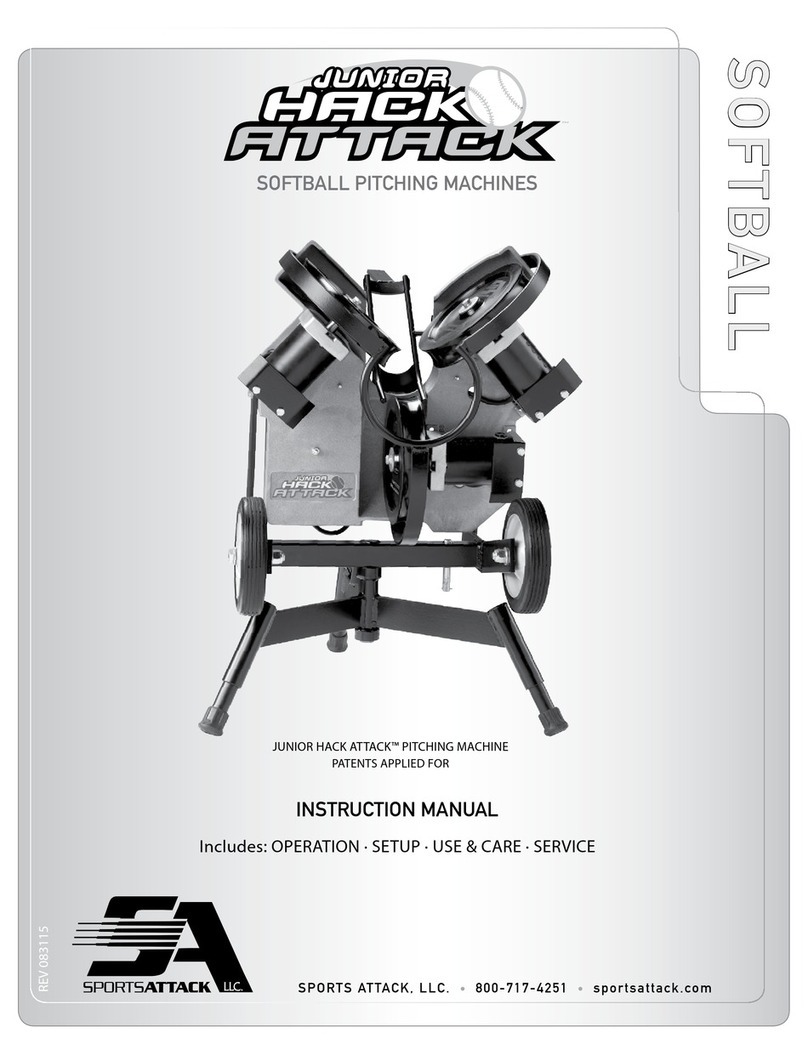

Sports Attack Hack Attack User manual

INSTRUCTION MANUAL

BASEBALL PITCHING MACHINES

HACK ATTACK™ PITCHING MACHINE

PATENTS APPLIED FOR

REV 083115

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com

Includes: OPERATION · SETUP · USE & CARE · SERVICE

BASEBALLBASEBALL

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com xi

SHIPPING DAMAGE CLAIMS PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully

inspected and packaged by skilled personnel before leaving the factory.

Upon acceptance of this shipment, the transportation company assumes full responsibility

for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on

the freight bill or express receipt, and that the note of loss or damage is signed by the

delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: If damage is unnoticed until the merchandise is

unpacked, notify the transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This must be done within fifteen (15) days

from the date the delivery was made to you. Be sure to retain the container for inspection.

Sports Attack, LLC. cannot assume liability for damage or loss incurred in transit. We will,

however, at your request, supply you with the necessary documents to support your claim.

Warranty/Shipping

RETURNS

To return an item, please

contact our Customer Service

Department at 800-717-4251.

A 15% restocking fee will be

charged for any items accepted

for return. It is the customer’s

responsibility to handle the

repacking and shipment (as well

as all associated fees) back to

Sports Attack.

No returns will be accepted after

30 days of receiving product.

WARRANTY STATEMENT

What is most important to Sports Attack is that your machine meets your expectations of

quality and performance. We stand behind the material and workmanship of our machines

for five (5) years from the date or original purchase for institutional and residential use and

one (1) year for commercial environments, with the following exceptions:

-Throwing Wheels are warranted for two (2) years;

-Electronic Controller is warranted for two (2) years; and,

-Throwing Wheel Motors are warranted for two (2) years.

This warranty excludes any cosmetic issues or normal wear and tear of the unit, and is not in

effect if the machine has been misused, misapplied, improperly assembled, or modified with-

out the express written permission of Sports Attack. In addition, this warranty does not apply

to damage in transit, in any accident unrelated to the direct operation of the equipment, or

by fire, flood or act of God.

If you encounter any issues during the warranty period, Sports Attack will quickly get your

machine back in working order. If the warranty repair involves a replacement part, we will

make sure you get both the part and easy instructions for replacement at no cost to you. If a

service person is needed, Sports Attack will pay the pre-approved labor charge to get your

machine back in working order.

Please know that any problem can quickly be resolved with a phone call to our experienced,

responsive customer service department at 800.717.4251. We are here to answer your ques-

tions and to make sure your machine provides you years of service.

RETURNS

Sports Attack manufactures the highest quality sports training equipment in the world. If for

any reason you are not satisfied, a machine can be returned within 30 days of receipt for any

reason for a full refund less a 10% restocking fee. Cost of shipping the unit back to Sports At-

tack will also be the responsibility of the purchaser. Please note that the refund amount may

be reduced by any non-cosmetic damage to the machine.

If you have any questions or concerns, please give our experienced, responsive customer service

department a call at 800.717.4251.

To register the Warranty,

please go to our website:

www.sportsattack.com/warranty

For repairs and service after the

Warranty period, please call:

Sports Attack

Customer Service Dept.

Ph 800-717-4251

Fx 775-345-2883

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 1

Table of Contents/Introduction

TABLE OF CONTENTS

Warranty Statement ...................................................................xi

Safety Instructions .................................................................... 2

HACK ATTACK BASEBALL MACHINE OPERATION

Features & Operating Controls ...................................................... 4

Set-up & Preparation ............................................................... 5

Batting Practice .................................................................... 6

Fungo (Fielding Practice) ........................................................... 8

Shutting Down..................................................................... 9

MAINTENANCE & SERVICE

Care, Cleaning & Maintenance...................................................... 10

Component Replacement.......................................................... 11

Exploded View .................................................................... 13

Parts List.......................................................................... 14

Conversion, Baseball to Softball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SPORTS ATTACK

Product Line ...................................................................... 16

INTRODUCTION

Thank you for purchasing this Sports Attack, LLC. equipment.

Proper assembly, careful operation and consistent maintenance of this equipment will

ensure that it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly set up the Hack Attack Baseball

Pitching Machine, and to use, care for and maintain the Hack Attack in a manner which

will ensure its optimum performance.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 2

Hack Attack Safety Instructions

SAFETY INSTRUCTIONS

ELECTRICAL SAFETY

Use a 115 volt single phase 3-wire (2 wire with ground) grounded power source.

Up to 200 ft. from power source, use a minimum #14/3 grounded 3-wire 15 amp minimum

rating extension cord.

Over 200 ft. from power source, consult a licensed electrician for required power cord size.

OPERATING SAFETY

CAUTION: Never reach down near moving throwing wheels for any reason! If it is necessary

to reach into the throwing wheels, ALWAYS:

1. Turn all three speed dials to “0”.

2. Turn on/off switch “OFF”.

3. Unplug Hack Attack from power source

4. Wait until the throwing wheels have come to a complete stop before reaching hands or

fingers anywhere near the throwing wheels.

CAUTION: Carefully check Hack Attack for completeness and condition before connecting to

electrical power:

1. Throwing wheels must be tight on the motor shafts

2. Wheel guard and ball chute must be tightly fastened to the throwing head.

Carefully check the throwing wheels frequently for cleanliness, chips and cracks. Do not use

the machine if the throwing wheels are damaged, or if chips or cracks appear in the wheels.

(For damage within Warranty period, see Warranty Statement, page i.)

ALWAYS set the speed controls to “0” before connecting the machine to power. Check that

the speed controls are at “0” before turning the on/off switch “ON.”

Do not allow anyone to walk in front of the machine if it is connected to electrical power.

WARNING

PERSONAL INJURY HAZARD

Carefully read all instructions in

this manual, and all labels and

warnings on Hack Attack before

using this machine.

Use machine only under adult

supervision. Failure to operate

Hack Attack as described in this

manual can result in severe

personal injury or death.

•

Never loosen the horizontal

swivel lock while pitching to a

batter. If the lock is not secure,

the throwing head could pivot.

A loose swivel lock can allow a

pitch to be inside which could hit

the batter.

ELECTRICAL SHOCK HAZARD

Hack Attack must be connected

to a properly grounded electrical

receptacle.

•

Do not operate on wet ground.

CAUTION

PERSONAL INJURY HAZARD

Keep hands away from throwing

wheels anytime the machine is

connected to a power source.

•

Carefully check Hack Attack for

completeness and condition

before connecting to electrical

power.

EQUIPMENT ELECTRICAL

DAMAGE

Keep hands away from throwing

wheels anytime the machine is

connected to a power source.

•

Carefully check Hack Attack for

completeness and condition

before connecting to electrical

power.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 3

Hack Attack Safety Instructions

SAFETY INSTRUCTIONS (cont’d)

BALL SELECTION

Never mix leather balls with synthetic pitching machine balls.

Be careful not to mix new with old balls or balls from different manufacturers.

Balls must be consistent in type and amount of wear to produce repeatability.

Never use wet balls!

BATTING PRACTICE

The horizontal swivel lock must be securely tightened before the batter approaches the plate.

ALWAYS test and adjust the Hack Attack before a batter steps up to the plate:

1. Adjust so that Hack Attack throws a ball across the plate.

2. Throw test pitches until required velocity and break are reached.

3. Throw several pitches to verify pitch location repeatability.

DO NOT make any speed or pitch location changes while the batter is at the plate.

Batter and pitching machine operator must wear batting helmets.

Only one person at a time should operate the machine.

Always present the ball to the batter before feeding the ball into the machine.

Operator must stand behind a protective screen to prevent injury from balls off the bat.

Screen is not included with Hack Attack.

FIELDING PRACTICE

Both the elevation control and swivel lock must be released so that the throwing head

moves freely through the intended range of motion.

Never reach up chute to push ball into the throwing wheels.

Keep hands and fingers well away from the throwing wheels.

Be careful to keep all persons away from in front of Hack Attack.

For best accuracy, use dimpled pitching machine balls.

NOTE: Vertical (elevation control) must be adjusted whenever you change pitches (spins).

Knuckle Balls thrown too fast are dangerous and unrealistic!

CAUTION

PERSONAL INJURY HAZARD

ALWAYS use a protective screen

to protect the operator from

the ball off the bat. (Screen not

included with Hack Attack.)

ALWAYS wait for all three

throwing wheels to come to

a complete stop before

transporting Hack Attack, lifting

the throwing head or performing

any repairs.

ADDITIONAL INFORMATION

If you have any questions

regarding the safe operation of

this equipment, please call:

Sports Attack Customer

Service Department

Ph 800-717-4251

Fx 775-345-2883

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 4

Features & Operating Controls

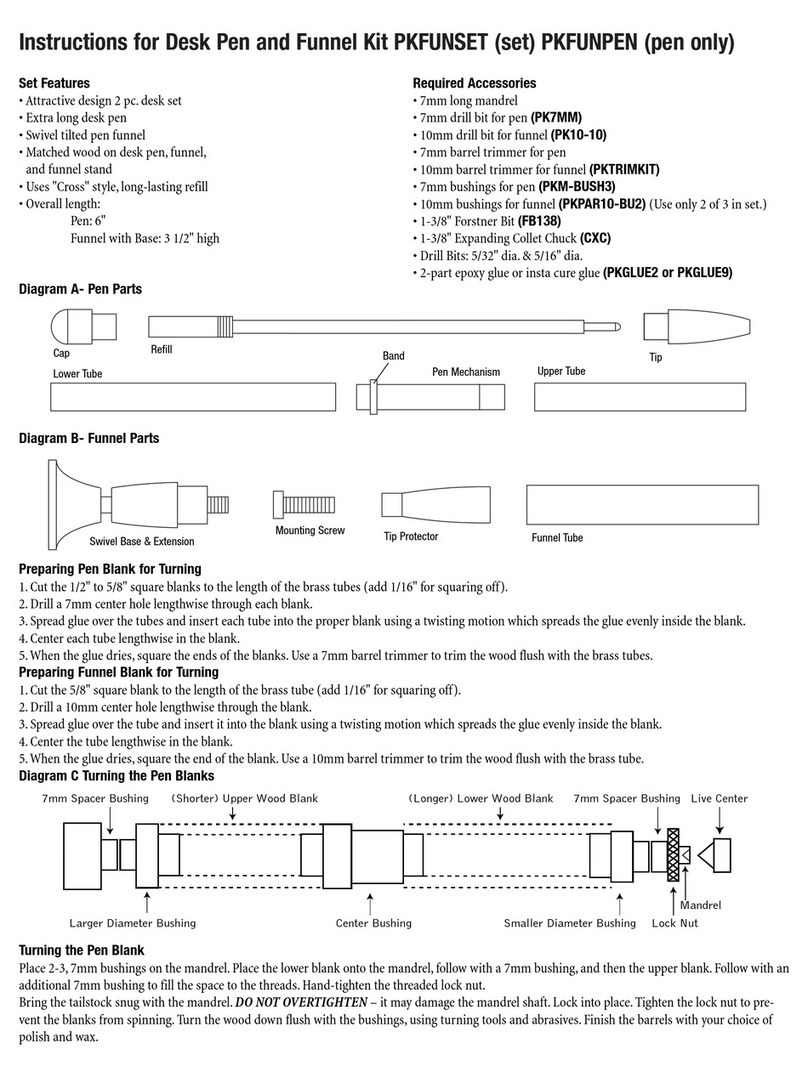

FEATURES & OPERATING CONTROLS

HACK ATTACK BASEBALL PITCHING MACHINE PATENTS APPLIED FOR

Ball Chute

Travel Lock

(opposite side)

Elevation

Control

Power Cord

Horizontal

Swivel Lock

Wheel Guard

Throwing

Wheel

Serial

Number

Transport

Wheel

Under Carriage

Travel lock must be secure prior

to movement.

ADDITIONAL PARTS & CONVERSION KITS

Exploded Views and Parts List......13

Baseball/Softball Conversion ......15

Figure 1 Position Hack Attack

Figure 2 Tip up onto wheel guard; Insert

two front legs

Figure 3 Set Hack Attack upright

Figure 4 Carefully tilt Hack Attack up onto

its legs

SAFETY HINT

Keep your back straight and lift

with your legs. Be ready to grab

the wheel guard and guide Hack

Attack into the upright position.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 5

Set-up & Preparation

SET-UP & PREPARATION

1. Install the rear leg (NOTE: the leg has a push button, which locks the leg into the

socket). Roll Hack Attack onto the mound approximately four feet in front of the rubber.

2. Be sure the horizontal swivel lock is tightened securely.

3. Tilt Hack Attack forward until it rests on the throwing wheel guard.

4. Insert the two front legs into the front sockets in the undercarriage (NOTE: the front

legs also have locking push buttons).

5. See Figure 2 on page 4.

Walk around to the front of Hack Attack, and, with your back to home plate, reach

down and grasp the wheel guards. Then, lift Hack Attack up and over the front legs

and set it gently onto the rear leg.

6. Position Hack Attack:

a. To approximate the release point of a live pitcher, position Hack Attack so that the

rear leg is just in front of the rubber.

b. Then, sight down ball chute. Move the rear leg right or left to adjust machine so

that it is pointing directly at home plate.

c. Check the horizontal swivel lock to make sure it remains tight.

7. Unlock the travel lock. Turn the handle of the elevation control counter-clockwise

until the bar of the travel lock snaps back out of the way.

8. Adjust the throwing head:

a. Turn the handle of the elevation control clockwise. Raise the throwing head until

it will throw somewhere near the required height.

b. This initial adjustment will come through experience. To start, turn the elevation

adjustment 10 turns clockwise.

9. Examine Hack Attack for condition and completeness:

a. Be sure the horizontal swivel lock is secured.

b. Throwing wheels must be tight on the motor shafts. Check that the keyway retaining

bolts are tight.

c. Wheel guard and ball chute must be securely fastened to the throwing head.

10. Be certain on/off switch is turned “OFF”, then plug Hack Attack into an extension

cord or other power source. (See generator information at right if applicable.)

WARNING

HAZARD FROM

HIGH-SPEED PROJECTILES

Being struck by a pitched ball

can cause serious injury or death.

Make sure that no one steps in

front of Hack Attack while it is

connected to electric power.

Clear all hitters away from home

plate, the batter’s box and the

backstop area before connecting

Hack Attack to electric power.

GENERATOR INFORMATION

1. Hack Attack requires a

generator capable of providing

clean electricity 2000 watts at

120 volts 60hz.

2. Be sure the on/off switch is

“OFF” before plugging Hack

Attack into the generator.

3. Start the generator and allow

it to reach full speed before

turning the on/off switch “ON”.

IMPORTANT: Generator speed

fluctuations can damage the

electronic speed control. Maintain

adequate fuel in the generator at

all times.

4. Turn the on/off switch “OFF”

before shutting off the

generator and before

unplugging Hack Attack.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 6

Batting Practice

NOTE: As wheel speeds are

changed for different velocities

and spins, the ball will be pitched

to differing locations. Compensate

for these changes by turning the

elevation control, and by moving

the rear leg.

Figure 3 Present the ball to the hitter

Feeding the ball

IMPORTANT: Hitter should stride

the instant he sees the ball release

from the feeder’s hand at the up-

per end of the ball chute.

BATTING PRACTICE

THE WIND-UP (getting ready to pitch)

1. Turn the on/off switch “ON”.

2. Set the speed control dials*:

Top Left to “4”

Top Right to “4”

Bottom to “7”

* This is the average setting for a high school fastball.

3. Check again to make sure no one is in front of Hack Attack or anywhere near the

batter’s box. Then, feed a ball down the ball chute to pitch the first ball.

4. Note where the pitch goes in relation to home plate. Adjust the pitch to the left or right

by shifting the rear leg:

a. To move the pitch left, move the rear leg to the right.

b. To move the pitch right, move the rear leg to the left.

5. Adjust the elevation:

a. Turn the elevation control clockwise to raise the pitch.

b. Turn the elevation control counter-clockwise to lower the pitch.

6. Adjust the speed control dials to produce the required speed. Larger numbers equal

higher speed.

7. Pitch a second ball.

8. Repeat steps 4, 5 and 6 until the proper path, elevation and speed are achieved.

9. Refer to “Selecting the Pitch”, page 7, for different pitches.

10. Pitch several more test balls to ensure the selected pitch repeats.

11. After you are sure desired pitch is repeating, allow the hitter to step into the batter’s box.

12. See Figures 3 and 4 at left.

a. Before each pitch present the ball to the hitter.

b. Drop the ball into the ball chute.

AND… THE PITCH

Proper feeding technique is important to take advantage of Hack Attack’s life-like vision

and timing.

When feeding:

1. Be sure hitter is ready.

2. Present the ball to hitter by raising it approximately to eye level, then place ball at the

top of the ball chute, seating it firmly against the ball chute. The ball should be held

back against the chute to ensure a smooth consistent feed.

3. Release the ball to roll down the ball chute and into the throwing wheels.

WARNING

HAZARD FROM

HIGH-SPEED PROJECTILES

Being struck by a pitched ball

can cause serious injury or death.

Make sure that no one steps in

front of Hack Attack while it is

connected to electric power.

Clear all hitters away from home

plate, the batter’s box and the

backstop area before connecting

Hack Attack to electric power.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 7

Batting Practice

BATTING PRACTICE (cont’d)

SELECTING THE PITCH

NOTE: Vertical (elevation) and horizontal (swivel) must both be adjusted whenever you

change speed or spin.

Always have the batter step away from the batter box before adjusting speed or spin.

BALL SELECTION

1. Never mix leather balls with synthetic pitching machine balls.

2. Be careful not to mix new with old balls, or balls from different manufacturers.

3. Balls must be consistent in type and amount of wear to produce repeatability.

4. NEVER USE WET BALLS!

Leather balls work well but will wear faster than synthetic pitching machine balls.

Watch to see that leather balls do not begin to soften from the great amount of hitting

they will receive.

Discard old or soft leather balls from your Hack Attack batting sessions. Similarly, discard

older worn synthetic pitching balls.

Figure 5

Pitch Selection Chart - These settings are a general guideline for professional pitches

for major league hitters only. Adjustments for players of lesser skill can be made from these settings.

WARNING

PERSONAL INJURY HAZARD

Never reach down near throwing

wheels for any reason! Always turn

all three speed control dials “OFF”,

turn the on/off switch “OFF”, unplug

Hack Attack from the power source

and wait until the throwing wheels

have come to a complete stop

before reaching hands or fingers

anywhere near throwing wheels.

•

Never loosen the horizontal swivel

lock while pitching to a batter.

If the lock is not secure, the

throwing head is free to pivot.

A loose swivel lock can allow a

pitch to be inside which could hit

the batter.

Right wheel

speed control

Left wheel

speed control

Bottom wheel

speed control

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 8

Baseball Fungo (Fielding Practice)

BASEBALL FUNGO (FIELDING PRACTICE)

1. Roll Hack Attack to home plate and face toward center field. Install legs, tilt it into

position and connect to electric power.

2. Turn the elevation control counter-clockwise to release the travel lock.

3. Loosen the horizontal swivel lock until the throwing head pivots freely.

By using the handle on the end of the ball chute, you can easily pivot Hack Attack

to aim at any point on the field.

You can simulate various line drives (slicing, fading, sinking, rising, etc.) by adjusting the

spin. Refer to Figure 5 on page 7.

See Figure 6 below:

For pop-ups, push the handle down. Using the opposite hand, situate ball on ball

chute and give the ball a shove hard enough that ball rolls up the chute and into the

throwing wheels.

4. When defensive work is completed, center the throwing head on the undercarriage and

securely tighten the horizontal swivel lock.

5. Secure the throwing head with the travel lock. Allow all three throwing wheels to come

to a complete stop before transporting Hack Attack.

Figure 6 Feeding the ball for pop-ups

WARNING

HAZARD FROM

HIGH-SPEED PROJECTILES

Being struck by a pitched ball can

cause serious injury or death. Make

sure that no one steps in front of

Hack Attack while it is connected to

electric power.

Clear all hitters away from home

plate, the batter’s box and the

backstop area before connecting

Hack Attack to electric power.

CAUTION

PERSONAL INJURY HAZARD

Never reach up chute to push ball

into the throwing wheels. Be sure

to keep hands and fingers well

away from the throwing wheels.

•

Be careful to keep all persons away

from front of Hack Attack any time

it is connected to electrical power.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 9

Shutting Down

SHUTTING DOWN

TURNING HACK ATTACK “OFF”

1. Set each speed control dial to “0”.

2. Turn the on/off switch “OFF”.

3. Unplug Hack Attack from the power source.

PUTTING HACK ATTACK AWAY

1. Be absolutely sure that the throwing wheels have completely stopped turning.

2. See Figure 7 at right:

a. Turn the elevation adjustment counter-clockwise until the throwing head is all the

way down against the elevation control nut.

b. Push and hold the travel lock all the way in.

c. Turn the elevation adjustment clockwise until the throwing head is held tightly

against the travel lock. Tighten just enough to secure the throwing head. It is not

necessary to over tighten.

3. Using the rear leg as a handle, tip Hack Attack up and over onto the wheel guard.

4. Remove (unsocket) both front legs and store by inserting in the travel storage sockets.

5. See Figure 8 at right:

Again, using the rear leg as a handle, tip Hack Attack back until machine can be

comfortably rolled on the travel wheels. Hack Attack can now be rolled and

maneuvered off of the field.

6. To transport Hack Attack in a car, remove the throwing head:

a. Be sure the travel lock is engaged and the throwing head is tightly secured to

the yoke.

b. Loosen the horizontal swivel control. Turn it counter-clockwise until the throwing

head is free to lift out of the swivel.

c. Lift the throwing head straight up and clear of the undercarriage.

SUGGESTION: The throwing head, while awkward, can be carried for short distances

by gripping the top section of the wheel guard and balancing the piece against your

thighs as you walk.

d. To prevent damage in transport, rest the throwing head on the wheel guard and yoke;

motors should be down, and the control panel pointing up.

Figure 7

Secure the Travel Lock

Figure 8 Maneuvering

Storing Legs in Travel Socket

ELEVATION

CONTROL

LOCKING

TAB ON

THROWING

HEAD

TRAVEL

LOCK

USE TRANSPORT

LEG AS A HANDLE

TO MANEUVER

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 10

CARE, CLEANING & MAINTENANCE

LUBRICATION (once per season, or as required):

1. Elevation Control

a. Apply fresh grease.

b. Reinstall, making sure that the tension spring is around the threads. (See item 30, 30B

and 31 on page 13).

2. Travel Lock

Apply a small amount of grease where the pin passes through the fitting. Make sure the

travel lock operates freely.

3. Horizontal Swivel Lock

a. Completely remove the horizontal swivel lock nut. Clean all old grease, dirt, etc. from

the threads.

b. Wipe the threads with a very small amount of fresh grease.

c. Reinstall.

THROWING WHEEL MOTORS

Motors are sealed and require no lubrication.

Check bolts for tightness once a season. Tighten bolts securely, but do not over-tighten.

See Figures 7 and 8 on page 11.

CLEANING THE THROWING WHEELS

The throwing wheels must be kept clean to maintain accuracy. Clean the wheels periodically

to control the build-up of grass and dirt.

1. Turn the on/off switch “OFF”and allow the wheels to come to a complete stop. Unplug

Hack Attack from electric power.

Dampen a rag with soap and water. Turn the throwing wheel by hand and scrub the wheel

until the build-up is removed. For very heavy build-up, a synthetic scouring pad, such as a

Scotch-Brite®scouring pad, or medium sandpaper may be used sparingly. Methyl Ethyl

Ketone (M.E.K.) may be required to help loosen the build-up of dirt or ball residue.

EXAMINE THE MACHINE

Examine Hack Attack for condition and completeness before every use:

1. For batting practice, be sure the horizontal swivel lock is secured.

2. Throwing wheels must be tight on the motor shafts. Check that the keyway retaining

bolts are tight.

3. Wheel guard and ball chute must be securely fastened to the throwing head.

CAUTION

PERSONAL INJURY HAZARD

Never attempt to clean the

throwing wheels while they are

turning. Rags or implements

caught in spinning wheels can

cause serious injury.

Unplug the machine before

cleaning the wheels or

performing any service.

CHEMICAL HAZARD

Methyl Ethyl Ketone (M.E.K)

Read and follow the directions

and safety instructions on the

M.E.K container.

FIRE HAZARD

Methyl Ethyl Ketone (M.E.K)

M.E.K. is flammable. Do not

use M.E.K. around a fire or

flame. Do not use M.E.K. near

a running generator or other

source of ignition.

Care & Cleaning

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 11

COMPONENT REPLACEMENT

THROWING WHEEL REPLACEMENT

1. Turn the on/off switch “OFF” and unplug the power cord. For the bottom throwing

wheel, remove 6 bolts holding the wheel guard to the main casting.

2. Hold the wheel so that it cannot move. Turn the keyway retaining bolt counter-clockwise

using a box end wrench.

3. Remove the bolt and washers.

4. Work the wheel off of the motor shaft. Be sure to catch the key as it is freed from

the keyway.

5. Ball throwing wheels are machine balanced. Small holes in the side of the wheel are

applied at the factory and are normal. A slight wobble is normal.

Reassemble in reverse order.

a. Install wheel to motor shaft with key slots aligned.

b. Be sure the key is in place, and inserted so that it is flush with the boss at the

wheel center.

c. Be sure the washer and lock washer are installed in the right order, and that the

keyway retaining bolt is tightened.

d. Test the wheel by spinning it by hand and making sure that it spins freely without

wobble before turning the unit “ON”.

e. Be sure the wheel guard is properly and securely reinstalled.

MOTOR REPLACEMENT

1. Turn the on/off switch “OFF” and unplug the power cord.

2. Remove the throwing wheel (see above).

3. Remove four screws holding controller into main casting. Note the position of the motor

wires on the controller, then disconnect the wires. See Figure 10 on page 12.

4. Note the routing of the motor wires. Loosen any wire clamps.

5. Remove four bolts holding the motor to the main casting. See Figures 7 and 8 below.

Reassemble in reverse order.

Component Replacement

NOTE: On the bottom wheel, the

Front wheel guard (part 43 on

page 13) must be removed prior

to the removal of the motor or

ball-throwing wheel

Hold wheel while loosening bolts.

NOTE: Check bolts for tightness once a season. Tighten bolts securely, but do not over-tighten.

When replacing the motor, you will

see two sets of bolts:

2 - 1/4” x 1 1/4” coarse thread bolts

2 - 5/16” x 1 1/2” coarse thread bolts

The wrench or socket size needed

for the 1/4” bolt is a 7/16”.

The wrench or socket size needed

for the 5/16” bolt is a 1/2”.

Figure 7 Shown using a 6”extension with 1/2”socket. Figure 8 Shown using a 6” extension with 7/16”socket.

1/2” KEYWAY

RETAINING BOLT

LOCK WASHER

FLAT WASHER

KEY

MOTOR

THROWING

WHEEL

HOLES DRILLED

FOR BALANCE

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 12

COMPONENT REPLACEMENT (cont’d)

CONTROLLER REPLACEMENT

1. Turn the on/off switch “OFF” and unplug the power cord.

2. Remove four screws holding controller faceplate into main casting. Note the position of

the main power and motor wires on the controller, then disconnect the wires. See Figure

10 on page 12 for the three motor wires. See Figure 11 on page 12 for the main power

cord wires.

3. Loosen the nuts holding the three speed control shafts to the faceplate, then remove

the controller.

Reassemble in reverse order.

Be sure wires are correctly reinstalled. Motor wire connectors are different sizes. Be

sure they are installed on the correct size terminal. See Figure 10 for the motor wires

and Figure 11 for the power cord wire.

Component Replacement

Figure 9 Wiring diagram from the control board side.

Figure 10

Wiring diagram for all three motors.

Right Motor

Circuit Breaker

Bottom Motor

Left Motor

CONNECTING WIRES

Motor Black White

Wire Wire

Right A- A+

Left A+ A-

Bottom A- A+

Black motor wires are 3/16” female

disconnect and white wires are

1/4” female disconnect.

#3

#1

#2

Figure 11

WIRING

POWER CORD

White or Blue Wire (1)

To middle male terminal marked “N.”

Black or Brown Wire (2)

To circuit breaker.

Green Wire (3)

Grounds to machine/motor.

MOTOR WIRE LEADS

Black 3/16” wide connectors.

White 1/4” wide connectors.

Black Wire (2) connects to A-

on circuit board.

White Wire (2) connects to A+

on circuit board.

CONTROLLER

Black Wire (2) 2 PR jumper wire:

- 1 from on/off switch to

circuit breaker

- 1 from on/off switch to

circuit board terminal “L”.

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 13

EXPLODED VIEW

Exploded View

1Cane Tip

2Leg - Standard Size (ea.)

5Undercarriage

13 Horizontal Swivel

Lock Handle

14 Swivel Lock Pivot

17 Snap-Button

19 Travel Wheel (with axle, bolt,

nut, washers)

21 Yoke

26 Pin, Travel Lock

27 Spring, Travel Lock

30 Fitting, Elevation Control

30B Tension Spring,

Elevation Control

31 Handle, Elevation Control

34 Main Casting,

Throwing Head

35 Clamp, Cable

36 Hinge Assembly,

Throwing Head

37 Motor, Variable

Speed 90V

38 Throwing Wheel

39 Ball Chute

43 Wheel Guard (ea.)

49 Grommet, Wiring

50 Plate, Travel Lock, and

Elevation Control

60 Plate, Control, Panel Cover

61 Knob, Speed Control

63 Controller Assembly

64 Safety Reset

65 On/Off Switch

Power Cord (not shown)

1

2

5

21

31

37

37

37

38

38

34

35

39

38

30B

30

27

26

2

17

2

19

14

13

43

19

63

60

49 61

64

65

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 14

Parts List

PARTS LIST

Parts List

To order additional parts,

please call:

Sports Attack Customer

Service Department

Ph 800-717-4251

Fx 775-345-2883

REF#s HA BASEBALL

PART#s DESCRIPTION

39 533-1307 Ball Chute

1280-1003 Cane Tip ea.

35 533-0002 Clamp, Cable

63 530-0006 Controller Assembly

30 531-1505 Fitting, Elevation Control

49 280-3007 Grommet, Wiring

31 531-1504 Handle, Elevation Control

13 533-0500 Horizontal Swivel Lock Handle

61 280-2003 Knob, Speed Control

2532-0001 Leg, Standard Size ea.

37 530-1012 Motor, Variable Speed 90V

65 223-0004 On/Off Switch (Rocker)

old 223-0002 On/Off Switch (Old Style - Toggle)

232-0000 Power Cord (US)

64 232-0002 Safety Reset

old 232-0007 Safety Reset (Old Style Breaker)

14 533-0501 Swivel Lock Pivot

30B 310-0021 Tension Spring, Elevation Control

38 531-0001 Throwing Wheel

19 281-0002 Travel Wheel ea.

281-0001 Travel Wheel, Extra-Heavy Duty

5533-1301 Undercarriage

43 533-1306 Wheel Guard ea.

21 533-1302 Yoke

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 15

CONVERSION

BASEBALL TO SOFTBALL KIT NO. 110-3001

SUGGESTION:

1. Turn the on/off switch “OFF” and unplug the power cord.

2. Remove all three baseball throwing wheels (see page 11).

3. Remove the ball feed chute.

4. Install part no. 520-0023 softball feed chute.

5. Install one part no. 531-0002 softball throwing wheel on each motor.

6. Install one part no. 532-0002 front leg in each front leg socket.

Install one part no. 532-0003 rear leg in rear leg socket.

Insert one part no. 532-0009 carry handle in the rear leg socket for transport.

7. Reinstall wheel guard. Test Hack Attack for proper operation.

SUGGESTION: Carefully mark and store all removed parts for later conversion back to

baseball operation.

Conversion

531-0002 Softball Throwing Wheels

532-0003

Rear Leg 532-0002

Front Legs

532-0009

Transport Handle

520-0023 Softball

Ball Chute

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 16

Please visit our web site sportsattack.com for information about Sports Attack sports

training products, or call 800-717-4251 for complete information and specifications.

SPORTS ATTACK PRODUCTS

SOFTBALL

SOCCER CRICKET

HACK ATTACK SOFTBALL

STRIKE ATTACK

JUNIOR HACK ATTACK SOFTBALL (shown with optional feeder)

CRICK ATTACK

HACK ATTACK™BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. •800-717-4251 •sportsattack.com 17

Please visit our web site sportsattack.com for information about Sports Attack sports

training products, or call 800-717-4251 for complete information and specifications.

SPORTS ATTACK PRODUCTS

TENNIS FOOTBALL

ACE ATTACK SNAP ATTACK

ATTACK (shown with optional ball bags) SKILL ATTACK

VOLLEYBALL

ATTACK II (shown with optional ball bags)

Table of contents

Other Sports Attack Accessories manuals

Popular Accessories manuals by other brands

Dorner

Dorner AquaGard 7350 Series Installation, Maintenance, and Parts Manual

Toshiba

Toshiba HCV-1JBU Vacuum Contactor, 1.5kV - 600A HCV-1KAU Vacuum Contactor, 1.5kV -... instruction manual

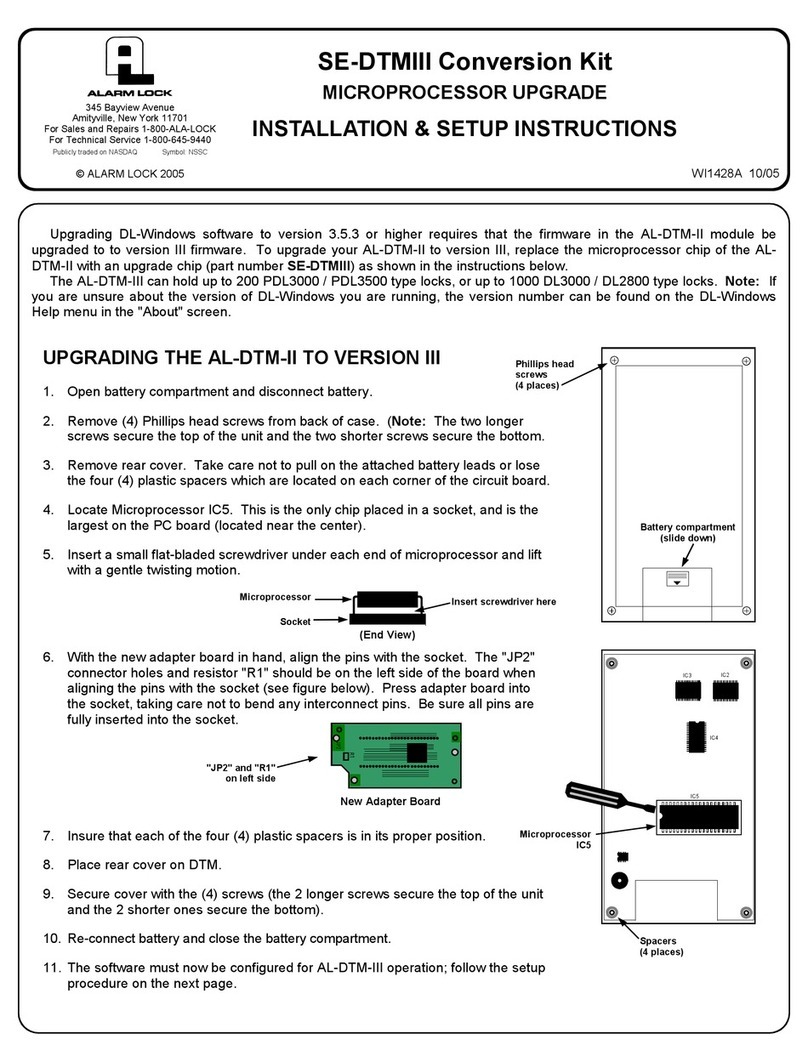

Alarm Lock

Alarm Lock SE-DTMIII Conversion Kit Installation & setup instructions

PSI Woodworking Products

PSI Woodworking Products PKFUNSET instructions

X10

X10 MS13E2 manual

Alula

Alula NanoMax RE122 install guide