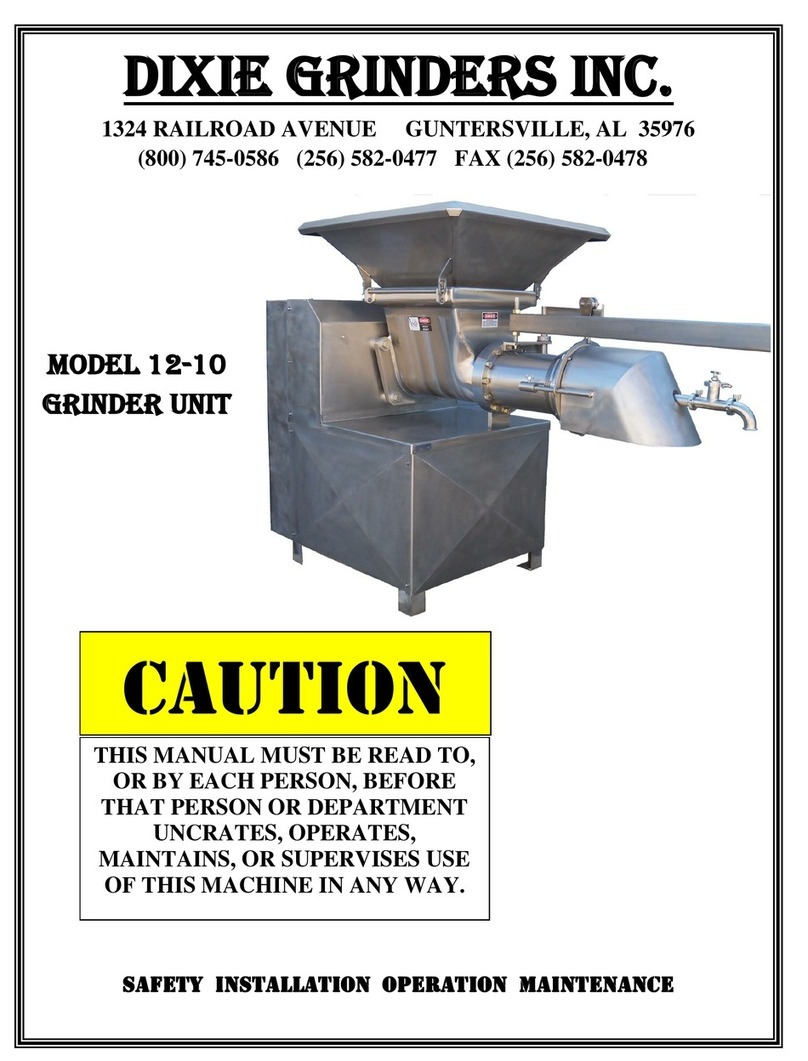

SITE CONSIDERATIONS:

It is important that the permanent position of

the grinder unit provides clearance of several

feet behind, to either side, and approximately

eight feet or more in front of the grinder unit.

If the grinder is set on a stand, or leg extensions

are attached, an adequate platform must be

provided to provide safe access to the grinder

unit. It will be necessary to have an approved

platform or device to provide access so the unit

can be properly sanitized, disassembled,

assembled, and maintained. Consideration

must be given to allow for complete service to

the grinder unit.

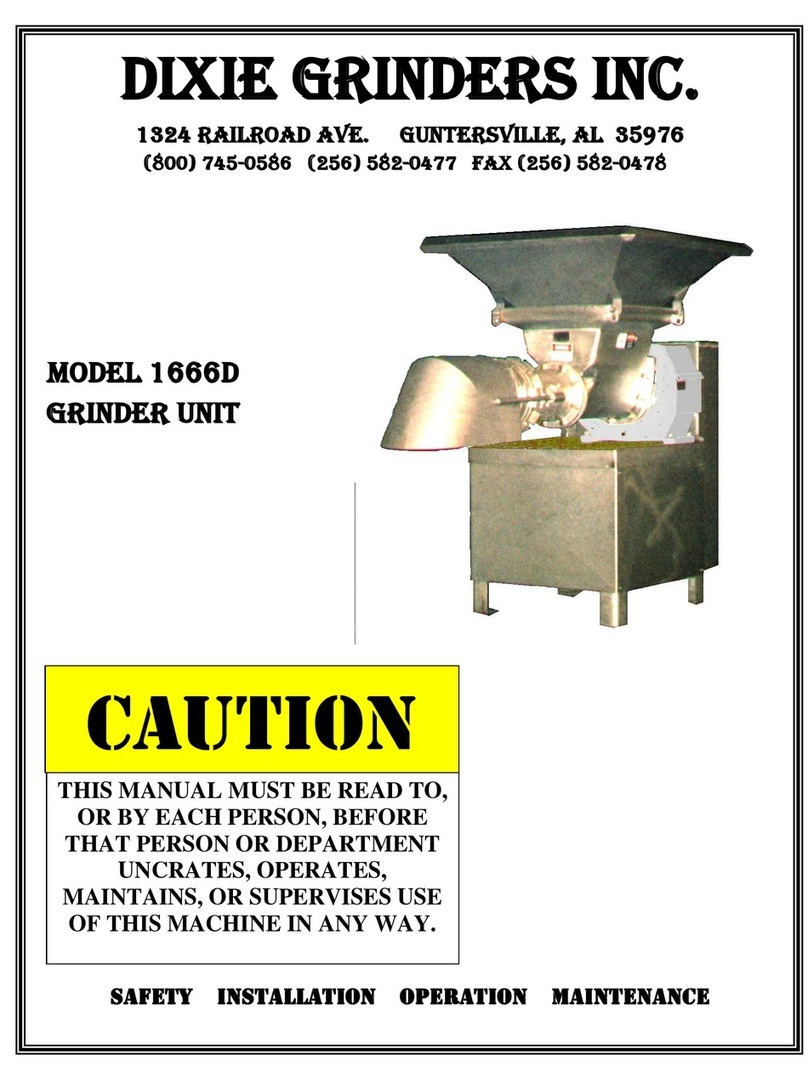

Platforms should be so designed not to make

the hopper guard, or other guarding,

ineffective. The hopper guard is not a hopper

for holding a large amount of material, it is

designed to keep the operator away from the

feedscrew. If the location of this grinder unit

compromises this feature, special guarding may

be necessary. Consult your Safety Engineer,

Plant Engineer, and O.S.H.A. for all regulations

related to the guarding of this machine.

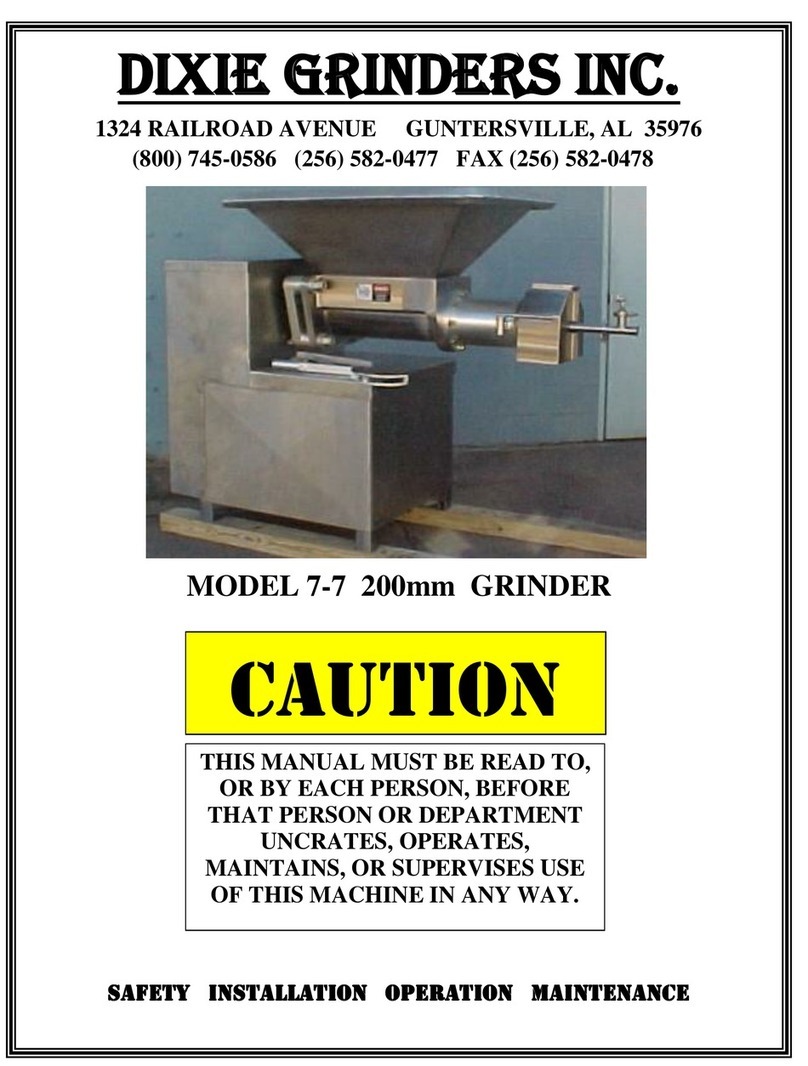

Only the feedscrew puller and ring lift can be

attached to the grinder unit directly. Do not

use the grinder frame to support other

equipment without prior approval from Dixie

Grinders Inc. The grinder frame is not to be

used as a personal stand, and under no

circumstances should anyone be allowed to

climb on it or use it as a platform. Remember

to Work Safely!

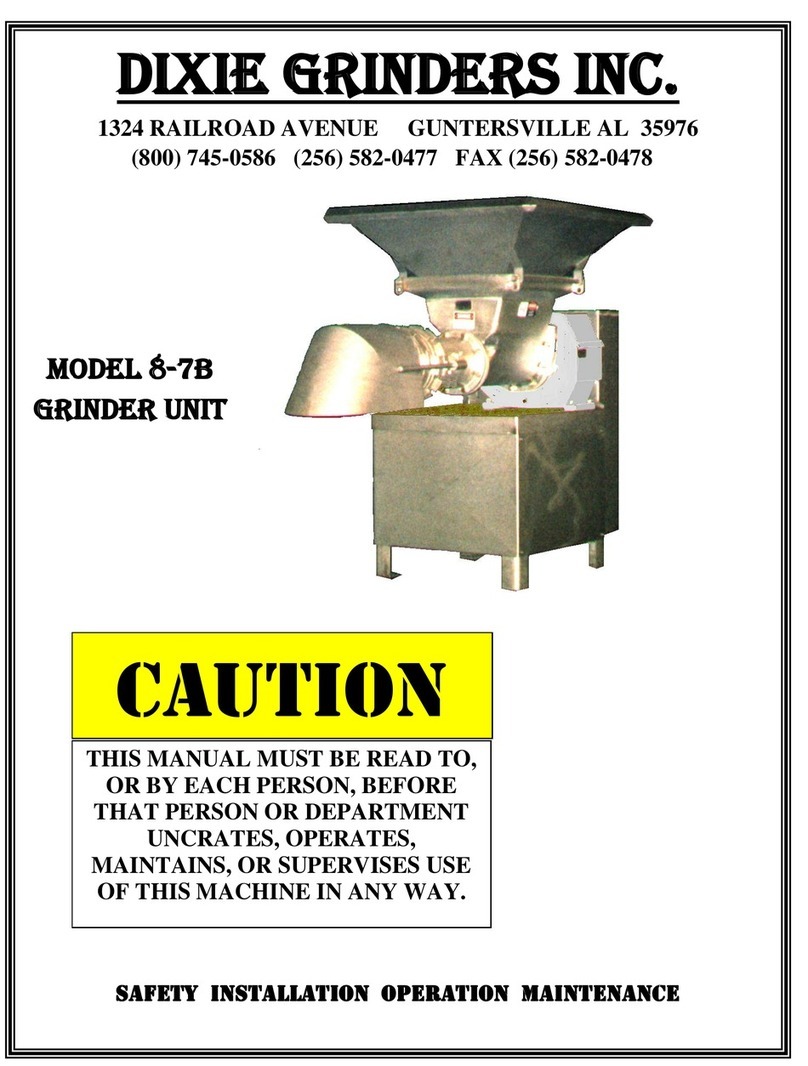

"THE GRINDER HAS ARRIVED"

LIFT EQUIPMENT REQUIRED:

We recommend using a 5,000 pound capacity

fork lift with 48" or longer forks. Do not

attempt to unload the grinder unit from a

commercial van from ground level! Only

authorized and properly trained equipment

movers should attempt to unload the grinder

unit. Remember to Work Safely!

PRE-UNLOADING INSPECTION:

Before the grinder unit is unloaded, inspect the

unit for any damage before unloading. If the

machine is damaged consult your management,

the trucking company, and Dixie Grinders Inc.

before unloading the machine!

UNLOADING GRINDER UNIT:

With the commercial van properly chocked and

secured to the loading dock, and using only

approved and adequate dock plates should any

attempt be made to unload this machine. Lift

only under the grinder frame, never attempt to

pick up a grinder from the hopper or gearbox.

The forks should be long enough to extend

beyond the end of the frame a safe distance.

Unload the grinder unit and all parts that have

been shipped with the grinder unit. Consult the

packing slip to insure that all pieces have been

unloaded.

UNPACKING:

When the grinder has been properly unloaded it

should be placed in a suitable location for

unpacking. The belt guard protector and the

shipping skids may be removed. Remove any

spare parts that may have been shipped in the

grinder hopper. Use appropriate equipment

and appropriate personal safety equipment in

this process. Remember to Work Safely!

5