spotzero Mobile Pro Mini User manual

Table of Contents

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Common Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Pre-Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pump and Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Feed Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Normal Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

General Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Filling A Vessel’s Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vessel Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sample System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LCD Display Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

PC Board and LCD Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

LCD Maintenance Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

LCD Programming and Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unlocking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Resetting the Maintenance Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Membrane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparing System for Storage or Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Recommissioning System After Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Winterization of the Spot Zero Mobile Pro Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Recommissioning System After Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Temperature Correction Factors for Membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LCD Fault Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

LCD Fault Indicators Explained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Bap Feed Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Over Current Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Over Temperature Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Over Pressure Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Low Feed Pressure Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Consumable Items � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Optional Spare Components � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Optional Dockside Pre-Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Owner’s Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Disclaimer

The following manual was written by Spot Zero Reverse Osmosis specically for the Spot Zero Mobile

Pro Mini reverse osmosis system. The information prepared within this manual has been compiled by

Spot Zero with the best attempts to make it both comprehensive and accurate but Spot Zero makes

no denitive claim or guarantee of the completeness and accuracy of the presented information.

Spot Zero disclaims all liability for inaccuracies, omissions and outdated information.

Furthermore, any direction, recommendation, or instruction provided directly by Spot Zero Reverse

Osmosis will take precedence over the information provided within this manual.

Status at Time of Printing

Spot Zero Reverse Osmosis has always pursued continued innovation to ensure superior customer

service and produce industry leading technology. In this effort, it is possible that some of the features

and functionality discussed in this document may differ from those found within your Spot Zero

system. Therefore, it is the responsibility of the customer to take the information provided as a

reference only and to conduct due diligence to ensure proper system performance, maintenance,

and general ownership

Limitations of the Manual

To ensure proper system performance, you must use common sense and diligence when operating

your Spot Zero unit. A variety of marinas, geographical locations, and residential complexes,

have specic regulations in regards to water purication, discharge of contaminants, electrical

consumption, water consumption, and other various processes involved in reverse osmosis. It is the

responsibility of the operator to follow the ecological, biological, municipal, and other regulations

involved with the operation of the Spot Zero system. Compliance with these regulations is beyond

the scope of this manual and Spot Zero is not responsible for proper instruction in these areas.

Manufacturer’s Statements

Spot Zero Reverse Osmosis

100 SW 16th St

Fort Lauderdale, FL, 33315

Telephone: 954-533-5640

www.spotzerowater.com

Mobile Pro Mini Introduction Revision Date: 3/16/2023

4

Introduction

The Spot Zero Mobile Pro Mini is a self-contained water purication system used to remove up

to 99% of all waterborne contaminants such as heavy metals, bacteria, chlorine and many

others. Product water from the Spot Zero Mobile Pro Mini can be used to wash-down a boat,

car, RV or airplane as well as ll your vessel’s tank or ll up a glass of the purest water on Earth.

Safety

The safety section of this User Manual outlines the various safety headings used through this

manual’s text which are enhanced and dened below.

Before operating or servicing the Spot Zero Reverse Osmosis system, this User’s Manual must

be read and fully understood. Keep it and other associated information for future reference

and for new operators or personnel involved with the system.

DO NOT UNDER ANY CIRCUMSTANCES REMOVE ANY CAUTION, WARNING, OR OTHER

DESCRIPTIVE LABELS FROM THIS SYSTEM�

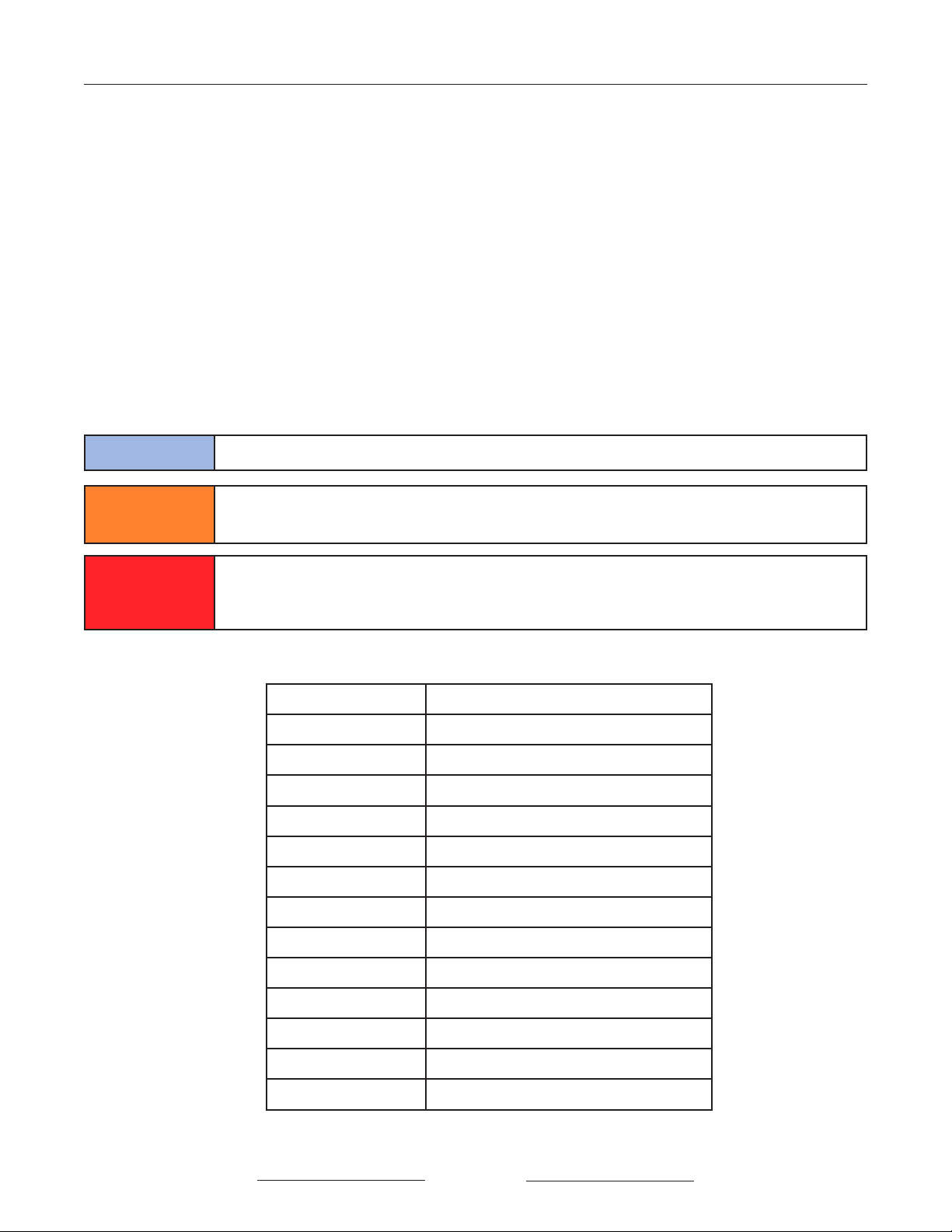

NOTE INDICATES STATEMENT THAT PROVIDE FURTHER INFORMATION OR CLARIFICATION

⚠ CAUTION INDICATES STATEMENTS THAT ARE USED TO IDENTIFY CONDITIONS OR

PRACTICES THAT COULD RESULT IN EQUIPMENT OR OTHER DAMAGE.

⚠ WARNING INDICATES STATEMENTS THAT ARE USED TO IDENTIFY CONDITIONS OR

PRACTICES THAT COULD RESULT IN INJURY OR LOSS OF LIFE. FAILURE TO FOLLOW

WARNINGS COULD RESULT IN SERIOUS INJURY OR EVEN DEATH.

ACRONYM DEFINITION

RO Reverse Osmosis

PSI Pounds per Square Inch

GPM Gallons Per Minute

GPD Gallons Per Day

TDS Total Dissolved Solids

PPM Parts Per Million

TCF Temperature Correction Factor

PC Board Printed Circuit Board

MGH Male Garden Hose

NPT National Pipe Thread

LED Light Emitting Diode

LCD Liquid Crystal Display

SDI Salt Density Index

Common Acronyms and Abbreviations

Mobile Pro Mini Revision Date: 3/16/2023

5

Operating Specications

Operating Specications

Your system is designed to operate with a product pressure between 10-150 psi. Ensure you

use a good quality hose capable of handling 150 psi.

Pre-Filtration

Spot Zero™ Mobile Pro Mini systems are supplied with a pre-lter (Part #: FI-FW0021) that is

used to lter out most particles over 1-micron as well as remove chlorine, chloramine, VOCs

and other heavy metals. The lter removes these waterborne contaminants through an

absorption process that consumes the life of the carbon and other activated materials within

the lter. Therefore, the pre-lter should be changed every 100 hours of use and you should

NEVER attempt to clean used lter cartridges as this may result in permanent system damage.

The pump and membranes are susceptible to damage from sediment and debris that results

from a dirty or clogged lter.

Pump and Motor

The high pressure pump used on the Spot Zero Mobile Pro Mini require a continuous and non-

turbulent ow of water to the system with a minimum feed pressure of 10-psi during operation

and not exceeding a temperature of 100°F.

⚠ CAUTION IF THE PRE-FILTER BECOMES CLOGGED OR DAMAGED AND THE WATER FLOW TO

THE PUMP IS REDUCED OR INTERRUPTED, CAVITATION WILL OCCUR. THIS CAN

LEAD TO PERMANENT PUMP DAMAGE.

Feed Water

Nothing has a greater effect on the life and performance of a reverse osmosis system than

the feed water quality. Specications for the feed water are found in the table below:

Max. Feed Temperature °F (°C) 100 (45) Min. SDI Rating < 3

Min. Feed Temperature °F (°C) 40 (4.4) Max. Free Chlorine ppm 0

Max. Ambient Temperature °F (°C) 100 (37.7) Max. TDS ppm 1,000

Min. Ambient Temperature °F (°C) 40 (4.4) Max. Hardness gpg 3

Max. Feed Pressure psi (bar) 85 (5.9) Max. pH (Continuous) 9

Min. Feed Pressure psi (bar) 10 (3.1) Min. pH (Continuous) 6

Max. Operating Pressure psi (bar) 150 (10.34) Max. Turbidity NTU 1

NOTE IT IS VERY IMPORTANT TO MEET THE MINIMUM FEED WATER REQUIREMENTS.

FAILURE TO DO SO WILL CAUSE THE MEMBRANES TO FOUL AND VOID THE

MANUFACTURER’S WARRANTY.

Mobile Pro Mini Revision Date: 3/16/2023

6

Operating Specications

Electrical Requirements

The motor used on the Spot Zero Mobile Pro Mini requires single-phase, 115-Volt, 60-Hz AC

power. Please ensure that the electrical circuit supplying the system is compatible with the

requirements of the Spot Zero Mobile Pro Mini model. A good quality extension cord, with

12-gauge wiring or better, is required providing power to the system along with a 15-Amp

breaker.

VOLTAGE AMP DRAW FREQUENCY PHASE BREAKER

115-V 10 A 60-Hertz Single 15 A

NOTE IT IS RECOMMENDED THAT A QUALIFIED ELECTRICIAN WIRES YOUR SYSTEM IN

ACCORDANCE WITH ALL APPLICABLE CODES, RULES, LAWS, AND REGULATIONS.

⚠ WARNING TO REDUCE THE RISK OF ELECTRICAL SHOCK, THE INCOMING POWER SUPPLY

MUST INCLUDE A PROTECTIVE GROUND.

Plumbing Connections

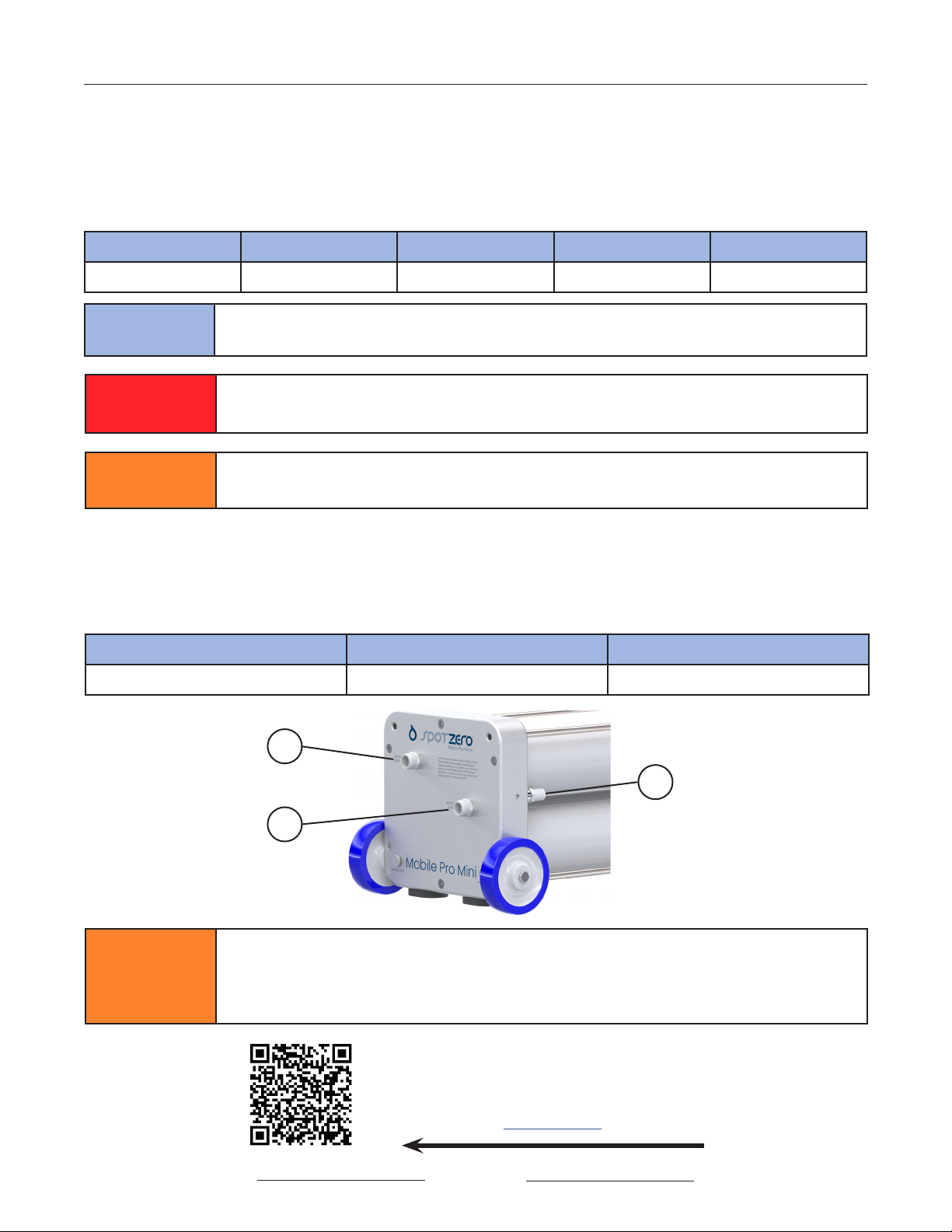

The Spot Zero Mobile Pro Mini has 3 unique plumbing connections that must be made to

ensure proper system performance. Please see the specications and accompanying Figure

below for the external plumbing ttings sizes and locations.

1 - FEED WATER 2 - PRODUCT OUTLET 3 - DISCHARGE OUTLET

3/4” Male Garden Hose 3/4” Male Garden Hose 3/4” Hose Barb

⚠ CAUTION

ANY RESTRICTIONS OR BLOCKAGE IN THE DISCHARGE LINE CAN CAUSE

MEMBRANE SCALING AND BACK PRESSURE, WHICH WILL INCREASE THE SYSTEM’S

OPERATING PRESSURE. THIS MAY RESULT IN PERMANENT DAMAGE TO THE

SYSTEM.

1

2

3

Figure 1: Plumbing

Fitting locations

⚠ CAUTION FAILURE TO USE A PROPERLY RATED EXTENSION CORD AND/OR CIRCUIT BREAKER

CAN RESULT IN INEFFICIENT SYSTEM OPERATION OR USER INJURY OR DEATH.

For a Complete Collection of

Operating Videos and Set-Up,

Scan the QR Code or

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

7

Normal Operation

Normal Operation

Set Up

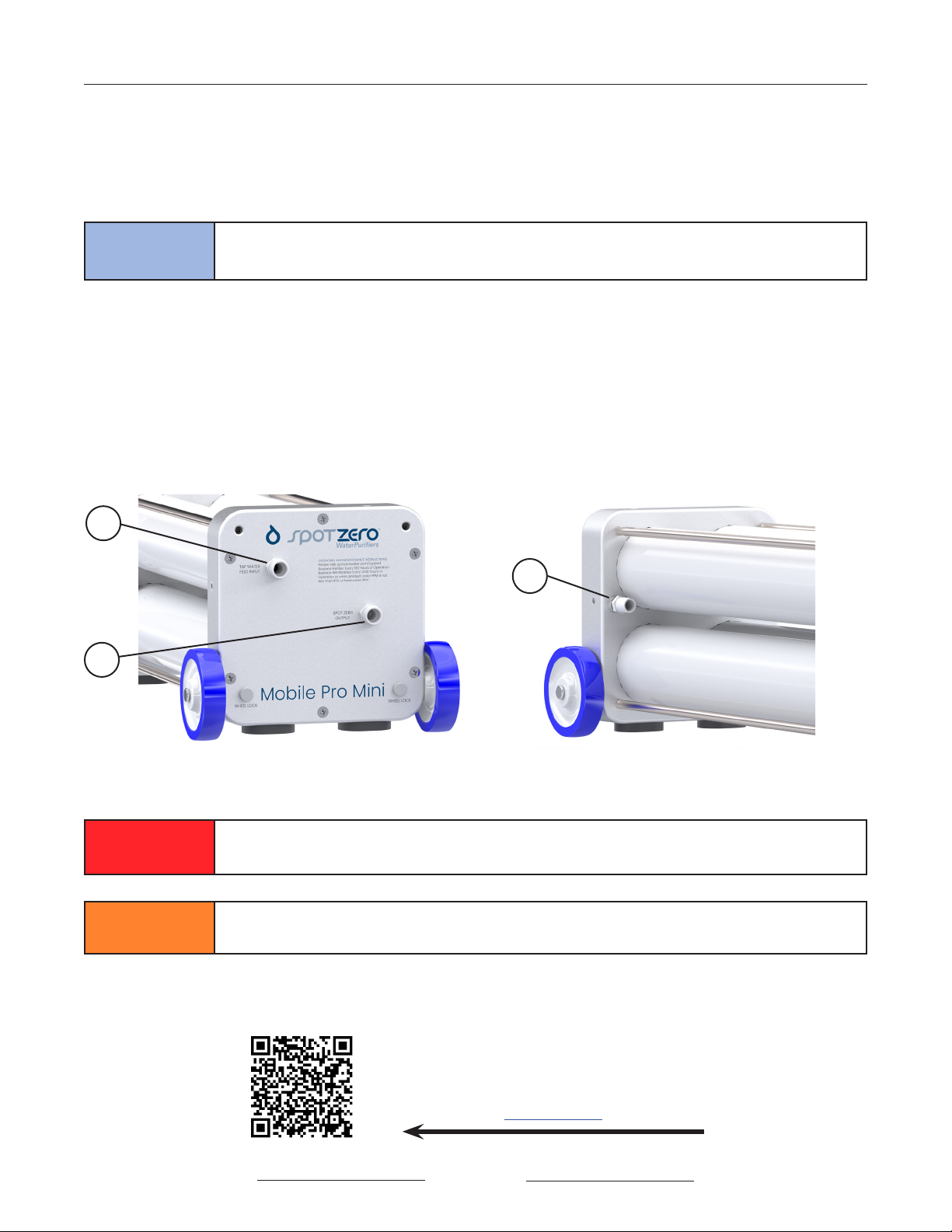

1. Attach a feed water hose to the connection port labeled TAP WATER FEED INPUT (Fig. 2, #1).

Ensure the hose used is rated with a minimum pressure rating of 150-psi to avoid bursting.

⚠ WARNING A GFCI PROTECTED OUTLET SHOULD BE USED TO SUPPLY POWER TO THIS

SYSTEM. FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH!

⚠ CAUTION FAILURE TO OPERATE SPOT ZERO EQUIPMENT WITHIN SPECIFIED PARAMETERS

MAY RESULT IN PERMANENT DAMAGE TO SYSTEM.

Figure 2: garden Hose Plumbing connections Figure 3: Hose barb Plumbing connection

1

2

3

2. Attached a hose to the connection port labeled SPOT ZERO OUTPUT (Fig. 2, #2). Ensure the

hose used is rated with a minimum pressure rating of 150-psi to avoid bursting.

3. Ensure the discharge hose connected to the concentrate outlet hose barb (Fig. 3, #3) is

attached and free of any restriction, debris, and allows for easy water escape to an open

area.

4. Plug the attached power cord to a GFCI protected AC power receptacle.

5. Ensure the feed water conditions fall within the Feed Water Quality Specications, Pg. 5.

NOTE FOR BEST SYSTEM PERFORMANCE, UTILIZE AS SHORT OF A 3/4” HOSE AS

POSSIBLE WITH A MAXIMUM REQUIRED HOSE LENGTH OF 25-FEET.

For a Complete Collection of

Operating Videos and Set-Up,

Scan the QR Code or

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

8

Normal Operation

General Use

1. Once the LCD display is powered on, the system will be in Standby mode as indicated by

the word STANDBY intermittently displaying on the screen.

2. Once you are ready for operation, turn on the pressurized tap water feed to the system.

3. The system will begin purging air for a brief period of time.

4. Once the air is purged from the system and there is adequate feed ow, the system will

begin priming as indicated by the LCD showing PRIMING.

5. Once the system is primed and ready for performance, it will enter Ready mode as indicated

by READY displaying on the LCD.

6. The pump will turn on and the LCD will show RUNNING. The system is now ready for use.

NOTE

THERE IS A STANDBY TIMER SET FOR 10 MINUTES OF INACTIVITY. MEANING, IF THE

PRODUCT VALVE IS CLOSED FOR A PERIOD OF TIME LONGER THAN 10 MINUTES,

THE SYSTEM WILL RETURN TO STANDBY MODE INDICATED BY STEP 1 IN THE

GENERAL USE SECTION ABOVE.

System Performance

As with any uid ow application, there is a linear relationship between uid pressure and ow

rate. The same principle is applicable to the Spot Zero Mobile Pro Mini. Please see the brief

description below for best system performance based on specic application.

Filling A Vessel’s Tank

When lling a vessel’s tank, you want to achieve the greatest possible ow rate to reduce ll

time and system use. As stated in the principle above, with the greatest available ow, the

system will produce the least amount of pressure.

To achieve this type of ow, remove any nozzles or valves on the Spot Zero Output of the

Mobile Pro Mini so the ow is free from obstruction.

Vessel Washing

When spraying down a vessel with Spot Zero water, you want to achieve the greatest pressure

and ow rate to quickly and efciently wash down the vessel. As stated in the principle above,

achieving sufcient product pressure while also maintaining an ample ow rate is a balance

in the restriction of the product output from the machine.

To achieve this type of ow, most users incorporate a spray nozzle on the product output of

the system. In most applications, some restriction of the product is required to generate the

most velocity of the product water and therefore the most distance. An example of the above

application is shown on the next page.

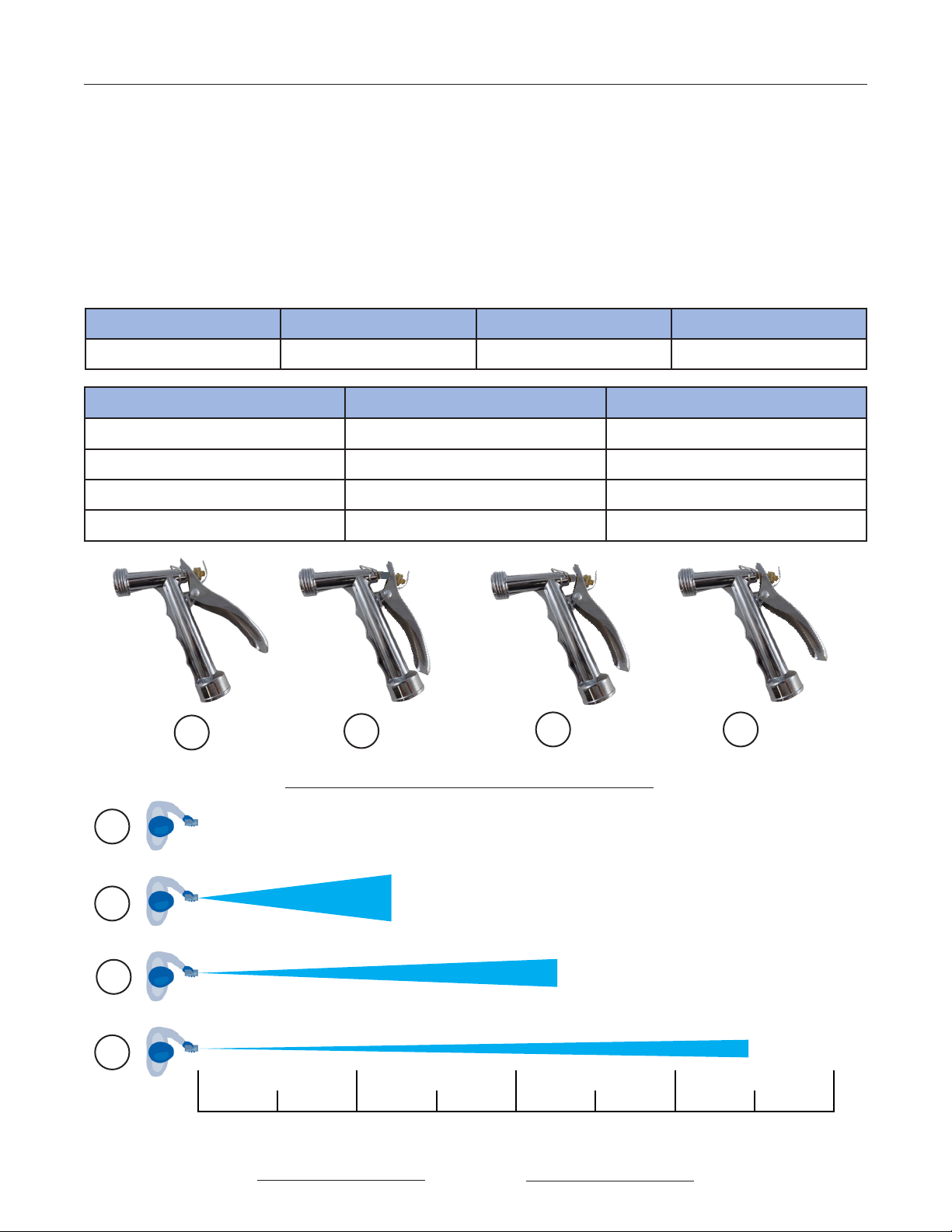

*The tables below shows feed conditions and results for a Spot Zero Mobile Pro Mini operating

with no restrictions or nozzle on the product output� Results may vary for each customer�

PRODUCT WATER

RESULTS

GPM PPM Hose Length

2.25 GPM 19 10 Feet

FEED SOURCE

CONDITIONS

GPM Pressure Temperature PPM Hose Length

3.25 60 PSI 77° F 165 PPM 10 Feet

Mobile Pro Mini Revision Date: 3/16/2023

9

Normal Operation

143

2

0’ 5’ 10’ 15’ 20’ 25’ 30’ 35’ 40’

4

3

2

1

Approximate Distance vs Nozzle Position

Figure Number Nozzle Position Product Flow Rate

1 CLOSED - 0% 0 GPM

2 FULLY OPEN - 100% 2.25 GPM

3 PARTIAL OPEN - ~60% 2.10 GPM

4 PARTIAL OPEN - ~40% 2.0 GPM

distance measured in Feet

Sample System Performance

System performance has been thoroughly tested and measured for the Spot Zero Mobile Pro

Mini. Performance metrics for the Mobile Pro Mini are shown below in the tables and graphics

for a washdown application where the customer is using a proportional nozzle on the product

water outlet of the system.

NOTE: The specied values for nozzle position, product ow rate, product pressure, distance,

and overall system performance were measured using new prelters, membranes and the

followingfeedwater parameters. Resultsmay varyforeachcustomerbasedon feedconditions,

temperature, lter and membrane life, pump condition and overall system condition.

Feed Source GPM Feed Source Temp� Feed Source PPM Feed Hose Length

3.25 75° F 80 PPM 10 Feet

Mobile Pro Mini Revision Date: 3/16/2023

10

Normal Operation

Shutdown Procedure

Please follow the steps below for proper shutdown of the Spot Zero Mobile Pro Mini. The system

is equipped with a built-in ushing cycle and does not require the use of a ball valve.

1. While the system is running (displaying RUNNING on the LCD), stop the flow from the SPOT

ZERO OUTPUT using an in-line valve or spray nozzle.

2. Once the product water is turned off, the system will begin auto-flushing. Allow the system

to flush uninterrupted for 3-minutes. To promote the longest membrane life, fill the vessel

with Spot Zero product water and utilize the product water and your on-board vessel

pump to feed the Mobile Pro Mini with the Spot Zero water�

3. After the flushing cycle, turn off the TAP WATER FEED INPUT. The system will shutdown

automatically.

4. Disconnect input power supply, and the TAP WATER FEED INPUT and SPOT ZERO OUTPUT

hoses.

5. Reinstall storage caps (Part Number: PF-PY0047) to SPOT ZERO OUTPUT and TAP WATER FEED

INPUT.

NOTE SYSTEM MUST BE USED OR FLUSHED EACH MONTH FOR 5-MINUTES TO PREVENT

FOULING.

NOTE IT IS NORMAL FOR THE LCD DISPLAY TO SHOW !LOW FP! FOR A SHORT PERIOD OF

TIME DURING THE SHUTDOWN CYCLE AFTER THE TAP WATER FEED SUPPLY HAS

BEEN SHUT OFF FROM THE SYSTEM.

NOTE TO PROMOTE THE LONGEST MEMBRANE LIFE, FILL THE VESSEL WITH SPOT ZERO

PRODUCT WATER AND UTILIZE THE PRODUCT WATER AND YOUR ON-BOARD

VESSEL PUMP TO FEED THE MOBILE PRO MINI WITH THE SPOT ZERO WATER.

⚠CAUTION SPOT ZERO MOBILE PRO MINI MUST BE USED/STORED IN AN ENVIRONMENT

WITH TEMPERATURES ABOVE FREEZING (32° F/0° C). DAMAGE CAUSED FROM A

FAILURE TO DO SO WILL NOT BE COVERED UNDER WARRANTY BY SPOT ZERO.

For a Complete Collection of

Operating Videos and Shutdown

Procedures, Scan the QR Code or

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

11

Normal Operation

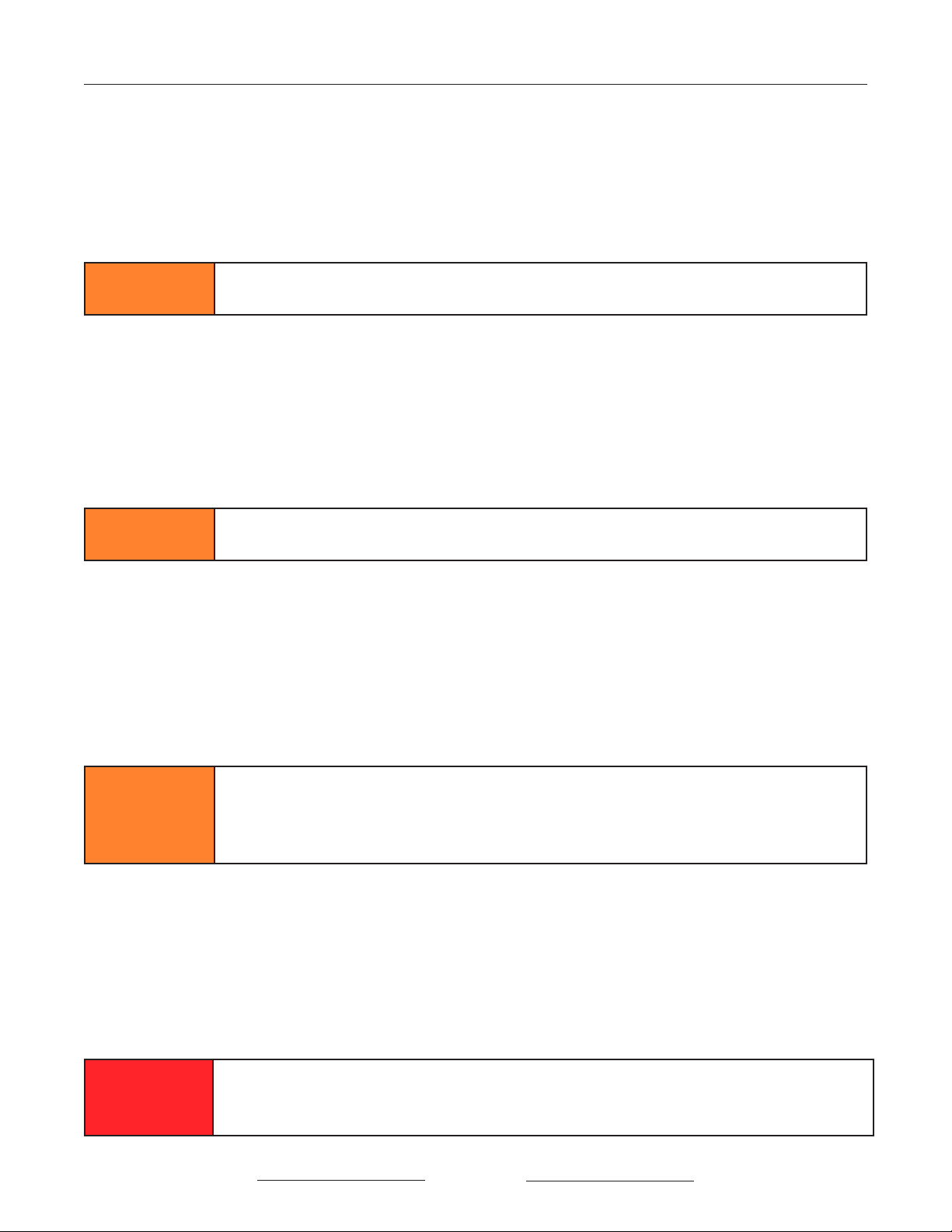

LCD Display Cycles

The LCD will display a sequence of parameters for 1.5-seconds at a time. The display follows

the same continuous sequence unless the operating mode is changed, a fault occurs, ow is

interrupted, or the power is disengaged.

The sequence for each operating mode is shown below.

LCD DISPLAY DESCRIPTION

SpotZero Manufacturer Label

Standby Indicates Operation Sequence

FP_XXX Feed Pressure

Flt_XXX Filter Hours

Mbn_XXX Membrane Hours

Hrs_XXX Total System Hours

LCD DISPLAY DESCRIPTION

Priming Indicates Operation Sequence

FP_XXX Feed Pressure

LCD DISPLAY DESCRIPTION

Ready Indicates Operation Sequence

FP_XXX Feed Pressure

LCD DISPLAY DESCRIPTION

SpotZero Manufacturer Label

Running Indicates Operation Sequence

FP_XXX Feed Pressure

Flt_XXX Filter Hours

Mbn_XXX Membrane Hours

Hrs_XXX Total System Hours

STANDBY

RUNNING

READY

PRIMING

Mobile Pro Mini Revision Date: 3/16/2023

12

Normal Operation

LCD Maintenance Indicators

The Mobile Pro Mini is equipped with smart maintenance tracking capabilities align with

programmed reminders for system maintenance. Please see the below table for reference

on LCD maintenance indicators and corresponding required action.

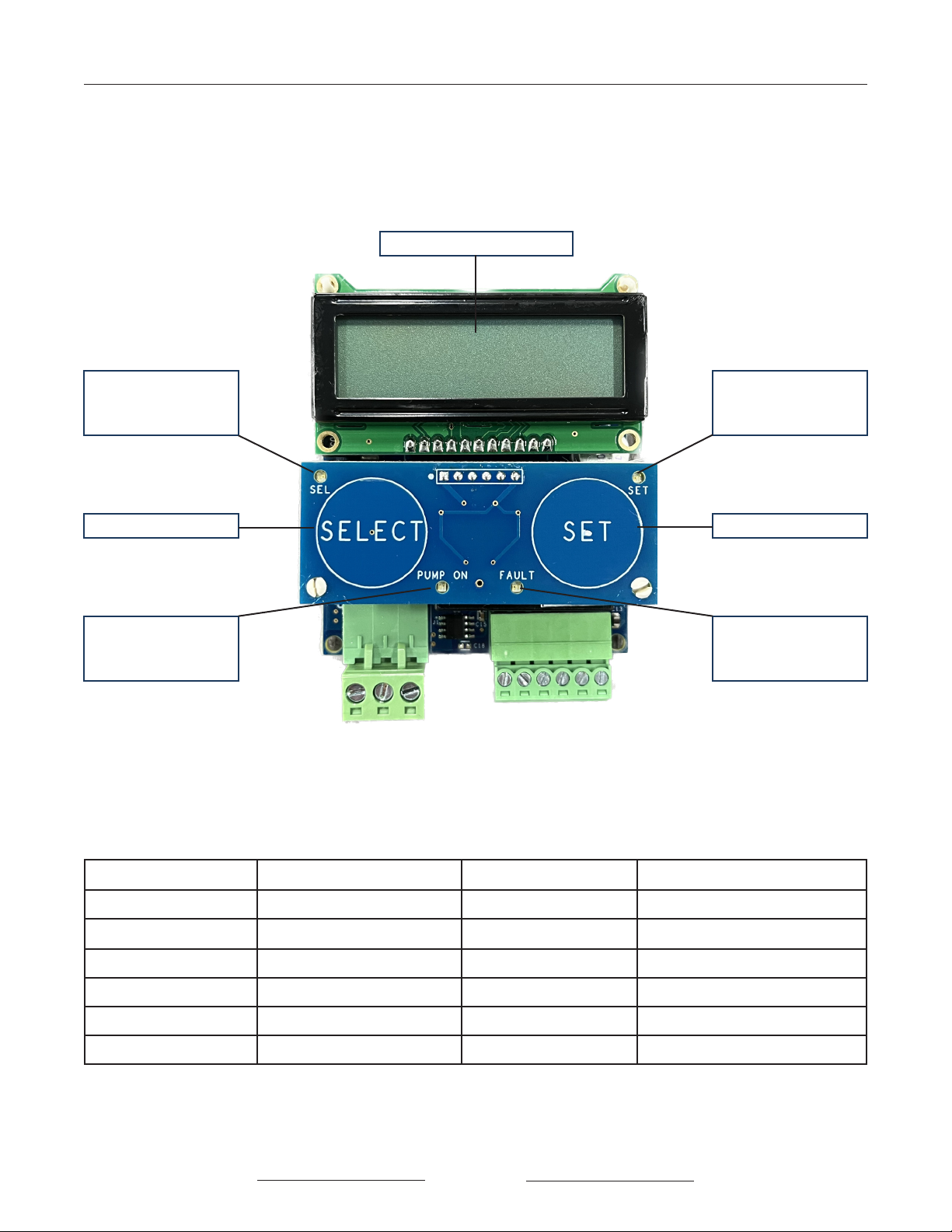

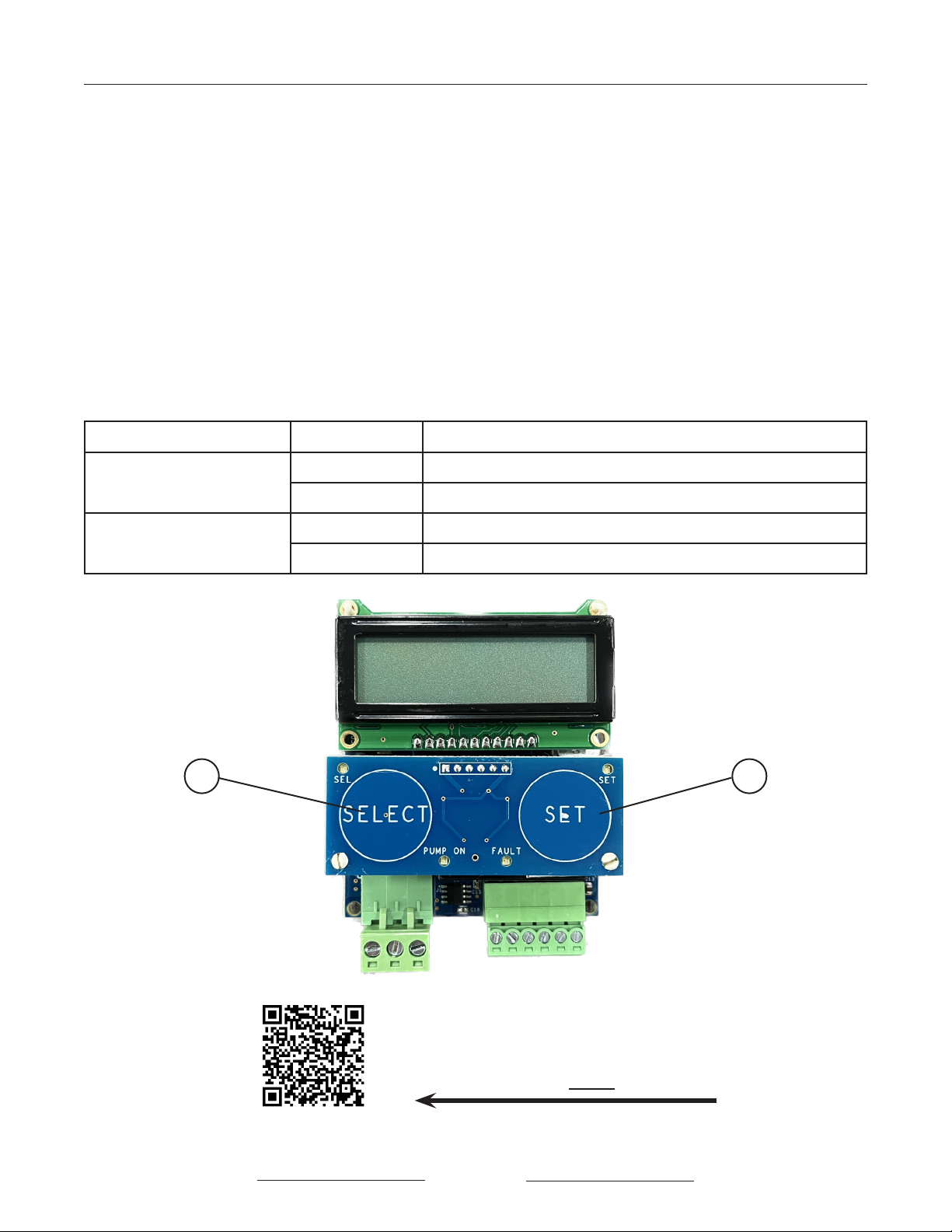

PC Board and LCD Components

The driving component behind the operation of the Spot Zero Mobile Pro Mini is the internal

PC Board and accompanying LCD Display. Indication and description of important LCD

components can be found below in Figure 4.

LED that indicates

when SELECT is

pressed

LED that indicates

when SET is

pressed

SELECT Button SET Button

LED that indicates

when the pump

is ON

LED that indicates

when the system

is in a fault state

Backlit LCD display

Figure 4: Mobile Pro Mini PC Board Reference

LCD Display LED Indicator Action Required Reference

ORDER FILTER NONE Order lter Part #: FI-FW0021

CHANGE FILTER FAULT LED slow RED ash Change lter Pg. 15

FILTER PAST DUE FAULT LED rapid RED ash Change lter Pg. 15

ORDER MEMBRANE NONE Order membrane Part Number: MM-FW0014

CHANGE MEMBRANE FAULT LED slow RED ash Change membrane Pg. 17

MEMBRANE PAST DUE FAULT LED rapid RED ash Change membrane Pg. 17

Mobile Pro Mini Revision Date: 3/16/2023

13

Normal Operation

LCD Programming and Navigation

The Spot Zero Mobile Pro Mini is preprogrammed with set recommended maintenance cycles

along with programming sequences that a customer can use to monitor system performance

more closely. Please see the below information for LCD navigation.

At any time during operation, if either the SET or SELECT buttons are pressed, the LCD will display

LOCKED for 0.5-seconds to prevent from any accidental programming or variable change.

Therefore, to reset parameters such as lter and membrane hour counters, the keypad must

be unlocked rst.

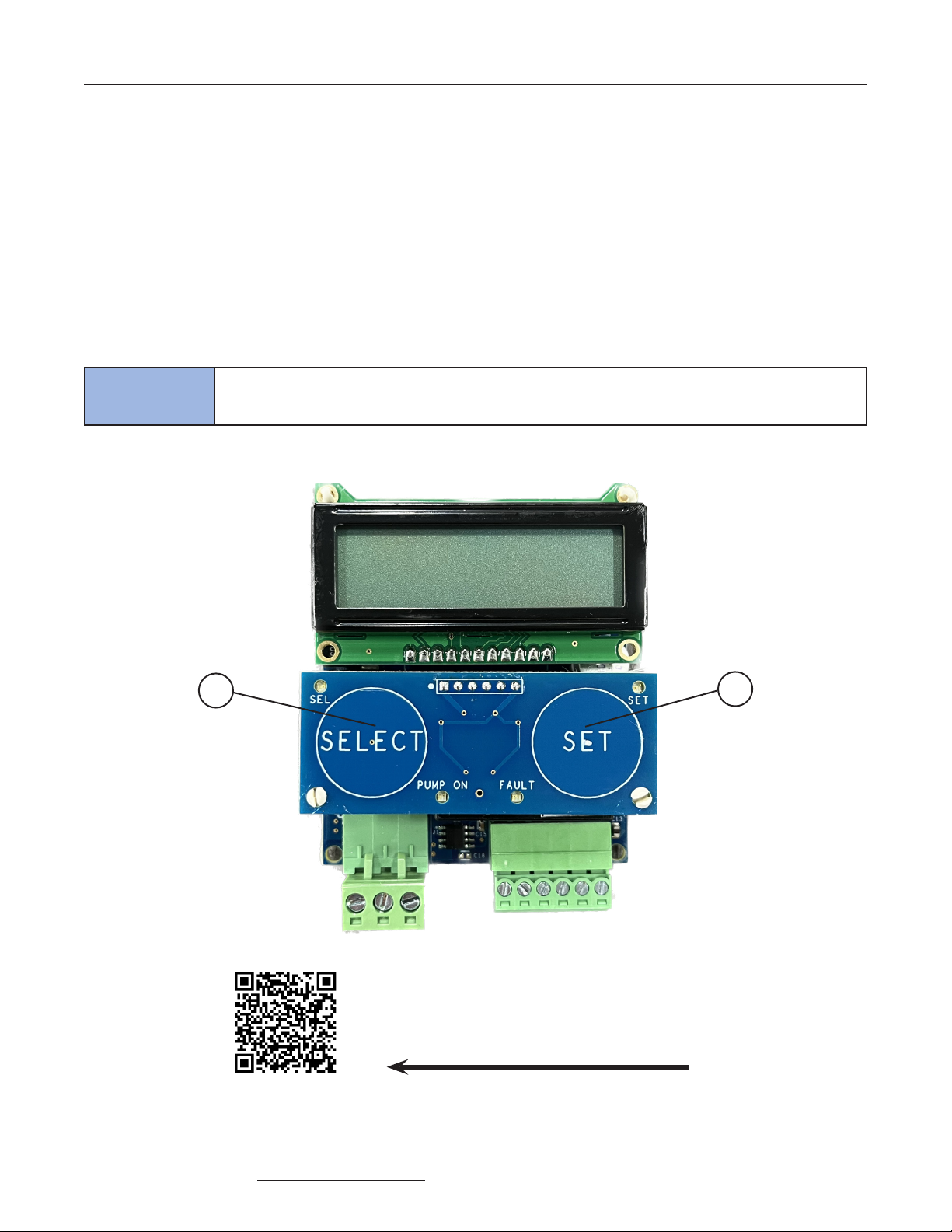

Unlocking the Keypad

Press and hold BOTH the SET (Fig. 5, #1) and SELECT (Fig. 5, #2) buttons for 3-seconds until you

see UNLOCKED display on the LCD for 0.5-seconds.

NOTE FEEDBACK TO DETERMINE IF EITHER SET OR SELECT ARE BEING PRESSED IS GIVEN

BY THE BLUE LED’S ABOVE EACH BUTTON AS SHOWN IN FIGURE 4 ON PG. 12.

12

For a Complete Collection of

Operating Videos and LCD

Navigation, Scan the QR Code or

Click HERE

Figure 5: Mobile Pro Mini PC Board Reference

Mobile Pro Mini Revision Date: 3/16/2023

14

Maintenance

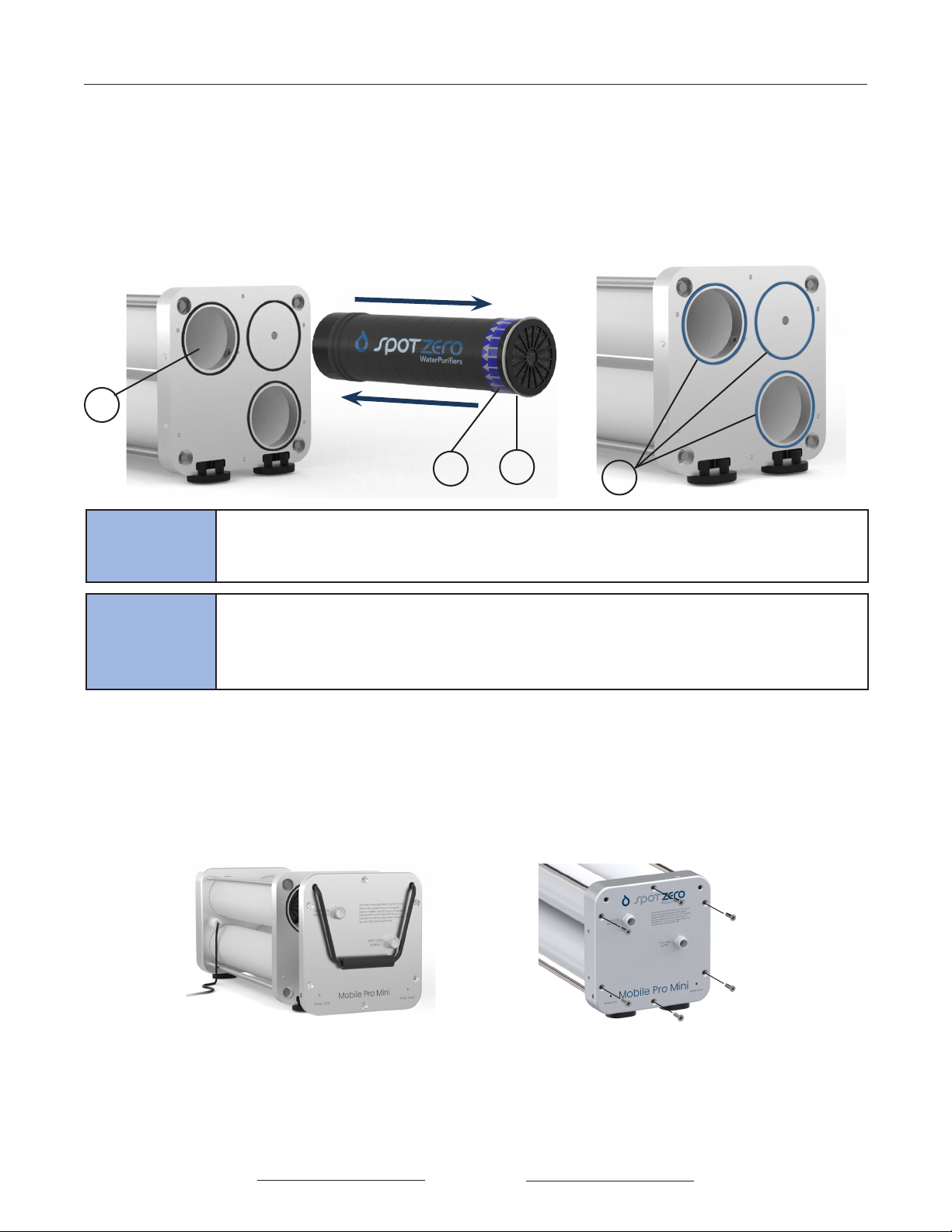

Filter Replacement

Each Spot Zero Mobile Pro Mini contains one prelter that is

responsible for removing suspended solids, heavy metals,

and other contaminants before the membranes. The lter

(Part #: FI-FW0021) must be replaced every 100 hours of

operation or as needed.

The LCD display is programmed with the following indicators

to show recommended lter change intervals:

TIME LCD DISPLAY LED SEQUENCE

90 Hours ORDER FILTER None

100 Hours CHANGE FILTER Slow consistent red ash

110 Hours FILTER PAST DUE Rapid red ash

1. Ensure the water supply is turned off and hoses are disconnected from the system.

2. Ensure power is disconnected from the power supply.

3. If wheels are installed, follow the brief instructions below to remove them before continuing.

a. Unthread the Wheel Lock set screw (Part #: HW-SC0016) half-way from the plate on

the backside of the system as shown Figure 6, Item 1.

b. Slide wheel axle assembly (Part Number: MA-MP0000) out of the retaining channel

and set aside for re-installation later (Fig. 6, Item 2)

c. Repeat on opposite side.

4. Once the wheels and plumbing have been removed, unscrew the 6 end plate retaining

screws shown in Figure 6, Item 3, one at a time.

5. Hold end plate rmly with two hands and pull away from the unit to release the end plate.

2

2

1

Figure 6: WHeel assembly/removal

3

Maintenance For a Complete Collection

of Maintenance Videos

Scan the QR Code Below or

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

15

Maintenance

6. As shown in Figure 7, the lter is located in the top left hole through the inner end plate (#1).

7. Using either pliers or your hand, reach into the housing and rmly grasp the lter.

8. Remove the lter from the housing by pulling away from the system.

9. Install the new lter in the direction of the arrow label as shown in Figure 7, #2.

NOTE: the white seal should be the last side of the lter to enter the vessel.

10. Push the lter inside the housing until it stops.

11. Retrieve the end plate and return to the system top side up as shown in Fig. 9.

12. Align the end plate and push inward toward the system until the external edges of the

plate are ush with those of the internal end plate.

13. Return all screws to the system, properly fastening each one by hand to a torque of 50 in-lb

14. Reconnect all hoses to the system and turn on water for approximately 30-seconds to

bleed air out of the unit.

NOTE

THE NEW FILTER HAS A MEMBRANE CLEANER IN IT THAT WILL ASSIST IN CLEANING

THE MEMBRANE FILM. REMOVAL OF THESE IMPURITIES WILL ASSIST IN THE OVERALL

EFFICIENCY AND PERFORMANCE OF THE SYSTEM. DO NOT USE ANY PRODUCT

WATER UNTIL THE FOLLOWING STEPS ARE COMPLETED.

1

231

Figure 7: Filter cHange Figure 8: o-ring emPHasis

NOTE BEFORE RETURNING END PLATE TO SYSTEM FACE, ENSURE ALL O-RINGS ARE

PROPERLY INSTALLED AND HAVE NOT COME LOOSE IN THE REMOVAL PROCESS

AS SHOWN IN FIGURE 8, #1. IF NEEDED, RELUBRICATE WITH MOLYKOTE.

15. Allow the membrane cleaner solution to soak for a minimum of 30-minutes by turning

off the water supply. Longer soak times will promote greater performance. Do not let the

cleaner soak for more than 24-hours.

16. Turn the water supply on to allow the system to ush with the Spot Zero product outlet shut

for 10-minutes to remove residual cleaner. DO NOT plug in the system to power yet.

17. Reset Filter Maintenance Hours as shown on Pg. 16. Return to Normal Operation

Figure 9: end Plate re-installation Figure 10: screW re-installation

removal

installation

Mobile Pro Mini Revision Date: 3/16/2023

16

Maintenance

Resetting the Maintenance Hours

1. Unlock the keypad as explained on the previous page.

2. Press the SELECT button to see the rst programmable parameter. Continuing to press

SELECT will toggle through all parameters and will wrap around back to the beginning.

3. To begin editing a parameter, navigate to the desired parameter and press the SET button.

4. Once the parameter value is displayed, press the SET button again to change the value to

the alternate value. Each subsequent press of SET will change the value by a step.

5. To save the parameter value, press and hold both SET and SELECT buttons for 3-seconds

until the LCD displays SAVED for 1.5-seconds. Parameter setting mode will be exited and

you will be returned to the normal display sequence.

6. To exit parameter setting mode WITHOUT saving, press the SELECT button at any time, this

will return you to the parameter menu.

*The programmable parameters are shown below with all available options�

Parameter Value 1 Explanation if Saved

Flt Hrs KEEP Filter hours will remain unchanged

RESET Filter hours will reset back to 0

Memb Hrs KEEP Membrane hours will remain unchanged

RESET Membrane hours will reset back to 0

1 2

For a Complete Collection of

Operating Videos and LCD

Navigation, Scan the QR Code

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

17

Maintenance

Membrane Replacement

Each Spot Zero Mobile Pro Mini contains two RO membranes

that are responsible for the ultra-ltration of incoming

water supply. The membranes (Part #: MM-FW0014) must

be replaced every 500 hours of operation or as needed.

The LCD display is programmed with the following

indicators to show recommended membrane change

intervals:

TIME LCD DISPLAY LED SEQUENCE

490 Hours ORDER MEMBRANE Slow consistent red ash

500 Hours CHANGE MEMBRANE Slow consistent red ash

510 Hours MEMBRANE PAST DUE Solid red

1. Ensure the water supply is turned off and hoses are disconnected from the system.

2. Ensure power is disconnected from the power supply.

3. If wheels are installed, follow the brief instructions below to remove them before continuing.

a. Unthread the Wheel Lock set screw from the plate on the backside of the system as

shown in the image below.

b. Slide wheel axle assembly out of the retaining channel and set aside for re-

installation later.

c. Repeat on opposite side.

4. Once the wheels and plumbing have been removed, unscrew the 6 end plate retaining

screws shown in Figure 11 one at a time.

5. Hold end plate rmly with two hands and pull away from the unit to release the end plate.

2

2

1

Figure 11: WHeel assembly/removal

3

For a Complete Collection

of Maintenance Videos

Scan the QR Code Below or

Click HERE

Mobile Pro Mini Revision Date: 3/16/2023

18

Maintenance

6. As shown in Figure 12, the rst membrane is located in the bottom right hole through the

inner end plate (Fig. 12, #1). Using either needle nose pliers or your hand, reach into the

housing and rmly grasp the membrane by one of the black ns, ensuring not the grasp

the product tube in case inspection or reuse is required (Fig. 12).

7. Remove the membrane from the housing by pulling away from the system (Fig. 12, #2).

8. Remove the new membrane from the packaging and inspect for any nicks, cuts, or

deformities. If the white brine seal (Fig. 12, #3) is damaged, replace with a new one.

9. Lubricate the white brine seal (Fig. 12, #3) with a food grade lubricant such as Molykote.

10. Install the membrane element so the brine seal is on the side that is last to enter the

housing (Fig. 12, #3). Push the membrane into the housing until it stops, using a slight

twisting motion to ensure the brine seal stays properly seated.

11. Continue to rmly push on the membrane until it feels like it set in place.

123

Figure 12: membrane rePlacement WHeel side Figure 13: membrane o-ring emPHasis WHeel side

1

CORRECT INCORRECT

Figure 14: correct Plier use on membrane Figure 15: incorrect Plier use on membrane

NOTE BEFORE RETURNING END PLATE TO SYSTEM FACE, ENSURE ALL O-RINGS ARE

PROPERLY INSTALLED AND HAVE NOT COME LOOSE IN THE REMOVAL PROCESS

AS SHOWN IN FIGURE 13, #1. IF NEEDED, RELUBRICATE WITH MOLYKOTE.

installation

NOTE THE SIDE WITH THE WHITE SEAL

MUST BE THE LAST SIDE TO

ENTER THE HOUSING

Mobile Pro Mini Revision Date: 3/16/2023

19

Maintenance

15. Move to the opposite side of the unit and repeat Steps 5-14 to replace the second RO

membrane using Figures 18 and 19 instead of 12 and 13. The membrane is contained in the

only open hole that is visible when the second outer end plate is removed, Figure 18.

16. Reset Membrane Maintenance Hours as shown on Pg. 16. Return to Normal Operation

3211

Figure 18: membrane rePlacement lcd side Figure 19: membrane o-ring emPHasis lcd side

Figure 20: end Plate re-installation lcd side Figure 21: end Plate screW re-installation lcd side

12. Retrieve the end plate and return to the system top side up as shown in Fig. 16.

13. Align the end plate and push inward toward the system until the external edges of the plate

are ush with those of the internal end plate.

14. Return all screws to the system, properly fastening each one by hand to a torque of 50 in-lb

Figure 16: end Plate re-installation Figure 17: screW re-installation

Mobile Pro Mini Revision Date: 3/16/2023

20

Maintenance

Preparing System for Storage or Shipment

If the unit will be sitting idle for a signicant amount of time (i.e. anything longer than 1 month),

the membrane vessels must have static water replaced with membrane storage chemical

solution. The CH-03 Membrane Storage Chemical is Part #:252404263 and can be purchased

through any dealer of Spot Zero. To prepare for storage, please follow the steps below.

1. Turn the system on and ll a 5-gallon bucket with the Spot Zero product water that comes

out of the Mobile Pro Mini.

⚠ CAUTION PRODUCT WATER FROM THE MOBILE UNIT MUST BE USED FOR THE BELOW STEPS,

FAILURE TO DO SO MAY RESULT IN PERMANENT MEMBRANE DAMAGE.

2. Disconnect the inlet hose from the TAP WATER FEED INPUT tting.

3. Remove the lter from the system using Steps 1-8 shown on Pgs. 14-15.

4. Return end plate to the system and secure properly as shown in Steps 11-13 shown on Pg. 16.

5. Thoroughly mix contents on the Membrane Storage Chemical with the 5-gallons of Spot

Zero water produced in Step 1 above.

6. Run a hose from the bucket with the solution to an auxiliary pump to circulate the solution

into the unit. This pump should be hooked up into the TAP WATER FEED INPUT.

⚠ CAUTION

THE SYSTEM SHOULD NEVER BE PLUGGED IN FOR ANY OF THE ABOVE STEPS. ONLY

AN AUXILIARY PUMP SHOULD BE USED TO CIRCULATE THE SOLUTION. PLUGGING

IN THE SYSTEM AND ALLOWING THE PUMP TO RUN CAN PERMANENTLY DAMAGE

THE MEMBRANES IF ALL THE STORAGE CHEMICAL HAS NOT BEEN REMOVED FIRST.

Recommissioning System After Storage

1. Install a new pre-lter (Part #: FI-FW0021) into the system following Steps 1-17 on Pgs. 14-15.

Reconnect the TAP WATER FEED INPUT to a hose feed, as well as connect the Overboard

Discharge and SPOT ZERO OUTPUT to their respective hoses.

2. Turn on the water supply to the unit. DO NOT PLUG IN THE UNIT TO POWER YET.

3. Allow the system to ush without the pump running for approximately 30-minutes.

4. After the 30-minute ush, provide power to the unit and commence normal operation.

7. Connect a hose to the SPOT ZERO OUTPUT and run the open end to the 5-gallon bucket

from Step 1 above.

8. Connect a hose to the Overboard Discharge and run the open end to the 5-gallon bucket

from Step 1 above.

9. Turn the auxiliary pump on and circulate the solution throughout the system for a minimum

of 15-minutes. Do not drain the solution from the system.

10. Be sure to remove the hoses from the system and plug the inlets and outlets of the system

to ensure that the storage solution does not leak out of the system.

⚠ CAUTION ENSURE THE PUMP DOES NOT EXCEED 30-PSI INTO THE SYSTEM AND THE WATER

IS BELOW 110°F (44°C).

⚠ WARNING ENSURE ALL OF THE PRODUCT WATER DURING THE 30-MINUTE FLUSH IS

DISCARDED OVERBOARD. THIS IS NON-POTABLE, HIGH PPM WATER AND COULD

FOUL PLUMBING FIXTURES AND/OR DISCOLOR OR STAIN MATERIALS IT CONTACTS.

Table of contents

Other spotzero Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Hydac

Hydac OLS 10-Z Series Installation and maintenance instructions

Sartorius

Sartorius Sartoclear 29XDL10-FCFFF Directions for use

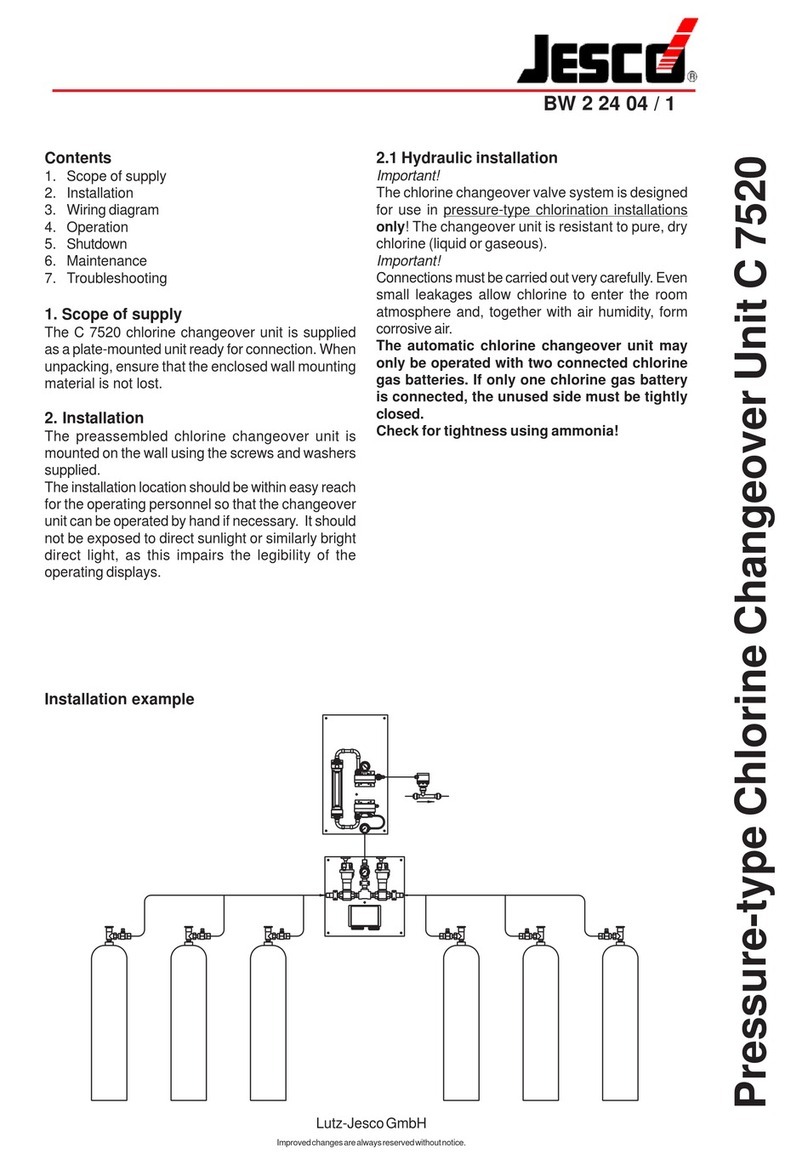

Jesco

Jesco C7520 manual

Kessel

Kessel G round NS 0,25 Installation and operating instructions

novaris

novaris SFH3-800 275 Series Installation and operating instructions

GE

GE SmartWater GXUT05Z owner's manual