IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

2

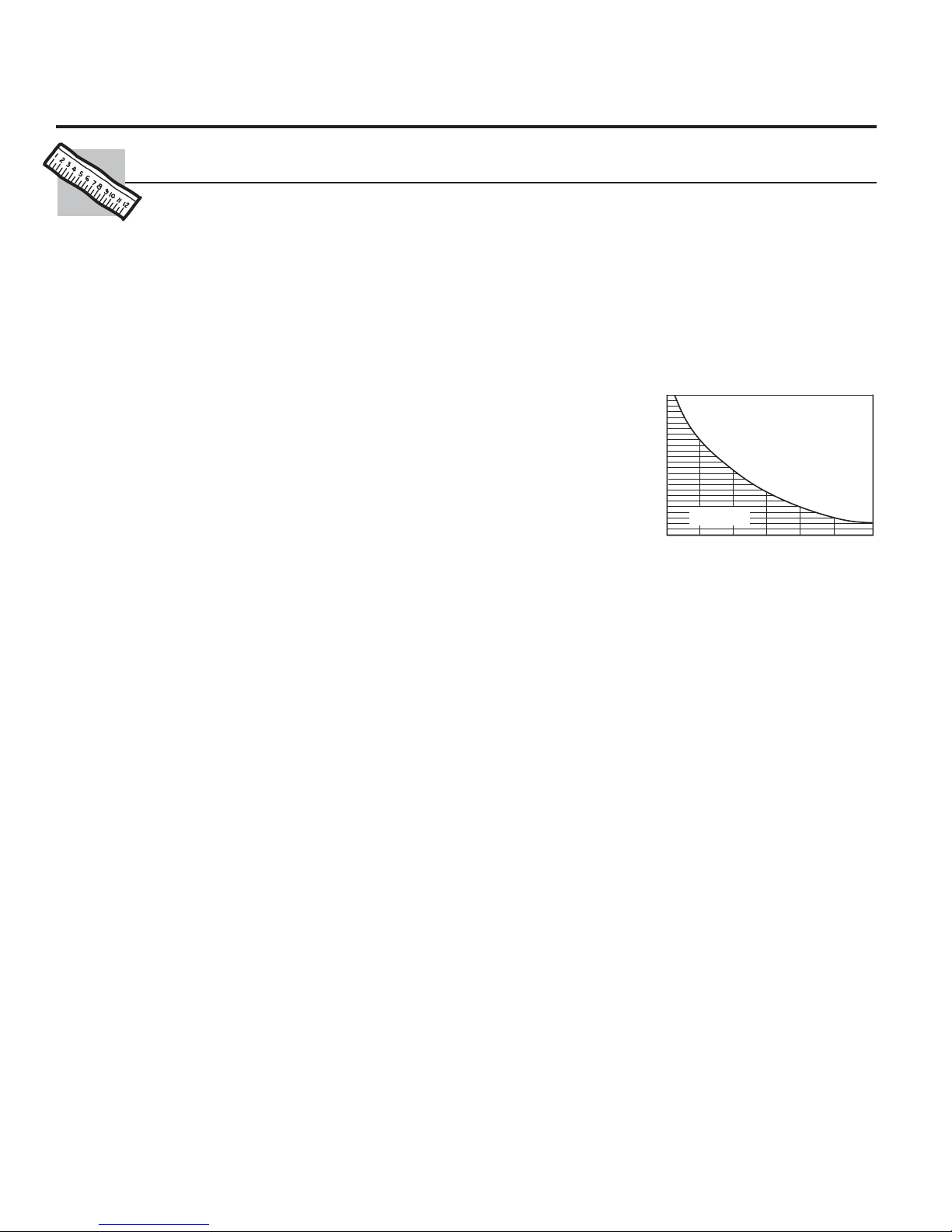

Be sure the water supply conforms with the Specification

Guidelines. If the water supply conditions are unknown,

contact your municipal water company or your local health

department for a list of contaminants in your area and a list of

laboratories certified by your state to analyze drinking water.

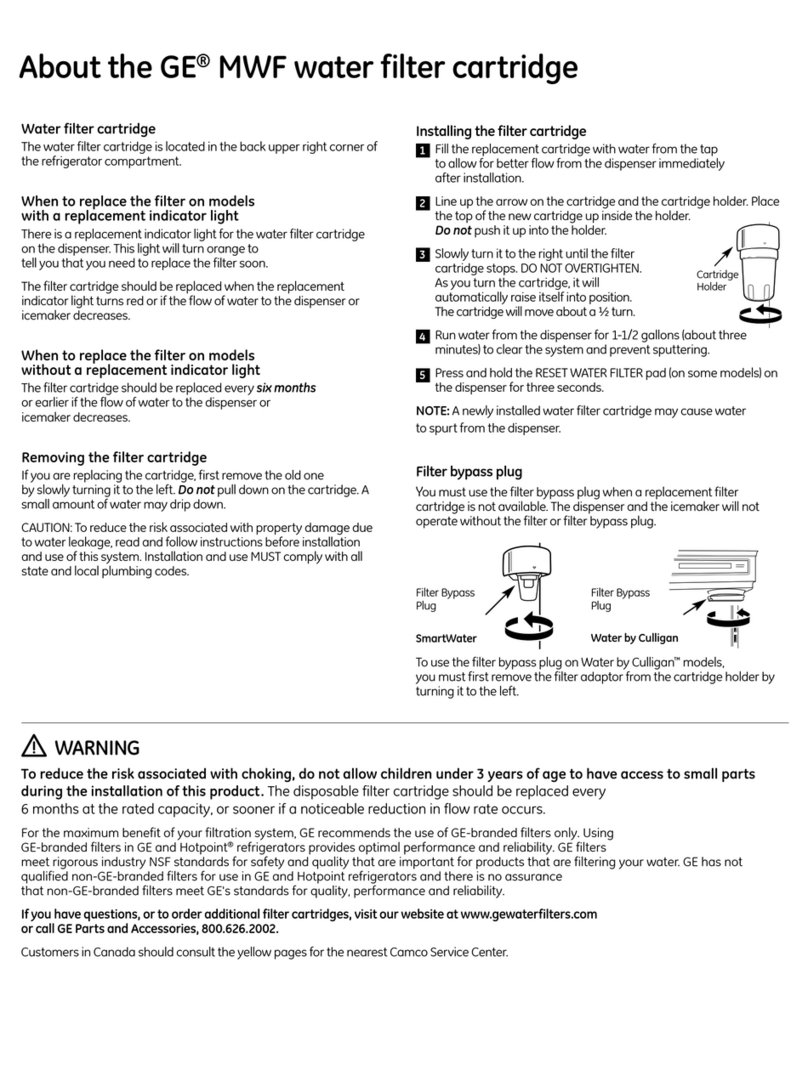

WARNINGTo reduce the risk associated with

choking:

Do not allow children under 3 years of age to have access

to small parts during the installation of this product.

WARNINGTo reduce the risk associated with

the ingestion of contaminants:

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or

after the system. Systems certified for cyst reduction may be

used on disinfected water that may contain filterable cysts.

EPA Establishment #10350-MN-005.

WARNINGTo reduce the risk associated with

hazardous voltage due to an installer drilling through

existing electric wiring or water pipes in the area of

installation:

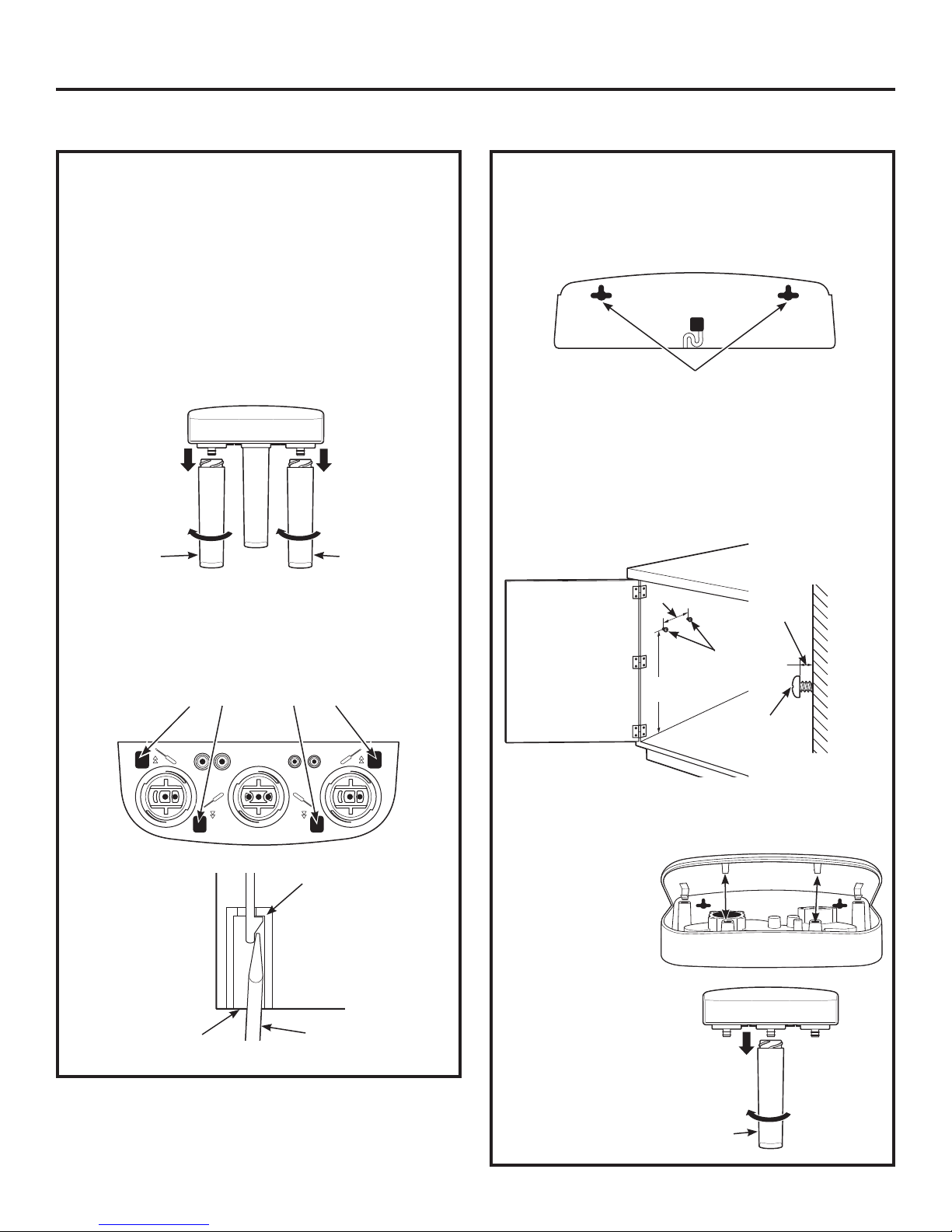

Do not install near electric wiring or piping which may

be in path of a drilling tool when selecting the position to

mount the filter bracket.

WARNINGTo reduce the risk of physical injury:

'HSUHVVXUL]HV\VWHPDVVKRZQLQPDQXDOSULRUWR

cartridge removal.

WARNINGTo reduce the risk of physical injury due

to hydro-pneumatic tank rupture:

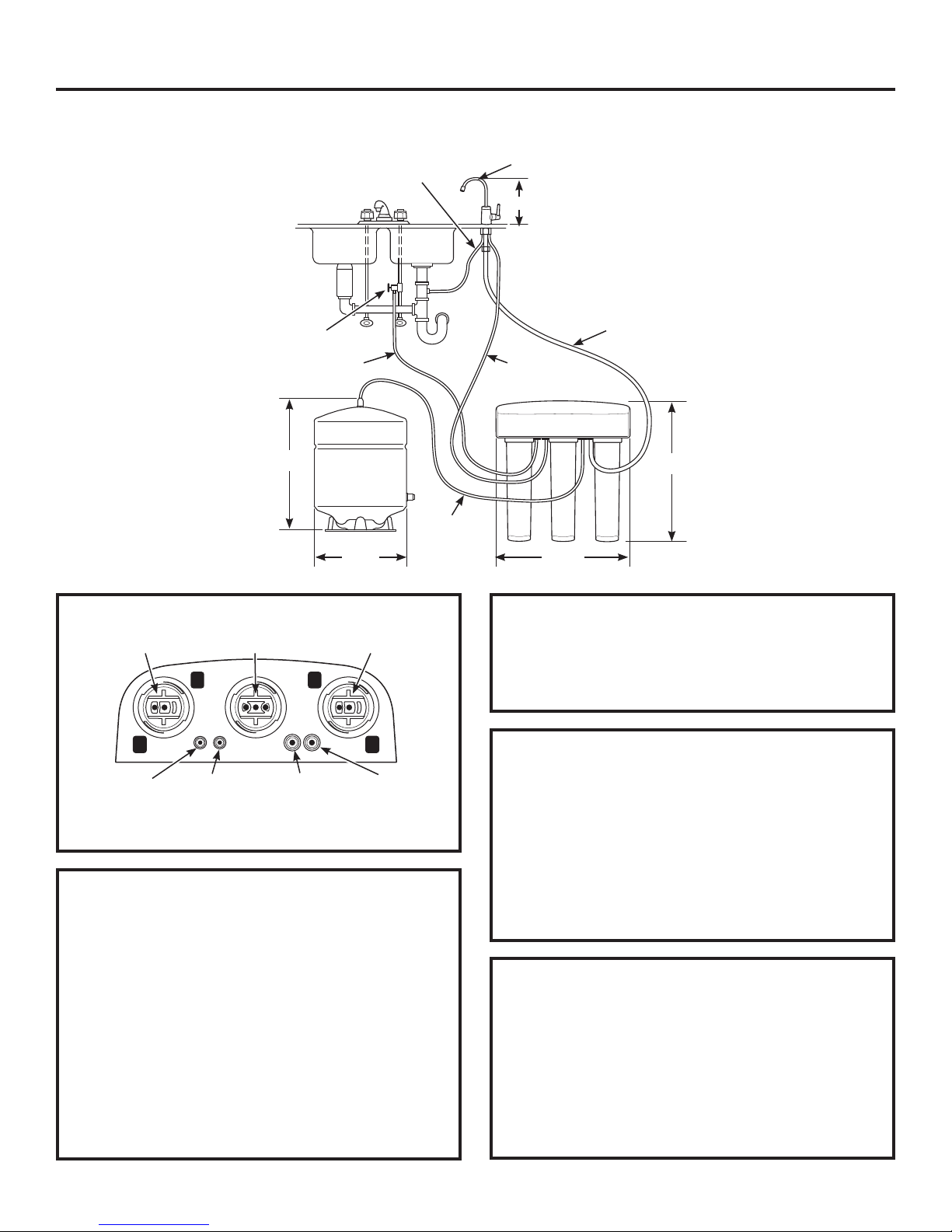

Do not install if water pressure exceeds 120 psi (827

kPa). If your water pressure exceeds 80 psi (552 kPa),

you should install a pressure limiting valve. Contact a

plumbing professional if you are uncertain how to check

your water pressure.

Do not install where water hammer conditions may occur.

If water hammer conditions exist you should install a

water hammer arrester. Contact a plumbing professional

if you are uncertain how to check for this condition.

:KHUHDEDFNIORZSUHYHQWLRQGHYLFHLVLQVWDOOHGRQD

water system, a device for controlling pressure due to

thermal expansion should be installed.

WARNING To reduce the risk associated with

irritation from Sodium Metabisulphite during installation:

6RGLXP0HWDELVXOSKLWH&$6LVXVHGLQD

preservative solution within the reverse osmosis membrane.

To request an MSDS relating to this product call

203-238-8965 or visit the web at http://solutions.3m.

com/wps/portal/3m/en_us/msds (click MSDS search).

For emergencies, call 800-364-3577 or 651-737-6501 (24

hours).

WARNINGTo reduce the risk associated with

ingesting of water contaminated with sanitizer:

$IWHULQVWDOODWLRQVDQLWL]HU0867EHIOXVKHGIURPWKH

system before first use as directed within the installation

instructions.

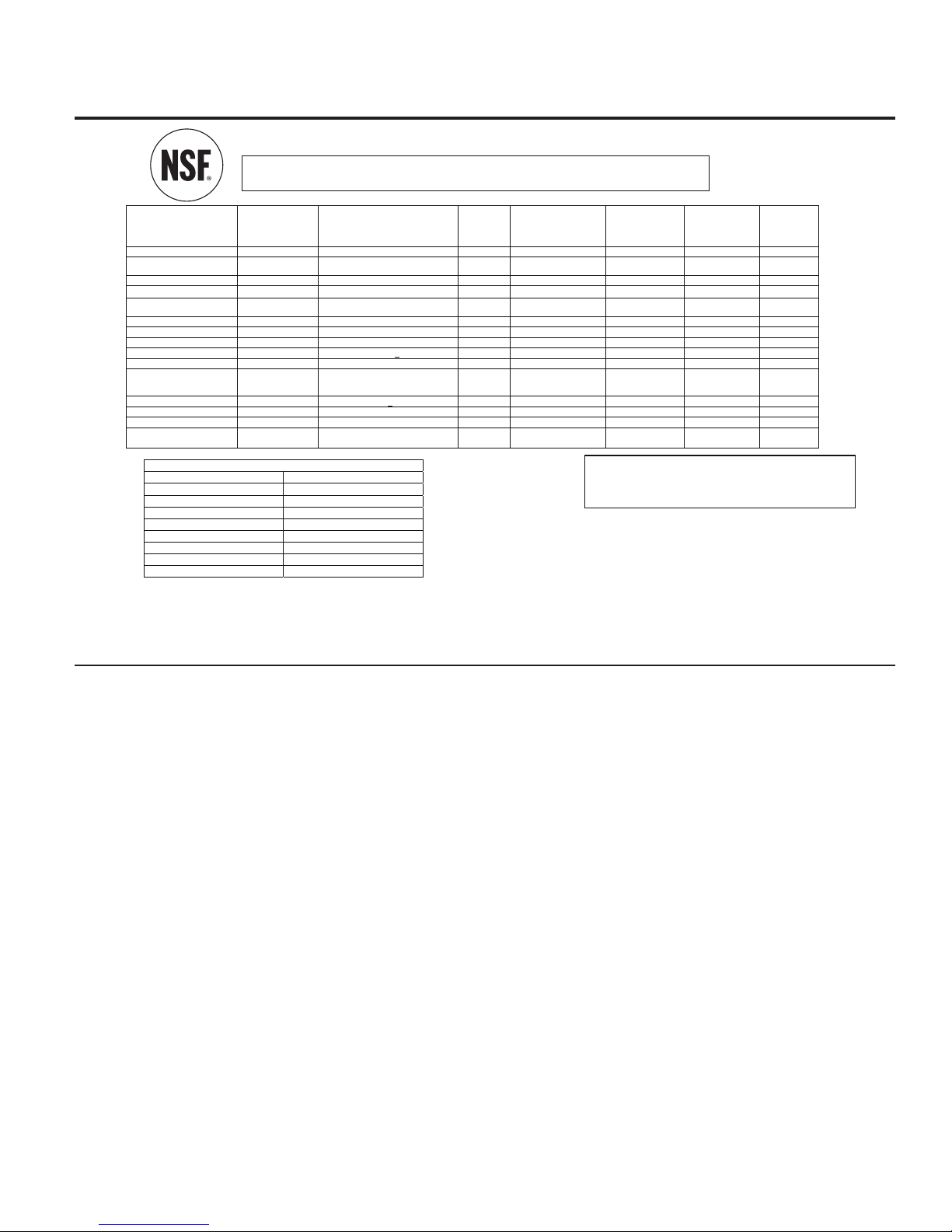

This system has been tested for the treatment of water

containing pentavalent arsenic (also known as As(V), As(+5) or

arsenate) at concentrations of 0.050 mg/L or less. This system

reduces pentavalent arsenic, but may not remove other forms of

arsenic. This system is to be used on water supplies containing

a detectable free chlorine residual or on water supplies that

have been demonstrated to contain only pentavalent arsenic.

Treatment with chloramine (combined chlorine) is not sufficient

to ensure complete conversion of trivalent arsenic to pentavalent

arsenic. Please see the Arsenic Facts section of the Performance

Data Sheet for further information.

This reverse osmosis system contains a replaceable

component critical to efficiency of the system.

Replacement of the reverse osmosis component should

be with one of identical specifications, as defined by

the manufacturer, to assure the same efficiency and

contaminant reduction performance.

SAFETY PRECAUTIONS

SAFETY INFORMATION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the GE Reverse

Osmosis systems. Retain these instructions for future reference.

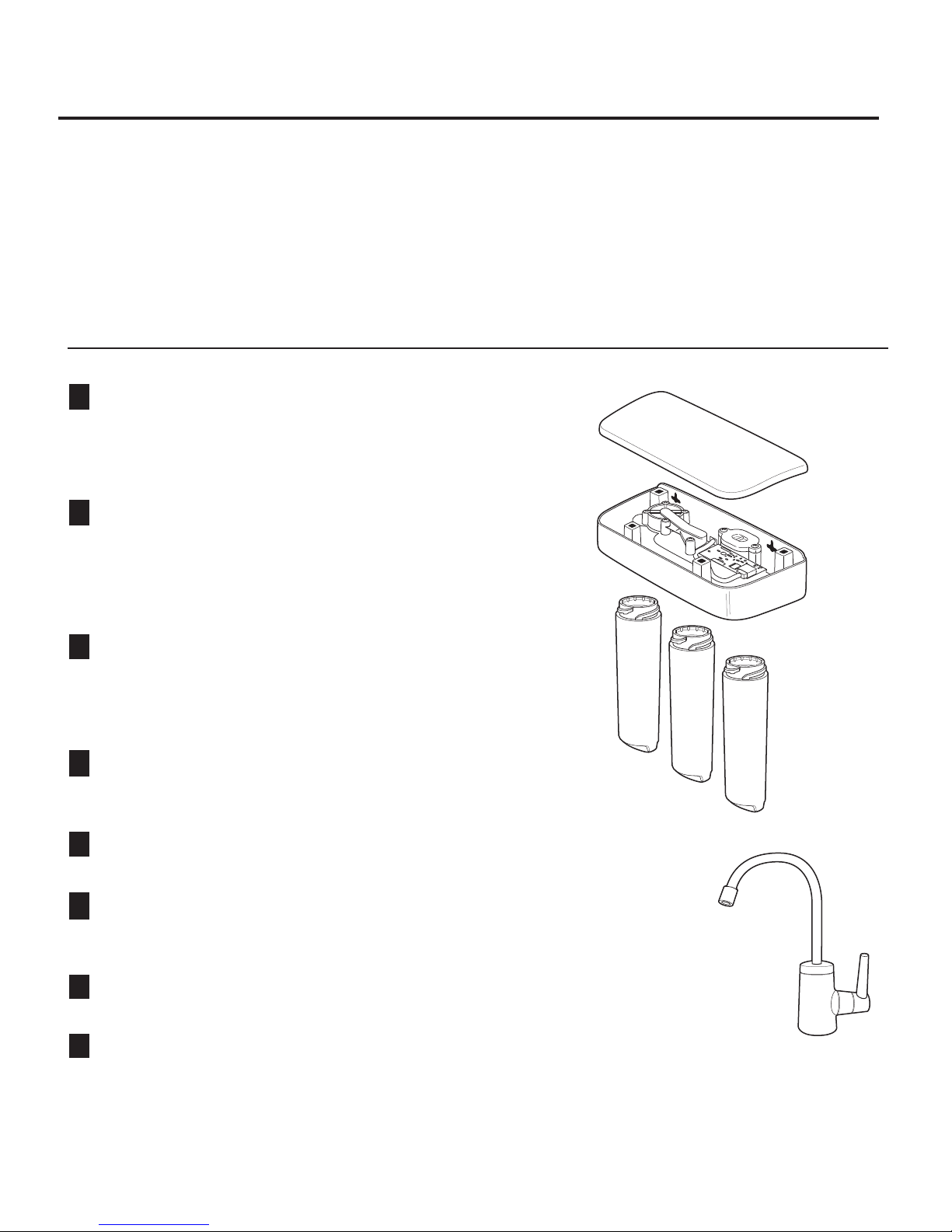

Intended use:

The GE Reverse Osmosis systems are intended for use in filtering potable water in Residential applications, and have not been evaluated

for other uses. The system is typically installed at the point of use, and must be installed as specified in the installation instructions.

Contact a plumbing professional if you are uncertain how to install.

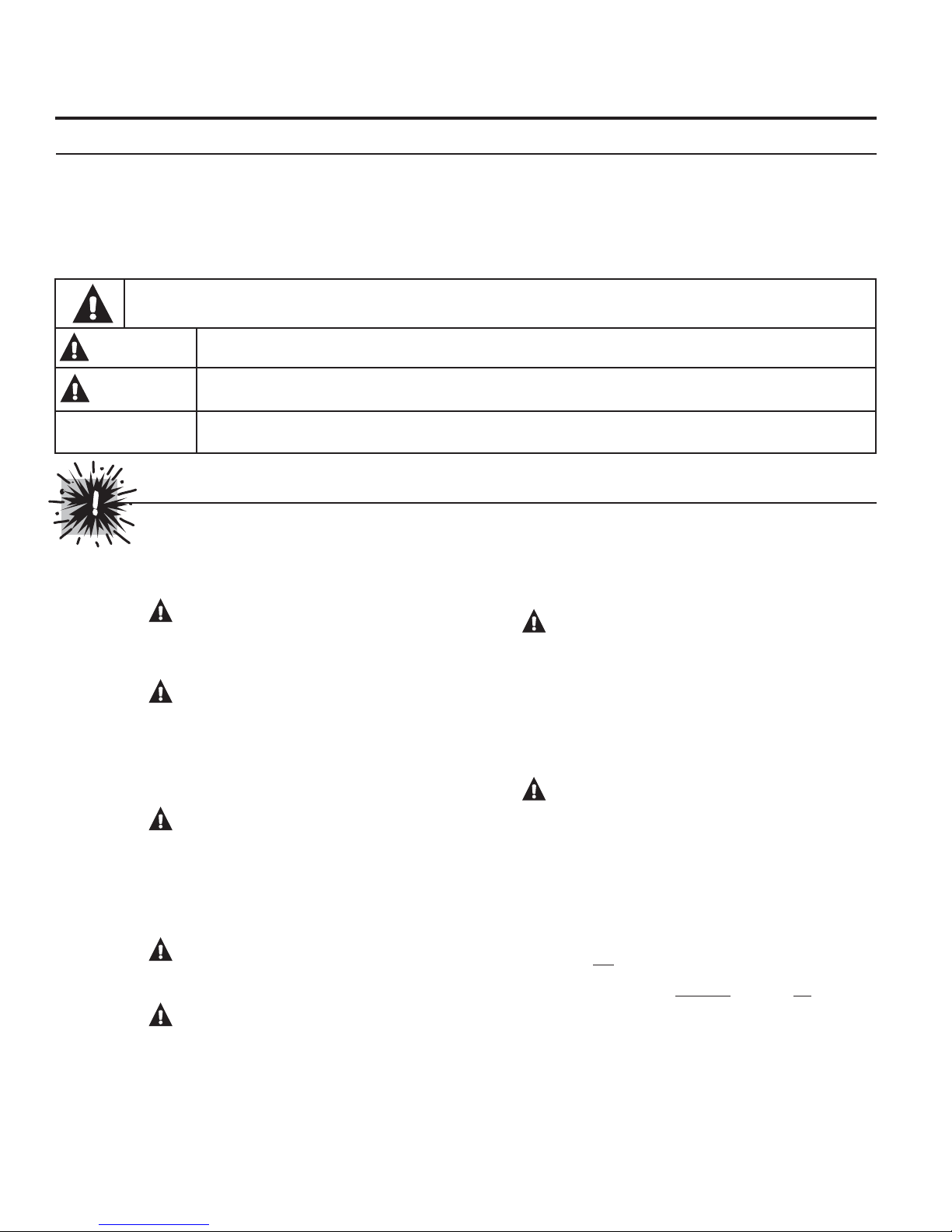

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor to

moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result property damage.

WARNING

CAUTION

CAUTION