Spitznas 2 2418 0010 User manual

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 1 of 11

Hydraulic

Rotary Hammer

Type 2 2418 0010

also for underwater application

Illustration can differ from the original

Operation and

Maintenance Manual

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 2 of 11

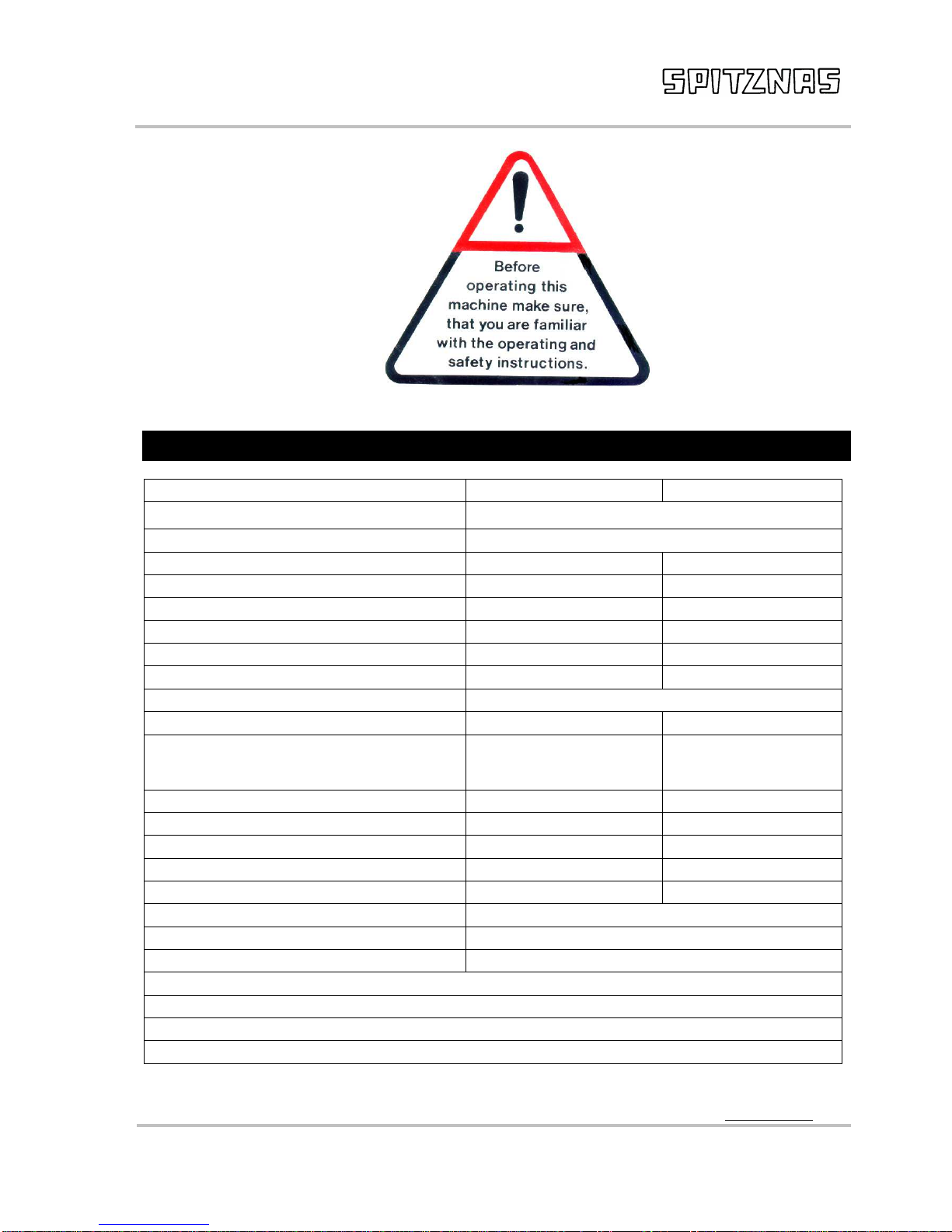

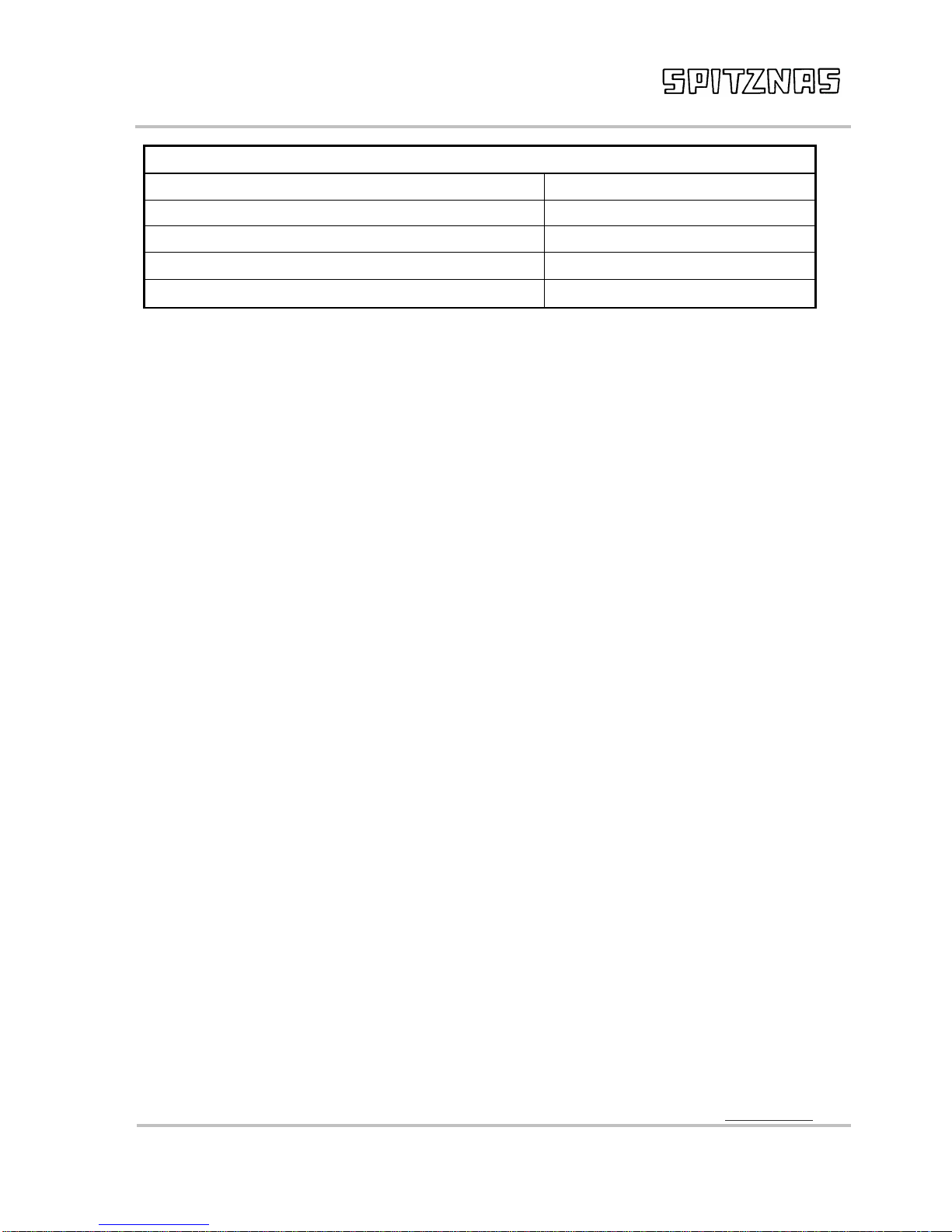

TECHNICAL SPECIFICATIONS

Operating pressure

max. 1137 PSI

max.

80

bar

Oil connection machine SAE PORT No. 8 (3/4 x 16 UNF – 2 B)

Hose coupling set

Flat

-

Star A250

-

OM/OF

-

1/2”BSP

Motor output 1.6 HP 1.2 kW

Oil volume/F

low

4

–

11.9

gallons

/ min

15

-

45

l/min

Water connection ball

valve

R1/4"

R1/4"

ID of hose

0.3937 inch

10 mm

Free spe

ed

2

7

0

rpm

27

0

1/

min

Load speed

2

5

0

rpm

2

5

0

1/

min

Percussion drilling under load

0

-

2300 blows/

min

Drilling range in concrete

0.4724

–

1.9685

inches

∅

12

-

50 mm

Drilling performance in medium-hard concrete 0.7874 dia. =

7.08 cu. in =

14.57

i

nches/ m

in

∅20 mm = 116 cm

3

/min.

= 370 mm/min

Optimum performance in concrete

0.7874

–

1.57

inches

∅

20

-

40 mm

Drilling in

steel with quick

-

release chuck

0.3937

–

0.7874

inches

∅

10

-

20 mm

Drilling i

n wood with quick

-

release chuck

0.3937

–

1.2598 inch

∅

10

-

32 mm

Weight (without hoses)

30.86 lbs

14

kg

Dimensions (length x height x width)

25.2 x 4.92 x 11.73 inches

640 x 125 x 298 mm

Tool holder

SDS

Max

Sound level

at 1 m distance

92 dB(A)

Vibration

at free speed

9

m/s²

Safety clutch for protection a

gainst overloading and accidents

Gears sealed dust tight with central and permanent lubrication (maintenance free)

Adjustable side handle with depth gauge and water flushing

Supplied kit: 1 carrying case, 1 dust guard

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 3 of 11

SAFETY INSTRUCTIONS

Any tool can be dangerous.

Please follow these simple procedures.

They are for your protection.

Wear goggles ( chips – risk of injury)

Wear gloves (cutting damages by sharp edged work pieces)

Wear safety shoes

Wear protective clothing

Remove rings, watches, ties etc. that could be torn by the machine.

Dress properly. Do not wear loose clothing or jewellery, it can be caught in

moving parts.

Follow the general current and appropriate Accident Prevention and Safety

Procedures.

Never work under the influence of alcohol, drugs or stronger medication.

Always make sure that you have a safe foothold.

Maintain a proper footing and balance at all time. Never work with the machine

while standing on a ladder or leaning against a scaffold.

Secure the working place well. Use clamps or a vice to fix the work piece. This is

safer than using hands and clears both hands for operating the machine.

Hold the machine tight during operation.

Keep your working area clean and uncluttered.

Keep children away and avoid other persons to come into contact with the

machine.

Switch off the machine if it stops - for any reason - to avoid the unexpected

starting in uncontrolled condition.

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 4 of 11

Do not operate the tool if it is damaged, improperly adjusted or not completely

and correctly assembled.

Check hydraulic hose for damage.

Avoid sparks in hazardous environment - created by the drill. Always flush

material and drill for cooling with sufficient water during working.

Do not employ machines by excessive force. Their performance is better and

safer, if they work at the prescribed speed.

Check damaged parts.

Before using the machine, damaged parts or protective devices should be

carefully checked to make sure they work soundly and fulfil the designated

function. Check alignment, connections and attachment of moving parts. Also

check if parts are broken. Parts or protective devices that are damaged should, if

nothing else is mentioned in these operating instructions, only be exchanged or

repaired by qualified personnel. The same applies to defective switches and

valve triggers. If the machine cannot be switched on or off with the valve trigger,

it should not be used.

The use of other accessories, or other additional items than recommended in

these operating instructions, may include the risk of bodily injury.

Only operate the tool after a thorough training or under supervision of a trainer.

Never exceed the maximum operation pressure.

Follow the valid national provisions in the country of application.

Do not operate tool at fluid temperatures above 140° F / 60°C. Operation at

higher temperatures can cause higher than normal temperatures at the tool,

which can result in operator discomfort.

ATTENTION! Never use the hydraulic hose as a lifting handle!

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 5 of 11

Use

Intended Use

The machine is designed for drilling into concrete and masonry. The machine is intended to be

used by professional operators. Only authorized and trained personnel may use, maintain and

repair the machine. The personnel has to be especially instructed on the potential dangers. The

working environment can be: construction site, factory, renovation, rebuilding and building.

Manipulation or modifications to the machine are not allowed. Observe the instructions regarding

the operation, care and maintenance in the operation instruction. Dangers can come from the

machines and the auxiliary materials, if improperly handled or used.

Improper Use

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment

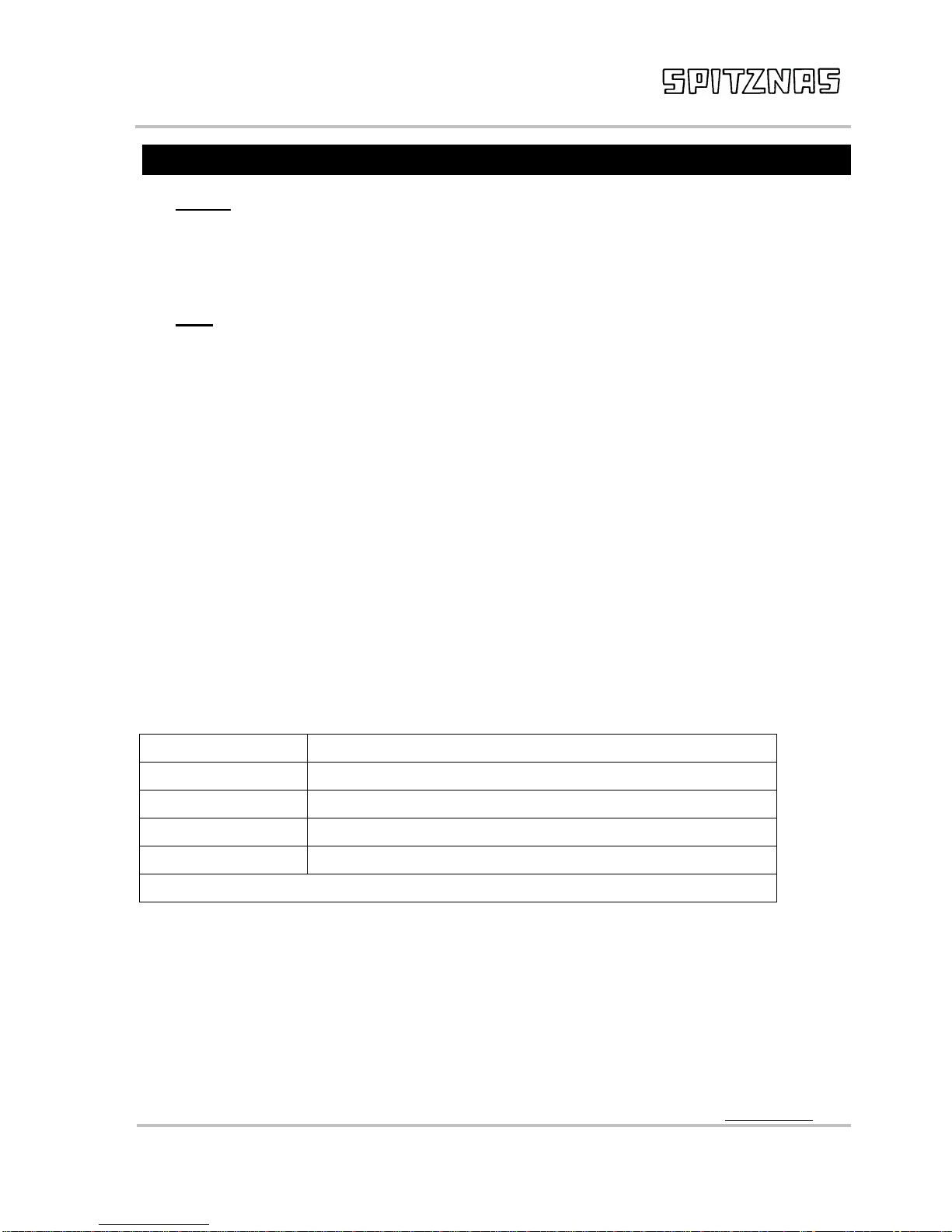

Danger Zones

Operational

condition

----------------

Life phase

Normal function Malfunction Improper use Expected use

Transport Transport of the

machine in an

inoperable

condition

Drop of the

machine Transport of the

machine in an

operable

condition

unknown

Operation

Machine only

works with

actuated switch

Machine runs

without actuated

switch

Switch is blocked

in actuated

condition

unknown

Machine moves

the tool

Tool blocks unknown unknown

Maintenance Filter at hydr.

assembly

Breakdown of the

machine unknown unknown

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 6 of 11

Hydraulic system requirements

An operation pressure of 80 bar/ 1137 PSI and a volume flow of 15 l/ min/ 4 gallons/ min is

required to achieve the specified performance data. Volume flow of more than 15 l/ min / 4 gallons/

min is conveyed back to the tank via a bypass. At pressure of more than 80 bar/ 1137 PSI,

a pressure control valve has to be used. (Pressure control valve 2 2406 9900)

WARNING!

Never use your hydraulic tool without a pressure relief valve in line!

The system should not have more than 250 PSI/ 17 bar back pressure measured at the tool end of

the operating hoses. The system conditions for measurement are at maximum fluid viscosity or

400 ssu / 82 centistokes (minimum operating temperature).

The hydraulic system should have sufficient heat rejection capacity to limit the maximum oil

temperature to 140° F / 60° C at the maximum expected ambient temperature. The recommended

minimum cooling capacity is 5 hp / 3.73 kW at a 40° F / 4° C difference between ambient

temperature and oil temperature.

The hydraulic system should have a minimum of 25 micron full-flow filtration. It is recommended

that filter elements be sized for a flow of at least 30 gpm/ 114 lpm for cold temperature startup and

maximum dirt holding capacity.

The recommended hose size is 0.500 inch / 12 mm I.D. to 50 ft / 15 m long and 0.625 inch /

16 mm I.D. minimum up to 100 ft / 30 m long.

The rotary hammer drill return hose must connect directly to the circuit return line and go straight

through the oil filter, thermal valve, and oil cooler to the reservoir. To prevent trapped or reversed

pressure, fluid should not be returned through a blocking or reversing valve.

The rotary hammer drill cannot be operated with the hydraulic flow reversed. Supply (IN) and

return (OUT) hoses must be connected as marked on the sides of the tool ports.

IMPORTANT!

Do not run the tool return hose through stack or directional valves. If the circuit is operated from a

stack valve, tap only the pressure port to the valve. Connect the tool return directly to the return

fluid line.

Your hydraulic rotary hammer drill is an open-center tool. Operate open-center tools from open-

center hydraulic circuits only. Operate closed-center tools from closed-center hydraulic circuits

only.

The rotary hammer drill can be operated with oil only.

Pay attention that the rotary hammer drill is not operated with pressure exceeding the

characteristics indicated, when power is supplied by the system.

Apply pressure reducing valves, otherwise the machine could be damaged or destructed.

When working in a surrounding at 4° C, impact interruptions can occur. Therefore it is

recommended to start the machine and warm it up first.

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 7 of 11

Characteristics

Hydraulic fluid Hydraulic oil

Feed pressure 80 bar / 1137 PSI

Volume flow 15- 45 l/ min / 4– 11.9 gallons

Temperature of oil 35°C÷80 °C

Oil filtering ISO purity degree 18/13

Equipment protection and care

Important!

In addition to the a. m. safety instructions, observe the following for equipment protection and care.

Always store the tool in a clean, dry space, safe from damage or pilferage.

Always keep critical tool markings, such as labels and stickers, legible.

Always replace hoses, couplings and other parts with replacement parts recommended by

SPITZNAS.

Supply hoses must have a minimum working pressure rating of 2500 PSI/ 175 bar.

Always use hoses that have an oil resistant inner surface and an abrasive resistant outer surface.

Whenever near electrical conductors, use clean hose labeled and certified non-conductive hose.

Tool repair should be performed by experienced personnel only.

Make sure all couplers are wiped clean before connection.

The hydraulic power supply valve must be in the "OFF" position when coupling or uncoupling

hydraulic tools. Failure to do so can result in damage to the quick couplers and cause overheating

of the hydraulic system.

Do not exceed 13.2 gpm / 50 lpm flow rate. Rapid failure of the tool's internal seals might result.

Make sure the circuit pressure hose (with female quick disconnect) is connected to the "IN" port

below the right-hand side of the tool. The circuit return hose (with male quick disconnect) is

connected to the "OUT" port below the tool center.

Do not reverse the fluid flow from that marked on the tool ports. Flows, when reversed, will not be

limited by the priority flow control valve

Always use the open-center (OC) tool on open-center circuits.

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 8 of 11

OPERATION INSTRUCTIONS

Do not exert undue pressure on the machine. This will not increase its performance. Just position

the bit and guide it into the hole.

Placing the machine into the box

Make sure the adjusting sleeve is locked at the setting "rotary hammer drilling".

Side handle

This can be turned through 360° and clamped in any desired position.

Depth gauge

Press unlock button, adjust the depth gauge and release button.

Lubrication of shank end

Occasionally clean shank ends and spray sparingly with lubricant sprayer. Do not spray into the

chuck.

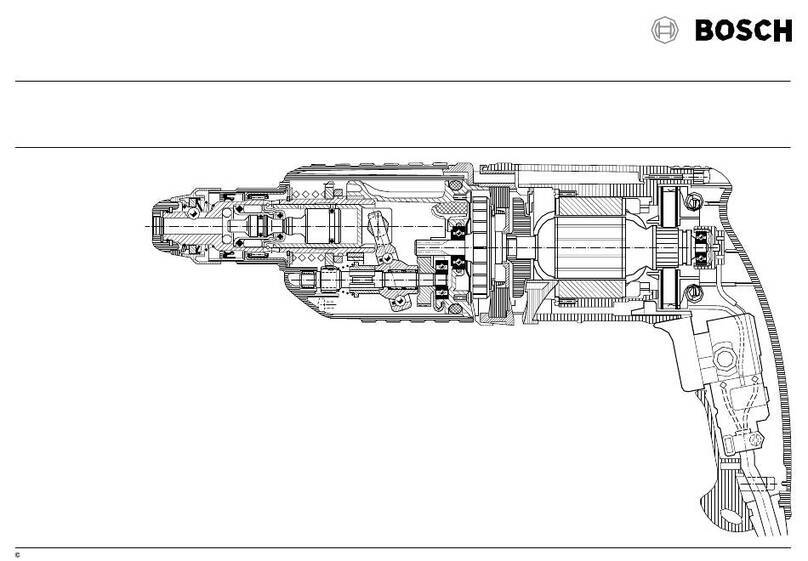

Bild 1 Bild 2 Bild 3 Bild 4 Bild 5

Drilling in explosive surroundings

Fig.1: The drill must be water cooled to avoid sparks. Water connection on ball valve

Rotary hammer drilling

Fig.2: Pull back the adjusting sleeve and turn it clockwise to lock. Do not use the quick-release

chuck at this setting because drills and tools will be damaged.

Fig.3: Pull back the locking sleeve and insert the drill. Turn the locking sleeve until it snaps back

into the outset position. Press the machine against the work surface before switching on otherwise

the tool will not hammer. If the drill sticks in the hole, withdraw and reinsert it several times when

drilling.

Fig.4: When starting to drill into brittle materials (tiles etc), unlock the adjusting sleeve to "rotary

drilling only", hold the machine by the adjusting sleeve and press it slowly against the work surface

until it hammers weakly. Hold and continue to drill the hole. Switch off the machine briefly and

relock the adjusting sleeve.

Rotary drilling only

Fig. 5: Unlock the adjusting sleeve. The quick-release chuck is used at this setting. Commercially

available twist drills can be used in the quick-release chuck.

Cold Weather Operation

If the machine is to be used during cold weather, preheat the hydraulic fluid at low engine speed.

When using the normally recommended fluids, fluid temperature should be at or above 50 °F/10 °C

(400 SSU/ 82 centistokes) before use. Damage to the hydraulic system or the machine can result

from use with fluid that is too viscous or too thick.

(400 SSU/ 82 centistokes) before use. Damage to the hydraulic system or the machine can result

from use with fluid that is too viscous or too thick.

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 9 of 11

OPERATING INSTRUCTION FOR UNDERWATER TOOLS

Before working under water

•Check the machine with regard to leakages

•Check the machine regarding functioning of all parts (drilling, striking, actuating valves, etc.)

•Spraying of all moving parts with spray OKS 8604 (or similar).

•Fitting the tools with grease.

After having worked under water

•Clean the machine

•Dry the machine by blowing out with compressed air

•Spraying of all moving parts with spray OKS 8604 (or similar).

For additional information refer to the machine specific operation and maintenance manual as

well.

For a long lasting operation of the machine we recommend a regular (every 3 months) general

overhaul by the company SPITZNAS.

Spray OKS 8601: Spitznas-part no. 9 9902 0120

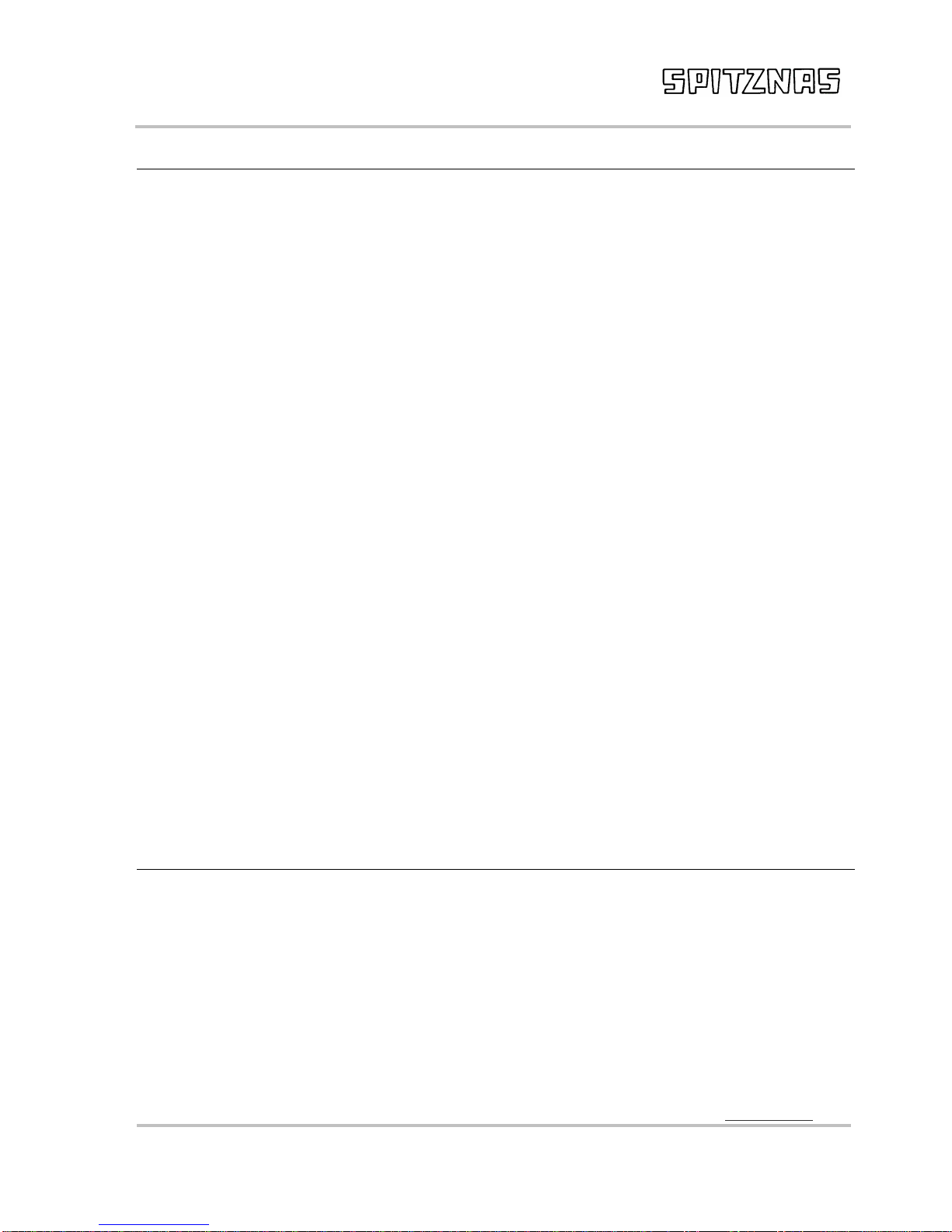

Maintenance Instruction

Good maintenance practice keeps the tool on the job and increases its service life.

The most important maintenance practice is to keep the hydraulic fluid clean at all times.

Contaminated fluid causes rapid wear and/ or failure of internal parts.

The proper quantity of grease is very important from the point of good lubrication and low heat

generation. The grease quantities listened in the following table must be complied with:

Grease Quantity in grams

In the crank casing 5

In the bevel gear 5

In the spur gear 10

In the planetary gear 10

Grease SPITZNAS reference no. 9 9902 0130 (400 g), 9 9902 0250 (100 g)

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 10 of 11

Maintenance of Hydraulic Tools

Only proper maintenance can

ensure constant performance,

reduction in wear and thus, a

decrease in operating costs and

an increase in service life.

Our hydraulic tools are equipped

for an operating pressure of up

to 100 bar. Regulator setting for

a lower operating pressure is

possible.

The tools should not run empty,

because this results in heat and

higher wear of the output section

and the tool holder.

The hydraulic oil should be

clean. This is ensured by

professional equipment.

Clean the connecting parts

before connecting the hydraulic

hoses.

For an economic use of the

hydraulic tools the required sizes

of pipe, fittings and hoses have

to be adjusted.

Proper greasing of the gear and

the tool heads is a must. See the

operation manual on this.

After finishing the work the tools

have to be cleaned and

protected against corrosion.

Visible grease nipples are

provided for regular lubrication of

the gears with a grease gun, or

the gearboxes have a long term

greasing.

Note the following for grease

lubrication: Every 60 hours of

operation check striking

mechanism, friction bearings

and antifriction bearings; if

necessary, grease them. Every

300 hours of operation grease

the gears and antifriction

bearings anew. In the case of

impact wrenches, use a grease

gun to grease the anvil guide

before beginning daily work, or

every 6-8 hours.

All inner parts of the drive (tool

holder must be lubricated before

storing for longer periods of time

in order to prevent rusting. It is

recommended to check the

vanes and bearings at regular

intervals. Store tools in dry

rooms only.

Grease to be used:

In general: SAE 5 W to SAE 10

For impact wrenches without gear only

SAE 5 W

For saw chain greasing on chain saws:

Machine oil with adhesive additive,

viscosity:

c ST 49-55’ (6,5-7,5 E)/ 50°C

GREASE (free of acids and

resins) Multi-purpose greases for

antifriction

and friction bearings and

gears

Special greases for high-speed miter

gears

Designation in accord. with DIN

51502

Consistency class (DIN 51818)

Saponification type

Dripping point

Worked penetration

Temperature range

K L 2 k

2

Lithium

185 °C

265 to 295

-25°C to + 125°C

G 000 h

00

Sodium

145°C

400 bis 410

-25°C bis + 100°C

For the operation of the hydraulic motor we recommend high-class hydraulic oil, e. g. HLP 46,

depending on the case of operation (temperature).

Hydraulic

Rotary Hammer Drill

2 2418 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 12.09.13 224180010_BA_en_Version_06 Page 11 of 11

Spare Parts and Accessories

Only original spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

The repairing of the machine is allowed authorized expert companies only.

The accessories applicable with our machine are listed in our brochure.

Troubleshooting

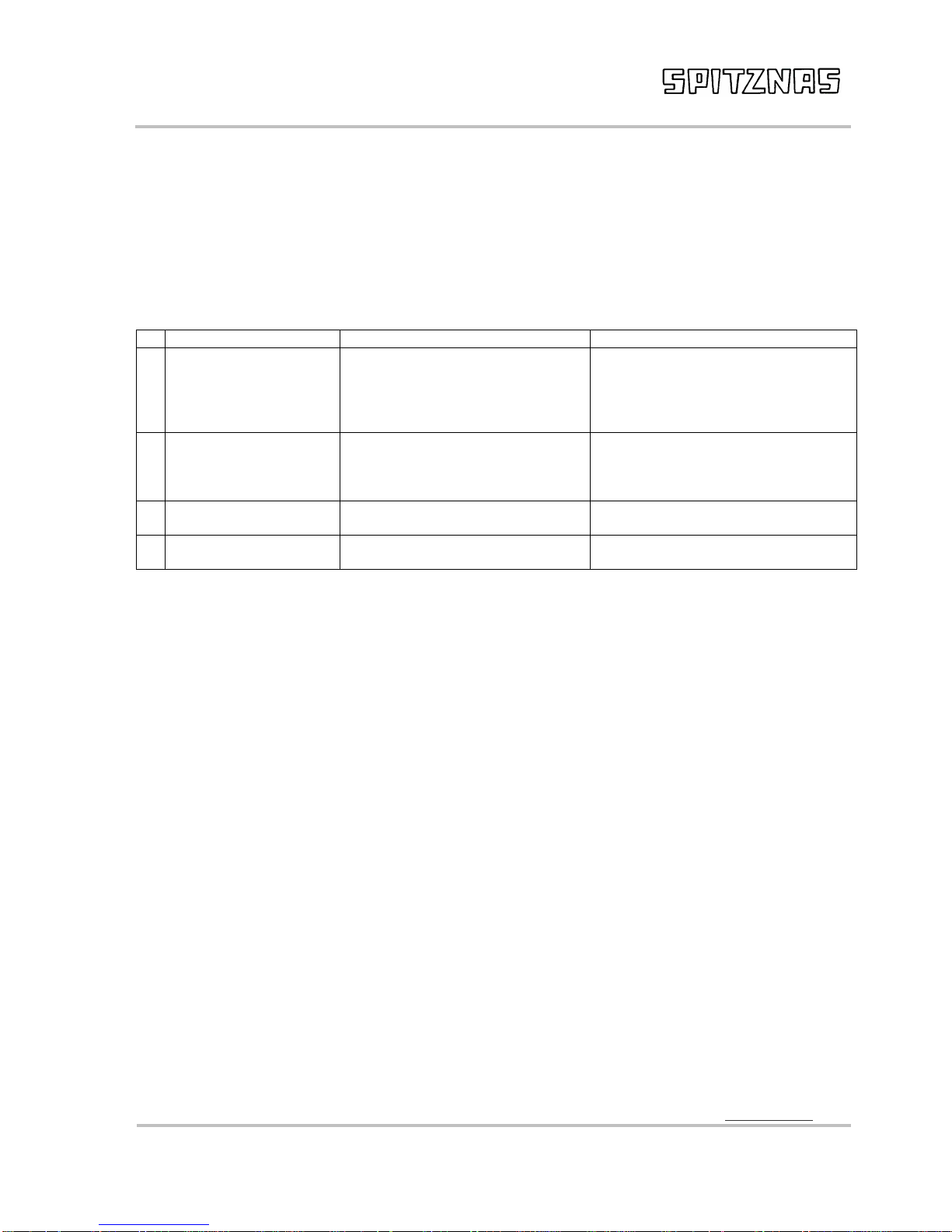

Problem Cause Remedy

a Machine does not

start No hydraulic connection

Connecting and opening of the

hydraulic line

Correct connection of hoses

b Machine rotates too

slowly Operating pressure too low

Increase operating pressure (on the

machine) to 140 bar

c Gearbox makes strong

noise Contact authorized expert company

d Other problems Contact authorized expert company

D e c l a r a t i o n o f C o n f o r m i t y

as defined in the European Union Machine Directive 2006/42/ EC

for usable machines

We, the company

SPITZNAS Maschinenfabrik GmbH, Fellerstraße 4, 42555 Velbert– Langenberg,

declare that the following product

Description: Hydraulic Hammer Drill

Model : 2 2418 0010

complies with the provisions of the European Union Machine Directive 2006/42/ EC

and conforms to the following standards or standardized documents:

DIN EN ISO 12100

DIN EN ISO 11148-5

Name of the authorized person for documentation: Mr. Simon Witt

Address of the authorized person for documentation: see manufacturer’s address

42555 Velbert, 11.02.13

Table of contents