REC Indovent AB, Box 37, 431 21 Mölndal | tel.031-675500 |www.rec-indovent.se

DESIGN & TECHNICAL INFORMATION

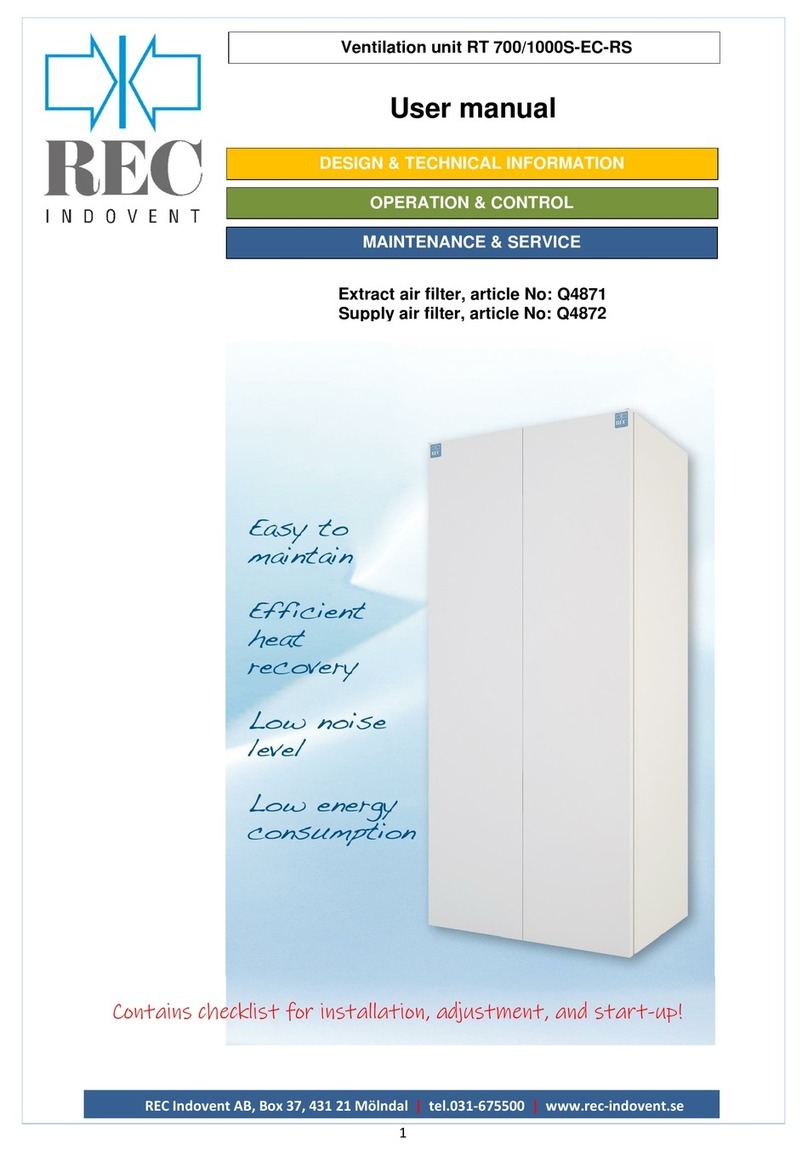

Ventilation unit RT 700/1000S-EC-RS

General description

RT 700/1000S-EC-RS is designed for ventilation of

homes, offices, nurseries or other similar premises.

The Temovex unit is intended to be placed in

heated spaces such as laundry room, boiler room,

corridor or similar.

RT 700/1000S-EC-RS has everything integrated in

one unit.

The system consists in it´s standard version, of a

counterflow heat exchanger, two fans, two filters,

reheater, bypass damper and a control system.

Placeringsguide

1. Casing

2. Extract air filter (behind hatch)

3. Bypass damper motor 1

4. Extract air fan (behind hatch)

5. Supply air fan (behind hatch)

6. Heat exchanger

7. Supply air filter

8. Inspection hatch

9. Adjustable feet

10. Condensate drain

11. Control panel

12. Reheater

13. Bypass damper motor 2 (behind hatch)

1. Casing

The casing is made of hot galvanised sheet metal

with 30 mm insulation between the sheets. As a

standard, the side panels and the front are powder

coated in white. The front door has a magnetic strip

which keeps the door closed. The unit top has

sleeve connections where all ducts are connected.

2. Extract air filter

Coarse 60%, bag (art. No. Q4871)

3. Bypass damper 1

The Temovex AHU has an automatic bypass

damper which makes the air bypass the heat

exchanger whenever heat recovery is not

necessary. The bypass setting is adjusted on the

control panel. The bypass function is splitted in two

dampers with one motor each.

4. Extract air fan

The unit has low-energy fan of EC type with

integrated overheating.

5. Supply air fan

The same type as extract air fan (see point 4)

6. Heat exchanger

Temovex counterflow heat exchanger is designed

by our own staff and is the result of 30 years

experience of high efficient counterflow heat

exchangers.

The heat exchanger is made of thin aluminium

sheets, and is completely sealed beetween the

supply air and exhaust air. This is important in

order to avoid odours and other contaminants to

seeping through to the fresh air side. The heat

exchanger has no moving parts, which eliminates

wear.

7. Supply air filter

ePM1-50%, bag (art. No. Q4872).

8. Inspection hatch

When cleaning the heat exchager or controlling the

condensate drain, the Inspection hatch is opened.

(See chapter "Maintenance & service").

9. Adjustable feet

The cabinet has adjustable rubber feet.

10. Condensate drain

The Temovex unit is fitted with a condensate drain

at the bottom of the unit. This should be connected

to a drain or fed to a floor drain.

11. Control panel

All settings for fan speed, reheating, bypass etc.

are made via the control panel and the AHU's

integrated control system.

If you have added optional parts to your Temovex

AHU, these functions, too, are set via the control

panel.

12. Reheater

The unit is as standard fitted with an electric

reheater. The heater is integrated in the unit and

settings are made via the control panel.

By water heating, is the water coil delivered

separatly and shall be placed in the supply air duct

outside the unit. Even a two-way valve and valve

motor is included in the delivery from REC.

12. Bypass damper 2

(see point 3)

2

3

4

7

8

10

1

5

6

9

11

12

13