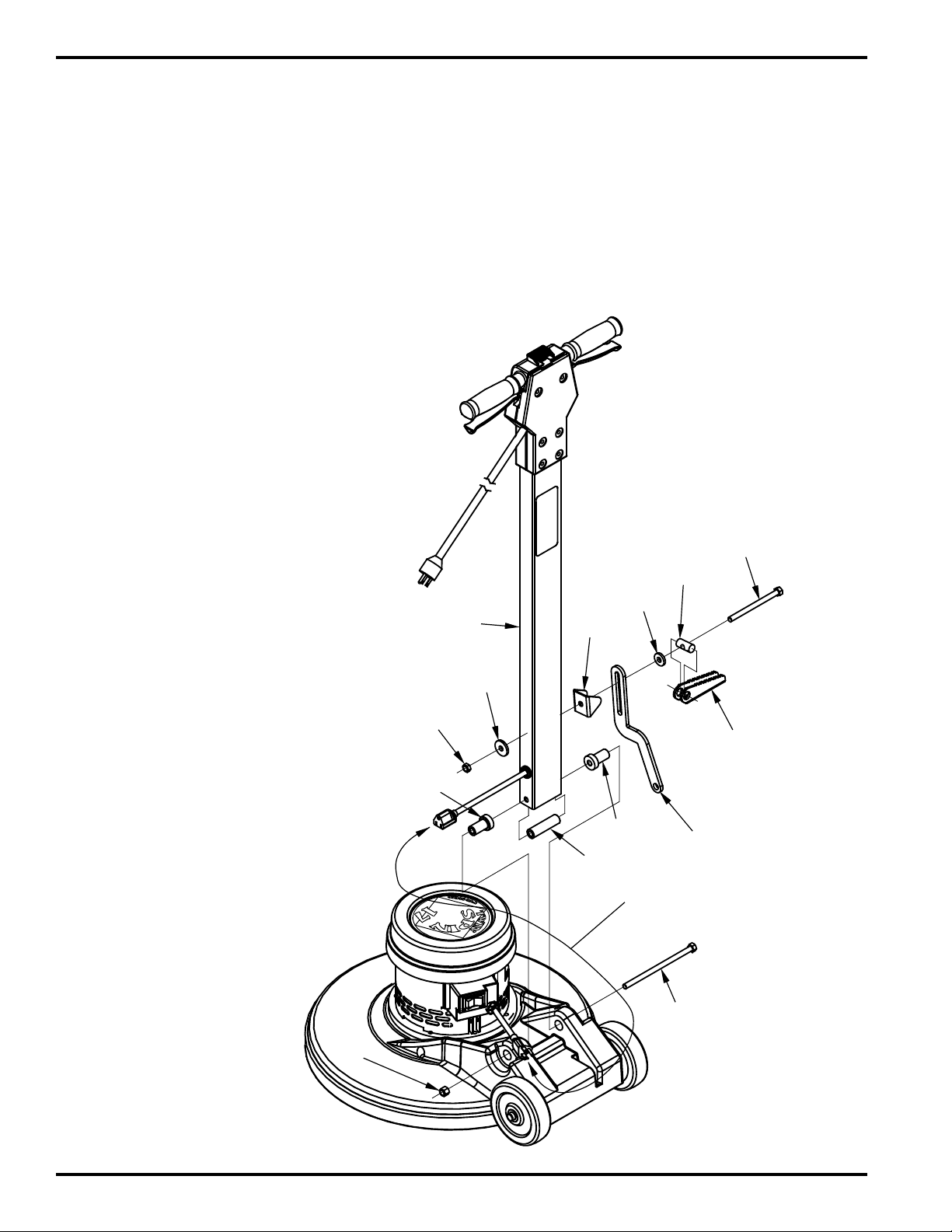

4 - FORM NO. 041332 / TWIN SPIN 17/20

IMPORTANTES MESURES DE SÉCURITÉ

L’utilisation d’un appa eil élect ique demande ce taines p écautions:

LIRE TOUTES LES INSTRUCTIONS AVANT DE FAIRE FONCTIONNER (CET APPAREIL)

AVERTISSEMENT:

Pou édui e les isques d’incendie, de choc élect ique ou de blessu e:

*Ne pas laisse l’appa eil sans su veillance lo squ’il est b anché. Déb anche lo sque l’appa eil n’est pas utilisé et avant

l’ent etien.

*Pou édui e les isques de choc élect ique, utilise à l’inté ieu seulement.

*Ne pas pe mett e aux enfants de joue avec l’appa eil. Une attention pa ticuliè e est nécessai e lo sque l’appa eil

est utilisé pa des enfants ou à p oximité de ces de nie s.

*N’utilise que confo mément à cette notice avec les accessoi es ecommandés pa le fab icant.

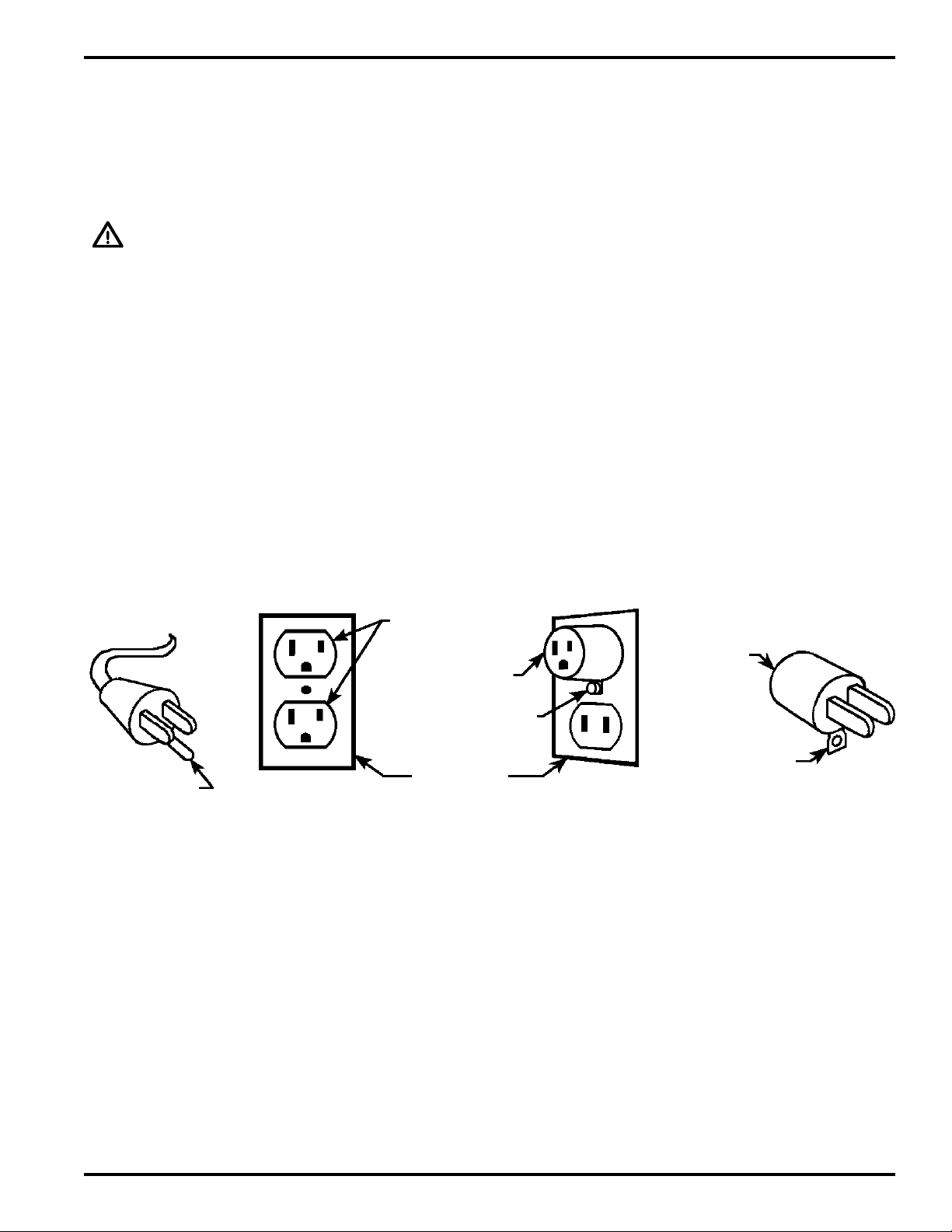

*Ne pas utilise si le co don ou la fiche est endommagé. Retou ne l’appa eil à un atelie de épa ation s’il ne fonctionne

pas bien, s’il est tombé ou s’il a été endommagé, oublié à l’exté ieu ou imme gé.

*Ne pas ti e souleve ou t aîne l’appa eil pa le co don. Ne pas utilise le co don comme une poignée, le coince dans

l’emb asu e d’une po te ou l’appuye cont e des a êtes vives ou des coins. Ne pas fai e oule l’appa eil su le co don.

Ga de le co don à l’éca t des su faces chaudes.

*Ne pas déb anche en ti ant su le co don. Ti e plutôt la fiche.

*Ne pas touche la fiche ou l’appa eil lo sque vos mains sont humides.

*N’insé e aucun objet dans les ouve tu es. Ne pas utilise l’appa eil lo squ’une ouve tu e est bloquée. S’assu e que

de la poussiè e, de la peluche, des cheveux ou d’aut es matiè es ne éduisent pas le débit d’ai .

*Mainteni les cheveux, les vêtements amples, les doigts et toutes les pa ties du co ps à l’éca t des ouve tu es et des

pièces mobiles.

*Mett e toutes les commandes à la position ARRÊT avant de déb anche l’appa eil.

*Use de p udence lo s du nettoyage des escalie s.

*Ne pas aspi e des liquides inflammables o combustibles, comme de l’essence, et ne pas fai e fonctionne dans des

end oits ou peuvent se t ouve de tels liquides.

*Ne b anche qu’à une p ise de cou ant avec mise à la te e. Voi les inst uctions visant la mise à la te e.

CONSERVER CES INSTRUCTIONS