Spinner SM100 Operator's manual

Technical Product Documentation

Serial number:

Version: SM-2-12/02

Valid until:

Article number: 61511

SPINNER WERKZEUGMASCHINENFABRIK GmbH

D-82054Sauerlach,Rudolf-Diesel-Ring24

Tel:+498104/803-0,Fax:+498104/803-19,

Tool grinder SM100

Technical product documentation

2

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Keep this Technical Product Documentation always

at the machine!

It must always be available!

Technical product documentation

3

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

I. Table of contents

1 BASIC INFORMATION............................................................................................... 1-1

1.1 Basic information...................................................................................................................................1-2

2 BASIC SAFETY INFORMATION................................................................................ 2-1

2.1 Warnings and symbols...........................................................................................................................2-2

2.2 Appropriate use .....................................................................................................................................2-2

2.3 Application limits ..................................................................................................................................2-3

2.4 When the machine can be used..............................................................................................................2-3

2.5 Working safely – Organizational measures ...........................................................................................2-3

2.6 Personnel selection and qualifications...................................................................................................2-4

2.7 General hazards on the machine ............................................................................................................2-4

2.7.1 Mechanical hazards.........................................................................................................................2-4

2.8 Special types of hazards.........................................................................................................................2-4

2.8.1 Electrical .........................................................................................................................................2-4

2.8.2 Oil, grease and other chemical substances ......................................................................................2-5

2.9 Other hazards.........................................................................................................................................2-5

3 DESCRIPTION, TRANSPORTATION, INSTALLATION INSTRUCTIONS.................. 3-1

3.1 EC Declaration of conformity................................................................................................................3-2

3.2 Application............................................................................................................................................3-3

3.3 Technical data........................................................................................................................................3-3

3.3.1 Noise emission ................................................................................................................................3-3

3.4 Elements of delivery..............................................................................................................................3-4

3.4.1 Basic equipment..............................................................................................................................3-4

3.4.2 Special equipment...........................................................................................................................3-4

3.5 Transportation of the packed machine...................................................................................................3-5

3.6 Installation instruction...........................................................................................................................3-6

4 OPERATING ELEMENTS........................................................................................... 4-1

4.1 Clamping lever.......................................................................................................................................4-2

4.2 Operating elements................................................................................................................................4-2

4.3 Device to suck off the dust ....................................................................................................................4-3

5 ELECTRICAL CONNECTION..................................................................................... 5-1

5.1 Electrical connection .............................................................................................................................5-2

6 MAINTENANCE INSTRUCTION................................................................................. 6-1

6.1 Maintenance instruction.........................................................................................................................6-2

7 QUICK CHANGE UNIT FOR GRINDING WHEEL...................................................... 7-1

7.1 Quick change unit for grinding wheel....................................................................................................7-2

8 ASSEMBLY OF THE GRINDING WHEEL FLANGE .................................................. 8-1

8.1 Assembly of the grinding wheel flange..................................................................................................8-2

8.2 Assembly fittings...................................................................................................................................8-2

8.3 Assembly...............................................................................................................................................8-2

8.4 Grinding wheels.....................................................................................................................................8-3

9 DRESSING THE GRINDING WHEEL......................................................................... 9-1

9.1 Operating elements................................................................................................................................9-2

9.2 Handling................................................................................................................................................9-2

10 UNIVERSAL SWIVEL HOLDER............................................................................. 10-1

10.1 Universal swivel holder.....................................................................................................................10-2

11 DIVIDING APPARATUS ......................................................................................... 11-1

11.1 Dividing apparatus.............................................................................................................................11-2

Technical product documentation

4

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

12 CLAMPING PLATE FOR SQUARE TOOLS........................................................... 12-1

12.1 Clamping plate for square tools.........................................................................................................12-2

13 GRINDING THE RADIUS ....................................................................................... 13-1

13.1 Grinding the radius............................................................................................................................13-2

14 GRINDING THE CUTTER....................................................................................... 14-1

14.1 Grinding the cutter.............................................................................................................................14-2

15 COOLANT UNIT..................................................................................................... 15-1

15.1 Coolant unit .......................................................................................................................................15-2

15.1.1 Recommended coolant................................................................................................................15-3

16 ACCESSORIES...................................................................................................... 16-1

16.1 Accessories........................................................................................................................................16-2

16.2 Other accessories (if not delivered with the machine).......................................................................16-3

17 CIRCUIT DIAGRAM................................................................................................ 17-1

17.1 Circuit diagram..................................................................................................................................17-2

18 MICROSCOPE ....................................................................................................... 18-1

18.1 Mikroskope........................................................................................................................................18-2

18.1.1 Axial adjustment of the microscope............................................................................................18-2

18.1.2 Radial adjustment of the microscope...........................................................................................18-3

Technical product documentation

5

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

II.Index

A

Accessories ....................................................................................................................................................................3-4; 16-3

Adjusting the clearance angle ................................................................................................................................................10-5

Adjustment scale....................................................................................................................................................................10-4

Appropriate use........................................................................................................................................................................2-2

C

Centering bracket...................................................................................................................................................................13-2

Circuit diagram......................................................................................................................................................................17-2

Clamping plate for square tools .............................................................................................................................................12-2

Connection of the coolant pump..............................................................................................................................................5-3

Contacting aid........................................................................................................................................................................13-2

Coolant unit ...........................................................................................................................................................................15-2

Cross table .............................................................................................................................................................................10-3

Cutter grinding.......................................................................................................................................................................14-2

D

Dividing apparatus.................................................................................................................................................................11-2

Dressing the grinding wheel ....................................................................................................................................................9-2

E

Electrical connection................................................................................................................................................................5-2

G

Grinding the cutter.................................................................................................................................................................14-2

Grinding the radius ................................................................................................................................................................13-2

Grinding wheel flange (assembly)............................................................................................................................................8-2

Grinding wheels.......................................................................................................................................................................8-3

M

Main connection ......................................................................................................................................................................5-2

Maintenance instructions.........................................................................................................................................................6-2

O

Operating elements ..................................................................................................................................................................4-2

Q

Quick change unit....................................................................................................................................................................7-2

R

Radius grinding......................................................................................................................................................................13-2

U

Universal swivel holder .........................................................................................................................................................10-2

W

Warnings and symbols.............................................................................................................................................................2-2

Technical product documentation

6

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

III. List of figures

Figure 3-1: Transportation of the grinding machine.............................................................................................3-5

Figure 3-2: Installation instruction........................................................................................................................3-6

Figure 4-1: Operating elements ............................................................................................................................4-2

Figure 4-2: Device to suck off the dust.................................................................................................................4-4

Figure 5-1: Main connection.................................................................................................................................5-2

Figure 5-2: Sockets...............................................................................................................................................5-2

Figure 5-3: Coolant pump.....................................................................................................................................5-3

Figure 6-1: Maintenance instructions for the grinding spindle .............................................................................6-2

Figure 6-2: Lubricating the swivel holder.............................................................................................................6-2

Figure 6-3: Lubricating the dividing apparatus.....................................................................................................6-3

Figure 7-1: Quick change unit - lever “closed“.....................................................................................................7-2

Figure 7-2: Quick change unit - lever “open“.......................................................................................................7-2

Figure 7-3: Quick change unit - changing the grinding wheel..............................................................................7-3

Figure 8-1: Assembly fittings................................................................................................................................8-2

Figure 8-2: Assembly............................................................................................................................................8-3

Figure 8-3: Grinding wheels.................................................................................................................................8-3

Figure 9-1: Operating elements ............................................................................................................................9-2

Figure 9-2: Handling.............................................................................................................................................9-3

Figure 10-1: Clamping lever and adjusting elements..........................................................................................10-2

Figure 10-2: Cross table......................................................................................................................................10-2

Figure 10-3: Cross table......................................................................................................................................10-3

Figure 10-4: Fine adjustment..............................................................................................................................10-3

Figure 10-5: Swivel movement...........................................................................................................................10-4

Figure 10-6: Adjustment scale............................................................................................................................10-4

Figure 10-7: Handling.........................................................................................................................................10-5

Figure 10-8: Adjusting the clearance angle ........................................................................................................10-5

Figure 11-1: Dividing apparatus.........................................................................................................................11-2

Figure 11-2: Shifting the dividing apparatus ......................................................................................................11-2

Figure 11-3: Adjusting the dividing scale...........................................................................................................11-3

Figure 11-4: Handling.........................................................................................................................................11-3

Figure 11-5: Indexing.........................................................................................................................................11-4

Figure 11-6: Grinding.........................................................................................................................................11-4

Figure 12-1: Clamping plate...............................................................................................................................12-2

Figure 12-2: Clamping bracket of the camping plate..........................................................................................12-2

Figure 12-3: Stopper...........................................................................................................................................12-3

Figure 13-1: Centering bracket...........................................................................................................................13-2

Figure 13-2: Contacting the tool.........................................................................................................................13-2

Figure 13-3: Contacting the tool.........................................................................................................................13-3

Figure 13-4: Adjusting the radius.......................................................................................................................13-3

Figure 13-5: Adjusting the radius.......................................................................................................................13-4

Figure 13-6: Adjusting the clearance angle ........................................................................................................13-5

Figure 13-7: Turning angle.................................................................................................................................13-5

Figure 13-8: Grinding the radius.........................................................................................................................13-6

Figure 13-9: Grinding the radius.........................................................................................................................13-6

Figure 13-10: Grinding the radius.......................................................................................................................13-7

Figure 13-11: Grinding the radius.......................................................................................................................13-7

Figure 14-1: Halving the cutter...........................................................................................................................14-2

Figure 14-2: Halving the cutter...........................................................................................................................14-2

Figure 14-3: Grinding the cutter.........................................................................................................................14-3

Figure 14-4: Setting the turning angle ................................................................................................................14-3

Figure 14-5: Adjusting the turning angle............................................................................................................14-4

Figure 14-6: Setting the clearance angle.............................................................................................................14-4

Figure 14-7: Grinding the cutter.........................................................................................................................14-5

Figure 14-8: Grinding the cutter.........................................................................................................................14-5

Figure 14-9: Handling.........................................................................................................................................14-6

Figure 14-10: Grinding the cutter relief..............................................................................................................14-6

Figure 14-11: Grinding the cutter relief..............................................................................................................14-7

Figure 14-12: Milling cutter ...............................................................................................................................14-7

Figure 15-1: Coolant unit....................................................................................................................................15-2

Figure 15-2: Coolant hose ..................................................................................................................................15-3

Technical product documentation

7

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Figure 18-1: Microscope ....................................................................................................................................18-2

Figure 18-2: Axial adjustment of the microscope...............................................................................................18-2

Figure 18-3: Radial adjustment of the microscope .............................................................................................18-3

1-1

SPINNER Werkzeugmaschinenfabrik GmbH

SM-1-03/02

Basic information

Technical Product Documentation

Machine type: Tool grinder SM100

Serial number:

Version: SM-1-03/02

Valid until:

Article number: 61511E

1 Basic information

1-2

SPINNER Werkzeugmaschinenfabrik GmbH

SM-1-03/02

Basic information

1.1 Basic information

This technical product documentation should make it easier for you to familiarize yourself

with the machine and use the machine in accordance with its intended areas of

application.

The document contains important information on how to safely, correctly and

economically use the machine. Paying close attention will help you to avoid hazardous

situations, reduce repair costs and down-times and increase the reliability and life span of

the machine.

The technical product documentation includes instructions on how to prevent accidents

and help protect the environment in accordance with the existing national laws relating to

these subjects. The documentation must always be available at the location where the

machine is used.

The documentation is to be read and used by everyone who works on the machine, for

example, persons who are assigned to carry out the following tasks:

− Operation, including setup, correcting errors in the work procedure, care and disposal of

operational and additional materials

− Maintenance (maintenance, inspection, repair) and/or

− Transportation

The recognized technical regulations relating to the safe operation and appropriate usage

of the machine are to be observed in addition to the technical product documentation and

the applicable regulations relating to accident prevention in the country where the

machine is used.

The personnel assigned to carry out tasks on the machine must have read and

understood the technical product documentation, especially the chapter "Basic safety

instructions", before he or she begins working on the machine. It is too late to start

reading this material once you have started working. The basic safety instructions must

be observed.

The technical product documentation was created in accordance with the following

guidelines and norms:

− Machine guideline 89/392/EC of the commission dated June 14, 1989 to

standardize the legal guidelines of the member states for machines in draft

93/68/EC

− VDI 4500 Sheet 1: Technical documentation – Information for user (1995)

− DIN V 8418: User's information – References for the presentation (1988)

− DIN EN 292 Part 1 and 2: Safety of machinery – Basic terminology, methodology

(1991)

The Spinner company reserves the right to make changes at any time to the product

without prior notification. In addition, the information contained in this technical product

documentation can be changed without prior notification.

The SPINNER company assumes no responsibility for faults and consequential damage

which arises due to the use or misinterpretation of the information in this documentation.

1-3

SPINNER Werkzeugmaschinenfabrik GmbH

SM-1-03/02

Basic information

This technical product documentation contains copyright information protected by

copyrights. All rights reserved. It is not permitted to reprint, photocopy or store this

technical product documentation or any excerpt on an electronic storage medium without

the expressed consent of the Spinner company.

Spinner Werkzeugmaschinenfabrik GmbH

2-1

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Basic safety information

Technical Product Documentation

Machine type: Tool grinder SM100

Serial number:

Version: SM-2-12/02

Valid until:

Article number: 61511E

2 Basic safety information

2-2

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Basic safety information

2.1 Warnings and symbols

The following designations and symbols are used for especially important information in

this technical product documentation:

F

2.2 Appropriate use

The machine is built in accordance with the current state of the technology and

recognized safety regulations. However, the machine can be a source of danger when it

is not used by trained, or at least instructed, personnel, or when it is used incorrectly or

for something for which it is not intended. The following can occur in these cases:

• Danger of bodily injury or death of the user or others

• Damage to the machine and other material goods belonging to the user

• Inefficient operation of the machine

Only use the machine when it is in technically perfect condition and for its intended

purpose, and be aware of the hazards and safety instructions stated in this technical

product documentation! In particular, correct (or have someone correct) any malfunctions

that affect the safety of the machine immediately!

The machine is only to be used for tool grinding that means to manufacture and sharp

small cutting tools using the tools intended for this purpose. Both the use of this machine

for any other use and the overloading of the machine are considered inappropriate usage.

The manufacturer is not liable for any damage resulting from inappropriate use. The user

alone carries the responsibility in this case.

Appropriate use also includes the observance of the operation, maintenance and repair

guidelines as well as of the information in the technical product documentation.

You may not make any changes or structural modifications to the machine or add

equipment that may affect the safety of the machine without authorization from the

supplier. This also applies to the installation and setup of safety equipment.

NOTE

Special statements/information regarding the (economic) use of

the machine

DANGER

Information, regulations and prohibitions to prevent bodily harm

CAUTION

Special information, regulations and prohibitions to prevent

damage to equipment and materials

2-3

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Basic safety information

2.3 Application limits

The application limits are determined by the maximum values of the machine, especially

those for:

• Largest radius that can be ground

• Largest adjustment of the swivel holder parallel to the grinding spindle

• Largest adjustment at the side over the cross slide

• Length of the clamping collet

These values are listed in the technical data. Familiarize yourself with this data before

using the machine to avoid severely damaging the machine.

2.4 When the machine can be used

• You are only to operate the machine when all safety equipment and safety-

related equipment, e.g. removable safety equipment or exhaust equipment, are

available and function properly!

2.5 Working safely – Organizational measures

• Do not carry out any work steps that negatively affect the safety of the machine!

• All information on hazards on the machine are to be observed!

• All safety information and information on hazards on the machine are to be

maintained in a readable format together with all related documentation!

• The personnel should not have long exposed hair or wear loose clothing or

jewelry (including rings), otherwise there is a danger of bodily harm (e.g. when

clothing gets caught or the operator is pulled into the machine)! The operator

must conform to the personal safety measures in the national regulations related

to accident prevention (hair net, protective goggles, gloves, ear plugs or related

gear, protective steel-tipped shoes, etc.)!

• Check at regular intervals to ensure that the personnel are aware of the safety

measures and dangers in accordance with the technical product documentation!

• The responsibilities for the various tasks to be carried out in conjunction with the

operation of the machine must be clearly defined and maintained so that there

are no undefined areas of responsibility when it comes to safety! When making

changes to the machine that affect its safety or changing the way you operate

the machine, switch off the machine immediately and inform the office/person

responsible!

• Original parts and accessories are specially designed for this machine. We would

especially like to call your attention to the fact that original parts and accessories

not supplied by us have also not been tested and released by us! The installation

and/or the use of such products can therefore negatively affect the structural

properties of the machine! The manufacturer is not liable for any damage that

results from the use of parts and accessories that are not original parts and

accessories!

• Observe the fire prevention regulations when handling flammable materials!

• Switch off the machine immediately and lock it when a malfunction occurs! Have

the malfunction corrected as soon as possible!

• Before switching on or engaging the machine, make sure that no one will be

placed in a hazardous situation as a result of the machine startup!

• Observe and maintain the prescribed setup, maintenance, and inspection tasks

and schedules, including those specifications regarding the exchanging of

parts/components, in the technical product documentation! These tasks may only

be carried out by trained personnel!

2-4

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Basic safety information

• If the machine is switched off completely for maintenance and repair work, then it

must be protected against an unexpected startup!

• Ensure that the operational and auxiliary materials, as well as old, exchanged

parts, are disposed of in a safe and environmentally sound manner!

• The operator must also make sure that no unauthorized persons work on the

machine!

• The operator is required to inspect the machine at least once per shift for

external damage and defects, and to inform the appropriate persons when a

change is discovered that affects the safety (and operation) of the machine!

• If the safety equipment needs to be removed when adding new equipment to the

machine or when carrying out maintenance or repair work, then the safety

equipment must be remounted and inspected immediately after the maintenance

and repair work is completed!

2.6 Personnel selection and qualifications

• Allow only trained or instructed personnel to work on the machine! Clearly define

which persons are responsible for the operation, equipping, maintenance and

repair of the machine!

• Make sure that the only persons that work on the machine are those assigned to

work on the machine!

• Personnel in training, receiving instructions or who are still in a general training

program are only to be allowed on the machine when under constant supervision

by experienced personnel!

• Work done on the electrical equipment of the machine may only be carried out

by an electrician or by trained personnel under the guidance and supervision of

an electrician in accordance with the regulations relating to electrical systems!

Work done on the hydraulic equipment of the machine may only be carried out

by personnel with special knowledge and experience in hydraulics! The

appropriate tools and equipment must be available!

2.7 General hazards on the machine

2.7.1 Mechanical hazards

• Danger of bodily injury in the form of bruises, cuts, bumps, stab wounds,

abrasions or any other injuries resulting from getting pulled into the machine,

etc.! These dangers are presented mainly by the moving machine parts, sharp-

edged workpieces/ sharp chips and filings, sharp tools, etc.! Do not reach into

moving machine parts!

2.8 Special types of hazards

2.8.1 Electrical

• Use only original circuit breakers with the prescribed current and voltage ratings.

Switch off the machine immediately when a malfunction in the electrical supply of

the machine is discovered!

• Work done on the electrical equipment or operating materials of the machine

may only be carried out by an electrician or by trained personnel under the

guidance and supervision of an electrician in accordance with the regulations

relating to electrical systems.

• Machine and equipment parts on which inspection, maintenance and repair work

must be done may not carry current or be under voltage when conducting such

work! Switch off the corresponding equipment!

2-5

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Basic safety information

• The electrical equipment of a machine is to be inspected regularly. Defects such

as loose connections must be repaired immediately!

2.8.2 Oil, grease and other chemical substances

• You must observe the applicable safety regulations for the product when

handling oil, grease and other chemical substances!

2.9 Other hazards

There is still a small potential for danger that cannot be eliminated even if you have taken

all safety precautions. These dangers may only arise under certain circumstances or

cannot be recognised as hazardous. We would especially like to point out that you should

pay attention every time you use the machine. Inattention can lead to bodily injury and

damaged equipment.

3-1

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Description, Transportation, Installation instructions

Technical Product Documentation

Machine type: Tool grinder SM100

Serial number:

Version: SM-2-12/02

Valid until:

Article number: 61511E

3 Description, Transportation, Installation

instructions

3-2

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Description, Transportation, Installation instructions

3.1 EC Declaration of conformity

EC Declaration of conformity

as defined by the EC machine direction 98/37/EC

EC direction Electromagnetic compatibility 89/336/EEC

EC direction Low voltage 73/23/EEC

The machine

Description Tool grinder

Type SM100

Serial number

has been developed, designed and built according to the above mentioned EC directions in the own

risk of:

Company SPINNER Werkzeugmaschinenfabrik GmbH

Rudolf-Diesel-Ring 24

D-82054 Sauerlach (bei München)

Tel.: +49 8104/803-0; Fax: +49 8104/803-19

E-Mail: [email protected]; [email protected]

If the machine has been modified or changed by the enduser, this certificate is not valid any more.

The following harmonised standards have been used:

EN 294 EN 13218

EN 292 T1 EN 61000-6-2

EN 563 EN 61000-6-4

EN 954-1 EN 60204 T1

Sauerlach, December 2002 .......................................................................

Nicolaus Spinner, Dipl. Ing (FH)

(Authorized signatory)

3-3

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Description, Transportation, Installation instructions

3.2 Application

The series SM100 is a small and compact grinding machine which can be used in a large

number of applications in workshops. The machine serves only to produce and grind

small cutting tools. The machine can be delivered as table machine or as machine with

coolant tank and base.

You can use grinding wheels with an outer diameter up to 100mm and a drilling of 25mm.

The max. height of the wheel is 50mm.

The machine can be equipped from a simple hand support on up to a comfortable dividing

apparatus. The grinding wheels can be changed in a matter of seconds by means of a

quick change unit which is patented.

3.3 Technical data

Electrical connection 230V AC, 50/60Hz

Power of the drive motor 250 watt

Revolutions per minute of the drive motor 2800 rpm

Revolutions per minute of the grinding spindle 4500 rpm

Largest radius that can be ground

- with swivel holder ca. 20

- with dividing apparatus ca. 10

Largest adjustment of the swivel holder parallel to the

grinding spindle

- Coarse adjustment by hand ca. 120

- Fine adjustment by micrometer ca. 15

Largest adjustment to the side over the cross slide ca. +/-10mm

Largest longitudinal adjustment

- of the tool holder plate ca. 30mm

- of the dividing apparatus ca. 50mm

Dividing apparatus

- Scale 360 degrees

- Engaging disk 12 fold

- Clamping collet 355 E up to 17.5mm,

alternatively W25 up to

25mm or with reduction

sleeve collets W20 up to

20mm

3.3.1 Noise emission

Determined sound pressure level according to the engineering method in an essential

free field over a reflecting plane DIN EN ISO 3744

Emission sound pressure level at a work station according to DIN EN ISO 11204

Condition of work: Sharpening a cutting tool = 74 dB(A)

3-4

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Description, Transportation, Installation instructions

3.4 Elements of delivery

3.4.1 Basic equipment

Table machine with base plate (basic machine SM100)

1 Technical manual

1 Socket screw wrench, 5mm, 6edges

1 Grease gun, 1 cable

1 socket wrench/box spanner for grinding wheel flange

Basic body with motor and complete electrical equipment 230V, 50/60 Hz

Quick change device for grinding wheel

Grinding wheel cover with wheel dresser without diamond

T-groove ledge to fix accessories

3.4.2 Special equipment

1) Grinding wheel flange

2) Grinding wheels in form T/I/II/III

3) Dressing diamond

4) Support for the hands (all-round adjustable)

5) Swivel holder with cross slide

6) Support for square tools with clamp

7) Dividing apparatus for collets 355E up to 17,5mm

8) Dividing apparatus for collets W25 up to 25mm or with reducing for collets

W20 up to 20mm

9) Single collets or sets

10) Collets with special design

11) Inserts W25 with MK1/2/3

12) Special clamping device

The table machine can be extended with:

1) Base SM100

2) Tank with coolant supply

ONLY USE ORIGINAL REPLACEMENT PARTS AND

ACCESSORIES FROM SPINNER!

3-5

SPINNER Werkzeugmaschinenfabrik GmbH

SM-2-12/02

Description, Transportation, Installation instructions

3.5 Transportation of the packed machine

The machines are delivered as shown in the figures below. Only transport the good with a

lift truck of appropriate length! We recommend to unpack and install the machine only on

the installation site. Lift the machine carefully from the pallet.

Figure 3-1:Transportation of the grinding machine

THE MACHINE SHOULD SET DOWN WITH EXTREME CARE!

MAKE SURE THAT THE TRANSPORTATION GOOD DOES NOT

FALL!

Weight: about 150kg

Weight: about 50kg

Table of contents

Popular Grinder manuals by other brands

Bosch

Bosch GWS Professional 22-180 LV Original instructions

Grizzly

Grizzly H6193 instruction sheet

Elektra Beckum

Elektra Beckum Double Grinding Machine SL 125 W Mode d'emploi et liste des pieces detaches

Rupes

Rupes GL040 Operating and maintenance instructions

Makita

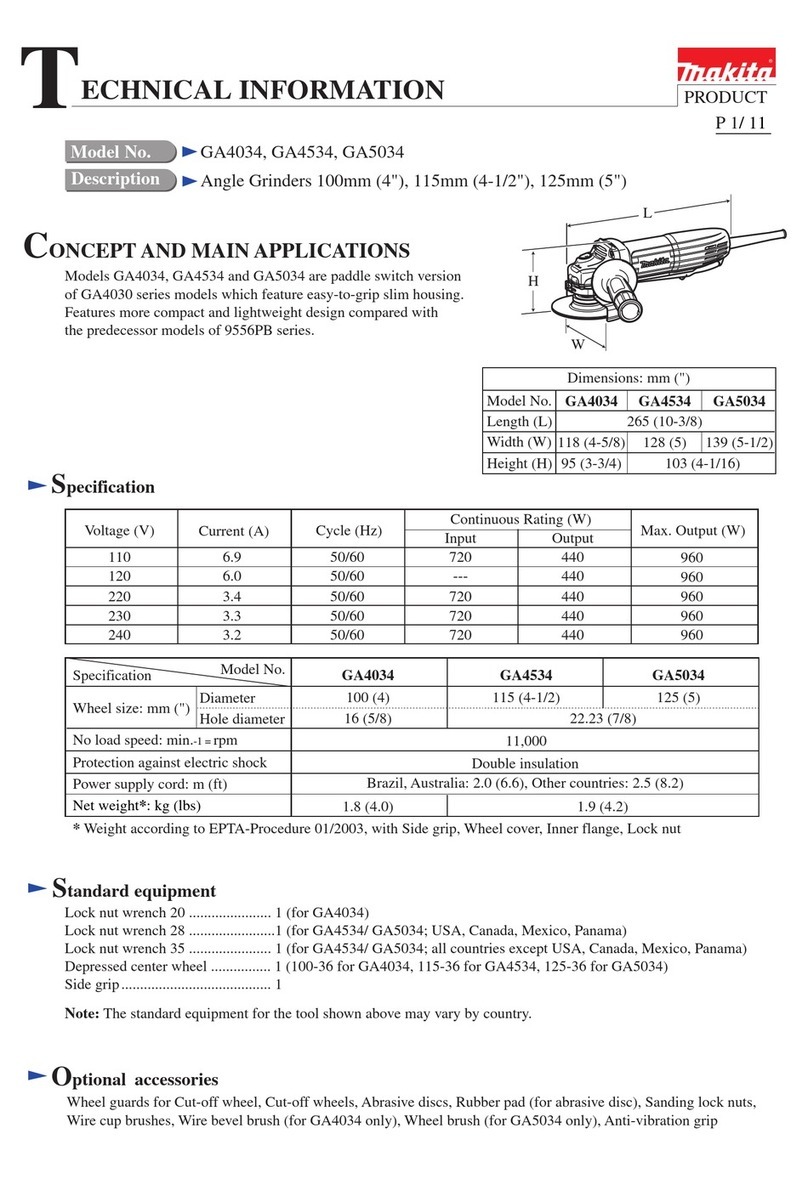

Makita GA4034 technical information

Universal Tool

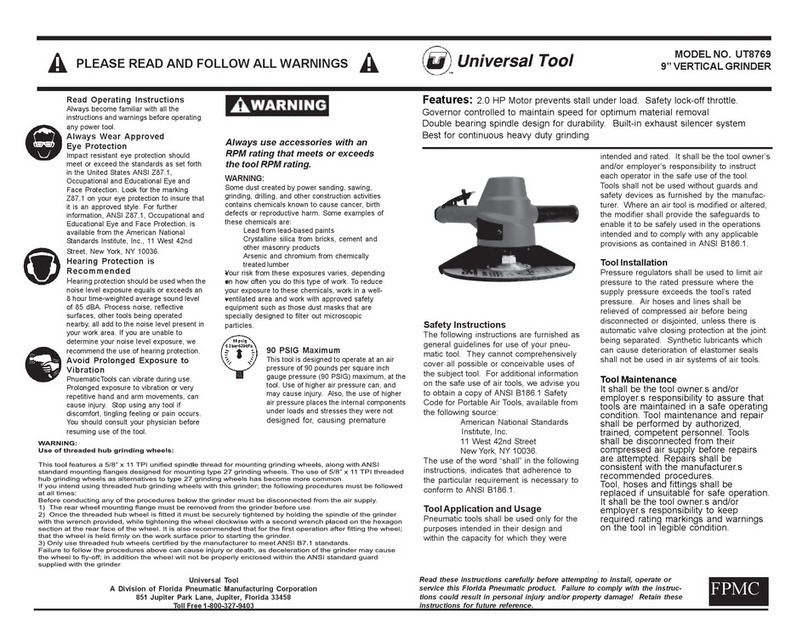

Universal Tool UT8769 operating instructions