Spring Air Systems HT-B User manual

VENTILATOR

MAINTENANCE MANUAL

___________________________

Spring Air Systems Inc., Oakville, Ontario

Phone (905) 338-2999, Fax (905) 338-0179

Ventilator Operating and Maintenance

Manual

Table of Contents

Introduction 1

Model Numbers 2

Water Wash Control Panels 2

Control Panel Operation 3

Single Sequence Wash 3

Two Sequence Wash 4

Three Sequence Wash 5

Four and Five Sequence Wash 6

Remote Piping 7

Cleaning the Exterior 7

Wash Timer Settings 7

Automatic Wash Systems 8

Setting the Automatic Time Clock 9

Grease Extractor Operation: Type “C” 14

Grease Extractor Operation: Type “H” 14

Grease Extractor Operation: Type “D” 15

Ventilator Wash System 15

Hot and Cold Water Requirements 18

Second Line Fire Suppression: Arrangement “D” 20

Second Line Fire Suppression: Arrangement “T” 21

Second Line Fire Suppression: Arrangement “F” 22

Variflow Baffles 23

SB10H One Sequence Wash Plumbing Schematic 24

SBA10C One Sequence Wash Plumbing Schematic 25

MP20C Two Sequence Wash Electrical Schematic 25

MP20H Two Sequence Wash Electrical Schematic 25

AP30C Three Sequence Wash Electrical Schematic 26

MP30H Three Sequence Wash Electrical Schematic 26

SBA10C/SBA10H One Sequence Wash with time clock electrical 27

AP10C/AP10H One Sequence Wash with time clock electrical 27

AP20C/AP20H Two Sequence Wash with time clock electrical 28

AP30C/AP30H Three Sequence Wash with time clock electrical 28

Maintenance Schedule 29

Measuring the Exhaust Airflow 30

Start Up Procedure 31

Trouble Shooting 31

Start Up Report 33

Detergent Pump Parts List 35

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 1

VENTILATOR

OPERATING AND MAINTENANCE MANUAL

INTRODUCTION

Thank you for selecting a SPRING AIR SYSTEMS INC. commercial exhaust water wash grease extractor. Your system

consists of a water wash ventilator hood, a water wash control panel and plumbing box, an exhaust fan and make air unit.

Others may have supplied the exhaust fan and make up air unit.

SPRING AIR commercial kitchen ventilators have been designed and constructed in accordance with the National

Building Code, the National Fire Protection Association (NFPA-96), and listed by Underwriters Laboratories of Canada

and Underwriters Laboratories Inc. In addition the SPRING AIR SYSTEMS ventilator will meet all municipal code

requirements.

Each SPRING AIR ventilator is individually constructed to suit the space limitations of your commercial kitchen. The

SPRING AIR ventilators are fabricated from No. 4 finish stainless steel with all the edges ground and polished. All

ventilators are manufactured to stringent quality standards and are guaranteed to enhance the appearance of any

commercial kitchen.

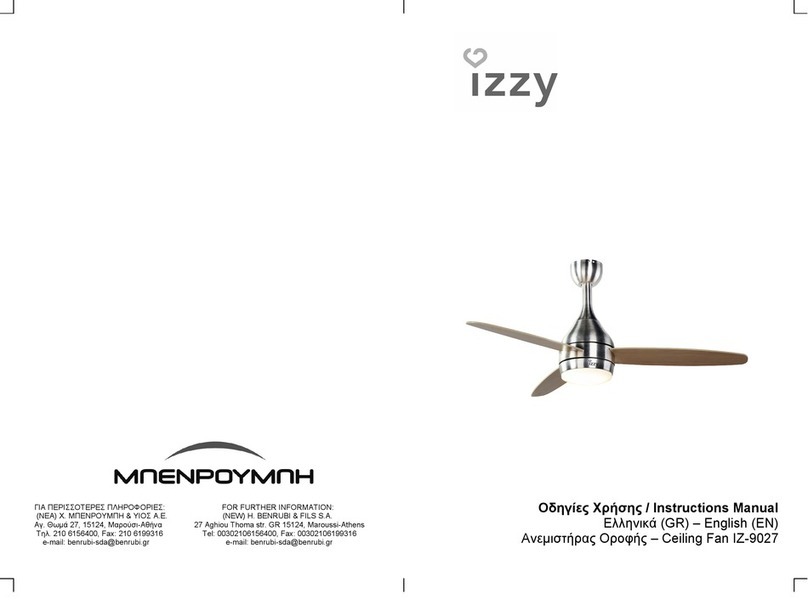

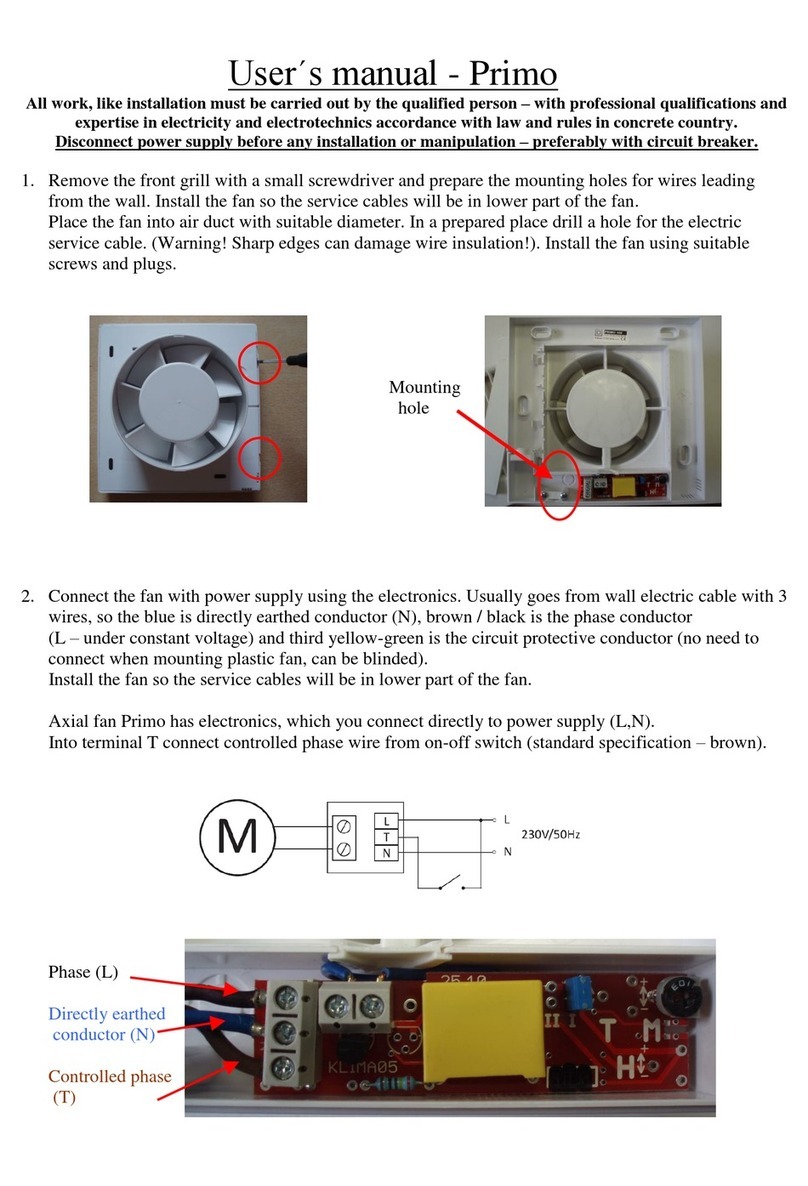

Model HT-B Water wash Ventilator and model MP10H-19 Control Panel

Figure 1

The exhaust fan operation is controlled by a selector switch on the control panel or automatically by an electronic

microprocessor based, 24-hour timer. Each time the exhaust fan is turned off the internal grease extractor portion of the

ventilator hood is washed with a detergent and hot water mixture.

The SPRING AIR water wash grease extractor was designed to best meet the needs of your commercial kitchen. The

SPRING AIR ventilator (hood) provides the following important benefits:

1. Maximum Grease Extraction.

2. Automatic Daily Wash.

3. Second Line Fire Protection.

4. Minimum Exhaust Requirements.

Please read the manual carefully to familiarize yourself with your water wash ventilator. A factory trained service

technician will complete a startup of your system. A copy of the start up report is available upon request.

Each ventilator and control panel is described in detail. Refer to the UL/ ULC plate on your ventilator and water wash

control panel for your model numbers before proceeding.

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 2

MODEL NUMBER DESIGNATIONS - VENTILATORS

A well-designed commercial kitchen ventilation system must consider proper ventilation, superior grease collection, and

daily cleaning and second line fire protection.

There exist numerous types, styles and arrangements of SPRING AIR SYSTEMS ventilators that meet these design

requirements. Refer to the ULC label for the complete model number of your ventilator. The ULC label is located on the

underside of the grease trough on the right hand side of the ventilator.

SPRING AIR SYSTEMS HOOD MODEL NUMBER DESIGNATIONS

H T B MP 10 4

C Cold water spray/hot water wash

H Hot water wash

D Dry Grease Extractor

T Thermostatic Fire Damper

F Fusible link, spring loaded fire damper

D Fusible link, dead weight fire damper

S Shelf type hood

B Box type hood

BS Box shelf type hood

DB Double box type hood

MG Make up air through front grilles

MP Make up air through perforated panels

MI Make up air internally

F Single row canopy finished on all sides, Rev-

Low type

10 The length of the ventilator in feet

4 The width of the ventilator in feet

Model Number Designation - Ventilators

Chart No1

MODEL NUMBER DESIGNATIONS - CONTROL PANELS

A P 10 C 19

A Automatic stop/start with time clock

M Manual stop/start

S Single sequence small panel

P Large size plumbing box

B Small size plumbing box

BA Small size plumbing box with time clock

10 One sequence

20 Two sequence

30 Three sequence

40 Four sequence

50 Five sequence

C Cold water spray/hot water wash

H Hot water wash

19 Diameter of inlet to panel in mm

Model Number Designation - Control Panels

Chart No.2

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 3

An integral part of any SPRING AIR SYSTEMS water wash ventilator is the water wash control panel. The water wash

control panel controls the exhaust fan operation the daily wash and second line fire protection system.

CONTROL PANEL OPERATION

Sequence of Operation: All panels

Exhaust fan: To start the exhaust fan rotate the fan selector switch to the “ON” position. The green “FAN ON” pilot and

exhaust fan will turn on. The exhaust fan starter coil is energized through terminals 3 and 4 in the water wash control

panel.

Supply fan: Power is provided for a fresh air motorized shut off

damper through terminals 4, 8, & 9. The damper motor is energized

through terminals 4, & 8. Once an end switch closes 120V/1/60

power is supplied back to the control panel through terminal 9. The

supply fan motor starter is then energized through terminals 4 & 9.

When a motorized damper with end switch is not used in the

installation the field electrician must jumper terminals 8 & 9 in the

water wash panel to provide 120V/1/60 power to the supply fan motor

starter.

MP10C & MP10H Wash Panel

Figure 2

Cold Water Spray Panels (SB10C/MPx0C/APx0C)

When the fan selector switch is rotated to the “ON” position the cold water spray solenoid valve is energized. The cold-

water spray operates while the exhaust fan is operating. The cold-water spray can be observed by looking into the inlet

slot of the grease extractor. All nozzles should be spraying to form a uniformed water pattern along the length of the

ventilator.

To stop the exhaust and supply fan rotate the selector switch to the “OFF” position. The green fan “ON” pilot and the

exhaust fan will turn off.

Cold Water Spray Panels (SB10C/MPx0C/APx0C).

In addition the cold-water spray solenoid valve will close.

SINGLE SEQUENCE WASH

MODEL: SB10C, SB10H

CAPACITY:

One ¾” (19 mm) to 1.25” (32 mm) hot water inlet and one ¾” (19 mm) to 1.25” (32 mm) hot water outlet connections for

washing p to 46 ft. (14 m) of ventilator.

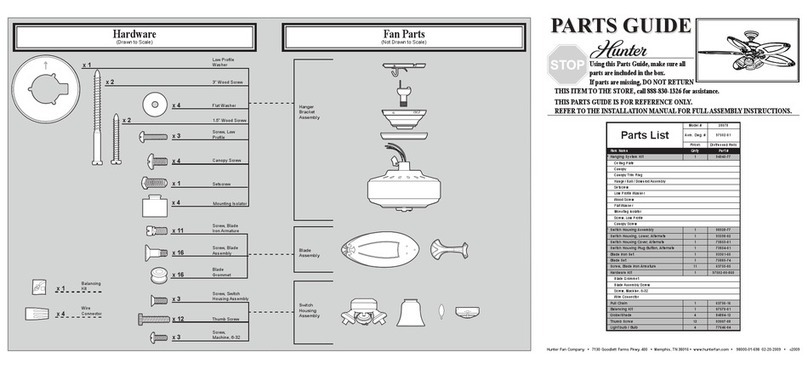

Model SB10C and SB10H control panel internal wiring

Figure 3

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 4

MODELS: MP10C, MP10H

CAPACITY:

One ¾” (19 mm) to 1.5” (38 mm) hot water inlet and one ¾” (19 mm) to 1.5” (38 mm) hot water outlet connections for

washing up to 50 ft. (15 m) of ventilator.

When the selector switch has been rotated to the “OFF” position, after a 60 second time delay, the blue “WASH” pilot the

detergent pump and hot water solenoid valve are energized. The hot water and detergent mixture flow to the ventilator

and enter the grease extractor through an inlet pipe connected to the spray manifold. The detergent water mixture is

sprayed from nozzles spaced uniformly along the length of the wash manifold washing the grease dirt and lint from the

grease extractor baffle and into the drain.

The wash continues for the period of time set on the wash timer adjustable from 0 to 600 seconds. At the end of the

wash cycle the blue “WASH” pilot, the detergent pump and the hot water solenoid valve shut off. The system remains

idle until the next time the fan selector switch is turned to the “ON” position.

Single Sequence Wash MP10C & MP10H Electrical Wiring

Figure 4

TWO SEQUENCE WASH

MODELS: MP20C, MP20H

CAPACITY: One ¾” (19 mm to 1.5” (38 mm) hot water inlet and two ¾” (19 mm) to 1.5” (38 mm) hot water outlet

connections for washing up to 100 ft. (30 m) of ventilator.

When the fan selector switch has been rotated to

the “OFF” position, after a 60 second delay, the

blue “WASH #1” pilot, the detergent pump, and the

hot water solenoid #1 are energized.

The detergent and water mixture washes the first

group of ventilators (up to 50-ft. (15 m)). The wash

cycle remains on for the length of time set on wash

timer #1 (T1) adjustable from 0 to 600 seconds. At

the end of wash cycle #1 the “WASH #1” pilot and

the hot water solenoid #1 shut off and the blue

“WASH #2”

MP20C & MP20H water wash panel

Figure 5

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 5

pilot and hot water solenoid valve #2 is energized. The detergent and water mixture washes the second group of

ventilators (up to 50 ft. (15 m)). The wash cycle continues for the length of time set on wash timer #2 (T2) adjustable

from 0 to 600 seconds. At the end of wash cycle #2 the “WASH #2” pilot detergent pump and hot water solenoid valve

#2 shut off. The system remains idle until the next time the fan selector switch is turned to the “ON” position.

Two Sequence Wash Panel Model AP10C & AP10H Electrical Wiring

Figure 6

THREE SEQUENCE WASH

MODELS: MP30C, MP30H

CAPACITY One ¾” (19 mm) to 1.5” (38 mm) hot water inlet and one ¾” (19

mm) to 1.5” (38 mm) hot water outlet connection piped to three

¾” (19 mm)to 1.5” (38 mm) hot water connections to three

groups of hoods for washing up to 150 ft. (45 m) of ventilators.

When the fan selector switch has been rotated to the “OFF”

position, after a 60 second time delay, the blue “WASH #1” pilot, the

detergent pump, and the hot water solenoid #1 are energized.

MP10C & MP10H Water Wash Panel

Figure 7

Three sequence control panels have remote hot water solenoid valves. A 120/1/60 signal is supplied to each hot water

solenoid valve through terminals H1, H2, H3, and 4 in the control panel.

Terminals Component

H1 & 4 Hot water solenoid valve #1

H2 & 4 Hot water solenoid valve #2

H3 & 4 Hot water solenoid valve #3

OPTIONAL COLD

WATER SOLENOID

HOT WATER SOLENOID

H

CFAN PILOT

WASH PILOT

B

PUMP

DETERGENT

G

SMART RELAY

Q: 1 2 3 4 RUN

INTERNAL WIRING BY SPRING AIR

Mo 09:00

Q1 Q2

L

I: 1 2 3 4 5 6

NI1

OFF/AUTO/ON

FAN SWITCH

1

OK

Q3

ESC

Q4

I5I2 I3 I4 I6

10

9

8

4

4

4

3

5

2

CURCUIT BREAKER

PUMP TEST

FIRE TEST

1

WHITE TWO (2) WIRES TO THE

5

HEAD 120V/1/60 - 1A.

WET CHEMICAL CONTROL

ARRANGEMENT "F" FIRE DAMPERS:

ARRANGEMENT "T" FIRE DAMPER:

REMOTE WIRING FOR ARRANGEMENT "F" & "T" TYPE FIRE DAMPER HOODS

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

ONLY. ARRANGEMENT "D" FIRE DAMPER HOODS REQUIRES NO REMOTE WIRING.

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

FENWALL DETECTOR

DAMPER SOLENOID

DAMPER END SWITCH

1

2

4

2

1

1RED

ENS

SOE

OR

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

RELAY SUPPLIED AND INSTALLED BY ELECTRICAL DIVISION)

120V/1/60 - 2 AMPS MAXIMUM.

2 AMPS MAXIMUM.

POWER TO THE EXHAUST FAN MOTOR STARTER

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

SHUTOFF DAMPER AND END SWITCH 120V/1/60

POWER TO SHUNT TRIP TO DE-ACTIVATE ELECTRIC

COOKING EQUIPMENT IN THE EVENT OF A FIRE

120V/1/60 - 2 AMPS MAXIMUM. (SHUNT TRIP OR

NORMALLY OPEN

END SWITCH

4

10

4

9

8

9

4

4

3OR

REMOTE WIRING BY TRADES

POWER SUPPLY TO THE AP10H/C PANEL

24 HOURS/DAY - 120V/1/60 - 15 AMPS

1

4

xx

ox

oo

o

x

x

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 6

Three Sequence Wash Panel Models AP30C and AP30H Electrical

Figure 8

The detergent water mixture washes the first group of ventilators (up to 50-ft. (15m)). The wash cycle continues for the

length of time set on wash timer #1 (T1), adjustable from 0 to 600 seconds. At the end of wash cycle #1 the blue WASH

#1” pilot and the hot water solenoid valve #1 shut off and the blue “WASH #2” pilot and hot water solenoid valve #2

energize. The detergent and water mixture washes the second group of ventilators (up to 50 ft. (15m)). The wash cycle

continues for the length of time set on wash timer #2, adjustable from 0 to 600 seconds. At the end of wash cycle #2 the

blue “WASH #2” pilot and the hot water solenoid valve #2 shut off and the blue “WASH #3” pilot and the hot water

solenoid valve #3 energize. The detergent water mixture washes the third group of ventilators (also up to 50 ft. (15 m)).

At the end of wash cycle #3 the blue “WASH #3” pilot the hot water solenoid valve #3 and the detergent pump shut off.

The system remains idle until the next time the fan selector switch is rotated to “ON” position.

FOUR AND FIVE SEQUENCE WASH SYSTEMS

Four and five sequence wash control panels operate similarly

to the three-sequence wash. After the third wash cycle is

complete the system proceeds to the fourth and fifth wash

cycles.

Due to space limitations within the kitchen the four and five

sequence wash system also have remote solenoid valves.

The detergent pump and tank are still located in the wash

control panel. See wiring and piping diagrams in the back of

the manual for the four and five sequence wash systems.

MP40C & MP40H Water Wash Panel

Figure 9

H2

H3

WASH PILOT #3

WASH PILOT #2

HOT WATER SOLENOID #3

HOT WATER SOLENOID #2

B

B

I1

Q: 1 2 3 4 RUN

SMART RELAY

INTERNAL WIRING BY SPRING AIR

I1

SMART RELAY

Q: 1 2 3 4 RUN

H1

Set length

wash here.

and third

of second

B03=WASH3

B02=WASH2

Q1 Q2

I: 1 2 3 4 5 6

LN

C

N

Set clock L

B01=WASH1

B04=CLOCK

wash here.

and length

of first

Q1 Q2

Mo 09:00

I: 1 2 3 4 5 6

FAN SWITCH

OFF/AUTO/ON

ALL HOT WATER SOLENOID VALVES

ARE LOCATED REMOTE FROM PANEL

POWER SUPPLY TO THE AP20H/C PANEL

24 HOURS/DAY - 120V/1/60 - 15 AMPS

REMOTE WIRING BY TRADES

POWER TO THE EXHAUST FAN MOTOR STARTER

120V/1/60 - 2 AMPS MAXIMUM.

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

SHUTOFF DAMPER AND END SWITCH 120V/1/60

2 AMPS MAXIMUM.

POWER TO SHUNT TRIP TO DE-ACTIVATE ELECTRIC

COOKING EQUIPMENT IN THE EVENT OF A FIRE

120V/1/60 - 2 AMPS MAXIMUM. (SHUNT TRIP OR

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

RELAY SUPPLIED AND INSTALLED BY ELECTRICAL DIVISION)

DAMPER END SWITCH

REMOTE WIRING FOR ARRANGEMENT "F" & "T" TYPE FIRE DAMPER HOODS

ONLY. ARRANGEMENT "D" FIRE DAMPER HOODS REQUIRES NO REMOTE WIRING.

ESC OK

Q3 Q4

I3I2 I6I4 I5

HOT WATER SOLENOID #1

WASH PILOT #1

WATER SOLENOID

OPTIONAL COLD

FAN PILOT

B

G

4

1

2

1

2

5WHITE

RED

1

I6I4I3I2 I5

ESC OK

Q3 Q4

DETERGENT

PUMP

R5

FIRE TEST

PUMP TEST

8

10

9

R5

4

4

R5 4

4

10

9

4

8

4

9

1

1

2

3

5

4

4

3

1

NORMALLY OPEN

WET CHEMICAL CONTROL

TWO (2) WIRES TO THE

OR

ARRANGEMENT "F" FIRE DAMPERS:

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

ARRANGEMENT "T" FIRE DAMPER:

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

HEAD 120V/1/60 - 1A.

FENWALL DETECTOR

DAMPER SOLENOID

END SWITCH

OR

CURCUIT BREAKER

xxo

x

ox

o

ox

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 7

REMOTE PIPING

All remote piping must meet applicable local plumbing codes.

The panel must be installed with adequate protection to stop

the flow of detergent back into the potable water supply. This

may be accomplished, depending on the municipality, with a

vacuum breaker and check valve assembly or a back flow

preventor. SPRING AIR SYSTEMS will always prepipe the

detergent line into the main hot water outlet pipe in the

plumbing cabinet unless advised to do otherwise prior to

shipment.

IT IS IMPORTANT TO CHECK WITH LOCAL PLUMBING

INSPECTORS TO DETERMINE WHAT IS ACCEPTABLE

PRACTICE IN YOUR JURISDICTION.

Backflow Preventor Vacuum Breaker

Figure 10

CLEANING THE EXTERIOR

Normal soil can be removed with a mild detergent water mixture applied to a cloth.

To remove baked on grease, apply a cleanser to a damp cloth or sponge and rub on the metal in the direction of the

polishing lines. DO NOT RUB IN A CIRCULAR MOTION. Burnt deposits, which do not respond, can usually be removed

by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. Do not use ordinary steel

wool. Heat tint can be removed by a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE or

STAINLESS scouring pads in conjunction with powdered cleanser.

Once the wash cycle(s) are complete wipe of the interior surface of the ventilator canopy and the underside of the grease

trough and skirt.

During the wash cycle(s) condensation may form on these surfaces. The condensation will assist in cleaning off any

grease, dirt or lint, which may have built up during the daily operation.

Cleaning the Ventilator Exterior

Figure 11

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 8

WASH TIMER SETTINGS

All SB10C, MP10C, MP20C, MP30C, MP40C, & MP50C wash control panel timers are factory set at two minutes.

All SB10H, MP10H, MP20H, MP30H, MP40H, & MP50H wash control panel timers are factory set at three minutes.

After the first four days of operation open the front access door on the grease extractor. Visually check if the baffle and

interior surfaces are clean. If there are grease deposits check that the hot water pressure is between 40 psi (2.8 kg/cm2)

and 70 psi (4.2 kg/cm2) and the hot water temperature is between 120 F (49 C) and 180 F (82 C). If there is adequate

temperature and pressure either use a higher detergent concentration or increase the wash time.

• The detergent concentration can be adjusted by increasing the cam setting on the side of the detergent pump.

Loosen the wing nut on the side of the detergent pump and rotate the cam to the next setting. The cam is

adjustable from 0 to 6, 6 being the highest detergent concentration. Only increase one setting at a time. Inspect

the interior each day and adjust until all surfaces are clean.

• Only increase the wash time in 30-second intervals until all baffles and exposed interior grease extractor surfaces

are clean.

For type “C” water wash ventilators check that the cold water pressure is at least 10 psi 1.4 kg/cm2).

AUTOMATIC WASH SYSTEMS:

SBA10H, SBA10C, AP10H, AP10C, AP20H, AP20C, AP30H, AP30C, AP40H,

AP40C, AP50H, & AP50C

The automatic wash control panels are equipped with a solid-state microprocessor. The fan

selector switch is replaced with a three-position “OFF/AUTO/ON” switch. In the “OFF” and “ON”

positions the control panel operates identical to the standard SB, & MP manual wash panels.

When the fan switch is rotated to the “AUTO” position the solid-state time clock controls the

OFF/ON operation of the exhaust fan, supply fan and wash cycle.

Setting the clock (T6) is as simple as setting a digital watch.

Automatic Wash Panel

Figure 12a

SBA10C and SBA10H Automatic Wash Panel Wiring Schematic

Figure 12b

NOTE 1:

ALL REMOTE ELECTRIAL WIRING

AND NATIONAL CODE REQUIREMENTS

SHALL CONFORM TO ALL LOCAL

INTERNAL WIRING BY SPRING AIR

Q: 1 2 3 4 RUN

Mo 09:00

I: 1 2 3 4 5 6

SMART RELAY

Q1

L

Q2

NI1I2

FAN SWITCH

OFF/AUTO/ON

PUMP

DETERGENT

HOT WATER SOLENOID

WASH PILOT

HB

FAN PILOT

OPTIONAL COLD

WATER SOLENOID

CG

ESC

Q3

OK

Q4

I3 I4 I5 I6

CURCUIT BREAKER

4

4

8

9

3

5

1

END SWITCH TWO (2) WIRES TO THE

MOTOR STARTERS OVERLOADS

5

1

RED

WHITE WET CHEMICAL CONTROL

HEAD 120V/1/60 - 1A.

ELECTRICAL DIVISION

AND DISCONNECTS BY

NOTE 2:

SHUTOFF DAMPER AND END SWITCH 120V/1/60

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

POWER TO THE EXHAUST FAN MOTOR STARTER

24 HOURS/DAY - 120V/1/60 - 15 AMPS

POWER SUPPLY TO THE SB10H/C PANEL

NORMALLY OPEN

2 AMPS MAXIMUM.

9

4

8

9

4

REMOTE WIRING BY TRADES

120V/1/60 - 2 AMPS MAXIMUM.

3

4

4

1

OR

xxo

x

ox

o

ox

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 9

Programming the SMARTRELAY Time Clock

to return to the operating screen.

6. You have finished setting the clock.

3. To change the day of week press

move to year. Adjust the year by pressing

5. To change the date press again. The month will be highlighted. Press

until the correct month appears.

or

Adjust the day by pressing

Adjust the minutes by pressing

until the correct hour appears.

4. To change the time press once. The hour will be highlighted. Press

1. Press these two buttons together

Su 11: 25

Q: 1 2 3 4

I: 1 2 3 4 5 6

Su 11:25

Set Clock

11. 11. 01

MM. DD. YY

ESC

7. Press and

Su 11:25

MM. DD. YY

Set Clock

11. 13. 01

Set Clock

11. 13. 01

MM. DD. YY

Su 09:00

11. 13. 01

MM. DD. YY

Mo 09:00

Set Clock

Set Param

>Set Clock

Q: 1 2 3 4

Mo 09:00

I: 1 2 3 4 5 6

or

or

ESC

2. Press

OK

OK

until correct

y

ear a

pp

ea

r

or until the correct day appears.

until correct day appear. Press to

Press to move to day.

until correct minutes appears.

Press to move to minutes.

or

or

I3

Setting the Clock Time and Day

I: 1 2 3 4 5 6

Q: 1 2 3 4

Mo 09:00

SMART RELAY

Q1

LN

Q2

I2I1

OKESC

Q3 Q4

I5I4 I6

ESC

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 10

Setting the Weekly Fan “ON” and “OFF” Times

Mo 09:00

fan will not automatically operate on Saturday or Sunday.

the fan will not start automatically any given day.

to program a second (Weekend Operation) or third weekly setting go the the section

12. You have completed programming one weekly fan "On" and "Off" cycling. If you wish

11. If your selection is complete press and to return the the operating screen.

9. Press to move to the hour that the fan will stop in the evening. Press

8. Press to move to the hour that the fan will start in the morning. Press

7. Press to move to the next day of the week. Press each time the fan is

6. Press to remove Monday from the weekly schedule. The - dash indicates

5. To change the above settings press

4. The clock has been factory set to turn the fan on at 6:00 a.m. and off

to the minute the fan stop in the evening. Press to change the minutes.

to change the hour you want the fan to stop each evening. Press to move

to the minute the the fan will start in the morning. Press to change the minutes.

to change the hour you want the fan to start in each morning. Press to move

not required to operate on that given day. The screen on the left indicates the

at 23:00 hours or 11:00 p.m. When the fan shuts off the wash activates.

Off = 23: 00

D = - TWTF- -

Mo 09:14

Q: 1 2 3 4

I: 1 2 3 4 5 6

B04: No1

On = 06: 30

Off = 22: 30

Off = 22: 30

On = 06: 30

B04: No1

Off = 2 3: 00

On = 06: 30

B04: No1

Off = 23: 00

On = 0 6: 00

B04: No1

"Setting Weekend Operation"

10.Press

OK

D = - TWTF- -

D = MTWTF-S

B04: No1

On = 06: 00

Off = 23: 00

On = 06: 00

B04: No1

B04: No1

D = MTWTFSS

On = 06: 00

Off = 23: 00

>Set Clock

Set Param

Off = 23: 00

On = 06: 00

D = MTWTFSS

B04: No1

>Set Param

Set Clock

Q: 1 2 3 4

3. Press

OK

2. Press

ESC OK

ESC ESC

The cursor will move to M = Monday.

OK

1. Press these two buttons together

I: 1 2 3 4 5 6

D = - TWTF- -

D = MTWTF- -

D = MTWTF- -

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 11

Setting Weekend Operation

>Set Clock

11. You have completed programming weekend fan "On" and "Off" cycling.

If your selection is complete press and to return the

Press once to move to Sunday. Press to turn fan on Sunday.

7. Press five times to move to Saturday. Press to turn fan on Saturday.

6. Press to program the weekend operation.

or 10:30 p.m. When the fan shuts off the wash activates.

4. The clock has been set to turn the fan on at 6:30 a.m. and off at 22:30 hours

9. Press to move to the hour that the fan will stop in the evening. Press

to change the hour you want the fan to stop each evening. Press to move

to the minute the fan stop in the evening. Press to change the minutes.

to the minute the the fan will start in the mornin

g

. Press to chan

g

e the minut

e

to change the hour you want the fan to start in each morning. Press to move

8. Press to move to the hour that the fan will start in the morning. Press

Off = - - : - -

Q: 1 2 3 4

I: 1 2 3 4 5 6

Mo 10:24

D = - - - - - SS

D = - - - - - SS

Off = 23: 30

B04: No2

B04: No2

On = 10: 00

Off = - - : - -

On = 10: 00

OK

operating screen.

10. Press

On = - - : - -

B04: No2

D = - - - - - SS

On = - - : - -

Off = - - : - -

B04: No2

D = - - - - - SS

Off = - - : - -

On = - - : - -

D = - - - - - - -

B04: No2

Off = 22: 30

On = 06: 30

D = MTWTF- -

B04: No1

D = MTWTFSS

On = 06: 00

Off = 23: 00

Set Param

B04: No1

>Set Param

Set Clock

OK

5. To set Weekend Operation press

2. Press

3. Press

OK

ESC ESC

1. Press these two buttons together

Mo 09:14

Q: 1 2 3 4

I: 1 2 3 4 5 6

ESC OK

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 12

Setting the Wash Cycle Length

>Set Clock

9. Press and to return to the operating screen.

8. Press if the wash time is correct.

the length of wash in seconds. Press to change the seconds.

7. Press to change the length the wash in minutes. Press to move to the

The wash time has been factory pre-set at 2 minutes.

4. The clock has been factory set to turn the fan on at 6:00 a.m. and off

at 23:00 hours or 11:00 p.m. When the fan shuts off the wash activates.

To change these times see section "Programming the SMARTRELAY time clock.

Ta = 02:00m

Mo 09:12

I: 1 2 3 4 5 6

Q: 1 2 3 4 ESC ESC

T = 02:30m

T = 02:30m

Ta = 02:00m

Ta = 02:00m

T = 02:00m

T = 02:00m

Ta = 02:00m

Set Param

Off = 23: 00

On = 06: 00

D = MTWTFSS

B04: No1

>Set Param

Set Clock

B01: T

B01: T

B01: T

B01: T 5. Press

OK

6. To change the wash time press

2. Press

3. Press

OK

OK

1. Press these two buttons together

Q: 1 2 3 4

Mo 09:00

I: 1 2 3 4 5 6

ESC OK

OK

I5I1

SMART RELAY

I: 1 2 3 4 5 6

Mo 09:00

Q: 1 2 3 4

Q1 Q2

LN

ESC

Q3

I3I2 I4

Q4

I6

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 13

AUTOMATIC WASH SYSTEMS:

AP20H, AP20C

AP20C & AP20H Wash Panel Wiring Schematic

Figure 12c

I1

Q: 1 2 3 4 RUN

SMART RELAY

INTERNAL WIRING BY SPRING AIR

H2

H1

Set clock

and length

wash here.

B02=WASH2

B01=WASH1

B04=CLOCK

of first Mo 09:00

Q1 Q2

I: 1 2 3 4 5 6

LN

OFF/AUTO/ON

FAN SWITCH

REMOTE WIRING BY TRADES

120V/1/60 - 2 AMPS MAXIMUM.

24 HOURS/DAY - 120V/1/60 - 15 AMPS

POWER SUPPLY TO THE AP20H/C PANEL

2 AMPS MAXIMUM.

RELAY SUPPLIED AND INSTALLED BY ELECTRICAL DIVISION)

120V/1/60 - 2 AMPS MAXIMUM. (SHUNT TRIP OR

COOKING EQUIPMENT IN THE EVENT OF A FIRE

POWER TO SHUNT TRIP TO DE-ACTIVATE ELECTRIC

SHUTOFF DAMPER AND END SWITCH 120V/1/60

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

POWER TO THE EXHAUST FAN MOTOR STARTER

DAMPER END SWITCH

REMOTE WIRING FOR ARRANGEMENT "F" & "T" TYPE FIRE DAMPER HOODS

ONLY. ARRANGEMENT "D" FIRE DAMPER HOODS REQUIRES NO REMOTE WIRING.

FAN PILOT

C

WATER SOLENOID

G

OPTIONAL COLD

WASH PILOT #1

HOT WATER SOLENOID #1

HOT WATER SOLENOID #2

WASH PILOT #2

B

B

DETERGENT

PUMP

2

4

2

1

1

WHITE

RED

5

1

R5

ESC

Q3 Q4

OK

I2 I3 I6I4 I5

R5

R5

CURCUIT BREAKER

FIRE TEST

PUMP TEST

3

5

4

8

9

10

4

3

4

4

8

9

4

10

4

4

9

1

1

2

4

1

OR

ARRANGEMENT "T" FIRE DAMPER:

ARRANGEMENT "F" FIRE DAMPERS:

TWO (2) WIRES TO THE

WET CHEMICAL CONTROL

HEAD 120V/1/60 - 1A.

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

FENWALL DETECTOR

DAMPER SOLENOID

END SWITCH

NORMALLY OPEN

OR

xxo

x

ox

o

ox

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 14

GREASE EXTRACTOR OPERATION

TYPE “C” GREASE EXTRACTOR

The SPRING AIR SYSTEMS type “C” grease extractor has the highest grease

extraction efficiency available in a water wash ventilator.

The contaminated exhaust air enters the high velocity inlet slot A and flows

through a transition zone to the VORTEX CHAMBER B. The cold-water spray

manifold D sprays a fine cold-water mist into the path of the exhaust air. The

cold-water spray causes the grease particles to cool, congeal and coagulate

forming larger grease globules. The larger heavier globules are more readily

removed through centrifugal force as the exhaust air accelerates through a

complete 270-degree turn around the VORTEX BAFFLE C. The grease, dirt

and lint are deposited on the PRIMARY VARIABLE FLOW BAFFLE G and the

VORTEX BAFFLE C. The PRIMARY VARIABLE FLOW BAFFLE G is also

adjustable along the length of the grease extractor to provide varying exhaust

airflow. The sloping VORTEX BAFFLE C drains the collected grease to the

end of the ventilator into a grease trough.

Type “C” Extractor

Figure 13

The cold-water spray extends from the entrance to the exit of the VORTEX CHAMBER B, which provides a secondary

coverage as the exhaust air enters the secondary grease extraction chamber. The exhaust air continues into the

secondary extraction chamber, which contains an additional baffle, F. Residual grease is deposited on the secondary

baffle as the exhaust air gyrates through the secondary chamber. After leaving the secondary chamber the exhaust air

enters the ventilator fire damper and duct collar and discharges into the ductwork.

TYPE “H” GREASE EXTRACTOR

The SPRING AIR SYSTEMS type “H” grease extractor is a high

efficiency water wash grease extractor.

The contaminated air enters the high velocity inlet slot A and flows

through the transition zone to the VORTEX CHAMBER B. The

exhaust air accelerates through a complete 270-degree turn around

the VORTEX BAFFLE C. Centrifugal force causes the grease, dirt

and lint particles to deposit on the PRIMARY VARIABLE FLOW

BAFFLE G and the VORTEX BAFFLE C. The PRIMARY

VARIABLE FLOW BAFFLEG is also adjustable for varying exhaust

flows along the length of the extractor. The sloping VORTEX

BAFFLE C drains the collected liquid grease to the end of the

ventilator and into the grease trough.

The exhaust air continues into the secondary extraction chamber,

which contains an additional baffle, F. Residual grease is

deposited on the secondary baffle as the exhaust air gyrates

through the secondary chamber. After leaving the secondary

chamber the exhaust air enters the ventilator fire damper and duct

collar and discharges into the exhaust ductwork.

Type “H” Extractor

Figure 14

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 15

TYPE “D” GREASE EXTRACTOR

The SPRING AIR SYSTEMS type “D” grease extractor is a

high efficiency dry grease extractor. The type “D” grease

extractor removes grease, dirt and lint through centrifugal

force. Removing the front access door and wipe the interior

with a damp cloth to manually clean the grease extractor

chamber

Principle of Operation

The contaminated exhaust air enters the high velocity inlet

slot A and flows through the transition zone to the VORTEX

CHAMBER B. The exhaust air accelerates through a

complete 270-degree turn around the VORTEX BAFFLE C.

Centrifugal force causes the grease, dirt and lint particles to

deposit on the PRIMARY VARIABLE FLOW BAFFLE G and

VORTEX BAFFLE C. The sloping VORTEX BAFFLE C

drains collected grease to the end of the ventilator into the

grease cup H.

The exhaust air continues into the secondary extraction

chamber, which contains an additional baffle, F. Residual

grease is deposited on the secondary baffle as the exhaust

air gyrates through the secondary chamber.

Type“D”Extractor

Figure15

GREASE EXTRACTOR

TYPE RECOMMENDED COOKING USE

Type “C” Medium/heavy and heavy duty.

Mesquites, live charcoal, Gas charbroilers, heavy frying

Type “H” Medium and medium/heavy duty.

Gas charbroilers, Fryers, Ranges, Griddles.

Most commercial cooking applications

Type “D”

Light and medium duty.

Electric fryers, Ranges, Ovens, Kettles and Steamers

VENTILATOR GREASE EXTRACTOR SYSTEMS : TYPE “C”, “H” & “D”

SPRING AIR SYSTEMS ventilators are available with either automatic or manual wash systems. All water wash

ventilators must be interconnected with a water wash control panel.

Manual: Type “D” Ventilator

The type “D” incorporates a grease extractor similar to

type “H” but without the wash manifolds. The type “D”

is recommended for light to medium cooking

applications where grease is minimal.

The liquefied grease collects on internal baffles as

described in the “Grease Extractor” section of the

manual. The baffles are designed to drain the

liquefied grease to the end of the ventilator and into the

grease trough and grease cup.

To clean the grease extractor, the front access door

and grease cup are removed and manually washed in

a kitchen sink.

The two interior baffles and grease trough should be

wiped down with a damp cloth soaked in a water and

mild detergent mixture. If the cooking application

generates high temperatures, the grease trough may

require additional cleaning and/or scraping to remove

baked-on solidified grease.

Type “D” Grease Extractor

Figure16

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 16

Automatic Wash: Type “C” and “H:” Ventilators

The “C” and “H” ventilators have incorporated water wash manifold into the high efficiency grease extractor. The

PRIMARY BAFFLE C and SECONDARY BAFFLE F are both water wash manifolds.

Spray nozzles are spaced evenly along baffle/manifolds. The hot detergent water mixture enters the hot water inlet pipe,

and travels into the interconnecting pipe to the PRIMARY BAFFLE/MANIFOLD D and the SECONDARY

BAFFLE/MANIFOLD F. The water detergent mixture is sprayed uniformly within the interior of the grease extractor.

The water/detergent mixture washes the grease, lint and dirt into the sloping

VORTEX BAFFLE , which carries the mixture to the end of the ventilator, and into

the grease trough. The mixture travels along the grease trough to the drain. The

drain may be located at either end of the ventilator. Multiple ventilators may have

individual drains factory manifold to one common drain.

The wash time is adjustable from 0 to 10 minutes. The type “C” is normally set at 2

minutes while the type “H” is set at 3 minutes. Depending on the type of cooking

equipment the type “C” usually requires less hot water wash time because of the

continuous cold-water spray. During fan and cooking operation, the spray

continuously carries grease, dirt and lint down the drain, which reduces the daily

grease build-up.

The hot water required is approximately 1 gpm/ft. of ventilator at 40 psi (see Chart

No.1 and No. 3)

The cold-water continuous spray requires approximately 1.0 gph/ft. of ventilator at 15

psi (see Chart No.2 and No. 4)

See figure 19 for electrical and plumbing requirements for type “H” grease

extractors.

Type “C” and “H” Wash

Figure 17

The hot water wash manifold can be viewed by removing the front access doors on the water wash grease extractor.

Make sure the fan has been switched off and the wash is complete before opening these doors. All wash nozzles are

directed from the middle of the water wash grease extractor towards the two ends. One wash nozzle is located on a

manifold extending up towards the exhaust duct collar. This nozzle washes the exhaust fire damper and fusible link.

Wash water is therefore directed straight out the duct collar into the exhaust duct. If water is found on top of the hood

check for leaks in the exhaust ductwork connected to the hood. If the wash water pressure is over 70 psi over spray

many occur at the ends of the grease extractor. Open the access door and rotate the wash nozzles counter clockwise 45

degrees starting with the nozzle closest the end of the grease extractor. Continue until over spray stops.

Water wash Manifold Type B, S, & B-S Extractor

Figure 18

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 17

The schematic shown in Figure 19 is typical of a standard water wash installation. Remote wiring and plumbing are

shown for an exhaust fan, wet chemical systems, a Spring Air Systems water wash hood and a SB10H water wash panel.

In addition to the wiring indicated below power must be supplied to a shunt trip if electrical appliances are present under

the hood and under some circumstances a signal is required to the building fire alarm both from the wet chemical

system.

Field Piping and Wiring

Figure 19

_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01 18

Hot Water Required Model S, B, & B-S

Ventilator

Length

Hot Water Flow

USGPM

Hot Water Flow

USGPM

Hot Water Flow

l/m

Hot Water Flow

l/s

feet meter @ 40 psi @ 60 psi @ 2.8 kg/cm2 @ 4.2 kg/cm2

3.0 914 2.4 2.8 13.2 16.2

3.5 1067 3.1 3.8 17.3 21.2

4.0 1279 3.1 3.8 17.3 21.2

4.5 1372 3.1 3.8 17.3 21.2

5.0 1524 3.1 3.8 17.3 21.2

5.5 1676 3.7 4.5 20.5 25.1

6.0 1829 3.7 4.5 20.5 25.1

6.5 1981 4.3 5.3 24.1 29.5

7.0 2131 4.3 5.3 24.1 29.5

7.5 2286 4.9 6.0 27.3 33.4

8.0 2438 4.9 6.0 27.3 33.4

8.5 2591 5.5 6.7 30.5 37.3

9.0 2743 5.5 6.7 30.5 37.3

9.5 2896 6.7 8.2 37.3 45.7

10.0 3048 6.7 8.2 37.3 45.7

10.5 3200 7.3 8.9 40.5 50.0

11.0 3353 7.3 8.9 40.5 50.0

11.5 3505 7.9 9.7 44.2 54.0

12.0 3658 7.9 9.7 44.2 54.0

12.5 3810 8.5 10.4 47.4 57.9

13.0 3962 8.5 10.4 47.4 57.9

13.5 4115 9.2 11.3 51.4 63.0

14.0. 4207 9.2 11.3 51.4 63.0

14.5 4420 9.8 12.0 54.6 66.8

15.0 4772 9.8 12.0 54.6 66.8

Chart No.1

Cold Water Required Model S, B, & B-S

Ventilator

Length

Cold Water

Flow

USGPM

Cold Water

Flow

l/s

Ventilator

Length

Cold Water

Flow

USGPM

Cold Water

Flow

l/s

feet meter @ 10 psi @ 0.7

kg/cm2 feet meter @ 10 psi @ 0.7

kg/cm2

3.0 914 0.35 1.32 9.5 2896 0.91 3.44

3.5 1067 0.35 1.32 10.0 3048 0.98 3.71

4.0 1279 0.42 1.59 10.5 3200 1.05 3.97

4.5 1372 0.49 1.85 11.0 3353 1.05 3.97

5.0 1524 0.49 1.85 11.5 3505 1.12 4.24

5.5 1676 0.56 2.12 12.0 3658 1.19 4.50

6.0 1829 0.63 2.38 12.5 3810 1.19 4.50

6.5 1981 0.63 2.38 13.0 3962 1.26 4.77

7.0 2131 0.70 2.65 13.5 4115 1.33 5.03

7.5 2286 0.77 2.65 14.0. 4207 1.33 5.03

8.0 2438 0.77 2.91 14.5 4420 1.40 5.30

8.5 2591 0.84 2.91 15.0 4772 1.47 5.56

9.0 2743 0.91 3.44

Chart No.2

This manual suits for next models

23

Table of contents

Popular Fan manuals by other brands

AIGOSTAR

AIGOSTAR 8433325184933 instruction manual

Greenheck

Greenheck ASSURE-120S-S1 Installation, operation and maintenance manual

Honeywell

Honeywell TWINDOW HW-628 owner's manual

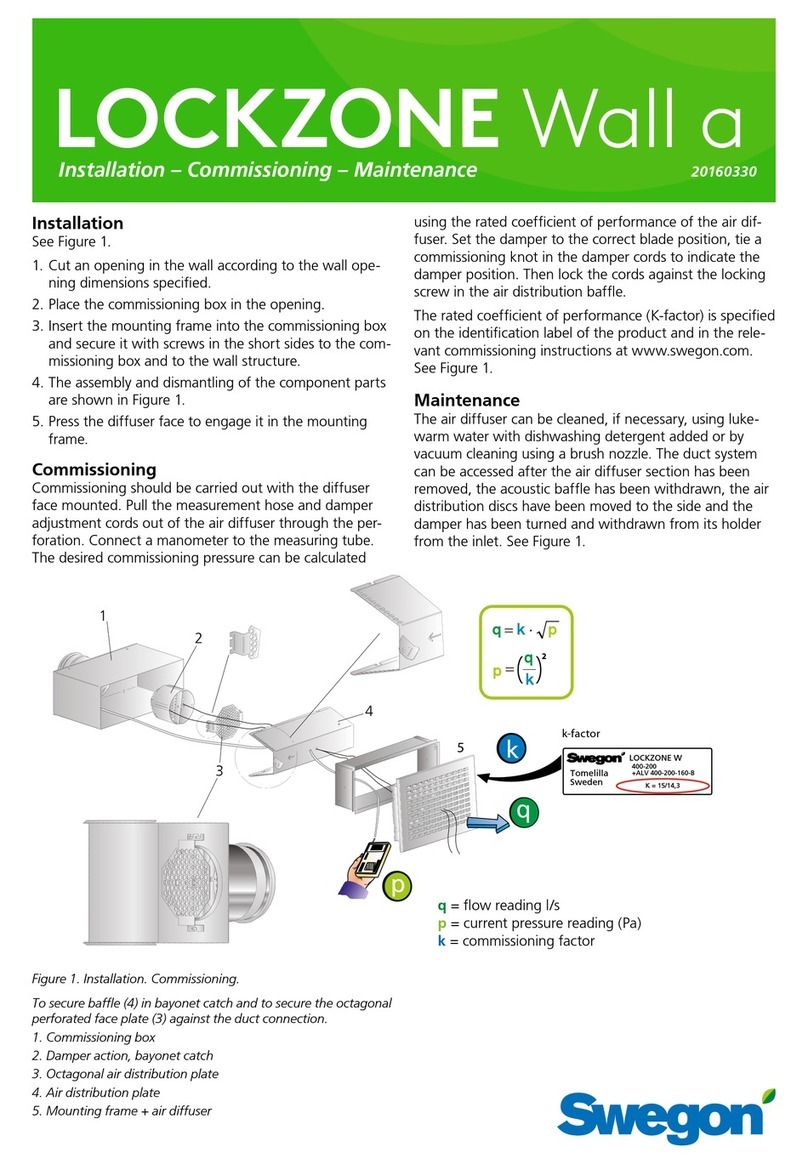

Swegon

Swegon LOCKZONE Wall a quick start guide

Kendal Lighting

Kendal Lighting AC11152P-ORB/WN installation instructions

Kooper

Kooper 2194486 User instructions