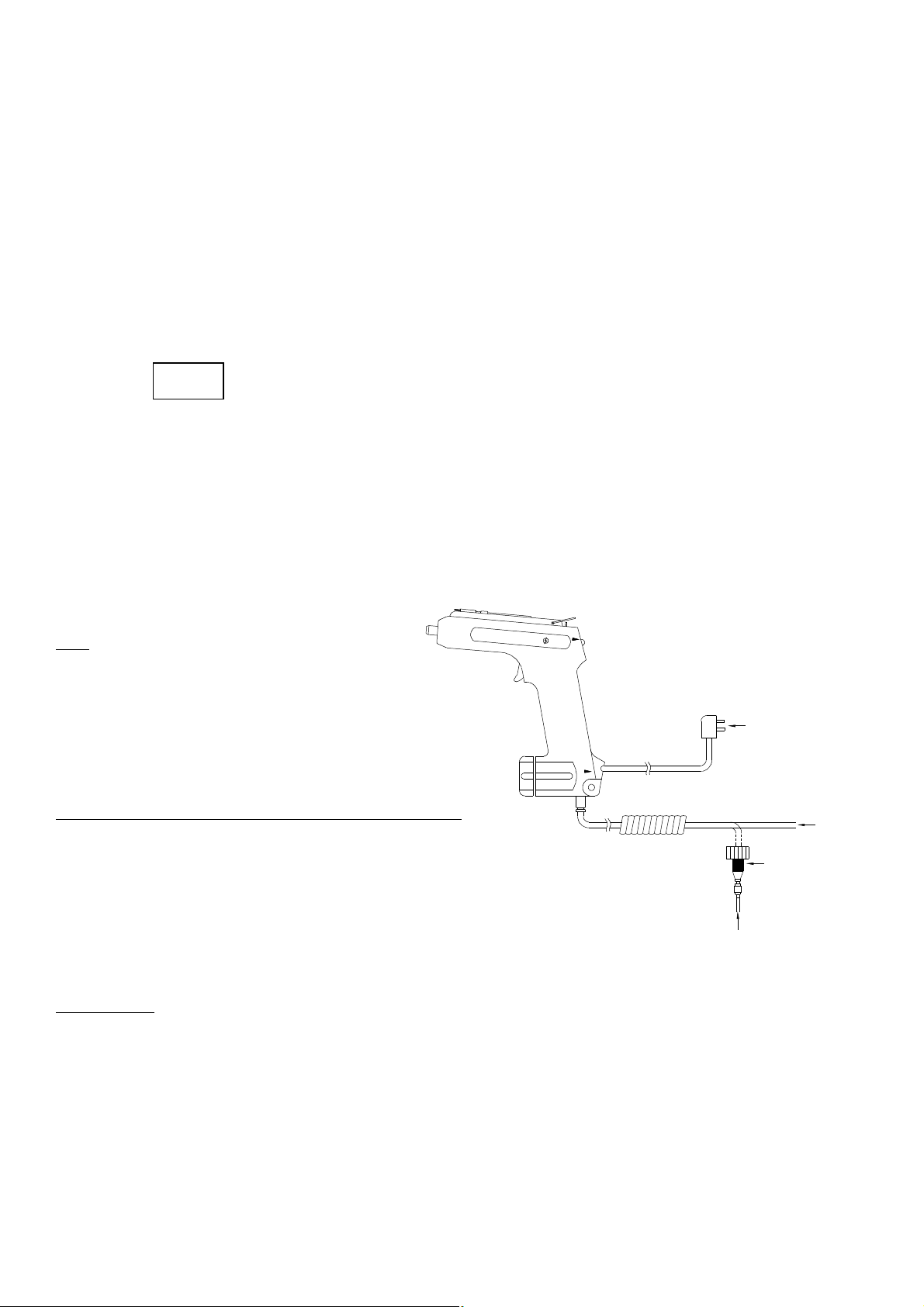

SPI Westek 94101 User manual

Portable IonizingAir Gun

PIA 离子风枪

号: 94101

SPIWESTEK 是DESCO 静电消除器品牌

MADEINAMERICA

IONGUN

SPI

wetek

Ion

DC

6V

出风口

小毛刷 挂钩

指示灯

220VAC-6VDC插口

高压进气口

电池盒

WE TEK

页1

IONGUN SPIwetek

Ion

DC

6V

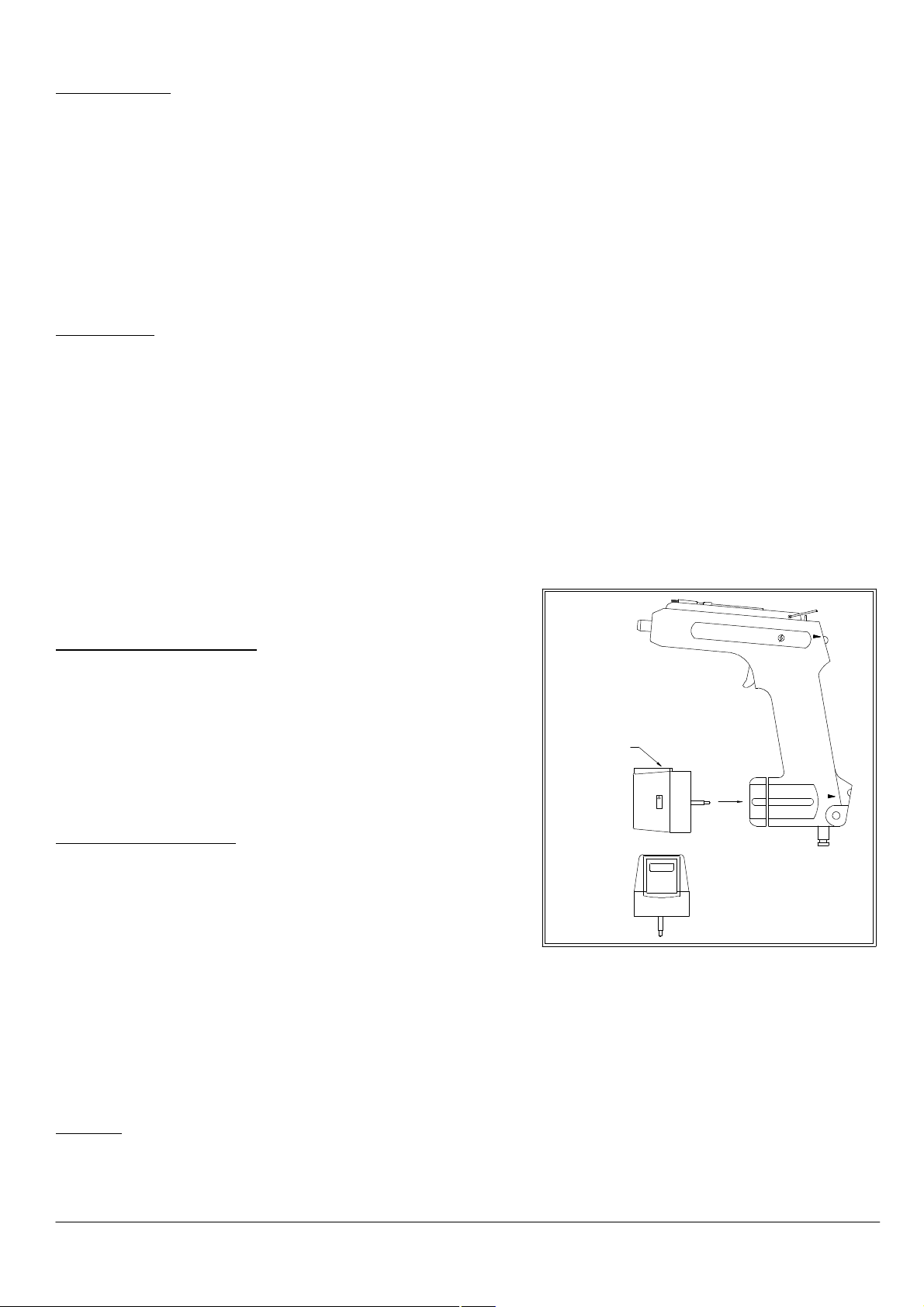

管道高压气体

罐装高压气体

220VAC-6VDC变压器

转换接头

根据 ANSI/ESDS20.20 中6.2.3.1 内容规定, 在静电绝缘物体或孤立的半导体产生静电时, 应使用电离技术产生正

负离子中和静电. 采用电离中和技术对具有大电容的物体无效, 例如人体, 但在接地无法实现的情况下, 电离中和

技术应该被采用.

根据 IEC61340-5-2:1 中所规定, 对导电物体和人体, 电离中和技术不应是第一选择.

SPI94101 离子风枪 以将空气电离为大量正负离子, 由高压气体输送到需除静电物体表面以中和静电, 同时将

表面灰尘吹除.

*使用 94101 风枪前, 请阅读本手册

l该设备不具防水功能, 请保持干燥以免短路

l不要剧烈震动该设备, 防止接触腐蚀性物体, 燃气体和灰尘

l不要对准人员脸部工作

l不要让儿童接触该设备

l当风嘴或枪体破损时不要继续使用

l不要拆开枪体外壳

l安全丢弃电池

安装

l打开电池盒盖, 装入4节AA 电池

l将进气管插入枪柄底部的进气接口

l当气源管口径小于配套气管时, 使用转换接头

打开包装箱后检查设备是否有损坏, 包装盒内有以下物品

气管: 1 个

毛刷: 1 个

AA 电池: 4 节

AC-DC 变压器: 1 个

产品使用环境

将变压器插入220VAC/50Hz 电源, 变压器输出6VDC, 2.5W

使用时环境最高湿度: 90%

操作温度: 0-50℃

产品储存温度: -10-50℃

产品储存湿度: 20-90%RH

输入气压: 10-65 PSI

产品重量: 310 克(包括电池)

警告!

页2

安装并检查产品

F打开电池盒盖, 放入 4节AA 电池. 把进气管插进枪柄底部的进气口. 安装好后, 按下1半机开关, 这时有气

体从枪嘴射出, LED 指示灯不亮.

F如果没有气体从枪嘴射出, 应检查气管是否连接紧密或气源是否正常.

F接着全部按下机, 这时产生正负离子,LED 指示灯为绿色. 如果LED 灯不亮, 应检查电池是否安装正确或没电,

如果电池没电, 用配套变压器充电.

F以连接配套变压器工作而不需电池.

产品工作原理

PIA 风枪枪嘴内装有离子放电极, 内置压电 高压产生器将6V 直流电转换为4KV 高频交流电并作用在离子放电极

上, 产生电晕放电将空气分子电离为大量正负离子. 由于采用高频交流电晕放电, 所以PIA 产生的正负离子比一般

的工频交流静电消除器更多更密集, 同时电晕放电电压比普通产品更低, 所以产生的臭氧更少.

PIA 将输入的高压气流电离为大量正负离子, 因此枪嘴内射出高压离子风, 作用到物体表面时将静电中和, 并将污

染物吹走.

PIA 离子风枪按ANSIEOS/ESDS3.1 标准检测, 正负离子平衡度低于+/-10V(ANSIEOS/ESD20.20 标准为低于

+/-50V)

使用配套 94049 静电探测器

1.把94049 静电探测器插入94101 风枪的电池盒的中间插孔内

2.向上推 ON 按钮开机

3.94049 静电探测器会自动开机清零,屏幕显示“0.00 KV

4.对准需检测物体,屏幕显示物体表面静电位(单位:千伏)

使用注意事项及产品维护

F输入的高压气源需干燥和洁净, 肮脏或有油水的气体会损坏

该设备, 一般气源需经过吸水预过滤器过滤

F输入气压不要超过 65PSI, 输入气压过高会造成电离效果不好,

同时损坏设备

F不要在具有易燃, 易爆炸物品的地方使用该设备

F使用过程中, 离子放极会被污染, 根据 IEC61340-5-2 建议 6个月清洗离子放电极, 同时检测离子平衡度

F设备散电时间和离子平衡度检测按EOS/ESDS3.1 标准采用平 监测器校正

F高压电晕设备会产生对人体有害的臭氧, PIA 风枪经检验产生的臭氧低于0.05ppm(符合 OSHA 标准)

产品保修

PIA94101 风枪保修期为1年, 由于操作不当引起的质量问题不在保修范围.

中文说明仅供参考, 请以英文说明书为准

Copyright ©APCEE Corporation

页3

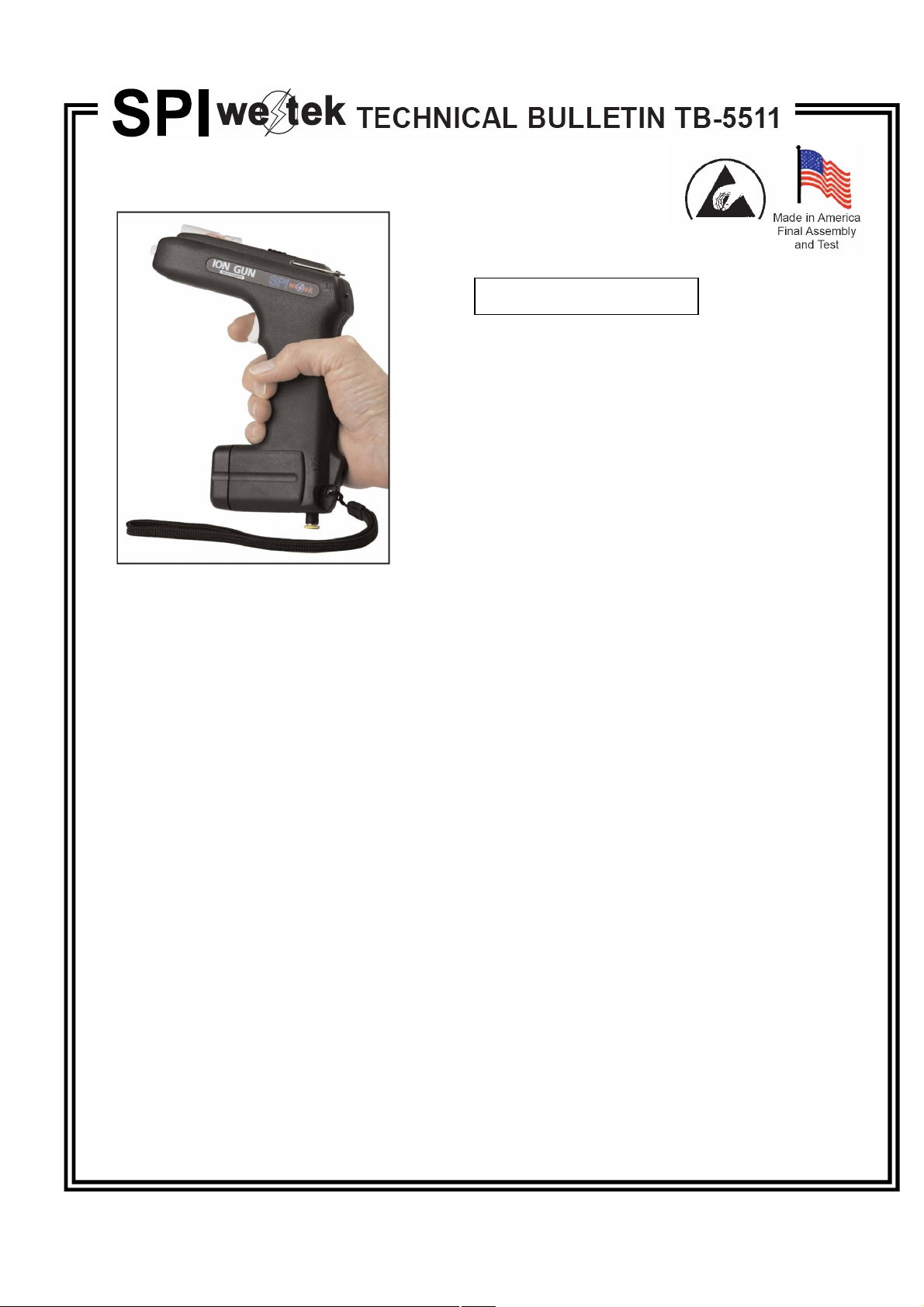

ION GUN SPIwetek

Ion

DC

6V

94049静电探测器

ON

STATICLOCATOR

SPI

测试范围: 0-19.99kV

测试距离: 2"(5cm)

测试误差: 5%或100V

电源: 6VDC

•TheIonizingAirGunisnotwaterresistant,therefore,keepit awayfrom

waterandmistaswaterwillcauseshortcircuitandinsulationfailures.

•Keeptheairgunawayfromvibration,corrosive/flammablegasanddust

astheycanbethecauseof fire, shortcircuits,rust, etc.

•DonotoperatetheIonizingAirGun neartheface.

•KeeptheIonizing AirGunawayfromchildren.

•DONOTusetheairgunforpurposesotherthanitsdesignedpurpose.

•DONOTuseifthenozzleorconnectorsaredamage

•DONOTdisassembletheairgun.

•Disposeofbatteriessafely.

INSTALLATION

Openthebatteryboxlidwithacoinandremoveit.Loadthe4AA batteries,

replacethebatteryboxlidand lockinplace. Connect theairtubetothe

Ionizing AirGunnozzle. Inserttheairtubeintotheconnectorfirmly.

ConnecttheQuickDisconnect Adaptertotheairsupply/source.

PortableIonizingAirGun

OperationandMaintenance

PLEASE READ THISMANUALINITS

ENTIRETY

BEFOREUSING THE94100IONIZINGAIRGUN.

WARNING

Removefromthecarton and

inspectfordamage. Included

withthePortableIonizing Air

Gun shouldbe:

1AirTube

1ExtensionBrush

1Quick DisconnectAdapter

4AA Batteries(Rechargeable)

1ACAdapter

POWERRATINGSAND

ENVIRONMENTAL

CONDITIONS

RatedvoltageforPlug-inPowerSupply(not

included): Output6VDC, 2.5W

Suitableforindooruseonly

Maximumrelativehumidityof 90%

(noncondensing)

OperatingTemperature:0~50°C

StorageTemperature:-10~50°C

StorageHumidity:20 ~90%RH

AirPressure: 10~65 PSI-Max

Weight(withbatteriesinstalled): 0.7pounds

FUNCTIONTESTS

AirInjection Test

Pushingthetriggerlightly, approximatelyhalfway, willreleaseairfromthe

gun nozzle. Thelighton thebacksideoftheairgun shouldnot comeon.If

theairdoesnot comeoutvigorouslywithahissingsoundcheck forthe

following: 1)makesurethattheairtubeisattachedfirmlytothegun;2)

makesuretheairsupplyconnectionsaresecure.

Ion Injection Test

Pushingthetriggerallthewayinwillreleasean ionizedairflowfromtheair

gun.Thelighton thebackshouldbeonatthispoint.Ifthe'green'lighton

thebacksideoftheairgunisnoton, check forthefollowing:1)Arethe

batteriesloadedproperly;2)Dothebatterieshaveenough power. Use

providedACAdaptertorechargethebatteries(unitcan alsobeoperated

from120volt linevoltageusingACAdapterwithout batteries).

Operation

Besurethatyoucompletebothfunctiontests:Air

injectionandIonInjection Test.

Toremovestatic,you mustpushthetriggerallthewayin.

Airandionswillbeemittedfromthegun. Thegreenlight

shouldbeonatthispoint.

Toblowdustaway,pushthetriggerlightlyorhalfway.

Onlytheaircomesfromtheairgun,andthegreenlight

shouldnotcomeon atthispoint.

UsetheExtension Brushtoremovedust.Whenthe

extension brushisused,ion'sarenotemittedfromthe

gun eventhoughthegreenlightison.

Description

SPIWestekPortableIonizingAirGun isaready-to-use

unitforuseinapplicationsandareaswhereelectrostatic

chargercancreatemanufacturingorhandlingproblems.

Theunit quicklyandeffectivelyneutralizebulkstatic

chargesandaidincontrollingcontaminationby

dislodgingdustand debrisattractedbystaticelectricity.

Theunitisdesignedforuseinapplicationsandareas

whereElectroStaticAttractioncontaminationcreate

manufacturingorhandlingproblems(Ref:ESD

HandbookTR20.20paragraph5.3.6.5.2.4Point of

UseIonization).

ThePortableIonizing AirGun meetsor

exceedstherecommendedtechnical

requirementsofANSI/ESDS20.20testedin

accordancewithANSI/ESDS3.1.

ThePortableIonizingAirGunisdesigned forpoint-of-use

applications.Ionizersareusefulinpreventing

electrostaticchargegeneration, ElectroStaticDischarge,

and ElectroStaticAttraction.ANSI/ESDS20.20

Paragraph 6.2.3.1ProtectedAreasRequirement states:

"Ionizationorotherchargemitigatingtechniquesshallbe

usedattheworkstationtoneutralizeelectrostaticfields

on allprocess essentialinsulatorsiftheelectrostaticfield

isconsideredathreat." Ionization isusedtoneutralize

chargesonprocess necessaryinsulatorsandisolated

semiconductors.Someexamplesofprocess necessary

insulatorsare:thePCboarditself,plasticteststands,

plastichousingwhereaPCBmaybemounted,aswellas

computermonitorscreensand regularcleaningwipes.

Examplesoffloatingorisolatedconductorsare:loaded

PCBmountedinastandwherethepinsarenot

contactingthedissipativeworkstation.

Airionization canneutralizethestaticchargeon insulated

and isolatedobjectsbyproducing separatechargesinthe

moleculesofthegasesofthesurrounding air.Whenan

electrostaticchargeispresent on objectsinthework

environment, itwillbeneutralizedbyattractingopposite

polaritychargesfromtheionizedair. Notethationization

systemsshouldnotbeusedasaprimarymeansofcharge

controlonconductorsorpeople. (Reference: IEC61340-5-

2:1paragraph5.2.9).

TheSPIWestek PortableIonizing AirGun is

NISTcalibrated.

NOTE:Theunitisnotrecommendedforcontinuoususe.

AirRequirements

AlwayssupplythePortableIonizingAirGun withfiltered, dry

noncombustiblegases, suchascompressedshopair.Ifthe

airisnotdry,damagetotheequipmentmayresultandthe

warrantywillbevoided.Dirtyaircan introducemoistureand

oil,contaminatingtheunits'emitterassemblyalongwiththe

materialstobecleanedorneutralized.

Filtersmustthereforebeusedatalltimesupstreamoftheair

nozzle. Awatertrap-typepre-filtershouldbeusedin

conjunctionwithanoil coalescing-typefilter. Alsodrainall

moisturetrapsregularlytopreventmoistureintheline.

Severaldrainingsperdaymaybenecessary, especiallyin

areasof highhumidity.

ThePortableIonizing AirGun maybeoperated

overarangeof10PSIto65PSI.

Thespecificpressureneededwilldepend uponthe

application.Pressuresexceeding 65 PSIarenot

recommendedsincethesehigherpressuresaredetrimental

toeffectiveionproduction,andmaydamagetheunit.

IMPORTANTNOTE:Theseairnozzlesarenot explosion

proof.Donotuseinenvironmentswherevolatilematerials

arepresent.

SPIWesteksolid-stateelectronicequipment iscompactand

ruggedbutshouldbetreatedassensitiveelectronic

equipment.Withproperinstallation and acontinued

preventivemaintenanceprogramyouwillensuretheproper

performanceoftheunit.

TheoryofOperation

Theemitterislocatedinsideofthenozzle. Thisemitter

produceslargeamountsofpositiveandnegativeions, which

mixwiththeairsupplyandcreateahighlyeffective

neutralizingfield. Anymaterialwithinthisfieldwill be

neutralizedrapidly.Theionizing airflowremoves

contaminationbydislodgingdustanddebriswhichis

attractedtoamaterial'ssurfacebystaticcharges.Once

staticchargesareneutralized, dust particlesandotherforms

ofcontamination arefreedand carriedawaybytheair

stream.SPI WestekionizersmeettheANSI/ESD

S20.20minimumrecommendedtechnicalrequirementrange

ofless than ±50 voltsvoltageoffsettestedinaccordancewith

ANSIEOS/ESDS3.1.TheSPI WestekPortableIonizing Air

Gunprovides ±30volt balance.

Maintenance

"Aswithallionizers,periodicmaintenancewillbeneeded

toprovideoptimumperformance." (Reference: IEC

61340-5-2:1paragraph5.2.9).

Thefrequency ofmonitoringionizersreallydependson

howandwheretheyareused.

EIA-625recommendscheckingionizersevery6months,

butthismaynotbesuitableformanyprograms

particularlysincean outof-balancemayexistformonths

beforeitischeckedagain.ANSI/ESDS20.20 paragraph

6.1.3.1ComplianceVerificationPlanRequirement states:

"Test equipmentshallbeselectedtomake

measurementsofappropriatepropertiesof thetechnical

requirementsthatareincorporatedintotheESDprogram

plan."And paragraph6.1.3.2. ComplianceVerification

PlanGuidancestates:"Inadditiontointernalaudits,

externalaudits(Organization and supplierofESDS

items)shouldbeperformedtoensuretheunit, alocking

screwisprovidedonthebackof theunittocompliance

withplannedrequirements. Verificationsshouldinclude

routinechecks of theTechnicalRequirementsinthePlan.

Thefrequency of verificationchecks shouldbebasedon

thecontrolitemusage,itsdurabilityand associatedriskof

failure."

Undernormalconditions,theionizerwillattract dirtand

dust(especiallyontheemitterelectrodes). Tomaintain

optimumperformance,cleaning mustbeperformedona

regularbasis.Theelectrodesshouldbecleanedatleast

everysixmonths.However,morefrequentcleaningmay

berequiredifusedinenvironmentswithmore

contaminants. Theseunitsneedverylittlemaintenance.

Inordertomaintaintheoptimumperformanceof your

unit,thefollowingmaintenanceproceduresmust be

performed onaregularbasis.Makesurethattheair

supplyisclean andfree of contaminationandmoisture.

Draincompressortankand filtersperiodically.

Thefiltersmayrequiredrainingseveraltimesdaily,

depending on yourcompressedairsystem.

Neutralization Efficiency(DecayTime)

Thecomparativeneutralizationefficiency ofionizersis

determinedbyastandardtestpublishedbytheESD

AssociationStandard3.1.

Testing and Calibration

Ionizersaretestedandcalibratedusingachargedplate

analyzer.Forpropertestingwerecommend using our19450

ChargedPlateAnalyzerandtheprocedureoutlinedinESD

Association'sStandard3.1. Thisstandardcanbeobtained

directlyfromtheESDAssociation,7902TurinRoad,Suite4,

Rome, NY13440-2069,(315)339-6937.

Health

Thereareno knownhealthrisksassociatedwithourdevices.

Theemittersworkatabout4-6kVandcancreateozone, but

therehavebeenno significantmeasurementofozonefrom

ouremittersets,asallourexistingunitstest wellbelowthe

OSHAlimit of0.05ppmozone. Foradditionalsafety

information,see "Dispellingan OldMyth"writtenbyWilliam

Metzof Hewlett PackardpublishedinEvaluationEngineering

magazine,September2001.

NOTE: Unauthorizedservicingofmodificationstoyour

PortableIonizing AirGunwillvoidtheproductwarrantyand

maycreatedangerousconditions.Servicingshouldbe

performed onlyatthefactory,orbyaSPIWestekapprove

technician.

Limited Warranty

SPIWestekexpresslywarrantsthat foraperiod of one(1)year

fromthedateofpurchase,SPI WestekPortableIonizingAirGun

willbefree ofdefectsinmaterial (parts)andworkmanship (labor).

Within thewarrantyperiod, aunitwillbetested,repaired or

replaced at SPI Westek’soption, free ofcharge. Callour

CustomerServiceDepartmentat909-664-9986 foraReturn

Material Authorization (RMA) andpropershippinginstructionsand

address. Pleaseincludeacopyof youroriginal packing

slip,invoice,orotherproof of dateof purchase. Anyunitunder

warrantyshouldbeshipped prepaidtotheSPIWestekfactory.

Warrantyreplacementswill takeapproximatelytwoweeks.

Ifyourunit isoutof warranty, call ourCustomerService

Departmentat909-664-9986foraReturnMaterial Authorization

(RMA)and propershipping instructionsandaddress. SPI Westek

will quoterepairchargesnecessarytobringyourunituptofactory

standards.

WarrantyExclusions

THEFOREGOINGEXPRESS WARRANTYISMADEINLIEUOF

ALLOTHERPRODUCTWARRANTIES, EXPRESSEDAND

IMPLIED. INCLUDINGMERCHANTABILITYAND FITNESS FOR

APARTICULARPURPOSE WHICH ARESPECIFICALLY

DISCLAIMED. Theexpress warrantywill notapplytodefectsor

damageduetoaccidents, neglect,misuse,alterations,operator

error,orfailuretoproperlymaintain, cleanorrepairproducts.

LimitofLiability

InnoeventwillSPIWestekoranysellerberesponsibleorliable

foranyinjury,loss ordamage,directorconsequential, arisingout

oftheuseof

ortheinabilitytousetheproduct. Beforeusing, usersshall

determine hesuitabilityoftheproduct fortheirintendeduse,and

usersassumeall iskandliabilitywhatsoeverin connection

therewith.

Table of contents

Popular Power Tools manuals by other brands

Wassermann Dental-Maschinen

Wassermann Dental-Maschinen HSM-500 user manual

Dexter Power

Dexter Power CMT18LD user manual

Pace

Pace TD-100 Operation and maintenance manual

Makita

Makita DHR202SYE instruction manual

Central Hydraulics

Central Hydraulics 45860 Operating information

EXTOL PREMIUM

EXTOL PREMIUM 8894570 Translation of the original user manual