10

Determining the optimum rotation speed needs to be carried out

in the actual application. A good rule-of-thumb is to divide 300

by the bit diameter in inches to determine RPM. This will get the

rotation speed in the ´ballpark´. However, a fine-tuned rotation

speed also needs to be correlated with penetration rate. It has

been found that a proper rotation speed usually results in a 5/8

in.- 3/4 in. (16mm - 19 mm) advance of the bit per revolution of

the DTH hammer. This measurement can normally be taken by

using chalk or soapstone to scribe a spiral on the drill pipe while

the drill is operating. The distance between the spirals (thread

pitch) can be measured to determine if rotation speed should be

increased or decreased. If the pitch is less than 5/8 in. (16 mm)

the drill RPM should be decreased, if it is more than 3/4 in. (19

mm) the drill RPM should be increased.

The picture following shows an example of the marks left on a

drill pipe when using chalk to mark the advance of the drill.

Another method for setting rotation speed involves observing

the wear flat developed on the gage (outer) carbide. The wear

flat on the should be directly on the top of the inserts. A flat

which is on the leading edge of carbide (side facing the direction

of rotation) indicates rotation speed is too slow. Conversely,

rotating too fast will cause rapid wear of the bit and the wear flat

will be on the trailing edge of the carbide.

Note: Due to the higher penetration rate of QLX drills over

conventional valveless drills, rotation speed will normally need

to be increased in proportion to the increase in drilling speed.

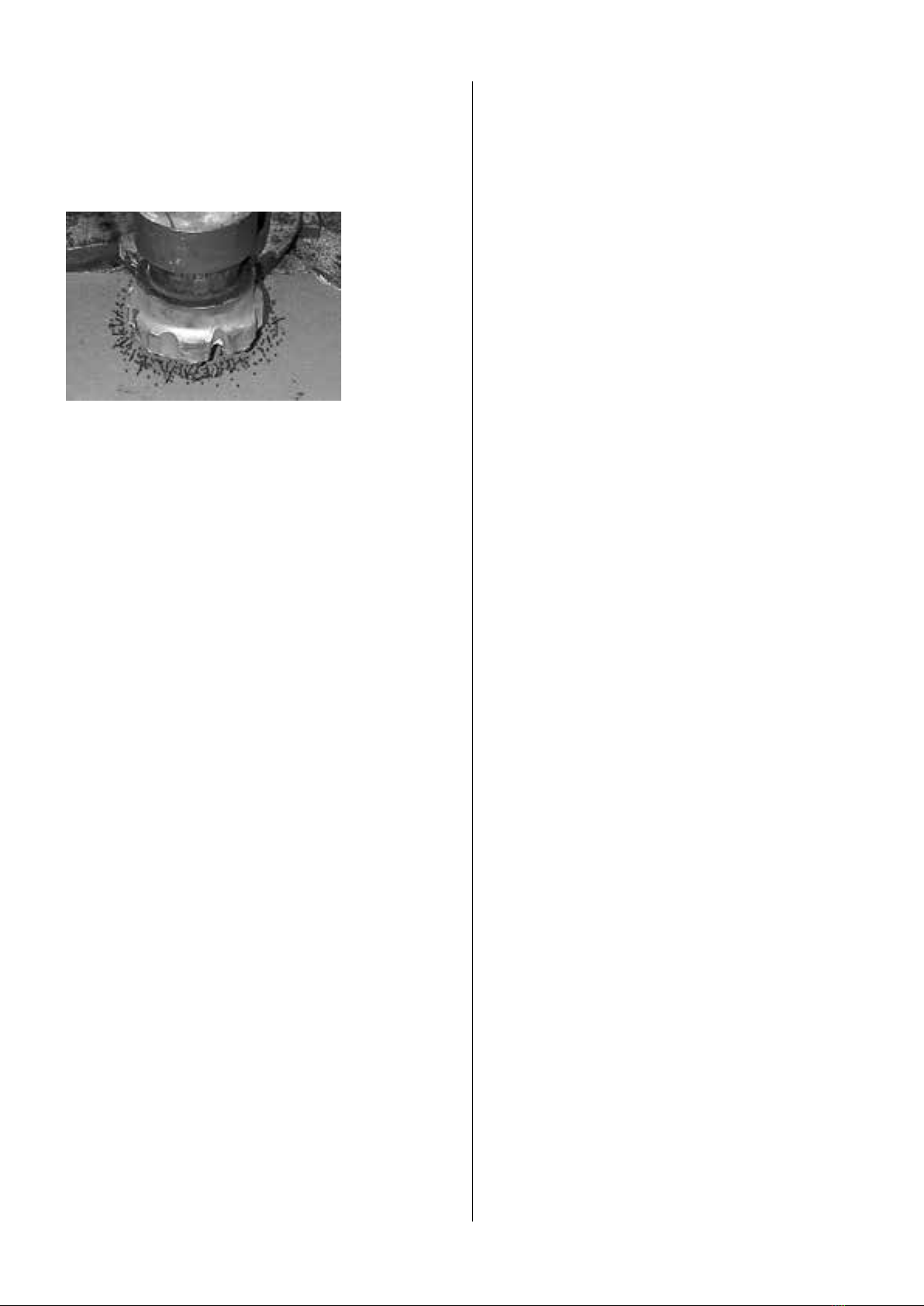

View showing wear flat on leading edge - indicates rotation too

slow. Note that carbide failure was caused by the leading edge

wear flat.

Feed force (hold down and hold back)

The force required to feed a percussive tool properly is directly

proportional to the level of output power.

As a rule of thumb, DTH hammers need to be fed with a force of

roughly 500 lb per inch (9 kg per mm) of hammer diameter when

operating at maximum power.

In many cases operators will simply adjust the feed pressure

until rotation pressure starts to pulse and then back off slightly

until rotation pressure becomes smooth. When a hole is first

started, if the weight of the starter rod or collars is not ufficient

to feed the drill then pull down will be needed. As the hole is

advanced and more weight is added to the drill string, the level

of pull down will need to be decreased. Eventually, the weight of

the string may exceed the proper feed force and the feed system

will need to be shifted to a pull-back mode.

When drilling through varying conditions such as hard and soft

or voided material, every effort should be made to keep the drill

fed properly. A loose running DTH hammer can cause damage to

the hammer and bit in a short period of time. The feed system of

a drilling rig should have a sufficiently fast response so the DTH

hammer can ´catch up´ with the bit when a void or soft seam is

encountered.

As with rotation speed, QLX drills will typically need to be fed

harder due to their higher output power level over valveless

drills. Adjust RPM to give 1/2’’ to 3/4 ‘‘ (13 to 19 mm).

Rotation Torque

As a general rule of thumb, you should apply roughly 500 foot/

pounds (27 newton/meter) of torque for each inch of bit

diameter.

Example: 6 inch diameter bit X 500 ft/ pounds =

3000 ft/pounds of rotation torque

It´s equally important to avoid feeding too hard through voided

and fractured material. The piston in a DTH hammer operates

within the casing with a clearance of about .003 in. (.076 mm) on

each side. While the casing appears very strong and stiff, it does

not take much sideways pressure to distort the casing enough to

cause interference with the piston as it reciprocates. If the casing

is overfed through voided ground it is likely that deflection of the

casing will occur. Frictional cracks will develop on the surface of

the piston if the piston rubs hard enough against the wall of the

casing while being distorted. These small frictional cracks can

eventually grow and break the piston.

Feed force should be reduced when drilling through voided,

unconsolidated or fractured ground to avoid twisting or

distorting the hammer casing.

Hole cleaning, flushing and dust suppression

As stated previously, the importance of good hole cleaning

cannot be over emphasized. A hole which is not cleaned

effectively will cause reduced production (penetration rate),

decreased bit and accessory life and could ultimately increase

the risk of losing the drill and string in the hole.

Deep Hole drilling requires that you maintain a proper annulus

around the casing, to reduce backpressure and maintain

performance.

Dry drilling

The most effective means for hole cleaning is drilling dry.

Cuttings are normally lifted and cleaned from the hole very

efficiently. Imagine blowing, or sweeping, dust or dirt from a

floor when the floor is dry and wet....which is more effective?

The same principle holds true for cleaning cuttings from a hole.

Wet drilling

Water injection is required in many applications for dust

suppression or hole cleaning. Water injection rates for dust

suppression only are usually less than 1 gpm (3.8 lpm) and

just sufficient to moisten fine dust. It is usually common to use

minimal water injection for dust suppression in shallow blasthole

applications where water intrusion into the hole is not a problem.

Heavier volumes of water injection are usually required in water

well and deep-hole applications where a number of factors come

into play;

• Water intrusion into the hole can develop mud rings where

dry cuttings meet a seam of water entering the hole. Mud

rings develop where dry cuttings stick to the wall of the

hole when they hit the moist area. Water injection is needed

to keep the hole wet enough to prevent these mud rings

from developing. Fluid injection rates can vary from 2 - 15

gpm (7.57 - 56.775 lpm) depending of the hole size, rate of

penetration and the type of material being drilled.

• Some materials such as those which drill fast or contain clay