SpreadNet SN980-SMOKE User manual

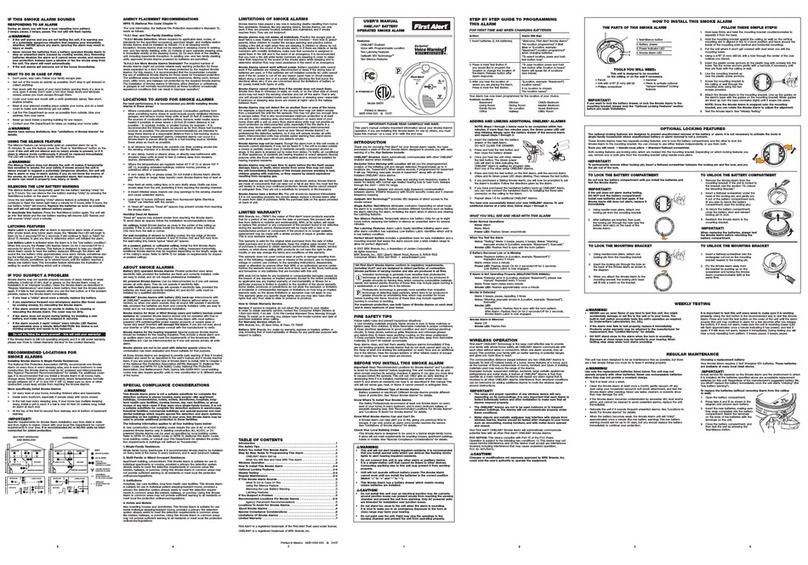

1

12"

(30cm)

Max.

Never mount

in this area

Acceptable here

Top of detector

acceptable here

4"

(10cm)

4"

(10cm)

Figure 1

Mounting location

considerations

SpreadNet®

Model SN980-SMOKE

RF Photoelectric Smoke Detector

Installation Instructions

The SN980-SMOKE is a

system type smoke detec-

tor, designed for open area

protection. The unit com-

bines a Spread Spectrum

wireless transmitter with a

photoelectric smoke detec-

tor.

Spread Spectrum technol-

ogy provides higher power,

lower noise, less interfer-

ence, and longer range

than single frequency transmitters. The RF transmitter is fully su-

pervised, ensuring reliable communications.

WHERE NOT TO PLACE THE DETECTOR

When selecting a mounting location, avoid areas containing large

metal surfaces, which could affect the RF transmitter. Always test

the transmitter prior to permanently mounting it to verify signal

reception.

Avoid placing the SN980-SMOKE in areas where smoke or steam

may affect operation, such as kitchens, bathrooms, near wood

stoves or furnaces. Also avoid areas such as garages, attics, and

areas where ambient temperature may exceed 100° F (37.8° C).

• Spread spectrum technology

• Up to 100 mW transmitter

power

• EEPROM memory

• Lithium batteries included

(1 yr. expected life)

• Simple installation

• Low standby current, 40µA

• Magnetic detector functional

operation check

• Vandal resistant security

locking feature

• Highly stable operation

• RF/Transient protected

FEATURES

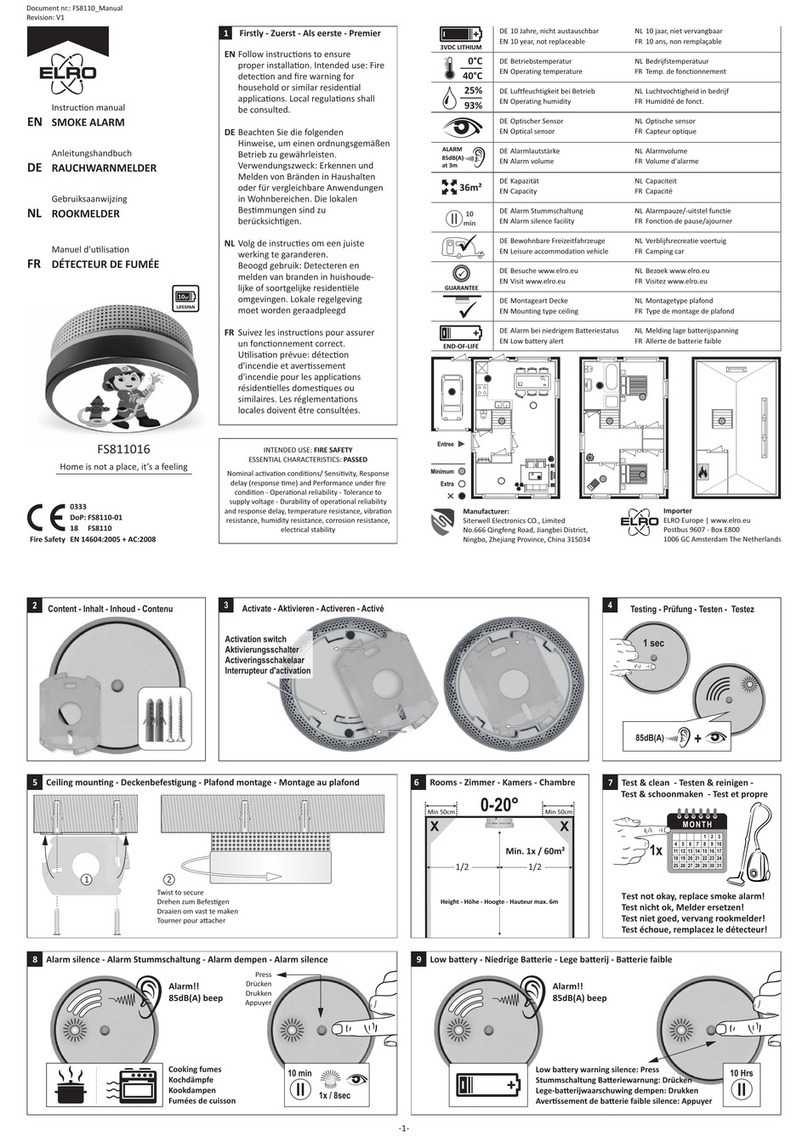

DETECTOR PLACEMENT

The SN980-SMOKE Photoelectric Smoke Detector is designed

to be either ceiling or wall mounted. When ceiling mounting the

SN980-SMOKE, be sure to mount the detector near the center of

the room, if possible. Do not place the detector less than 4" (10

cm) from the nearest wall. If wall mounting, do not mount within 4"

(10 cm) of the ceiling. (See Figure 1.)

Detector placement

should be established

byqualified personnel,

such as a Fire Alarm

Technician certified by

the National Institute

for Certification in En-

gineering Technolo-

gies (NICET), or a

Licensed Fire Protec-

tionEngineer. Location

and spacing of detec-

tors depends upon

such factors as ceiling

height, area to be cov-

ered, air flow conditions, and other conditions which may affect

response time. Additional information regarding detector place-

ment may be found in the National Electrical Manufacturers As-

sociation (NEMA)

Guide for the Proper Use of System Smoke

Detectors

as well as NFPA 72.

MOUNTING

The SN980-SMOKE will mount directly to the wall or ceiling.

Do NOT mount on any type gang box.

The SN980-SMOKE must be programmed prior to permanent

mounting. Refer to the PROGRAMMING THE TRANSMITTER

section below.

To mount the SN980-SMOKE, remove the detector head from

the base by turning the head counterclockwise. Mount the de-

tector base using #6 - #8 (M 3.5 - M 4) mounting screws. (See

Figure 2 below.)

Mounting Holes

Batteries (2 required)

Figure 2

SN980-SMOKE assembly,

top view (head removed)

Detector Head

Locking Screw

(Align with Alignment

Mark on Base.)

Detector Head

Alignment Mark Battery Tab

(Remove

prior to use)

To replace the head assembly, align the tamper Locking Screw

on the detector head with the Detector Head Alignment Mark

on the base. (See Figure 2 above.)

The SN980-SMOKE comes equipped with a vandal resistant

locking feature. The Locking Screw is a 1.5mm Allen head (hex-

agonal) set screw. After installing the detector head, tighten

the Locking Screw until snug.

PROGRAMMING THE TRANSMITTER

In order to program the SN980-SMOKE, the batteries must be

activated and the detector head must be in place. The follow-

ing procedure outlines the steps for programming the detector:

1 - Separate the detector head from the base as described in

the MOUNTING section.

2 - Remove the Battery Tab (see Figure 2 for Tab location).

3 - Replace the detector head, as described above. This will

enable the transmitter circuitry.

IMPORTANT: There is no power to the transmitter with the

detector head removed.

2

PROGRAMMING THE TRANSMITTER(continued)

4 - Remove the back cover (dust cover) from the detector base

by inserting a small screwdriver into one of the slots at the

edge and gently lifting the cover.

5 - To release the Transmitter PCB, press the PCB Retaining

Latch and gently lift the board out of the base. Be careful

not to bend the antenna.

6 - Connect the SN900-PROG RF Programmer to J1 on the

transmitter PCB. (See Figure 3 for location of J1.) Complete

programming information may be found in the SN900-PROG

Programming Manual (P/N 5-051-136-00).

7 - After programming the transmitter, carefully replace the PCB.

Fill out the Transmitter Device ID Label (supplied with the

unit) and apply the label to the rear dust cover.

Figure 3

SN980-SMOKE rear view,

(Back Cover and Trans-

mitter PCB Removed)

Programming

Connector (J1)

Transmitter PCB

Antenna

Transmitter

PCB Retaining

Latch Micro-

controller

P. CODE: The System Property Code.

CHANNEL: Spread Spectrum selected by

the system.

ZONE: Control panel zone number associ-

ated with the transmitter.

DEVICE: The number of the device associ-

ated with the zone.

CHECK-IN: Supervisory interval (in seconds).

BATTERY: Date batteries installed.

0253

2

01

01

30

4/27/95

P. CODE

CHANNEL

ZONE

DEVICE

CHECK-IN

BATTERY

NOTE: Only one (1) SN980-SMOKE may be connected per

zone. When using the SN910-RCVI/O, all devices

must use Device #1.

APPLICATIONS

The SN980-SMOKE can be used in all areas where Photoelectric

Smoke Detectors are required. It is best suited for smoldering fires.

CAUTION: The SN980-SMOKE is not an alarm sig-

nalling device. For proper operation, this detector

MUST be used in conjunction with an alarm signal-

ling system, consisting of the SN912-RCV, SN913-I/

O, an approved control panel and approved signal-

ling device(s).

OPERATION

The detector uses an LED light source and silicon photodiode

receiving element. In normal conditions, the light from the puls-

ing light source does not strike the photodiode. In the event of

a fire, smoke enters the detector chamber, causing light from

the LED source to be reflected off the smoke particles to the

photodiode. The amount of light received is proportional to

the density of the smoke particles.

The received light is converted into an electronic signal. The

signal is compared to a fixed reference. When two consecu-

tive signals exceed the reference level within a specified time

period, an alarm signal is generated.

TESTING THE INSTALLATION

When installing the SN980-SMOKE, you can perform a functional

test of the alarm circuitry by using a test magnet. The test is per-

formed as shown in Figure 4 below.

Test Magnet

Figure 4

Testing with the Test Magnet

The SN980-SMOKE must be programmed and operational prior to

testing. Remember, alarm signals are annunciated by the control

panel, not the detector.

Place the test magnet as shown in Figure 4 for at least 6 seconds.

The system should signal an alarm condition.

NOTE: An alarm signal generated using the test magnet does

not assure an alarm response in the event of a hazard-

ous fire condition. Additionally, this test does not check

the ability of smoke to enter the chamber, nor accurately

test the sensitivity of the device.

Transmitter Device ID

The following procedure is recommended for mounting the

label:

1 - Replace the back cover on the SN980-SMOKE.

2 - Remove the adhesive backing from the label and place

the label on the back cover.

3 - Mount the detector as described previously.

A sample of a completed Transmitter Device ID label is shown

below:

3

TESTING THE INSTALLATION (continued)

To test the ability of smoke to enter the chamber, you may use

a smoldering punk stick or a cotton wick. For convenience,

the TSE-A100 may be also used to test the detector with an

internal smoke source. Hold the smoke source near the smoke

entry openings of the detector and direct the smoke into the

detector. Continue for up to 20 seconds or until an alarm sig-

nals occurs. The actual time required will depend upon air flow

conditions surrounding the detector. This is a go/no-go test

and is not an accurate test of the sensitivity of the detector.Be

sure to properly extinguish the smoke source following the

test!

Smoke Detector:

Light Source:

GaAlAs infrared emitting diode

Supervisory Current:

51.5 µA maximum (40 µA nominal)

Alarm Current (Average):

3.2 mA for 2 seconds maximum

Sampling Interval:

2 seconds

Test Feature:

Use magnet; equivalent to 4 - 6% obscuration

Sensitivity:

2.3%/Ft. (+1.13%/Ft.; -1.24%/Ft.)

RF Transmitter:

RF Power Output:

up to 100 mW

Transmitting Period:

7.6 mSec

Transmitter Check-In Rate:

30 - 300 sec (programmable in 10 sec intervals)

Operating Frequency:

902 MHz - 928 MHz Spread Spectrum

RF Emission Standards:

USA: FCC Part 15

CANADA: IC

General:

Dimensions:

5.9" Diameter; 2.4" High

(15 cm Diameter; 6.1 cm High)

Weight:

8.5 oz (241 g), without batteries

11 oz (312 g), with batteries

Operating Temperature:

32o to 100oF (0o to 37.8o C)

Relative Humidity:

0 - 95% (non-condensing)

Rated Voltage:

6.4 - 7.2 VDC (6.8 VDC working voltage)

Input Power:

Two 3.6 VDC AA lithium batteries (included)

Replace Batteries only with

SAFT Model # LS14500

Tadiran Model # TL-2100

NOTE: Batteries should be replaced following a

Low Battery indication or every 1 year,

whichever occurs first.

SPECIFICATIONS

NOTE: The equipment for testing the SN980-SMOKE de-

tector (TSE-A100, TSA-B110, and YBC-R/6) are

available from Hochiki-America. Refer to C&K

Technical Note P/N 5-052-098-00 for test proce-

dures.

SENSITIVITY MEASUREMENT

The sensitivity of the SN980-SMOKE smoke detector may be de-

terminedusingtheTSA-B110 detector tester and theYBC-R/6 base

adapter. For detailed instructions on the operation of the test unit,

refer to the Adapter Installation Instructions (P/N HA-06-034).

Sensitivity measurements should be performed on each detector

in accordance with the requirements listed in NFPA 72 Chapter 7.

MAINTENANCE

Under normal circumstances, the minimum maintenance require-

mentsoftheSN980-SMOKEconsistsofanannualcleaningofdust

fromthedetector head withavacuum cleaner.(Morefrequentclean-

ing may be required in dusty areas.) Additional guidelines on de-

tectormaintenancerequirementsmaybe found inNFPA 72 Chapter

7 and the NEMA

Guide for the Proper Use of System Smoke De-

tectors

.

NOTE: Be sure to alert all concerned parties whenever any test-

ing or maintenance of the fire alarm system is to occur.

CAUTION:RemovingtheheadfromtheSN980-SMOKE

smoke detector will disable the transmitter, resulting in

aFailure-to-Communicateindicationatthecontrolpanel.

C&K is a registered trademark of C&K Components, Inc.

SpreadNet is a registered trademark of C&K Systems, Inc.

Printed in Hong Kong P/N 5-051-268-00 Rev A

Copyright 1996 C&K Systems, Inc.

All Rights Reserved

FCC NOTICE

The Model SN980-SMOKE Smoke Detector Transmitter generates and uses

radio frequency energy. If not installed and used in accordance with the man-

ufacturer's instructions, it may cause interference to radio and television recep-

tion.TheSN980-SMOKESmokeDetectorTransmitterhasbeentestedandfound

to comply with the specifications in Part 15 of FCC Rules for Class B Computing

Devices and FCC Part 15 Subpart C, Specifications for Intentional Spread

Spectrum Radiators.

If this equipment causes interference to radio or television reception - which can

be determined by turning the equipment on and off - the installer is encouraged

tocorrecttheinterferencebyoneor moreofthefollowingmeasures: 1) Reorient

the antenna of the radio/television. 2) Relocate the SN980-SMOKE transmitter

with respect to the radio/television.

If necessary, the installer should consult an experienced radio/television tech-

nician for additional suggestions, or send for the "Interference Handbook" pre-

pared by the Federal Communications Commission. This booklet is available

from the U.S. Government Printing Office, Washington D.C., 20402, stock

number 004-000-00450-7.

CAUTION: C&K does not support field changes or modifications to any of the

SpreadNet RF equipment unless they are specifically covered in this manual.

All adjustments must be made at the factory under the specific guidelines set

forth in our manufacturing processes. Any modification to the equipment could

void the user's authority to operate the equipment and render the equipment in

violation of FCC Part 15, Subpart C, 15.247.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and(2) thisdevicemustacceptanyinterferencereceived,includinginterference

that may cause undesired operation.

INDUSTRY CANADA

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus as set out in the Radio Interference Regula-

tions of Industry Canada.

This device complies with RSS-210 of Industry Canada. Operation is subject

to the following two conditions: (1) this device may not cause interference, and

(2) this device must accept any interference including interference that may

cause undesired operation of the device.

Le présent appareil numérque n'émet pas de bruits radioélectriques dépassant

les limites applicables aux appareils numérique de Classe B prescrites dans

le Règlement sur le brouillage radioélectriques édicté par le ministère des

Industrie Canada.

Table of contents