SPM BDM-40 User manual

Description

Bearing Display Modules measures the shock pulse values of rolling bearings in dBsv on two channels

and converts the result to analog signals, 4-20 mA. The measuring range can be jumper set on the lower

circuit board to either 0 – 80 dBsv or to 20 – 100 dBsv. Via coaxial cables with TNC connectors, the BDM

modules are connected to shock pulse transducers of type SPM 40000 (BDM-40) or of type SPM 42000

(BDM-42). The modules are supplied with 12 to 24 V DC ±10%, source referred to earth.

The Bearing Display Modules have two relay outputs, 24 V/100 mA. The relays can be controlled by

either input channel. When using one input channel ('r 1' mode), both relays are slaved to that channel

and provide relay switching at two levels (ALERT and ALARM). When using two input channels ('r 2'

mode), each channel uses one relay which switches at the ALARM level.

Measured quantities and ranges are selected from a list of 13 programs. The user can add 7 own

programs. Programmable parameters for each input channel are the measuring range, the two alarm

levels ALERT and ALARM, and the time delay for each. The user also selects the relay mode and either

manual or automatic reset of ALARM. These parameters are input with two push-buttons.

Status display is provided by three coloured LEDs. The green LED is on while measured values are below

the ALERT level. Measured values between ALERT and ALARM on either channel trigger a yellow LED,

and a red LED lights up when a measured value exceeds one of the ALARM levels. A blinking yellow LED

indicates a system fault (incoming signal below 4 mA).

The measured value is displayed with two digits. In 'two channel mode', the status LEDs and the display

alternate between the two channels. The display shows the channel number followed by the measured

value on this channel.

The display modules can be connected to the analog input (4-20 mA analog signals) and the digital input

(relays) of a PLC.

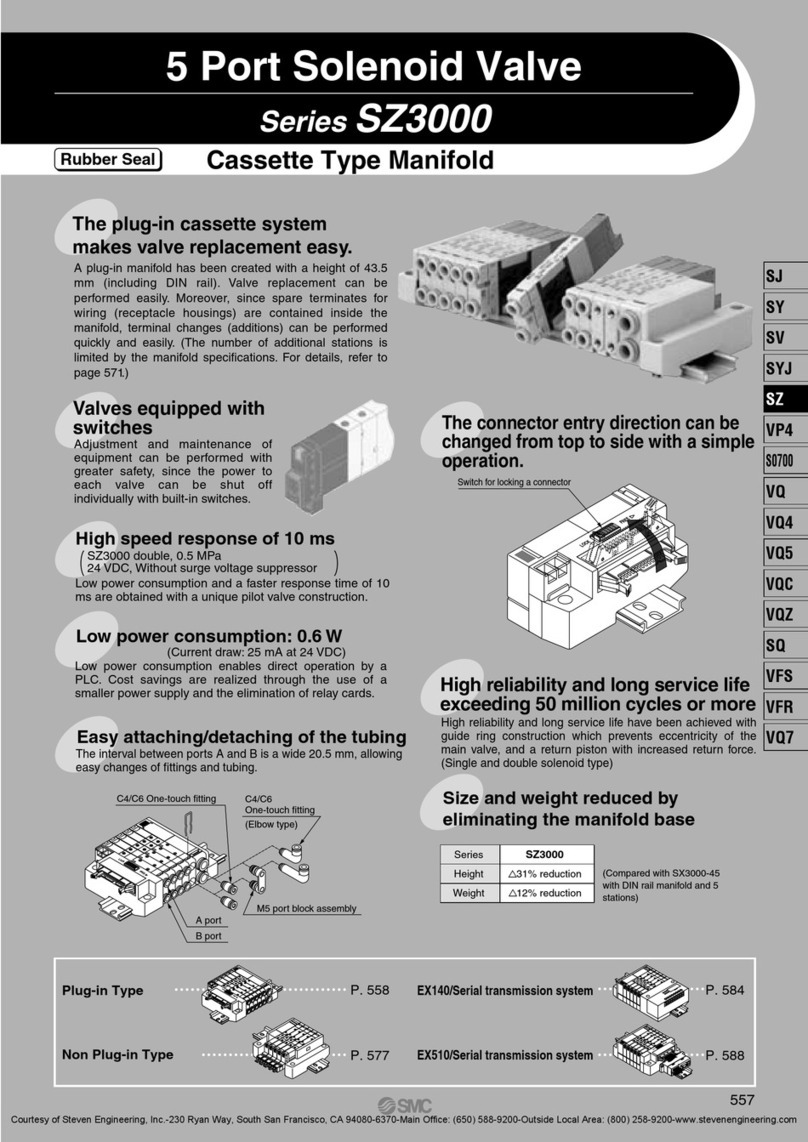

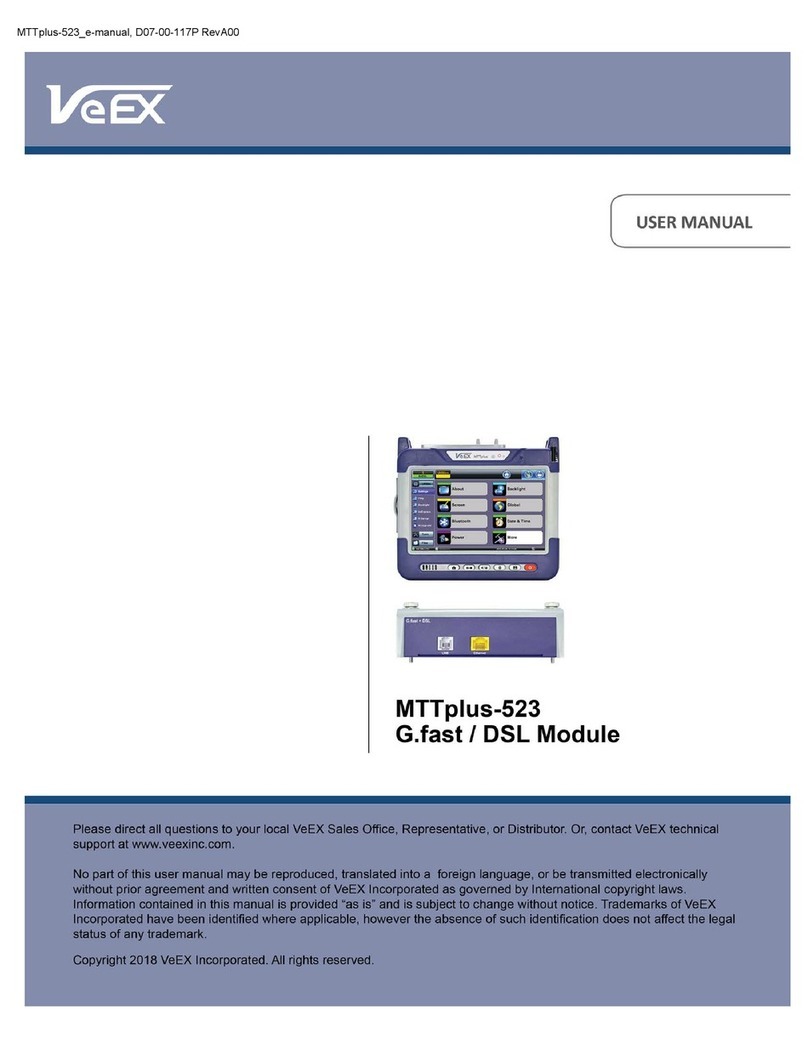

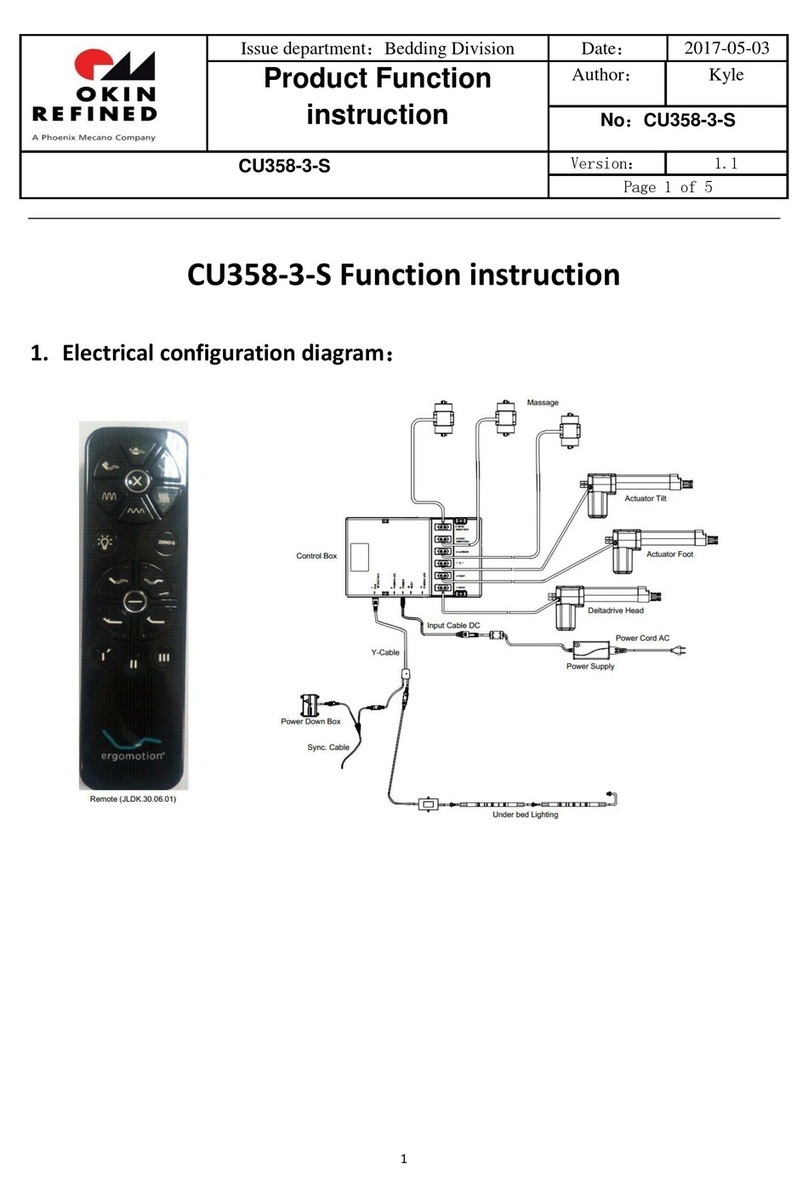

DC supply 12 to 24 V,

source referred to earth

Yellow on = ALERT

Yellow blinking = system fault

Red on = ALARM

Red blinking = ALARM and

system fault

Green on = power on,

no alarm

Value display

Control buttons

Relay 2

Relay 1

Measurement unit

stickers

Channel 1 Channel 2

Jumper for measuring range setting Jumper for TLT OFF

Installation of Bearing Display Modules BDM

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden

Technical data are subject to change without notice.

ISO 9001 certified. © SPM 2004-04. 71748.B

Installation of Bearing Display Module BDM

2

Technical data for Bearing Display Module BDM-40 and BDM-42

Measuring method: SPM dBm, unnormalized maximum value

Measuring channels: 2, multiplexing

Measuring range 1: 0 to 80 dBsv (5 dB /mA, 0.2mA/dB)

Measuring range 2: 20 to 100 dBsv (4 mA ≤20 dBsv)

Measuring time: approx. 1 second per channel

Transducer type: SPM 40000 (BDM-40), SPM 42000 (BDM-42)

Transducer cable: coaxial cable, SPM 90005-L, or 90267-L (L = length in m)

Analog output: 4 to 20 mA, no galvanic separation

Fault indication: ≤1 mA out = interrupted or faulty transducer line

Loop resistance: max. 450 Ωat 12 V, 1.1 kΩat 24 V

Power supply: 12 to 24V DC (±10%, tested according to EN 50082-2) source

referred to earth

Supply current: max. 0.15 A

Cable inlet: IP 65 at ø 5.5 to 10 mm

Housing: polycarbonate, IP65

Temperature range: 0 to 55 °C

Vibration exposure: max. 5 mm/s RMS

Dimensions: 110 x 149 x 56 mm

Mounting screws: 4 screws, ø 4 mm, spacing 109 x 94 mm

Weight: 400 g

Signal to display: 4 to 20 mA, 2 channels

Relays: 2, max. 24 V/100 mA

Value display: 3 digits LED

Condition display: green, yellow, and red LED

Alarm limits: 2 per input channel, set with push-buttons

Push-buttons: 2, for display control and settings

56

124

110

109

94

149

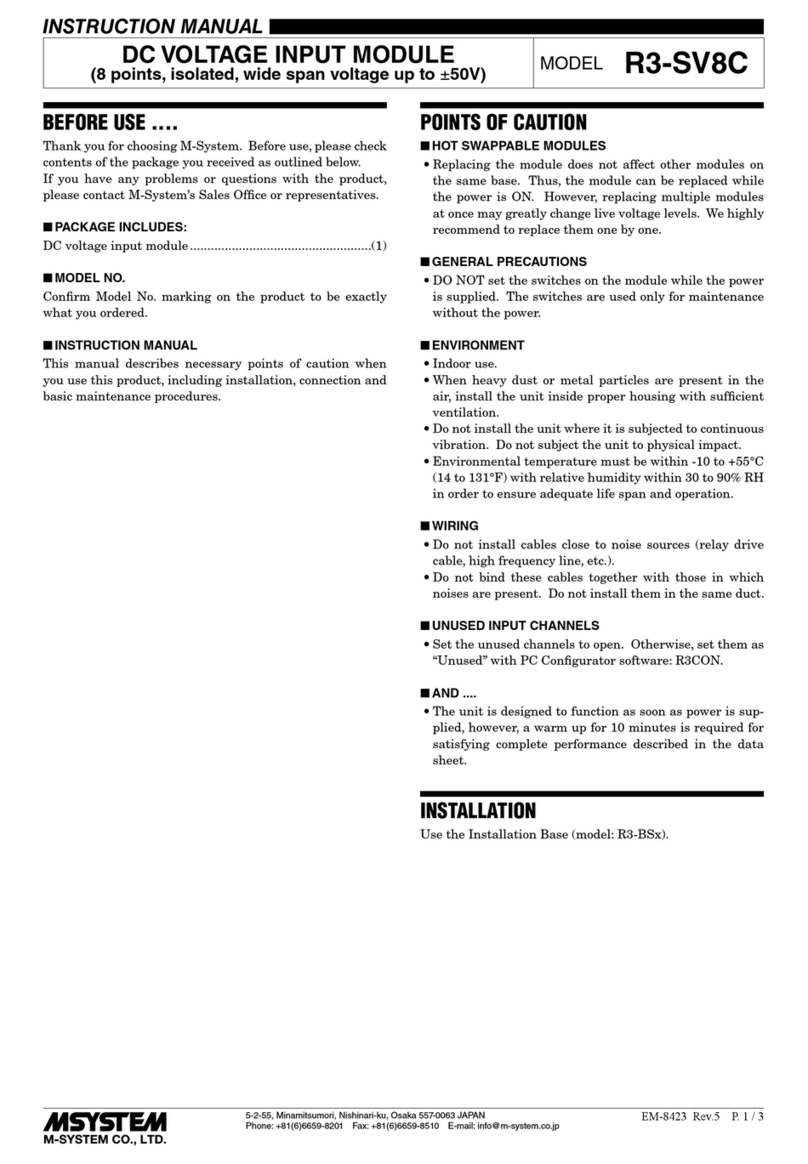

Coaxial cable with

TNC connectors Shock pulse transducer

Module Transducer Cable length

BDM-40 40000 max. 4 m

BDM-42 42000 max. 100 m

3

Installation of Bearing Display Module BDM

The analog signals 4 - 20 mA can also be used in

the AMS unit for on-line condition monitoring in

connection with the SPM Condmaster®Pro soft-

ware.

Note that the max. total loop resistance of a 4-

20 mA circuit depends on the signal source. As a

rule, loop resistance should not exceed 400 Ωin

a CMM system.

Loop resistance R = 47 + 47 + 75 = 169 Ω

+ cable resistance. Maximum 400 Ω

Electrical installation

When used as a stand-alone display unit, the module is connected to a 12 - 24 V DC power source with

earth reference. All electric connections are made to the upper circuit board. The jumpers connecting

the analog channels to earth are factory mounted and can be removed when connecting to a PLC.

BDM modules are delivered with jumpers that connect the 4 - 20 mA output of the lower measuring

circuit to the upper display circuit.

When connected to a PLC, the display module can get its power supply from it. The jumpers from the

analog channels are removed. The analog channels are connected to the PLC's AI (analog in) unit, the

relays to the DI (digital in) unit.

Please note: The return line from the current loop are connected to the negative pole on the power

supply.

Mechanical installation

The module is wall mounted, with 4 screws through the back of the casing. The screw diameter is 4 mm, the

spacing is 109 x 94 mm. The module housing has a transparent lid fixed to the box by four screws and has

to be opened for installation and programming. The maximum vibration exposure is 5 mm/s RMS. The

temperature range is 0 to 55 °C (32 - 130 °F). The incoming signal/power cables must have a diameter of 5.5

to 10 mm to maintain IP65.

Analog

signal

– + PLC

75 Ω

+ –

AMS

47 Ω

+ –

BDM

47 Ω

+ –

4–20 mA

BDM connected to PLC

measuring circuit board

(lower)

BDM

measuring circuit board

(lower)

Installation of Bearing Display Module BDM

4

Measuring

circuit board

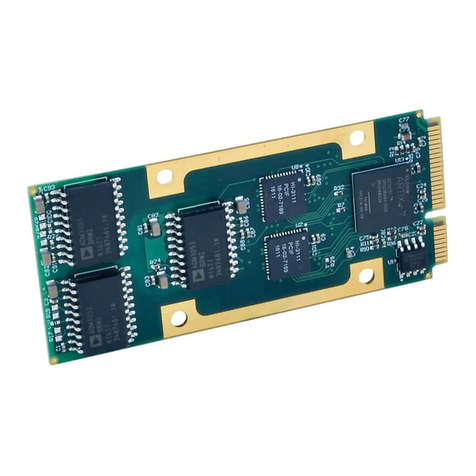

BDM modules contain two circuit boards, the bearing measuring circuit board (lower) and the display

circuit board (upper) for 4 – 20 mA analog signals. The analog output(s) on the measuring board are

factory connected to the display board.

All electric connections are made to the upper display circuit board. The lower board has two jumpers,

one is used to select the measuring range and one to select TLT OFF (this jumper is factory mounted on

one of the contact pins).

Measuring range setting

The jumper socket marked 1 2 in the upper left corner on the circuit board is used to set the measuring

range in unnormalized shock values:

1. 0 – 80 dBsv 2. 20 – 100 dBsv

One of these ranges must be selected and have effect on both channels. The factory setting is 0 - 80 dBsv.

The range can be changed at any time. Note that the display range program or the PLC must be changed

accordingly.

TLT OFF (test)

In case of transducer line fault (open or short circuit), the analog signal goes down to <1 mA. To avoid

problems with e.g. a PLC, one can move the jumper to both contact pins at ”TLT OFF” on the circuit

board. This will eliminate the transducer line test and keeps the channel output at min. 4 mA in case of

fault.

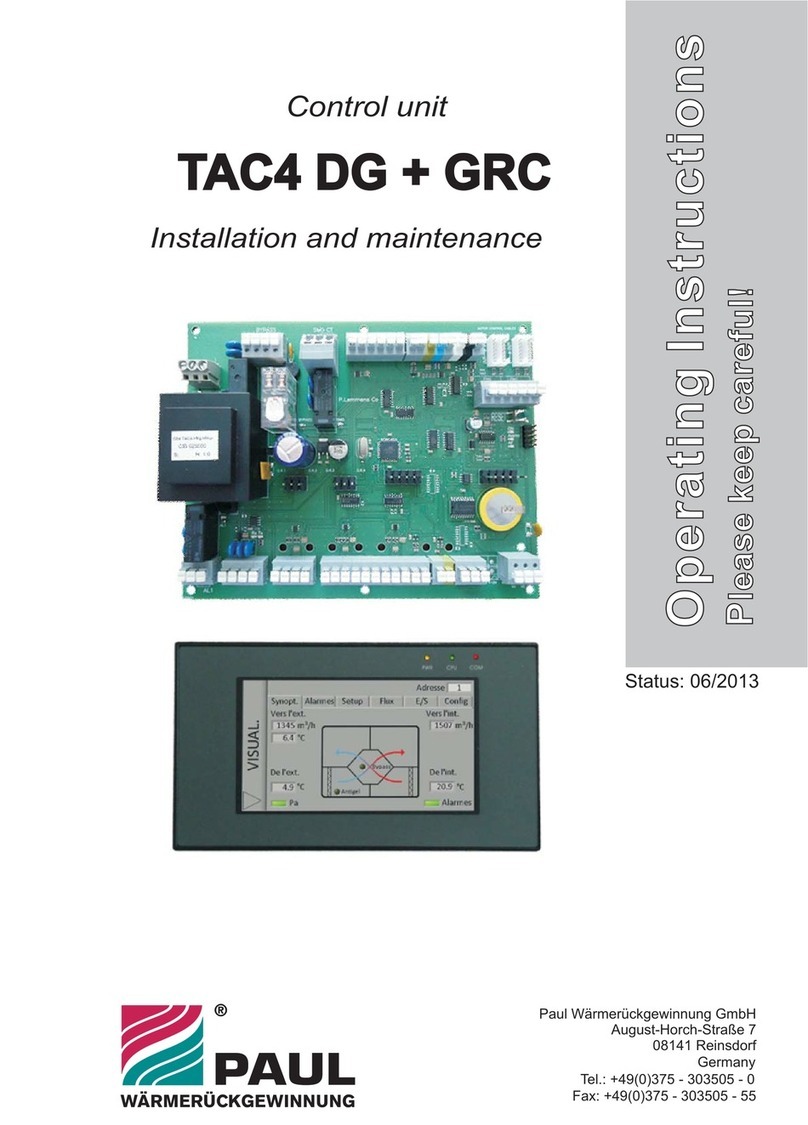

0 – 80 dBsv 20 – 100 dBsv

TLT OFF (test)

12

12

A jumper can be set at TLT OFF for test

(min. 4 mA in case of TLT fault)

TLT (normal)

Jumper for setting of measuring range

5

Installation of Bearing Display Module BDM

RPM

RPM

Measuring range 0 to 80 dBsv, alarm level at 35 dBn

Measuring range 20 to 100 dBsv, alarm level at 35 dBn

Shaft

diameter

mm

Shaft

diameter

mm

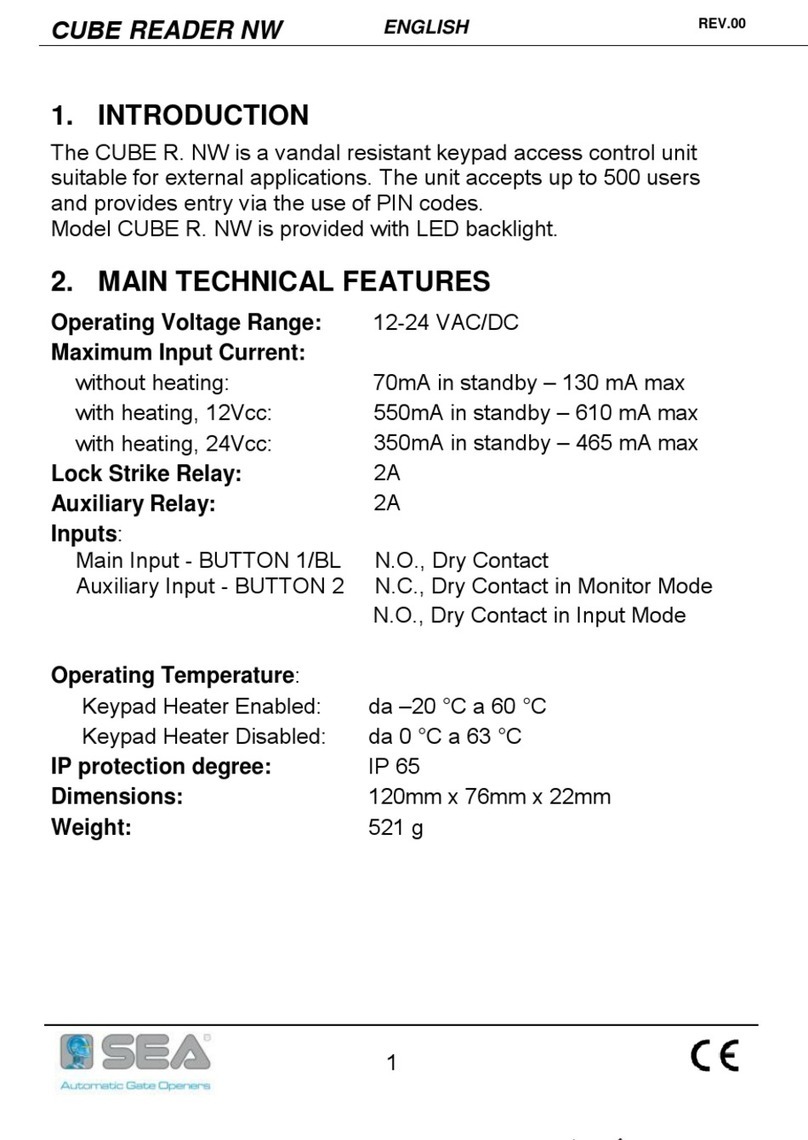

Alarm levels in relation to bearing seize and speed

The initial shock pulse level (dBi = decibel initial) of rolling bearings in good condition depends on bearing

size and rotational speed. The beginning of the red ”bad condition” zone is normally dBi + 35 dB (35 dBn on

the normalized scale). In the diagrams, this level is shown in dBsv (unnormalized shock value) and in mA.

Example:

A bearing with shaft diameter d = 20 mm and rotational speed = 1100 rpm has a dBi of 10. 35 dBn thus

corresponds to 45 dBsv, that is 13 mA for measuring range 0 to 80 dBsv, and 9 mA for measuring range 20 to

100 dBsv.

As signal strength also depends on the quality of the measuring point, it may be necessary to adjust the alarm

level to the individual bearing, normally downwards.

Whenever possible, the bearing should be measured with a SPM Tester before setting alarm levels. This

instrument will also show the exact initial value dBi of a bearing when shaft diameter and rpm are input.

Installation of Bearing Display Module BDM

6

No. Quantity Unit 4mA 20mA

00 Test 0-20 mA mA 4.0 20.0

01 Vibration mm/s 0.0 5.0

02 Vibration mm/s 0.0 10.0

03 Vibration mm/s 0.0 20.0

04 Vibration mm/s 0.0 40.0

05 Shock pulse dBsv 0 80

06 Shock pulse dBsv 20 100

07 Temperature °C-16 120

08 Vibration inch/s 0.00 0.19

09 Vibration inch/s 0.0 0.39

10 Vibration inch/s 0.0 0.78

No. Quantity Unit 4mA 20mA

11 Vibration inch/s 0.0 1.57

12 Temperature °F3248

13 Percentage % 0 100

14

15

16

17

18

19

20

( Free configuration of programs 14 - 20 )

Display during operation

In 'one channel mode', the number display shows the

value on channel 1. The LEDs show the status:

Level 2 ALARM red

Level 1 ALERT yellow

Signal < 4 mA flashing yellow (not program 00)

OK green.

Channel and active program

3seconds

One channel mode

Two channel mode

Active program

3seconds

One channel mode

Two channel mode

To check the active program(s), hold down A+B until all

LEDs light up and the number display flashes. The display

shows one digit for measuring mode/channel followed by

two digits for the active program:

0XX One channel mode, program no. XX

1XX Two channel mode, program no. XX on channel 1

2XX Two channel mode, program no. XX on channel 2.

The module returns to the measuring mode after 30

seconds.

The 'one channel mode' can be programmed for channel 1 even when both channels are receiving input

signals. In this case, no results for channel 2 will be shown until the mode is changed. It is not possible to

measure on channel 2 only. If channel 1 is disconnected while the module is active, there will be a

continuous 'interrupted circuit' status (flashing yellow LED, outgoing analog signal ≈0 mA). Please note

that this does not apply to program 00, which is a test function showing the actual input current.

If an alarm delay cycle is interrupted by a measured value below the alarm limit, it starts again from 0

when the next value above the alarm limit is received.

Measuring programs

Programs 05 (0 – 80 dBsv) and 06 (20 – 100 dBsv) are used for shock pulse measuring and should

correspond to the measuring range set by the jumper on the lower measuring circuit board.

In 'two channel mode', the display alternates between the channels, showing CH1 – value, then CH2 –

value. The alarm status for the active channel is shown by the LEDs as in 'one channel mode'.

7

Installation of Bearing Display Module BDM

1. Hold down A+B until all LEDs light up. The

display shows the active program(s).

2. Hold down A+B until the display flashes

”000”.

3. Press A for 'one channel mode'. The display

shows ”0XX”, where the flashing "XX" is the

number of the active program.

4. To change the program, press B repeatedly

until the desired program number is shown.

5. Press A to go to the reset setting. B toggles

between automatic and manual reset (see

below).

6. Press A to end the programming mode and

start normal operation.

3seconds

Selects program

Programming, one channel mode

Shows active program(s)

Starts programming mode

Sets 'One channel mode',

shows active program

One channel mode, programming

When programming in 'one channel mode', the button A is used to go to the next step while the button

B is used to make changes. You can step through the whole program and check all setting by simply

pressing A.

3seconds

Shows reset setting

Ends programming mode

Toggles between AAU

(automatic reset) and Art

(manual reset) of ALARM

Alarm reset

ALERT (yellow LED on) always has automatic reset: both the status display and relay positions are

controlled by the measured signal. This means that an alarm disappears when the measured value drops

to or below the alarm limit.

ALARM (red LED on) has the same automatic reset when 'AAU' is active. When manual reset 'Art' is

active, the status display and the relay positions are held until either A or B is pushed. This will reset the

status display and the relays if the alarm condition has disappeared.

Please note: if the incoming signal drops below 4 mA while ALARM is held, the red LED will flash instead

of the yellow LED.

Relay action in one channel mode

The relays are specified 24 V/100 mA. In one channel mode, the relay mode 'r 1' is active and can not be

changed by the user.

ALARM

red LED on

ALERT (no power)

yellow LED on

OK

green LED on

In one channel mode, the module receives the analog

signal on channel 1. Two alarm levels can be programmed

(see page 8).

Level 1 = ALERT = yellow LED is connected to Relay 1.

Relay 1 is NC = normally closed. It opens on power

failure and on alarm (value above the lower or ALERT

alarm level). Thus, it will be open when the yellow or the

red status LED is on.

Level 2 = ALARM = red LED is connected to Relay 2.

Relay 2 is NO = normally open. It closes on ALARM =

red status LED is on. NC NO

Installation of Bearing Display Module BDM

8

1. Hold down A+B until all LEDs light up. The

display shows the active program(s).

2. Hold down A+B until the display flashes

”000”.

3. Press B for 'two channel mode'. The display

shows ”1XX”, where 1 is the channel and

the flashing "XX" is the number of the active

program.

4. To change the program, press B repeatedly

until the desired program number is shown.

5. Press A to go to channel 2. The display

shows ”2XX”, where 2 is the channel and

the flashing "XX" is the number of the active

program.

6. To change the program, press B repeatedly

until the desired program number is shown.

7. Press A to go to the relay action setting (see

next page). B toggles between NO and NC.

8. Press A to go to the relay mode setting (see

next page). B toggles between 'r 1' and 'r 2'

mode.

9. Press A to go to the reset setting (see

below). B toggles between automatic and

manual reset.

10 Press A to end the programming mode and

start normal operation.

Two channel mode, programming

When programming, the point [ B ] is where you set 'two channel mode'. After that, the button A is used

to go to the next step while the button B is used to make changes. You can step through the rest of

program and check all setting by simply pressing A.

3seconds

Selects program, chan. 1

Programming, two channel mode

Shows active channels

and programs

Starts programming mode

Sets 'Two channel mode',

shows program on chan. 1

3seconds

Shows relay mode 1/2

Ends programming mode

Toggles between relay

mode 1 and relay mode 2

Selects program, chan. 2

Shows program on chan. 2

Shows relay action NO/NC

Toggles between NO

(normally open) and NC

(normally closed)

Shows reset setting

Toggles between AAU

(automatic reset) and Art

(manual reset) of ALARM

Alarm reset

ALERT (yellow LED on) always has automatic reset: both the status display and relay positions are

controlled by the measured signal. This means that an alarm disappears when the measured value drops

to or below the alarm limit.

ALARM (red LED on) has the same automatic reset when 'AAU' is active. When manual reset 'Art' is

active, the status display and the relay positions are held until either A or B is pushed. This will reset the

status display and the relays if the alarm condition has disappeared. Pushing A or B also starts

continuous measurement for 30 seconds on channel 1 (A) or channel 2 (B).

Please note: if the incoming signal drops below 4 mA while ALARM is held, the red LED will flash instead

of the yellow LED when the channel status is shown. Thus, you can have a situation where the loss of

incoming signal on both channels is show by flashing red on one channel and by flashing yellow on the

other (which has no latched alarm).

9

Installation of Bearing Display Module BDM

Relay action in two channel mode

The relays are specified 24 V/100 mA. In 'two channel mode', the user can select one of three alternative

relay modes.

ALARM

red LED on

ALERT (no power)

yellow LED on

OK

green LED on

Relay mode 'r 1'

In two channel mode, the module receives analog signals on both channel 1 and channel 2. Two alarm

levels can be programmed for each channel (see page 8). Relay mode 'r 1' implies, that both relays are

slaved to the channel with the higher alarm status.

The mode is set by selecting 'r 1' when programming.

This overrides the NC/NO setting in the program.

Level 1 = ALERT = yellow LED is connected to Relay 1.

Relay 1 is NC = normally closed. It opens on power

failure and on alarm (value above the lower or ALERT

alarm level). Thus, it will be open when the yellow or

the red status LED is on.

The alarm level 2 = ALARM = red LED is connected to

Relay 2. Relay 2 is NO = normally open. It closes on

ALARM = red status LED is on.

Relay mode 'r 2'

Relay mode 'r 2' implies, that relay 1 is slaved to channel 1 and relay 2 is slaved to

channel 2. The relays act on ALARM = red status LED is on. Thus there is no relay action

on power failure or yellow ALERT.

Relay action is program selected and set to either NO or NC. Thus, there are two alternatives:

ALARM channel 1 + 2

red LED on

ALARM channel 1

red LED on

ALARM channel 2

red LED on

OK / ALERT

green LED on

Mode 'r 2' + 'rn0'

NO (normally open)

ALARM channel 1 + 2

red LED on

ALARM channel 1

red LED on

ALARM channel 2

red LED on

OK / ALERT

green LED on

Mode 'r 2' + 'rnC'

NC (normally closed)

NO NO NC NC

NC NO

Installation of Bearing Display Module BDM

10

Increases

value

2 channel

Increases

value

(3 s)

(3 s)

(3 s)

1 channel

Increases

value

Increases

value

Ends programming

Alarm level 1

ALERT

Value

Alarm level 2

ALARM

Value

Alarm delay

ALERT

Delay in seconds

Alarm delay

ALARM

Delay in seconds

Setting alarm levels and delay

1. For channel 1, hold down button A until

either ”AL1” or ”Ch1” is displayed. For

channel 2, hold down button B until

”Ch2” is displayed. From there, the steps

are the same for both channels:

2. Keep pressing A until you reach the

parameter you want to change.

3. Change the (flashing) parameter value

with button B, then confirm and continue

with A.

If you overstep the desired number setting

with button B, you have to start over again

from the beginning. Pressing A while holding

down B takes you straight to the max. value.

By selecting a measuring program from the

list, you automatically adjust the display of

the module to the pre-programmed range.

The alarm level values are input in the pre-

programmed measuring unit (i. e. not in mA

except for the test program 00). The measur-

ing unit itself is not shown, so it should be

written on the channel label.

The module is back in measuring mode when

you finish programming with A. If you do not

press any button for 30 seconds, the unit will

automatically return to its normal operating

mode. All values confirmed with A will be

saved.

11

Installation of Bearing Display Module BDM

Own program (14-20)

Sets program number 14 – 20

3seconds

3seconds

Increases value at 20 mA

3seconds

Displayed value

at 20 mA

Displayed value

at 4 mA

Increases value at 4 mA

Sets decimal point position

Ends programming mode

• Positive value: jumps to max.

• Value 0: toggles between +and –

• Negative value: jumps to min.

Starts programming mode

• Positive value: jumps to max.

• Value 0: toggles between +and –

• Negative value: jumps to min.

Own programs

You can make programs for any type of meas-

ured quantity with a measuring range of –99 to

999 and represented by the incoming analog

signal. You set

•Program number 14 to 20

•Display format (max. 3 digits, 0 to 2

decimals.

•Measured value represented by 20 mA.

• Measured value represented by 4 mA.

If you overstep the desired number setting with

button B, you have to start over again from the

beginning. For any value on the display other

than 0, pressing A while you hold down B takes

you straight to the max. value.

To set negative values, use button B to set the

display to 0, then change from + to – by press-

ing A while holding down B.

1. Hold down A+B until all LEDs light up. The

display shows the active program(s).

2. Hold down A+B until the display flashes

”000”.

3. Hold down A+B until the display shows a

program number (flashing).

4. Press B repeatedly until the desired

program number (14 - 20) is shown.

5. Press A to go to the decimal point setting.

B moves from none to one to two decimal

places.

6. Press A to go to the value represented by

20 mA. B increases value.

7. Press A to go to the value represented by 4

mA. B increases value.

8. Press A to exit the programming mode.

Program number

Decimal

point

3seconds

3seconds

To select the program, go to programming "One

channel mode" (see page 7) or "Two channel

mode" (see page 8).

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________

Programming form

Program number

Measuring range and unit

Relay (NO/NC)

Relay mode (1 or 2)

Reset (automatic or manual)

ALERT level (AL1)

ALERT delay (dL1), seconds

ALARM level (AL2)

ALARM delay (dL2), seconds

Settings Channel 1 Channel 2

BDM type: .......................... Serial no.: ................................. Date: ............................. Sign.: ........................

Location: ..................................................................................................................................................................................

Measuring point, channel 1:.............................................................................................................................................

.....................................................................................................................................................................................................

Measuring point, channel 2:.............................................................................................................................................

.....................................................................................................................................................................................................

Machine data: ........................................................................................................................................................................

Comments:..............................................................................................................................................................................

.....................................................................................................................................................................................................

.....................................................................................................................................................................................................

.....................................................................................................................................................................................................

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden. Tel +46 152 22500 • Fax +46 152 15075 • [email protected] • www.spminstrument.com

Installation of Bearing Display Module BDM

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Allen-Bradley

Allen-Bradley 1492-AIFM16-F-5 manual

ICP DAS USA

ICP DAS USA M-7026 quick start guide

ICP DAS USA

ICP DAS USA LP-8 21 Series quick start

Phoenic Mecano

Phoenic Mecano Okin Q28-BNC quick start guide

Allen-Bradley

Allen-Bradley 1771-OFE installation instructions

RabbitCore

RabbitCore RCM2200 user manual