S+S GLS 350/150 GENIUS+ User manual

Operating Instructions

Metal detector

GLS

We reserve the right to change the con-

tents due to product innovation or tech-

nical improvement.

Please state type of equipment and se-

rial number when contacting us.

Please read these instructions and keep

the manual safe!

Please observe and follow the safety

notes!

S+S Separation and Sorting Technology GmbH

Regener Straße 130 * D-94513 Schönberg

Telephone: +49 8554 308-0 * Fax: +49 8554 2606

Internet: http://www.se-so-tec.com

Service: Telephone: +49 8554 308-180

1 GLSII-BA-EN-0106.doc

Manufacturer:

S+S Separation and Sorting Technology GmbH

D-94513 Schönberg, Germany

Contact:

S+S Separation and Sorting Technology GmbH

Regener Straße 130

D-94513 Schönberg, Germany

Tel.: +49 8554 3080

Fax.: +49 8554 2606

Internet: www.se-so-tec.com

Represented by:

2GLSII-BA-EN-0106.doc

Contents

Contents

1General notes 5

1.1 Introduction 5

1.2 Fields of applications 5

1.3 Application reasons 5

1.4 System identification 5

1.5 Symbols used 5

1.6 Important functional notes 6

1.7 Overall view 6

2Design and method operation 7

2.1 Functional principle 7

2.2 Functional elements 8

2.3 Combination scopes 8

3Dimensions and technical data 9

3.1 Technical data sheet, see annex 9

3.2 Interfaces, see technical data sheet in the annex 9

3.3 Environmental conditions for operation, storage, and transport 9

3.4 Noise levels 9

4Safety 10

4.1 Use to the intended purpose 10

4.2 Dangers arising from non-compliance with safety notes 10

4.3 Safety notes for the operator 10

4.4 Safety notes during operating, maintenance and cleaning 10

4.5 Safety information for commissioning 10

4.6 Safety information for storage and transport 11

4.7 Notes on residual risks 11

4.8 Notes on stable standing requirements 11

4.9 Consequences of unauthorized modification 11

4.10 Inadmissible operation 11

5Commissioning 12

5.1 Mechanical installation 12

5.2 Connections 14

5.2.1 Control Unit PRIMUS / SENSITY 14

5.2.2 Control Unit GENIUS+ 14

6Errors and fault rectification 15

7Maintenance and cleaning 16

7.1 Maintenance 16

7.2 Cleaning 16

7.2.1 Advice 16

7.2.2 Cleaning instructions 16

7.2.3 are advice for stainless steel 16

3

1. General notes

1 General notes

1.1 Introduction

The texts and illustrations in this instruction manual are for the exclusive purpose of explaining how to

operate and handle the GLS metal detector. S+S accepts no responsibility for damage resulting from

the use or misuse of this equipment. All appropriate safety rules and regulations for the use of this

equipment must be adhered to. If you have any questions with regard to the installation and operation

of this equipment please do not hesitate to contact us.

This instruction manual must not be copied, saved on computer or otherwise reproduced without prior

permission of S+S. Nor should any extract of this instruction manual be similarly reproduced.

1.2 Fields of applications

Metal detectors of the series GLS are used in plastics, wood, food, chemical and pharmaceutical indus-

tries for the inspection of metallic - magnetic and nonmagnetic- impurities in packed or unpacked goods

on a conveying line without interrupting the production flow. The GLS series metal detectors can be

used in similar applications in other industry areas.

1.3 Application reasons

• Product liability

• ISO 9000

• TQM (Total Quality Management)

• Protection of machines and operators

1.4 System identification

The information in this operating instructions only applies to the GLS metal detector. A label with the

respective data is attached at every system.

1.5 Symbols used

Symbol Signal word Meaning

Danger Warning: Possibility of severe or even fatal personal injuries.

Danger The lightning symbol is an explicit warning that there is danger from

electric current.

Warning Warning: Possibility of minor personal injuries or property damage.

Caution Warning: Possibility of defects or destruction of the equipment.

Important

information Indicates an important information for the function.

Important

hint Indicates an important hint for the function.

5

1. General notes

1.6 Important functional notes

The GLS metal detector offers best possible reliability for the detection and separation of metal con-

taminations.

Despite detection, however, the following circumstances still may be the cause for not separated metal

particles:

- Occurrence of metal conglomerations, i.e.

accumulations of many metal particles in one batch of the product flow, with a resulting malfunction

of the separating mechanism (jamming of products, overfilling of eject container, etc.)

- The distance between products is too small, which means that a metal signal cannot be clearly

assigned to the respective product.

- The conveyor speed is too high or too low.

- Type, size, and position of the metal contamination.

For these reasons no general guarantee can be given that the unit will operate with

100% accuracy.

1.7 Overall view

6

2. Design and method of operation

2 Design and method operation

2.1 Functional principle

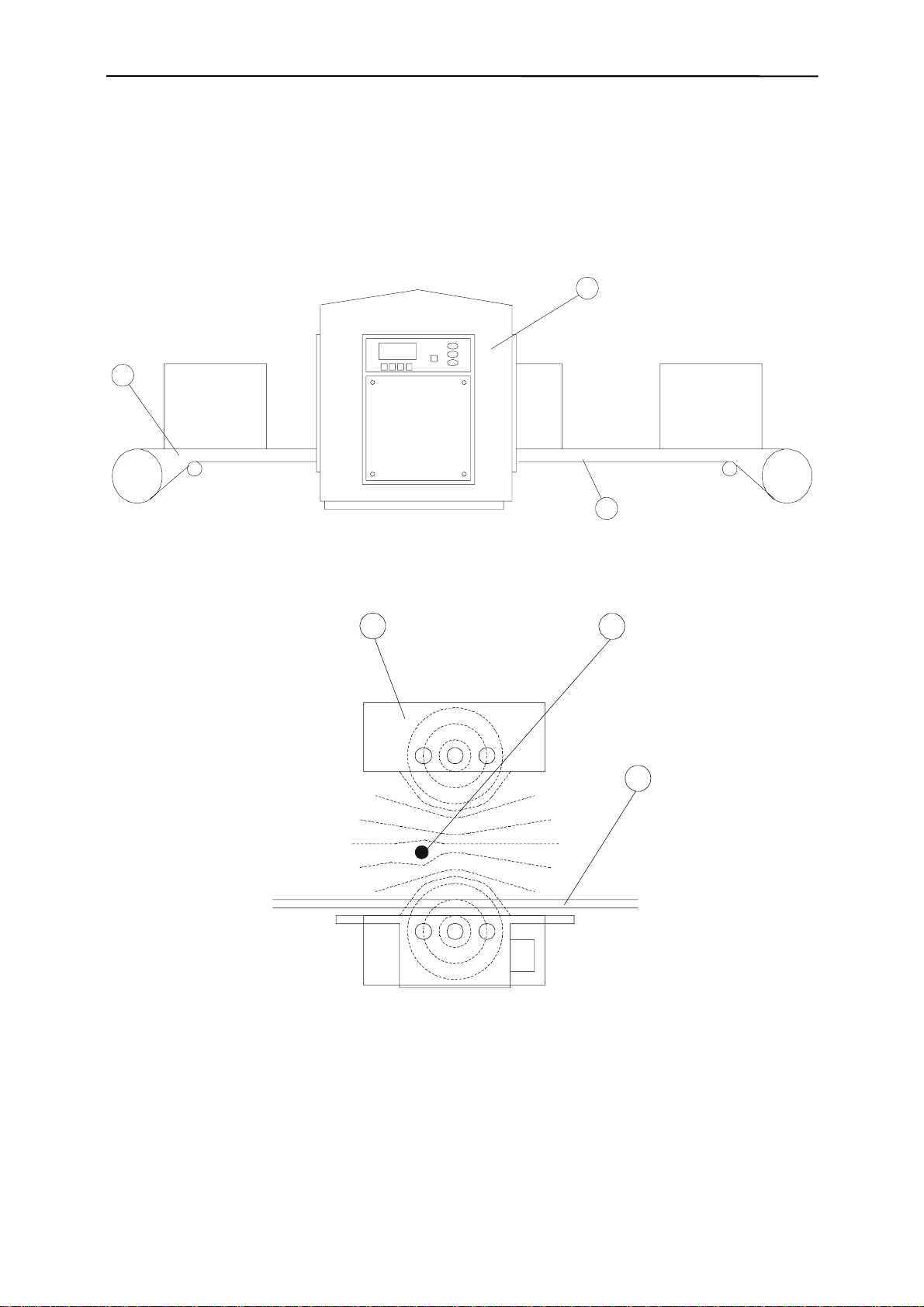

The material to be inspected (bulk or lump material) passes the detector head (2) on a belt conveyor

(1). The lower part of the belt can be put also through the detector head (3).

1

2

3

The material is penetrated within the aperture of the detector head by a high frequency electro-

magnetic field, which is generated by the control unit and the transmitter coil. Two identical voltages

are induced into the receiver coils, and are subtracted to zero if the system is in balance.

1

24

E

E

2

2

S

S

E

E

1

1

A metallic impurity (4) causes an unbalanced condition that generates a signal at the receiver. The

control unit processes this signal and triggers an output relay (see operational manual).

7

2. Design and method of operation

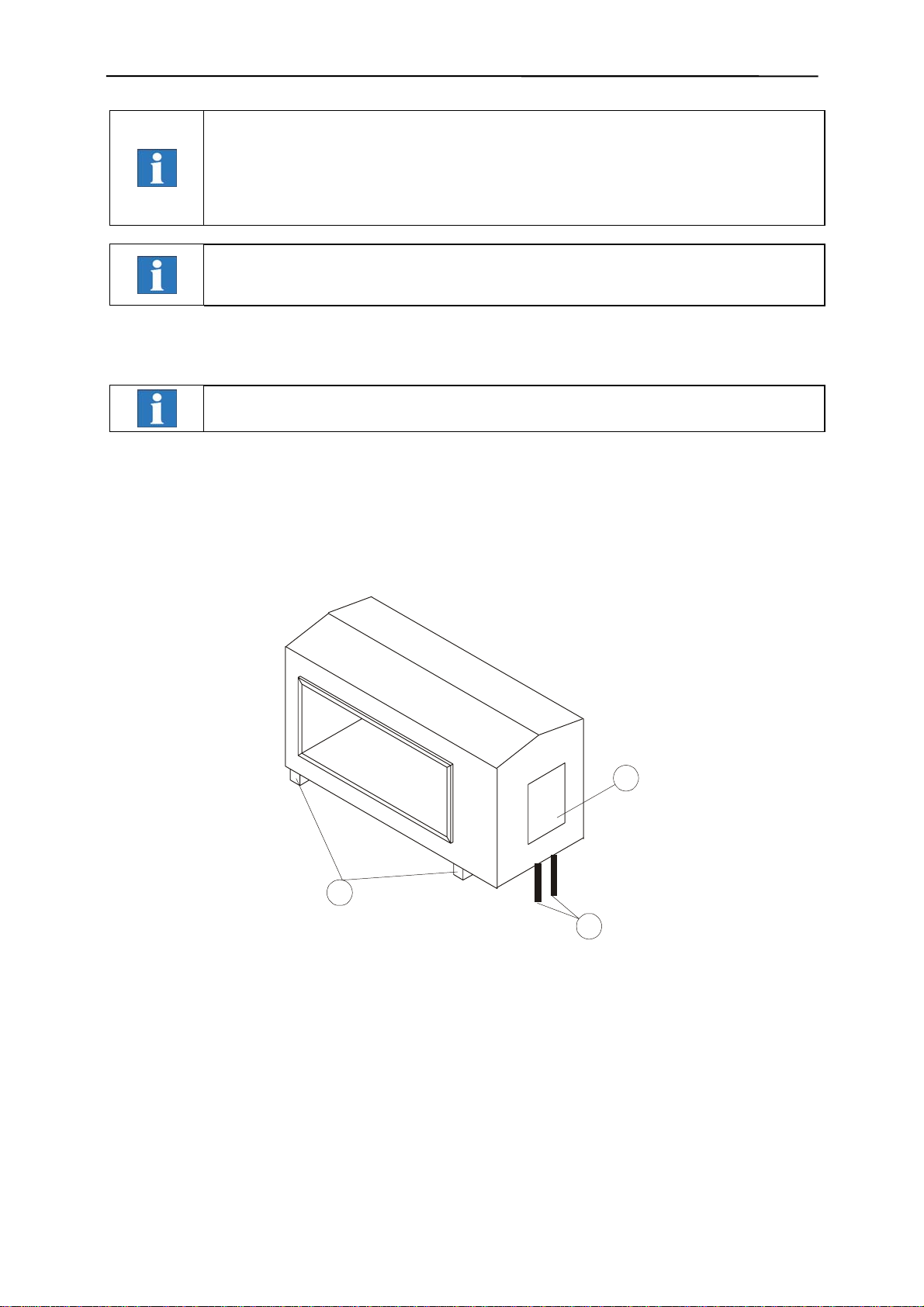

2.2 Functional elements

1

2

3

4

(1) Mounting elements for installation

(2) Coil connection box

(3) Connection cable for electronic unit

Options:

(4) Signalling device

2.3 Combination scopes

Different Control units can be used to control the detector head:

GENIUS+, PRIMUS or SENSITY.

8

3. Dimensions and technical data

3 Dimensions and technical data

3.1 Technical data sheet, see annex

3.2 Interfaces, see technical data sheet in the annex

3.3 Environmental conditions for operation, storage, and transport

The environment of the metal detector should be free of vibrations, of other influencing magnetic

fields, of chemical vapours such as softeners, chlorine, and similar substances. The metal detector

must not be exposed to direct sunlight. For the ambient temperature range please refer to the techni-

cal data sheet in the annex.

3.4 Noise levels

Sound pressure level measurements (in acc. with DIN 45 635)

Peak value of sound pressure level at distance of 1m from machine surface and 1.60m across the

floor, LpA, 1m, max.

Result:

Idling < 70 dB

Activated < 90 dB

Option signal horn or signal combination:

Activated < 105 dB

We reserve the right to change the contents due to product innovation or technical improve-

ment.

9

4. Safety

4 Safety

S+S equipment conforms with all official technical safety regulations. However, as a manufacturer we

believe it is our duty to make you aware of the following information.

The following safety and danger notes are intended for your protection, for the protection of

third parties, and for the protection of the equipment. The safety notes therefore should

always be observed! Please also observe the chapter on safety in the operating instruc-

tions of the control unit!

4.1 Use to the intended purpose

The intended purpose of the metal detector is the inspection of bulk or lump materials con-

veyed on belt conveyors, chutes or vibratory feeders with either the control unit GENIUS+,

PRIMUS or SENSITY. The metal detector system can be used for plastics, food, feed stuff,

chemical or recycling industry. The metal detector has to be fastened properly and stable.

At the operation field of the device, no steam (e.g. plasticizer) or other substances may

occur that attack cord insulation of PVC. Basically it is possible to also use the system in

other applications than the intended use stated herein, but such applications always require

the prior consultation and approval of S+S Separation and Sorting Technology GmbH.

4.2 Dangers arising from non-compliance with safety notes

Any non-observance of safety notes constitutes a danger for life and health.

4.3 Safety notes for the operator

The metal detector may only be operated in the intended purpose and in a perfect function-

ing condition. Particularly the covers of the detector connection boxes must be closed dur-

ing operation The operating instructions always have to be in a legible condition and com-

plete available. Ensure that up to date accident prevention procedures are in force prior to

commissioning. The operator may only appoint qualified personnel for operation, mainte-

nance and repair work. The electromagnetic field may cause malfunction of implants or may

affect health. People carrying implants, ie. heart pacemaker, should keep sufficient distance

to the detector head.

4.4 Safety notes during operating, maintenance and cleaning

Before opening the receiver and transmitter connection boxes remove dirt and moisture to

avoid them to get into the inside. Disconnect all power supplies or other connected circuits

Ingressed moisture must be removed.

In case of repairs of pc boards do not touch components or conducting paths with metallic

objects to avoid short circuits. Only qualified personnel should operate, maintain and re-

pair the equipment.

Signalling device option:

Always make sure that the electronics unit is not energised with mains or exter-

nal voltage before exchanging signalling elements!

4.5 Safety information for commissioning

When mounting the detector head there a risk of injury due to the weight of it.

Use suitable lifting gears for transportation.

Remove the lifting gear only after safe mounting.

If during installation the cable to the control unit has to be reconnected first close the

receiver/transmitter boxes before power up the system.

Please observe the information in 5.1 and 5.2.

10

4. Safety

4.6 Safety information for storage and transport

Always observe the information in paragraph 9 to avoid any transport damage and per-

sonal injuries.

4.7 Notes on residual risks

Electrical circuits may still be live even after having been isolated from the mains.

Switch off immediately if a fault occurs.

4.8 Notes on stable standing requirements

To avoid any loss of stable standing, the information for transport, commissioning and

operation must always be observed. Particularly take care that the detector head is bolted

4.9 Consequences of unauthorized modification

In case of unauthorized modification or repair work all the declarations and guarantees

given by the manufacturer will become void.

4.10 Inadmissible operation

For other applications as enumerated in 4.1 the GLS metal detector is not intended for –

that is regarded as inadmissible operation.

Inadmissible is the operation out of the specifications given in the technical data and the

operation under high mechanical static or dynamic loads (e.g. heavy system parts or

strong vibrations). Al It is furthermore not permitted to inspect any aggressive materials on

the conveyor, such as materials containing lyes, acids, and solvents, or materials that

react to electromagnetic fields, or living persons or animals.

It is not permitted to operate the metal detector in hazardous locations (explosion zones 0,

1, 20 und 21).

11

5. Commissioning

5 Commissioning

5.1 Mechanical installation

Use only enough stable lifting harnesses for big and heavy

detector heads.

Take care for a stable and vibrationproof mounting!

MZ

Metal-free zone must be strictly observed!

Within the metal-free zone no metallic parts must be situated.

For moving metal parts (pusher) the metal-free zone extends.

The dimensions of the metal-free zone are given in the at-

tached data sheet.

A nonmetallic slide (plastics or wood) must be used within

the aperture as a belt support.

The sliding board and also the run back belt underneath

should not touch the shaft walls inside of the detector

head opening.

The recommended gap between slide and detector is min.

10 mm.

Do not mount or operate the detector near sources of interferences (electric motors,

frequency and current converters). The required distance depends on the aperture size

of the detector head and the power of the source of interference.

12

5. Commissioning

Control unit mounted apart of the detector head:

Changes of the connection cables between the detector head GLS and the control unit

must be reconfirmed by S+S. Only original cables must be used

otherwise the CE-certification become unvalid.

The connections cable must be installed separate from other power and control lines

and carefully fixed or layed into a cable duct.

Installation of more then one GLS-coil:

In case that two or more GLS-coils are working in adjacent lines interferences can occur.

Therefore you need to reconfirm S+S.

Pay attention to the following order when mounting the GLS to conveying pipe:

Do not remove the plastic bars or replace them by other materials. This parts are not

only used as fastening elements but also as an electrical insulator.

1. If necessary disconnect the connection cable (3) (see also 5.2).

2. Put the belt and sliding board through the detector opening. Fasten the board and make sure that

neither the sliding board nor the belt touches the shaft walls inside of the detector opening.

3. For mounting the detector head use only the plastic bars.

4. Connect connector cable (3) according to picture 5.2.

1

2

3

13

5. Commissioning

5.2 Connections

If the connection cable between detector head and control unit has been removed reconnect it accord-

ing to the sketch:

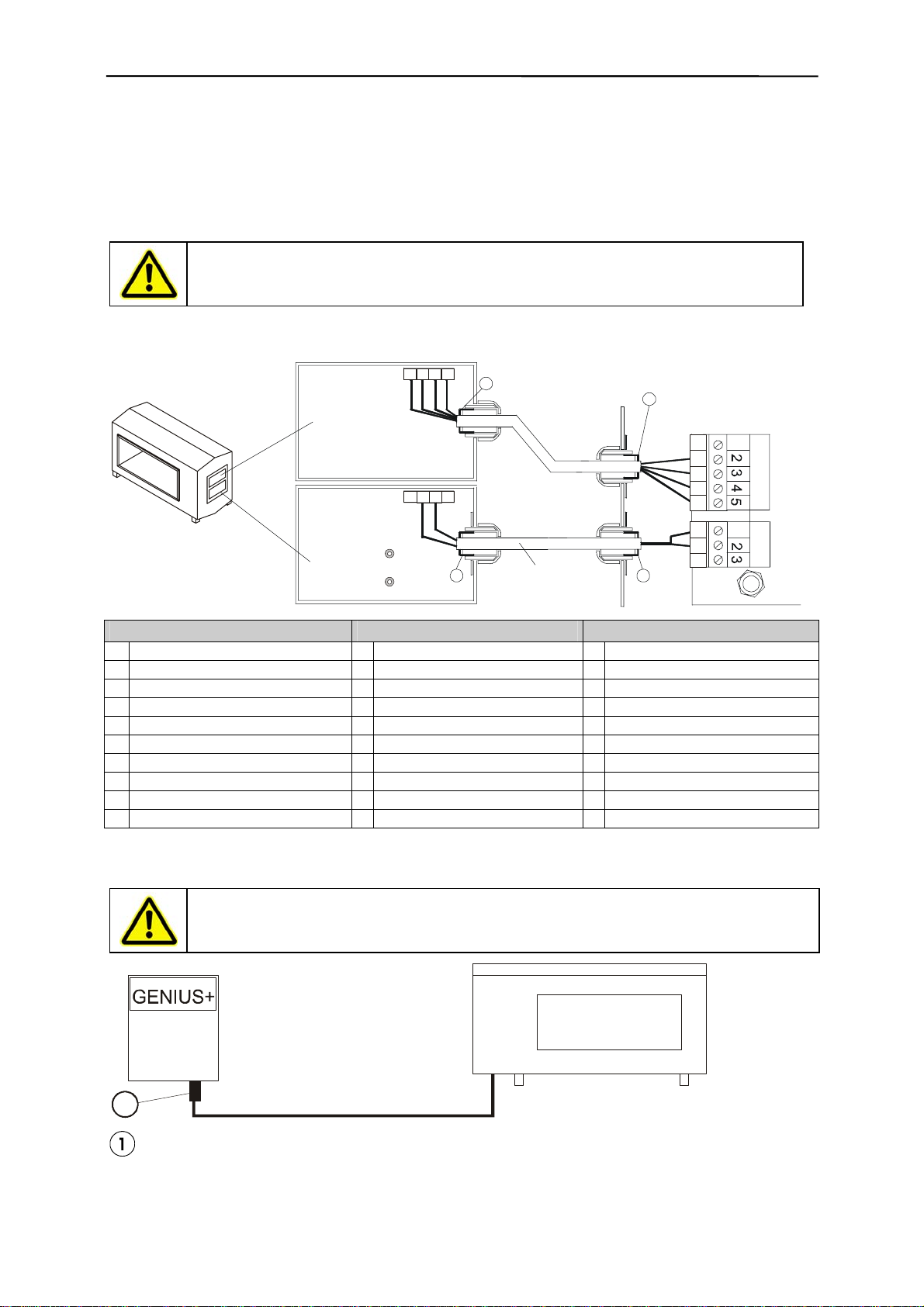

5.2.1 Control Unit PRIMUS / SENSITY

Electrical work should only be carried out by qualified personnel.

Before removing cover plates etc make sure the equipment is isolated from mains or

external voltage.

GLS metal detector Coil connection boxes Housing Control Unit

PRIMUS / SENSITY

Triax-Cable

11

Transmitter

Receiver

Receiver

Transmitter

1234

5678

9 9

9

9

Terminal coil connection box Connector receiver Connector transmitter

1 -----

1 white / brown 2 white / brown

2 2 x black (shield inside) 3 2 x black (shield inside)

3 yellow 4 yellow

4 green 5 green

5 -----

6 transparent 1 transparent

7 blue 2 blue

8 ----- 3 -----

9 shield outside

5.2.2 Control Unit GENIUS+

Electrical work should only be carried out by qualified personnel.

Before removing cover plates etc make sure the equipment is isolated from mains or ex-

ternal voltage.

GLS

1

Connector

The connection cable for control unit Genius+ and detector head can be plugged.

14

6. Errors and fault rectification

6 Errors and fault rectification

If you should have any questions, or if there should be any malfunctions, please contact

the manufacturer.

If you have any questions, please state the equipment type and serial number!

Service telephone: +49 (0) 85 54 - 30 8-180

15

7. Maintenance and cleaning

7 Maintenance and cleaning

Prior to any maintenance and cleaning work, disconnect the device from the mains

supply.

7.1 Maintenance

Although the GLS is maintenance-free, it is useful to check the equipment periodically:

- Check for loose bolts or nuts at the plastic bars

- Remove any objects laying on the detector head

- Remove any objects in the detector passage between slide and detector (remains of bulky goods

or accumulated dust)

- Check the throughput opening for damages and cracks, where water can enter?

- Check the connection cable for damages (i.e. the cable sheath).

7.2 Cleaning

7.2.1 Advice

- Please ensure you follow the instructions below.

- Specific machine components must be cleaned with specific substances. Please use the correct

materials and clean at regular intervals as suggested.

- Do not start cleaning until the machine has been switched off at the mains.

- If the building is being cleaned ensure the machines are covered up.

The following must not be used for cleaning:

- Sharp, hard or pointed objects

- Water or steam jet appliances

- Compressed air

- Hazardous and solvent-containing materials

- Cleaning agents that may attack the materials used

7.2.2 Cleaning instructions

We recommend cleaning the area with a soft, non-fibrous cloth using warm water and the appropriate

cleaning agent. Once weekly clean inside and underneath the detector thoroughly to remove dirt and

deposits. After cleaning wipe up any remaining drops of water with a dry, non-fibrous cloth. From time

to time apply oil to the stainless steel framework (eg Nirostol 55 cleaning and maintenance oil which

meets food industry standards).

7.2.3 are advice for stainless steel

The manufacturer uses only high-grade stainless steel. To prevent rust on the high-grade steel parts

do not use substances containing chloride (eg cleaning or disinfecting products) or site the machine in

an atmosphere containing chloride. If this is unavoidable the steel parts must be thoroughly rubbed

down immediately afterwards with cleaning oil eg Nirostol 55 cleaning and maintenance oil (which

meets food industry standards).

Important information for stainless steel models

Stainless steel models are extremely weatherproof and are therefore able to withstand most environ-

mental conditions.

However, even stainless steel can be susceptible to a slight film of rust.

These deposits are caused by contact corrosion and can be removed by following the instructions

below:

- Use a stainless steel cleaner: in principle any stainless steel cleaner may be used. Please ensure

you read the instructions prior to use.

- Use only cleaning agents that are halogen-free (ie without chlorides and fluorides), and salt and

hydrofluoric acid free.

- After each cleaning rinse the machine thoroughly with tap water

- Do not use the following: non-alloy materials or substances, abrasive cloths, cleaning agents con-

taining salt or hydrofluoric acid, chrome, silver or brass cleaners.

16

8. Spare parts

8 Spare parts

If you should have any questions please state equipment type and serial number!

Spare parts and wearing parts must always be obtained from the manufacturer of from a

supplier that is certified by the manufacturer.

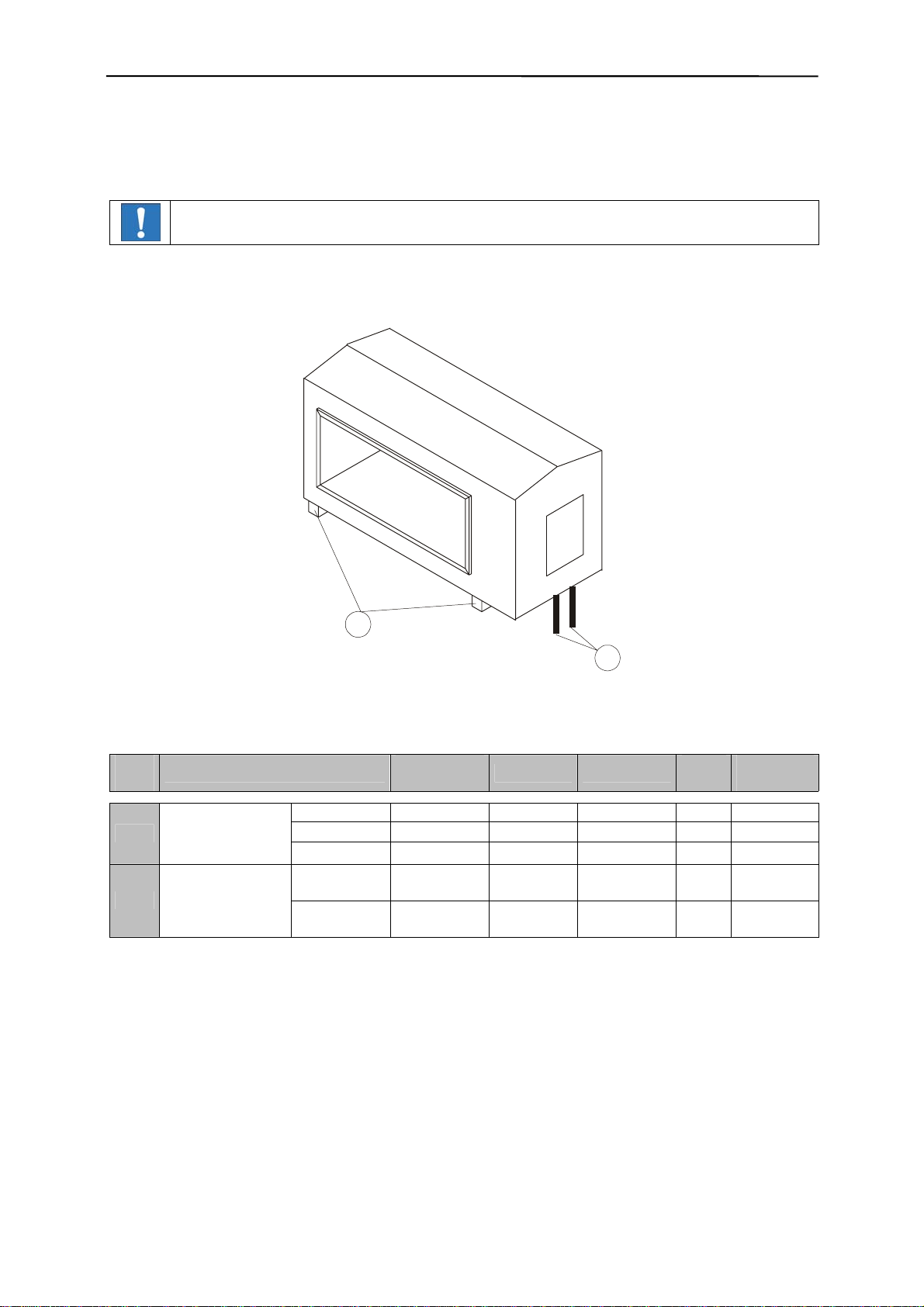

8.1 Spare parts drawing

1

2

8.2 Spare parts list

Item

No. Part Drawing

no. Material Part No. Sp/

Con+ Article

no.

for DH<350 Z0007315 polyamide 77008033 Sp 84799080

for DH≥350 Z0010960 polyamide 77021768 Sp 84799080

1

Mounting ele-

ments for instal-

lation for DH≥700 on request polyamide on request Sp 84799080

Receiver

cable

44005410 Sp 85444290

2 Electronic con-

nection cable 1) Transmitter

cable 04015444 Sp 85444290

*Sp/Con = Spare part / Consumable

1) Please state the cable length when ordering!

17

9. Shipping, preservation, waste disposal, transport, storage

9 Shipping, preservation, waste disposal, transport, storage

9.1 Shipping, preservation, waste disposal

1. Choose packing that is suitable for the type and size of unit, taking into account

whether the shipment is for export by sea or airfreight, or for national or international

road transport The packing material must protect the goods from all damage under

normal transport conditions.

2. Depending on the size, weight and nature of the goods packing in cardboard boxes,

boxed pallets etc is only suitable for road transport.

Use reinforced card, corrugated cardboard, blister packing and shredded paper to fill

and protect the goods.

Electrostatic sensitive components (electronic boards, electronic modules, etc.) must

be packed in antistatic foil or foil bags prior to packing! (this is essential!)

Stick additional warning labels on the outside of the packaging eg “Attention, elec-

tronic equipment, do not drop,” etc. The packing should be sealed with adhesive tape

and, where the weight exceeds 50 kg, additionally with wrapping tape.

2a. When packing for international road transport use the instructions above (see point

2). Larger and heavier shipments must also be protected as for export in wooden

crates. Care must be taken to ensure that the goods inside the packing are protected

against corrosion.

Any parts that will corrode easily must be wrapped in oil paper or corrosion-protective

foil. Care must be taken to prevent the components moving around within the pack-

aging.

2b. International air freight shipments must be packed in wooden crates or on export

paltainers.

Care must be taken that the goods are secure and well-protected inside the packing.

Any parts liable to corrode must be wrapped in oil paper, protective foil or sprayed

with anti-corrosion spray.

2c. Sea-freight must be packed in seaworthy export crates. These crates can be ob-

tained from specialist suppliers.

The crates must be lined with oil paper to make them resistant to sea water and pre-

vent corrosion. In addition the goods must be protected against corrosion by use of a

spray or be wrapping in protective foil.

Care must be taken to ensure that the goods cannot move around inside the crate.

After packing the sea-freight crates must be properly closed.

The sea crates must also be fastened externally with securing tapes.

During loading care must be taken not to damage the external packaging.

The carrier must certify that the shipment has been accepted and loaded correctly by

detailing this on the bill of lading, loading list etc.

3.

Waste disposal: Observe the national waste disposal regulations.

18

9. Shipping, preservation, waste disposal, transport, storage

9.2 Transport

• In order to avoid injury or damage to the unit it must be handled properly. In addition to

following the instructions below, general health and safety good practice and specific

accident prevention guidelines should be observed.

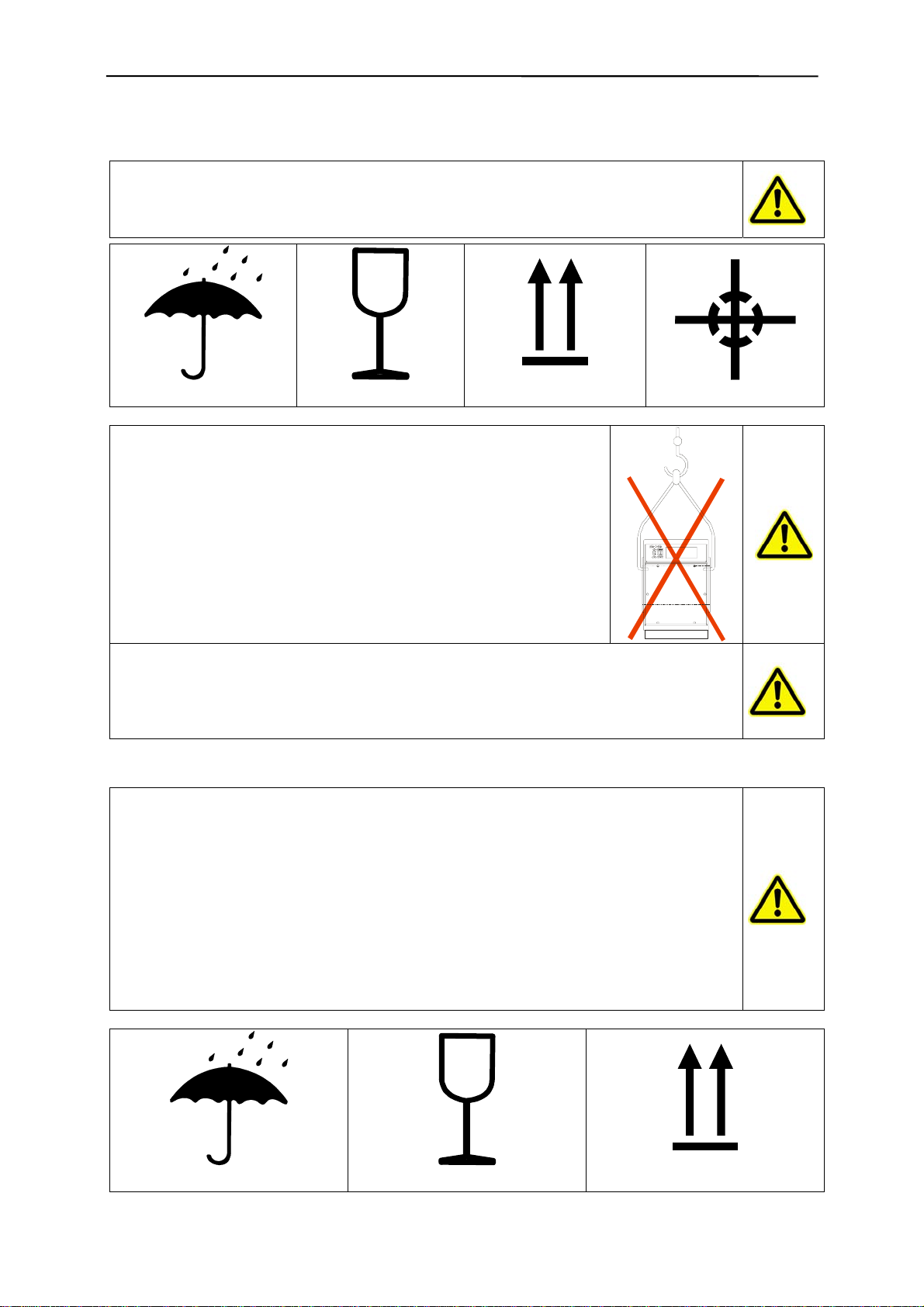

• For correct handling and storage comply with the following symbols:

Protect against moisture

Careful: glass

Up

Centre of gravity

• Do not lift the metal detector head at the through put opening.

• Use a lifting gear attached to the mounting brackets or lifting eyes.

• Do not compress the side walls of the unit or any attached parts by pulling obliquely on

ropes or chains.

• Only remove handling safeguards once all installation work has been completed.

• When handling in a loading area make sure the unit cannot topple over or slip.

• Damage caused during transportation must always be reported to the manufacturer.

9.3 Storage

• If possible the unit should be stored in a closed room until final installation.

• If the unit is stored in the open it must be covered over with tarpaulins and open un-

derneath, to allow condensation to drain off.

• Avoid any higher temperature fluctuations. It is possible that condensed water that has

formed in the packing cannot properly drain and may corrode equipment surfaces. If a

formation of condensed water cannot be avoided, suitable desiccants e.g. in the form

of bags must be placed in the packing.

• If the unit has been packed for transportation by sea the packaging must not be dam-

aged or opened during transit and storage.

• For storage temperature and permissible air humidity please refer to the technical data

sheet.

• For correct storage comply with all storage and handling symbols:

Protect against moisture

Careful: glass

Up

19

10. Annex

10 Annex

• Technical data sheet

• Installation suggestions for tunnel metal detectors

• Circuit diagrams, wiring diagrams, etc.

• Signalling device (option) operating instructions

20

Table of contents

Popular Metal Detector manuals by other brands

Kellyco

Kellyco Minelab X-Terra Quick start referen

Waldbeck

Waldbeck Yukon instruction manual

DeepTech

DeepTech Vista MINI instruction manual

Fisher Research Labs

Fisher Research Labs Gemini-3 operating manual

Quest Engineering

Quest Engineering V60 instruction manual

Minelab

Minelab PRO-FIND 25 Instruction guide