5

98-01504-ENUS R1

Aeros 9040 Field Computer

Multiple Sections with SDM/SFM and DCM with

ISM/ASB Setup

Multiple Sections with SDM/SFM and DCM with ISM/ASB Setup is

used when a Section Driver Module (SDM) or Switch Function Module

(SFM) is on the system along with a Dual Control Module (DCM) with

either a Input Status Module (ISM) or Automatic Switch Box (ASB).

The boom or delivery area can include up to 15 sections of varying

width and (in spreader mode) length. Additional options available with

an SDM include Application Overlap, Application Delay, and Staggered

Mode.

A Switch Function Module enables manual and automated boom

control (expandable to 20).

A Dual Control Module (DCM) connects to product implement actuators

and sensors, and controls release of the product by providing the

rate control function for the CAN Bus. Valve Control outputs can be

bidirectional or Pulse Width Modulated.

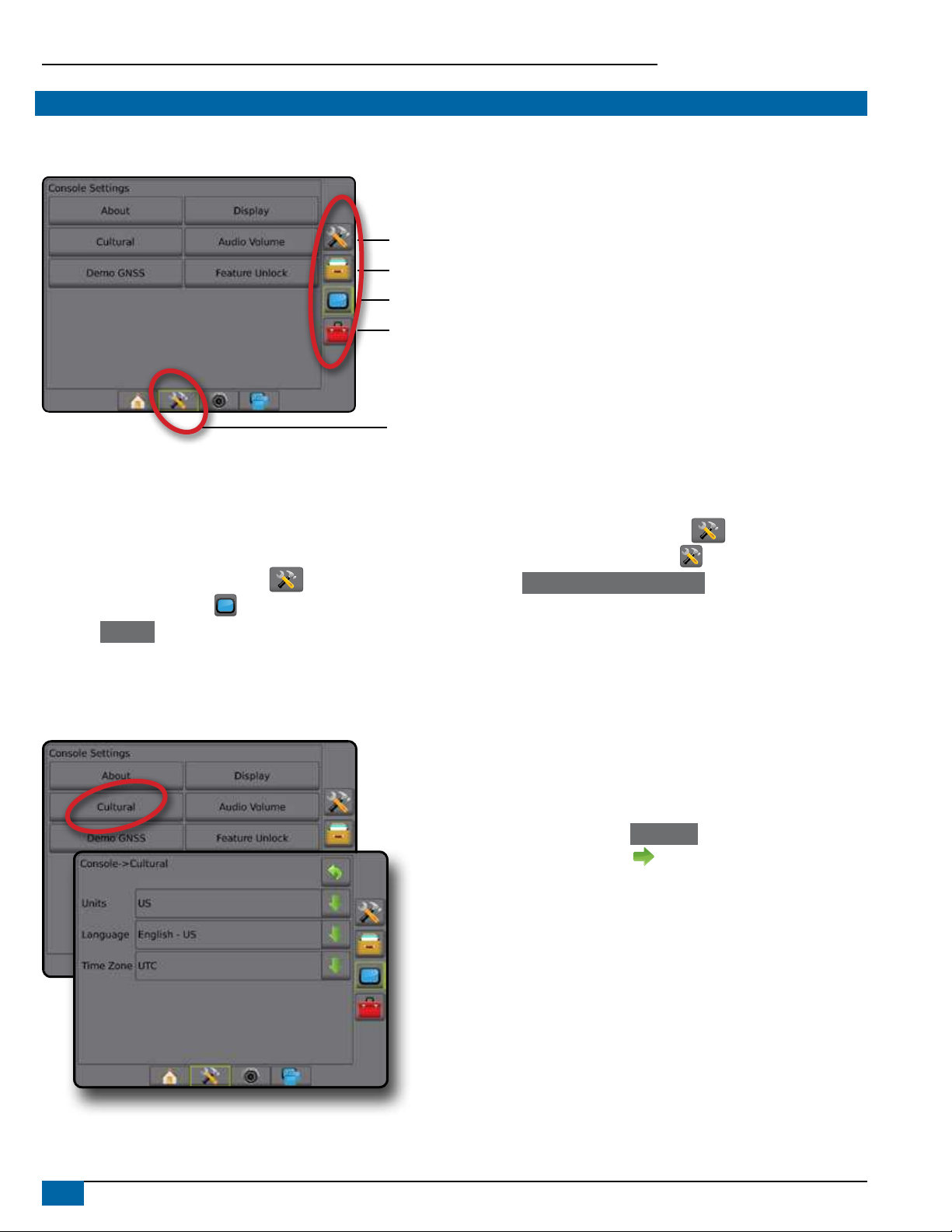

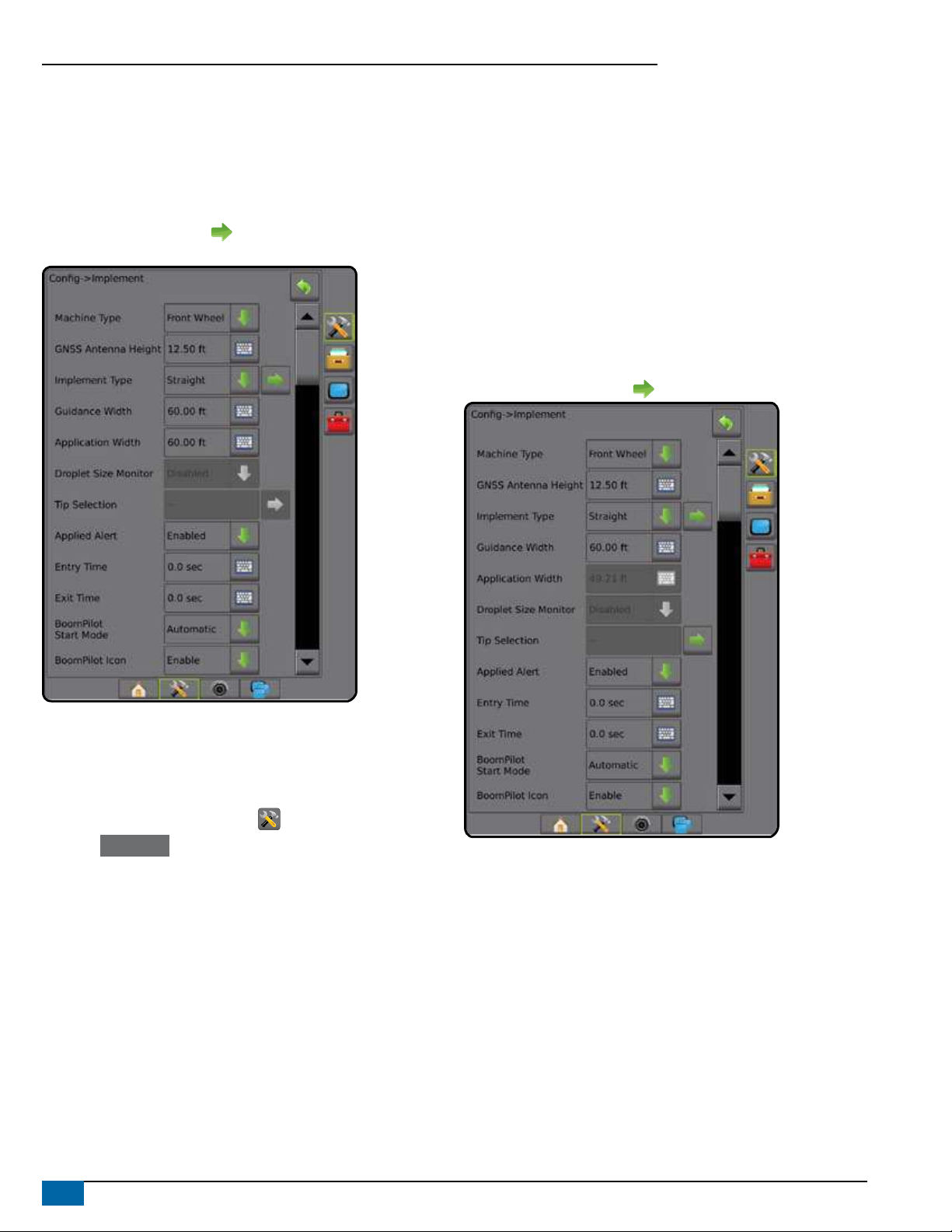

1. Press CONFIGURATION side tab .

2. Press Implement .

3. Select from:

►Machine Type [when available] – used to select the type of

machine that most closely represents your machine

►GNSS Antenna Height [when available] – used to measure the

height of the antenna from the ground

►Implement Type – used to select the layout of the sections for

the applied product location (see Implement Type section for

additional details)

►Symmetric Implement – used to establish if sections are paired

and share the same width, offset, and length values

►Multiple Section Output Modules – used to enable use of

multiple section output modules on the CAN bus

►Number of Implement Sections – used to select the number of

implement sections

►Guidance Width – used to enter the distance between the

guidelines

►Application/Working Width – enter the width of each section to

calculate the total width of all sections of the implement. Each

section can be a different width. Sections are numbered from left

to right while facing in the machine’s forward direction. Range for

each section is 0.0 to 246.06 feet / 0.0 to 75.0 meters. Total for

all sections must be greater than 3.28 feet / 1.0 meter.

NOTE: If Symmetric Implement Layout is enabled, only the

first of each pair of aligned sections will be available to be

highlighted.

►Tip Spacing – used to enter spacing between sprayer tips

►Ground Speed Override – used to set the minimum speed for

use with automatic application rate control

4. Press NEXT PAGE arrow to set up specic implement options.

Additional Settings per Implement Type

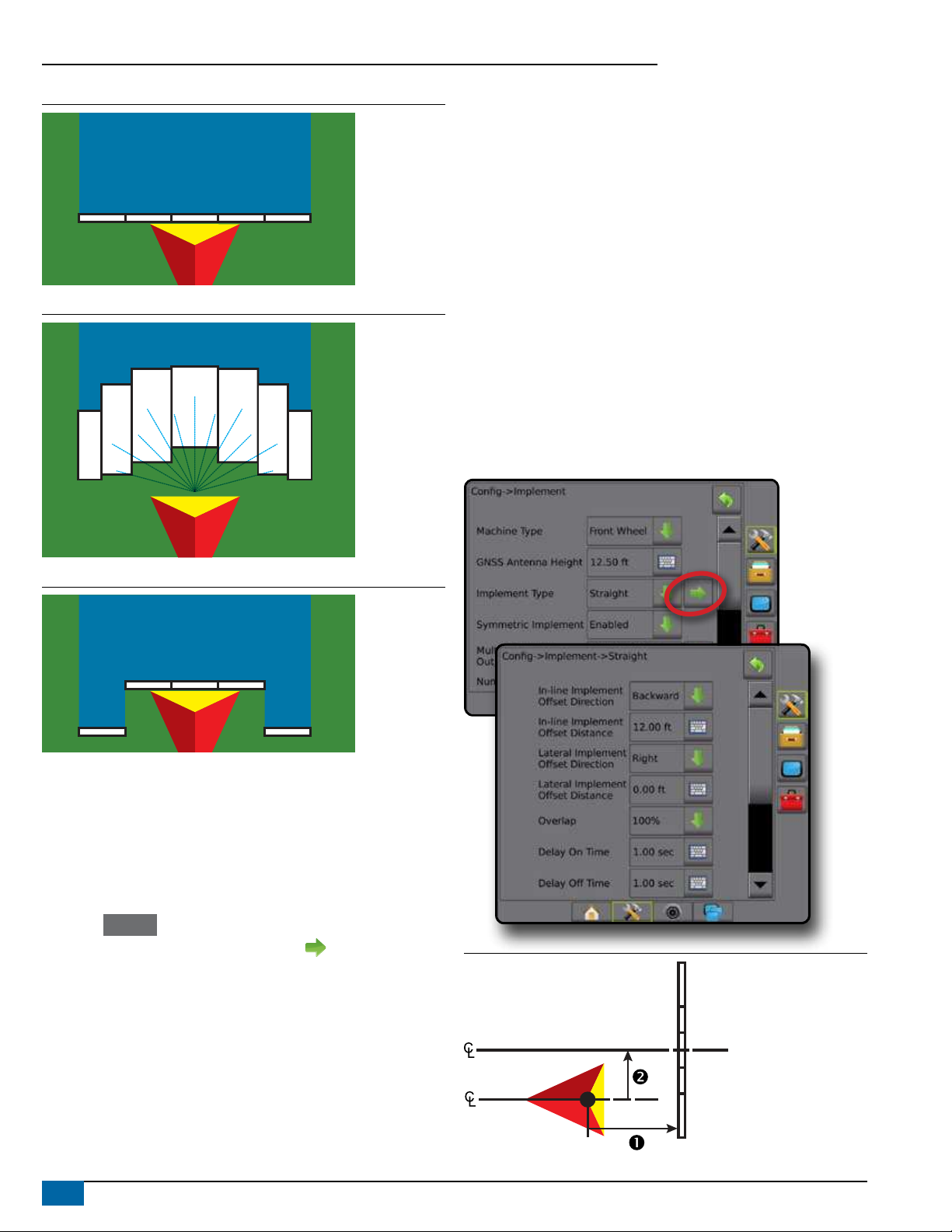

Implement Type selects the type of application pattern that most closely

represents your system.

● In Straight Mode – the boom sections have no length and are on

a line a xed distance from the antenna

● In Spreader Mode – a virtual line is created in line with the delivery

disks from which the application section or sections can vary in

length and can be at different distances from the line (availability

depends on the specic equipment in the system)

● In Staggered Mode – a virtual line is created in line with

Section 1 from which the application section or sections have

no length and can be at different distances from the antenna

(availability depends on the specic equipment in the system)