8

PAGE

Repair Instructions No.189.03/01

PHE 45 S

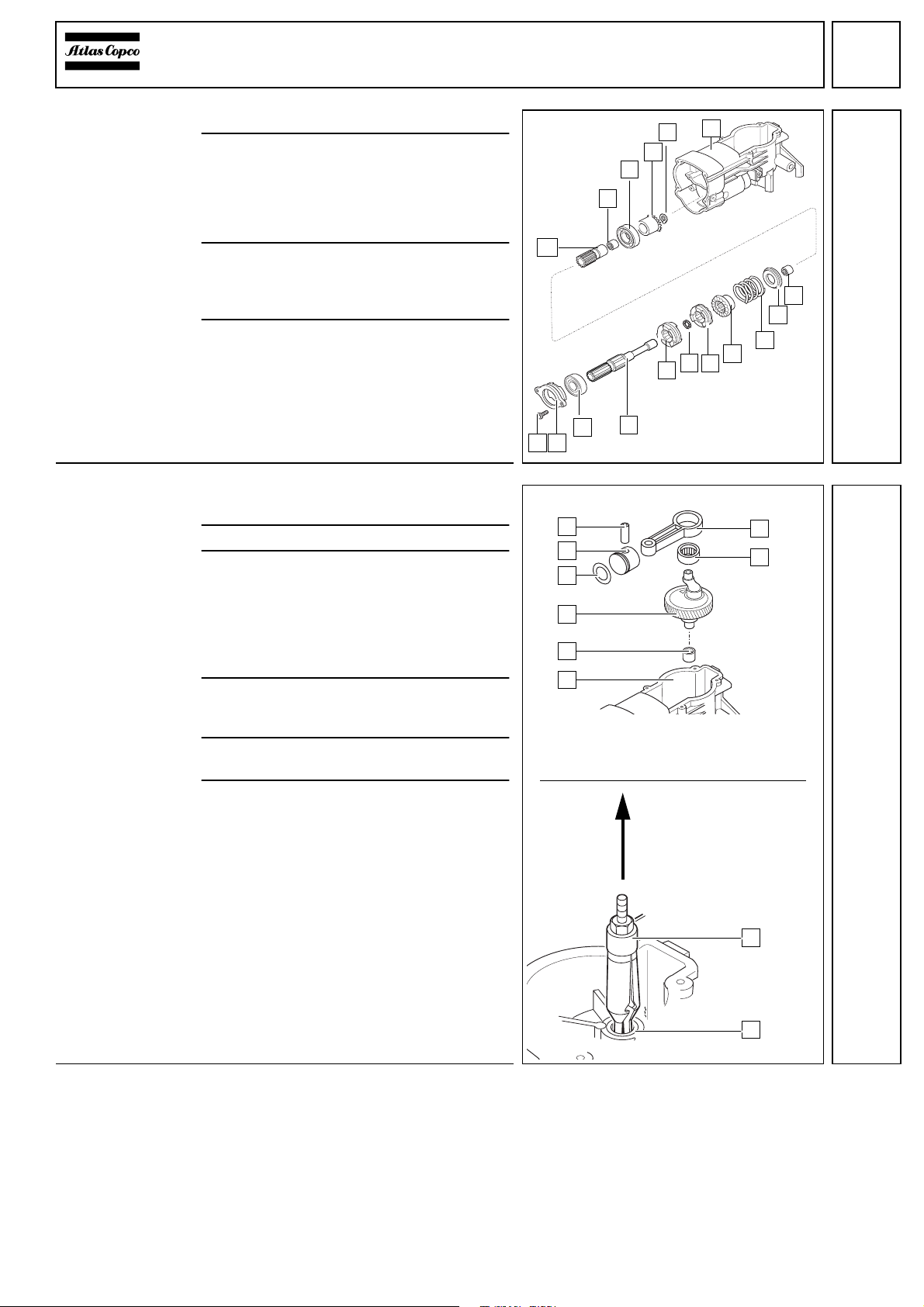

Assembling

the spindle 1Lightly grease the inner wall of the cylin-

der (4) and push it over the piston (O) (the

piston is illustrated on page 7, pos.5, ill. 1).

2Insert the cylinder (4) with the percussion

body (2), as well as the seal ring and the

O-ring (3) into the crankcase (5) and fas-

ten them with the four secured screws (1).

3Insert the O-ring (N), the snap die (M), the

disk(L), the O-ring (K)andthe disk (J) into

the spindle gear (G). Fit the disk (L) with

the phase facing the snap die. Mind the

right position!

4Push the spindle sleeve (7) with the

O-ring (6) over the spindle gear (G).

5Lock the spindle gear with the four

pins (H) using a magnet for support.

6Mountthe needlebearing (B),thedisks (C

and E), the cup springs (D) as well as the

needle bearing (F) in the bearing end

plate (A).

7Mount the locking ring (9) with aid of spe-

cial pliers.

8Insertthe sealring(8) into thebearing end

plate (A).

9Push the spindle sleeve (7) with the spin-

dle gear (G) into the bearing end plate (A).

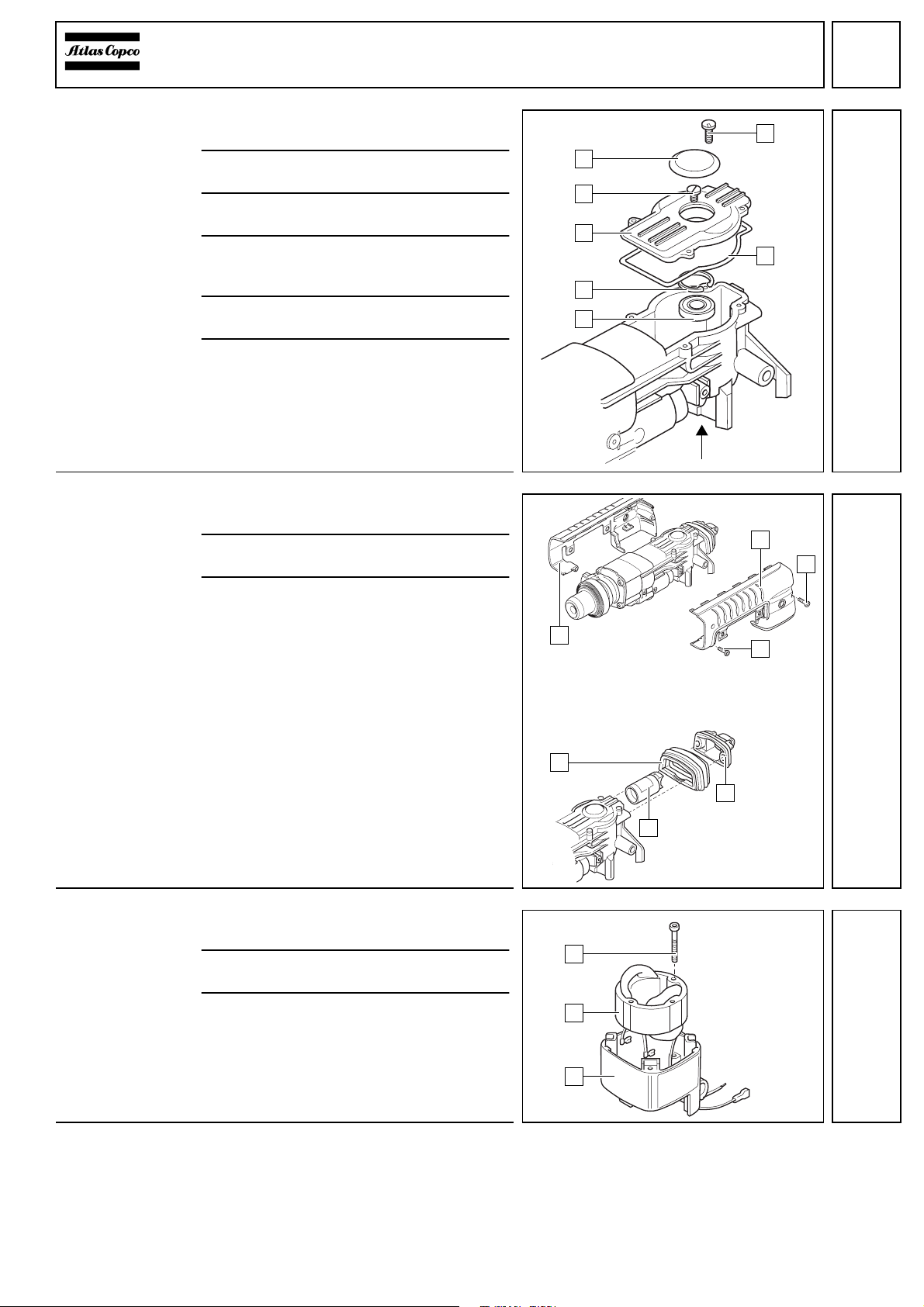

Mounting the

bearing end plate 1Push the backing flange (A) and the felt

washer (9) over the spindle sleeve.

2Fit the gasket (2) and the bearing end

plate (1) completely with the spindle

sleeve to the crankcase (8).

3Push the pressure spring (B) and the re-

taining plate (D) over the spindle sleeve

and depress them.

4☞Press in both locking levers (C) from

the side against resilience.

5Push the distance sleeve (6) and the

sleeve (7) over the spindle sleeve.

6Push the flange (E) over the spindle

sleeve (7) and fasten it tightly with the four

secured screws (F) (15 Nm).

7Push over the distance sleeve (4) and the

sleeve (5).

8Mount the cap (3).

D

1

6

54

3

2

7

8

9

A

B

C

EG

H

F

J

K

L

M

N

0

1

6

543

2

7

8

9A

BCDF

E

C