Splash Lab TSL.C.060 Maintenance and service guide

TSL 060.C.

channel hand dryer

installation + maintenance

contents

3 Safety and Warnings

4 Box Contents

5 Technical Data

6 BeforeYouInstall

8 HowtoInstall

13 Commissioning

15 Operation

15 Maintenance

16 Cleaning

17 Troubleshooting

18

18

Diagram

Spare Parts / Accessories

19 Warranty

BackCover ContactDetails

2 + TSL.C.060 CHANNEL HAND DRYER MANUAL

Read and save these instructions

WARNING !

TSL.C.060 CHANNEL HAND DRYER MANUAL + 3

General information

310 410 5008

Technical support

info@thesplashlabusa.com

For further contact information visit:

www.thesplashlabusa.com

Warehouse + Offices:

20809 Higgins Court, Torrance CA 90501

Showroom:

8745 Washington Boulevard, Studio D, Culver City CA 90232

TSL.C.060 channel hand dryer

To reduce the risk of fire, electric shock or injury to persons, observe the following:

+ Use this unit only in the manner intended by the manufacturer. If you have any

questions contactthemanufacturer(seebackpagefordetails).,

+ This equipment should be installed in a way that ensures all electrical parts are

keptdry.

+ A means of electrical isolation must be incorporated in the fixed wiring, in

accordancewiththecurrentlocalregulationsinforce.

+ Disconnectthepowersupplybeforeperforminganymaintenanceontheproduct.

+ Childrenshouldnotplaywiththisequipment.Cleaningandmaintenanceshallnot

beperformedbychildrenwithoutsupervision.

+ Thisequipmentisdesignedtobeusedincommercialandpublicareas;itisnot

intendedfordomesticorresidentialuse.

+ Ensurewiringandcoverisinstalledcorrectlybeforeconnectingtolivepower

supply.

+ Ifindoubt consultanelectrician.,

+ Thisproductisnotintendedforuseinadomesticorresidentialapplication.

+ Thedryermustbeinstalledinaccordancewiththeelectricalinstallation

regulationsinforceatthetimeofinstallation.

+ Thehanddryermustbegrounded.

A Dryerheadassembly

B Hand dryer motor unit

C Power cable

D Pad

E Gasket

F Washer

G Fixing nut

H Angled pipe

I Motor mounting screws

J

K

Hex wrench

Air hose

boxcontents

A

C

B

J

ID

E

F

G

K

4 + TSL.C.060 CHANNEL HAND DRYER MANUAL

H

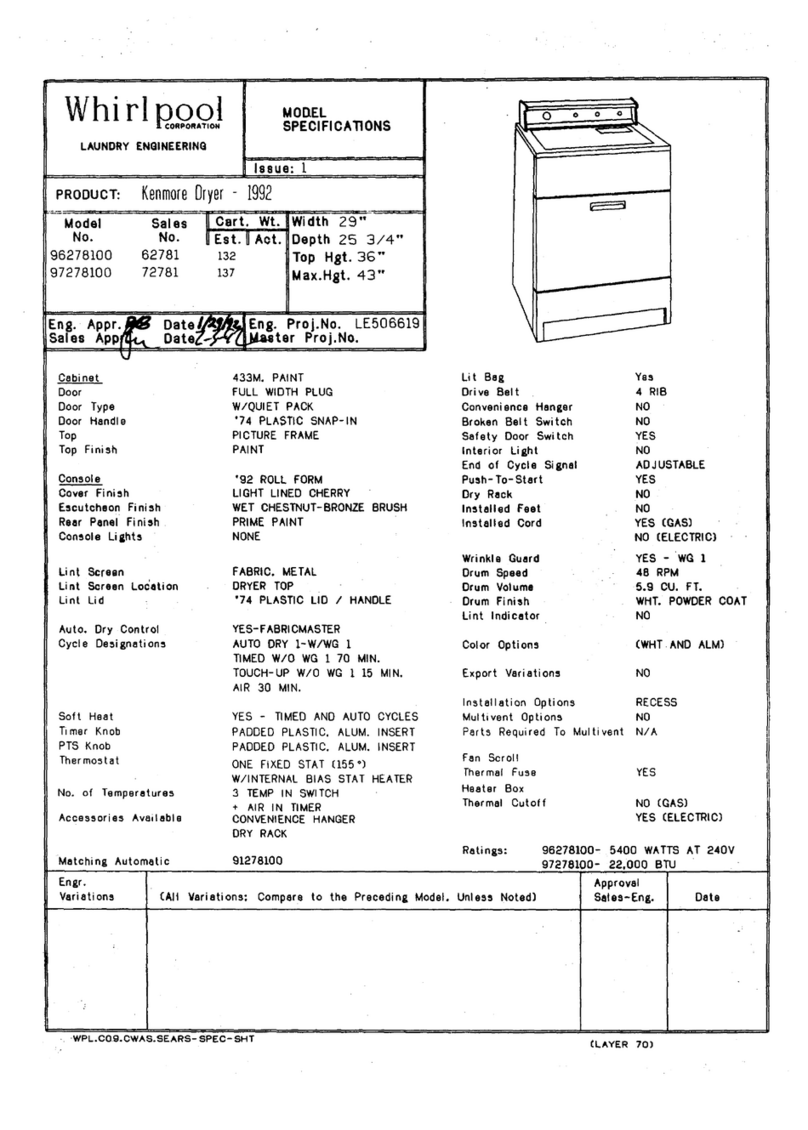

Current 7.6-8.4A

Powerconsumption 0.84-1.0kW

Standbypower 0.3-0.4kW

Dryingtime <15seconds

Weight 17lb

Material AISI316stainlesssteel

Noiselevels 68.6dB

Heatingelement 500W

Motortype Brushtype;dualballbearings;

Motorpower 500 - 350W

Airspeed 364ft/s

Airflow 27.6cuft/min

Sensorrange 5"+/-1"

technical data

Finishes TSL.C.060.C

TSL.C.060.CS

TSL.C.060.CP

TSL.C.060.BK

TSL.C.060.BR

Voltage 110-120V ac; 60Hz

Securitycut-of f time 60seconds

Motorthermalprotection Autoresettingthermostatsetat203°F

Heaterthermalprotection Autoresettingthermostatsetat185°F

Thermalcutoutfusesetto288°F

Insulation Class1

IPrating IP35

Approvals CE UL cUL, RoHS, ADA,,

Warranty1 year parts and labor

Filter 3M filter assembly (HEPA filter is available for this

product, please enquire for technical information)

Bright Polished

Brushed Stainless

Brushed Copper

Brushed Black

Brushed Brass

TSL.C.060 CHANNEL HAND DRYER MANUAL + 5

before you install

Basins

The Splash Lab Monolith (Series C or D)

basin isrecommendedforusewiththe

Channel rangeofproducts. If an alternative

basin is used, please confirm with

The Splash Lab that there will be no

reflection or splash issue.

Powersupply

A15Afusedsupplymustbeprovidedfor

connectiontothemainspowersupply.

Spacing

If the Channel Hand Dryer is installed with

other units from the Channel range, the

Channel Faucet, which is at the center,

should be 8" to the left of the Hand Dryer.

The Channel Soap Dispenser should be 6"

to the left of the Faucet.

Location

Disclaimer:Circuitsshouldonlyuse

80%oftheirgivenamperagetoprevent

overloads.ThestandardUS120V15Amp

circuitshouldonlyuseupto12ofits15

amps.

6 + TSL.C.060 CHANNEL HAND DRYER MANUAL

Channelhanddryersaresuppliedwith48"

offlexiblehose,sothedryermotorunit

mustbefittedwithin48"oftheheadunit,

toensurethatthemotorair-outlethead

canbeconnected.

The Splash Lab offers an optional backplate

for the fixtures that means the fixtures can

be mounted from the front and have simpler

access.

Backplate

6"8"

Back wall

Fixture insert

Washbasin

Front view

Ø 7/8"

Soap Faucet Dryer

Ø /"

1316

Ø "

1 3/16

8"MIN

10"MAX

Distance between

the sensor and

the bottom of the basin

FIXING

before you install

SIDEFRONT

2 "

9-5/16"

10-3/4"

12-1/16"

7-9/16"

5-7/8"

110-120V / 15A plug

51-3/16"

TSL.C.060 CHANNEL HAND DRYER MANUAL + 7

Default

Sensor

Range

3/4" - 5-1/8"

48"

23-5/8"MIN

39-3/8"MAX

how to install

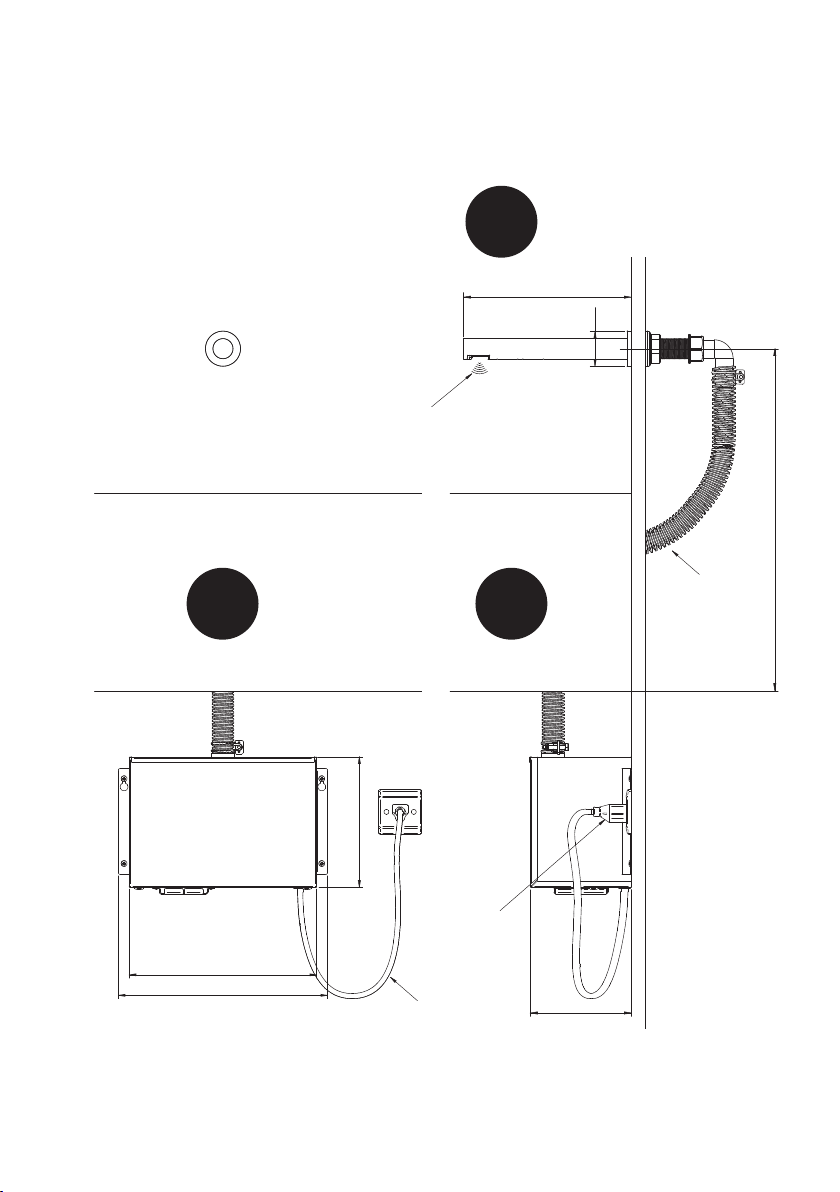

1 2

Fit dryer body into the 1 3 16" hole in wall.- /

Ø -/"1 3 16

8 + TSL.C.060 CHANNEL HAND DRYER MANUAL

Drill hole 1 3 16" diameter in wall 8-10" - /

above the bottom of the basin.

When step 3 is finished, run the sensor wire

and ground wire through angled pipe and fix

it to the fixing nut.

43

Thread the sensor and cables ground

through the gasket, washer and

fixing nut, and tighten the nut

against the installation wall.

TSL.C.060 CHANNEL HAND DRYER MANUAL + 9

how to install

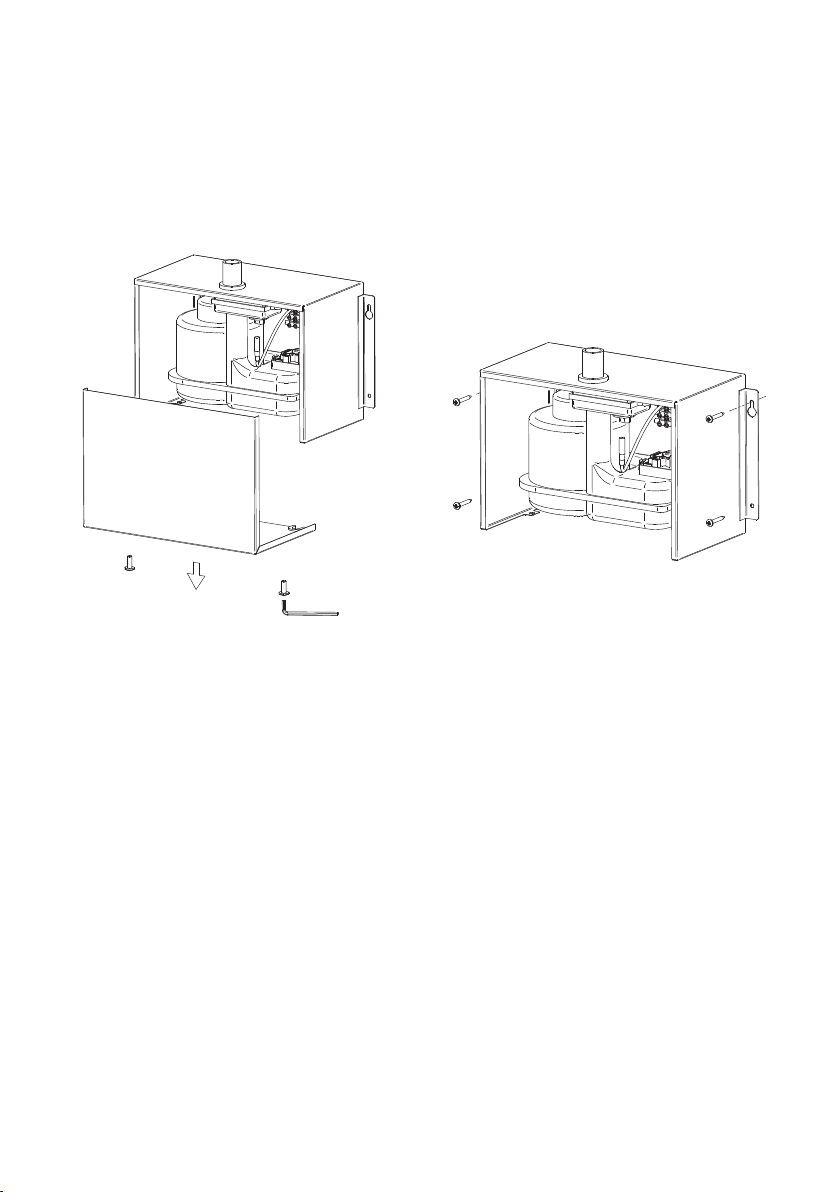

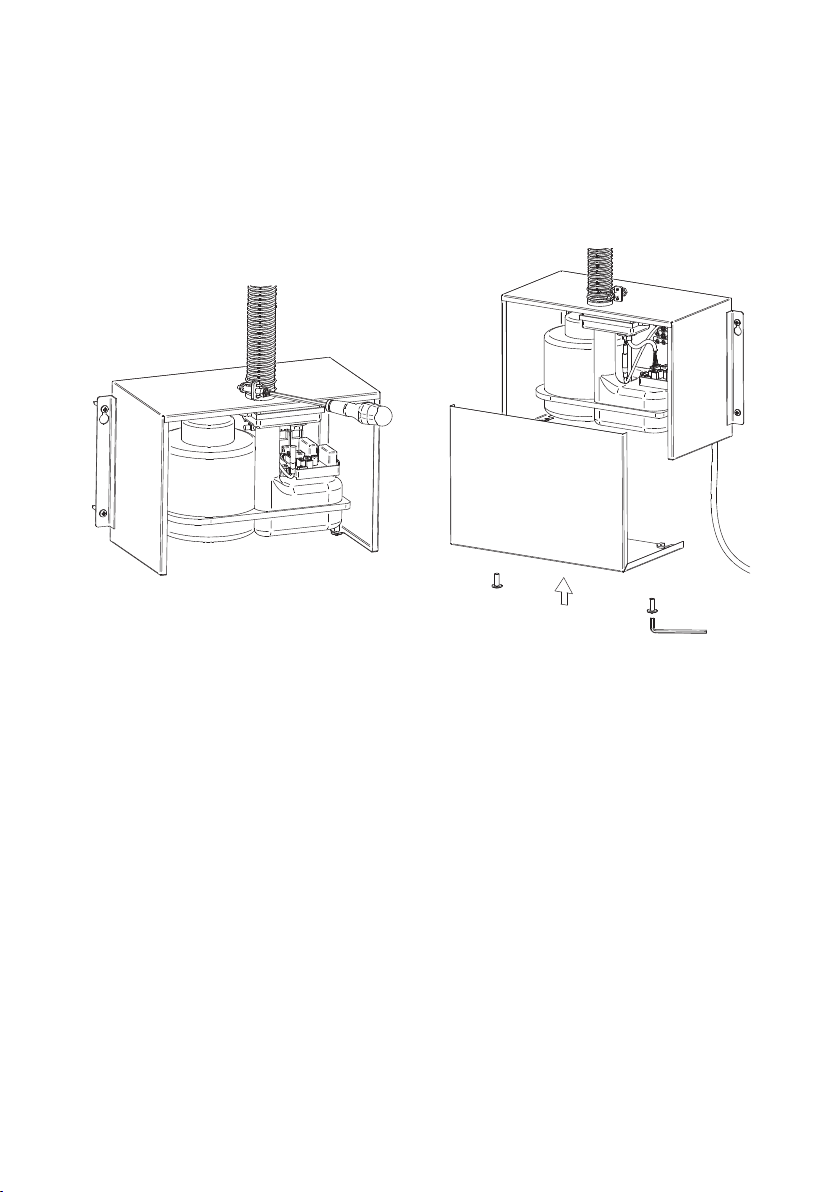

Fit the dryer motor unit to wall or cabinet,

within 48" of the dryer nozzle already

installed in the wall.

6

10 + TSL.C.060 CHANNEL HAND DRYER MANUAL

Remove cover-fixing screws from

underside of dryer motor using the

security hex key provided, and then

remove the cover.

5

TSL.C.060 CHANNEL HAND DRYER MANUAL + 11

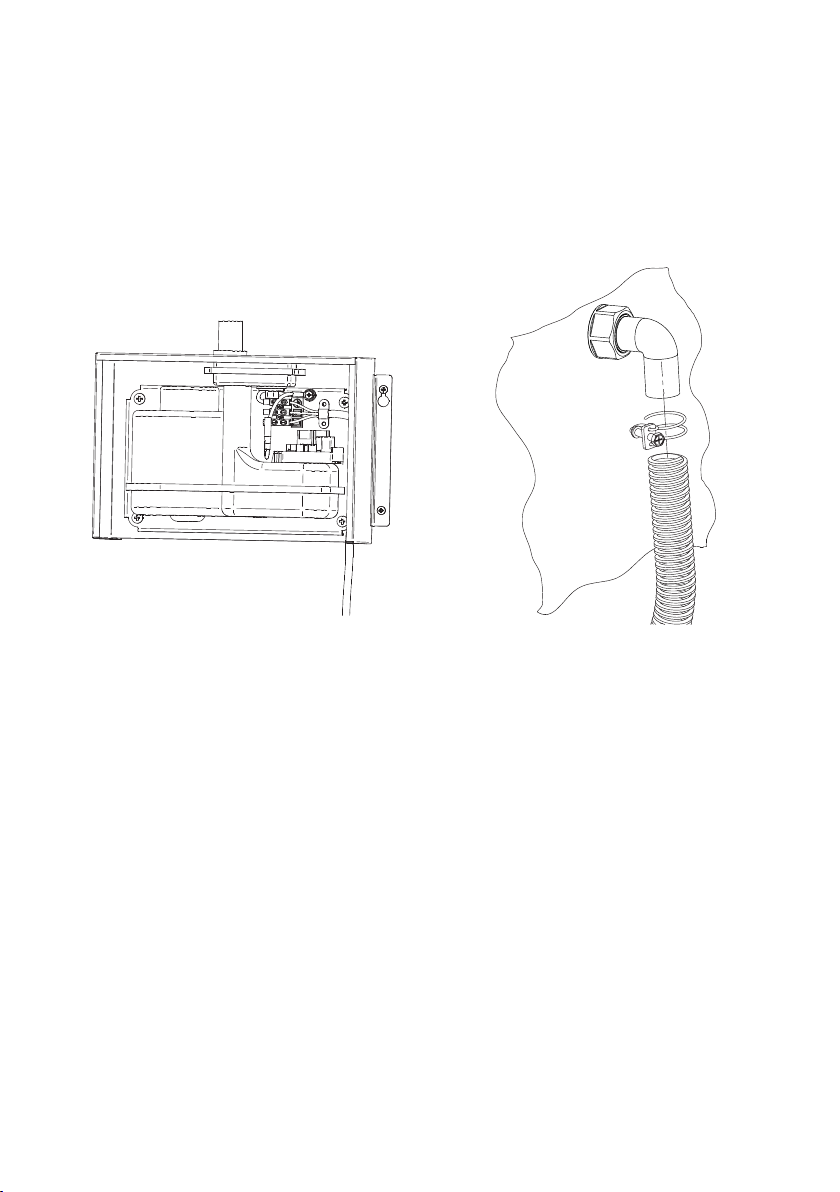

Feed sensor cable through angled pipe

connector and fit flexible hose.

8

Thread the power cable through the

knockout in the back or base of the dryer

and feed to connector block. Connect

the cables as marked on the dryer unit.

(Cable supplied pre-fitted)

7

how to install

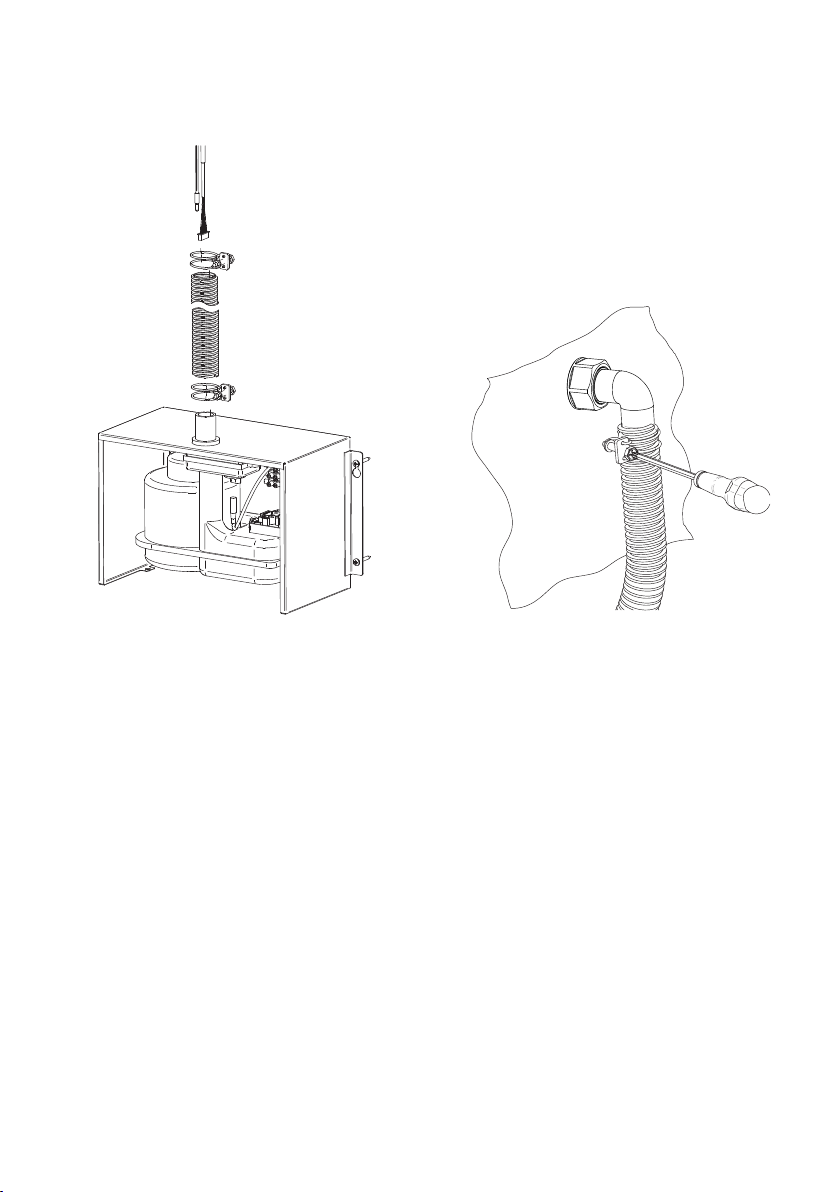

Fasten pipe clip and tighten with

screwdriver.

10

12 + TSL.C.060 CHANNEL HAND DRYER MANUAL

9

Thread the sensor and ground cables

through the air-hose.

12

Connect the sensor cable to the 6-pin

fitting on the PCB control, and the

ground cable to the corresponding earth

connector in the dryer motor unit.

TSL.C.060 CHANNEL HAND DRYER MANUAL + 13

11

Feed cables into air outlet nozzle and

then through cable exit grommet.

Note: grommet is split to allow cable

installation.

14

Re-fit the dryer cover and tighten the

fixing screws.

how to install

14 + TSL.C.060 CHANNEL HAND DRYER MANUAL

13

Connect air hose onto outlet nozzle on

dryer motor and tighten hose clamp.

Turn on the power supply to the dryer, and then test that the dryer will operate when

the user’s hands are placed within the detection range.

The motor speed and sensor range can be adjusted to suit user preference and the

environment, if required. The heater element can also be switched of f if desired.

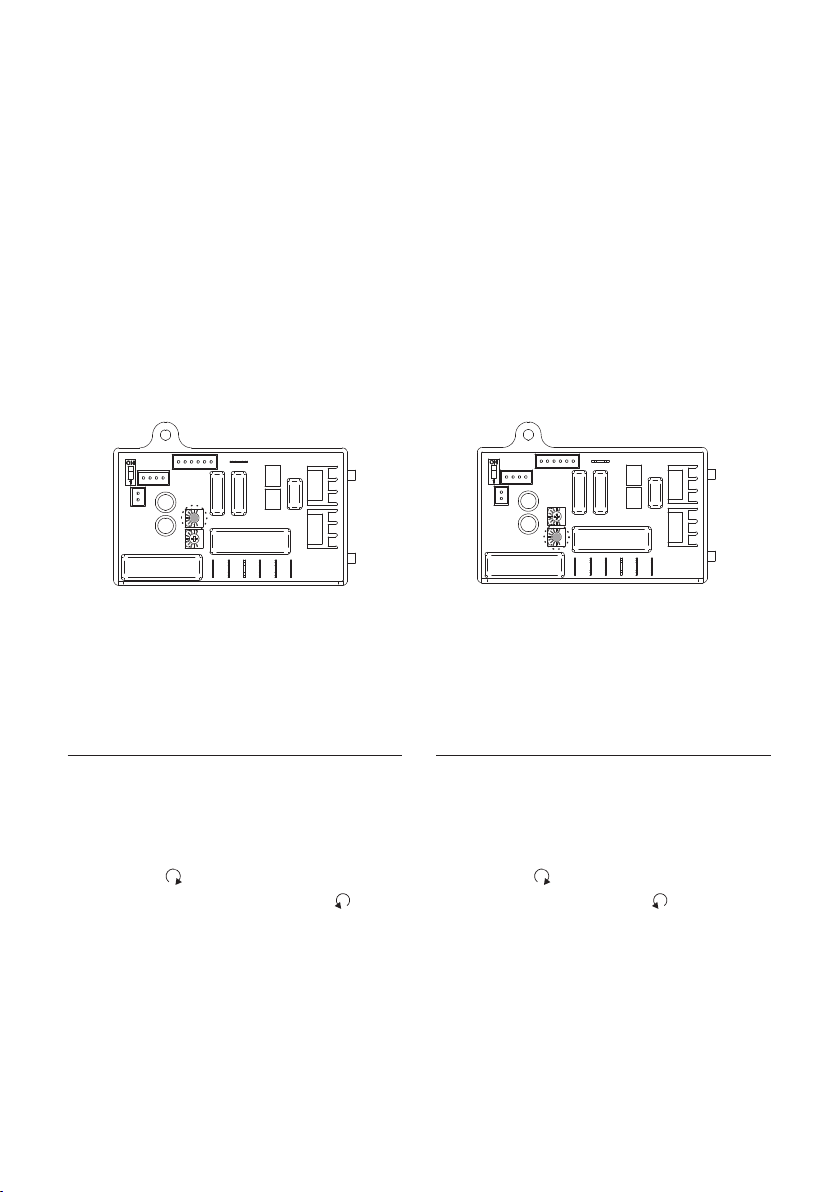

Warm air speed adjustment

1.Switch of f the power, loosen the cover

screws and remove the cover.

2.Use small Phillips head screwdriver

to turn variable resistor shaft. Turn

clockwise to increase the motor

speed; turn counter-clockwise

to reduce the motor speed.

Sensor range adjustment

1.Switch of f the power, loosen the cover

screws and remove the cover.

2.Use small Phillips head screwdriver

to adjust the variable resistor. Turn

clockwise to increase the sensitivity;

turn counter--clockwise to reduce

the range.

commissioning

TSL.C.060 CHANNEL HAND DRYER MANUAL + 15

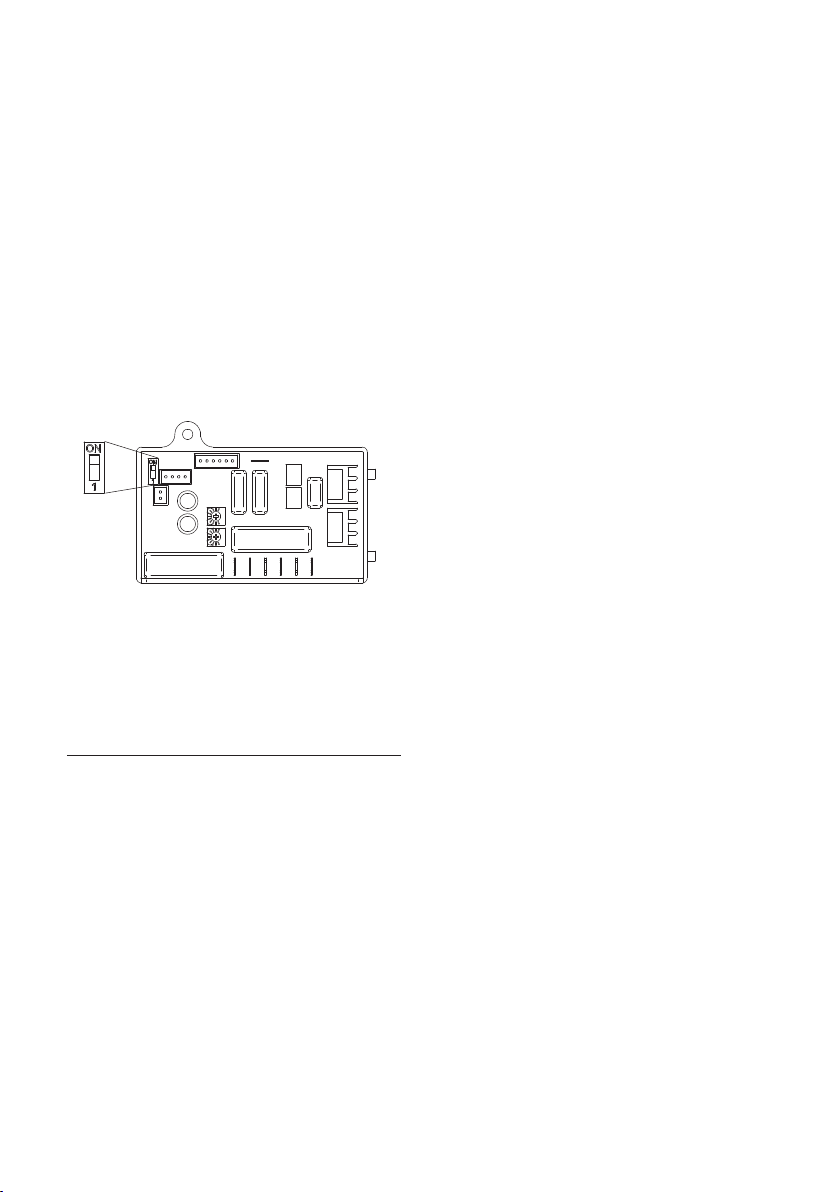

1. Switch of f the power, loosen the

cover screws and remove the cover.

2. Adjust the heater switch on the

PCB with a small plastic or wood

flat blade probe.

2-1 Slide the switch to ‘ON’:

Enables heater

2-2 Slide the switch to ‘1’:

Disables heater

Heater Element Switch ON/OFF

16 + TSL.C.060 CHANNEL HAND DRYER MANUAL

commissioning

+ The user is to shake excess water of f their hands.

+ The user then places their hands within the detection range of the sensor to

activatethehand dryer.

+ The motor will start and air is blown onto the user’s hands.

+ The motor will stop when the user’s hands are removed from the detection range.

maintenance

The hand dryer should be serviced on a regular basis to ensure long service life of

the unit.

+ Isolate the unit from the power supply before any servicing or maintenance work is

carried out.

+ Remove the cover by unscrewing the fixing screws on the underside of the cover.

+ Remove any dust or foreign body from the air intake and (both inside and outside

the dryer). Where necessary, use a brush or vacuum cleaner.

operation

+

TSL.C.060 CHANNEL HAND DRYER MANUAL + 17

All grades of stainless steel will stain or discolor if due care and attention is not

taken. The surface must be regularly cleaned to ensure a long service life of the

hand dryer.

Use a soft cloth or sponge with a mild solution of soapy water as part of the regular

washroom janitorial routine. Do not use abrasive or cream cleaners as these will

damage the surface finish.

If the hand dryer is subjected to a highly chlorinated environment e.g. swimming

pools or marine coastal locations, a further treatment, in addition to the regular

cleaning as described above, is recommended to use a household cleaning product

containing silicone.

If further information is required, contact The Splash Lab Team for more detailed

stainless steel care guidelines.

cleaning

+

+

+

+

18 + TSL.C.060 CHANNEL HAND DRYER MANUAL

If the dryer will not run:

+ First ensure that the breaker supplying the dryer is operational. If it is, disconnect

the power and remove the dryer cover. Taking suitable precautions to avoid shock

hazard, reconnect the power and check for voltage at the terminal block. Verify

that connections are made correctly.

The dryer cycles by itself or runs constantly:

+ Ensure that there is no obstruction on or in front of the IR sensor. Clean any dirt or

debris of f the sensor lens. If problem persists, replace sensor.

The dryer makes a loud noise and does not run for a complete cycle:

+ Ensure that the supply voltage is correct. Dryer will make a loud humming noise

if the input voltage is too high. Verify voltage requirement on unit rating label and

correct supply as required. (If circuit board module has been damaged, replace it

and the infra-red sensor module.)

The dryer runs but air stream is low pressure and/or low velocity:

+ Ensure that the supply voltage is correct. Dryer will run weakly if the input voltage

is too low. Verify voltage requirement on unit rating label and correct supply as

required.

initial installation

troubleshooting

We are always looking to improve. If these steps

did not solve your problem please contact us

and we will endeavor to help.

Tel: 310 410 5008

Email: info@thesplashlabusa.com

TSL.C.060 CHANNEL HAND DRYER MANUAL + 19

If the dryer will not run:

+ First ensure that the breaker supplying the dryer is operational. If it is, disconnect

the power and remove the dryer cover. Replace the CBM and IR sensor module.

Taking suitable precautions to avoid shock hazard, reconnect the power and

check for Voltage at the terminal block.

The IR sensor only sees close range objects:

+ Ensure that there is no obstruction on or in front of the IR sensor. Clean any dirt

or debris off the sensor lens. Check variable resistor for sensor range setting. If

problem persists, disconnect the power and remove the dryer cover and replace

CBM, IR sensor module.

The heater gets hot but no air stream is produced:

+ Disconnect the power. Remove the dryer cover. Check variable resistor for speed

setting. Disassemble the blower- motor/ fan housing. Replace the fan motor.

Reassemble.

in-service failure

troubleshooting

The dryer only blows cold air during a full cycle:

+ Disconnect the power. Remove the dryer cover and check/ ensure heater switch

is ON. Disassemble the blower- motor/ fan housing. Test the thermostat for open

circuit. Check the heater element for signs of burning or breakage. Damaged

element must be replaced.

The air stream is low pressure and velocity:

+ Check the output nozzle for obstructions, If none are present, disconnect the

power. Remove the dryer cover. Remove any dust/lint buildup from intake vent

slots. Check VR for speed setting. Disassemble the blower / motor / fan housing.

Check motor brushes for wear; if less than 1 1/4" is remaining. Replace brushes.

20 + TSL.C.060 CHANNEL HAND DRYER MANUAL

This manual suits for next models

5

Table of contents

Other Splash Lab Dryer manuals

Popular Dryer manuals by other brands

Maytag

Maytag MEDB700BW0 installation instructions

Bosch

Bosch WTG86400KE Installation and operating instructions

Frigidaire

Frigidaire FAQE7077KB - 7.0 CF Chrome TRIM Drum 7... Use and care guide

LG

LG RT8DIH1Q owner's manual

ATC

ATC Z-2000M manual

Tricity Bendix

Tricity Bendix TM 221 W Operating & installation instructions