Springfield 63A Manual

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

With

PARTSLIST

RIDINGROTARYLAWNMOWERS

APRODUCTOFOUrCKMANUFACTURINGINC,SPRINOFIEID, OHI

"The

HoJse

ifPow'er

MODELS

63A,

63D,And

63DE

Form

139-63

Manufactured

By

QUICKMANUFACTURING,INC.

SPRINGFIELD,OHIO

PRINTEDINU.S.A

FOREWORD

The

riding

rotary

lawn

mowerisa precisionmachine

which

will

requirea

minimum

ofcare.Keepitclean

and

well

lubricated.

Keepthebladesharpand

bal-

anced.Useit

within

itscapabilities.Ifkeptingood

repair

and

adjustment,

itiscapableof

providing

years

of

dependableservice.

DEALER

RESPONSIBILITY

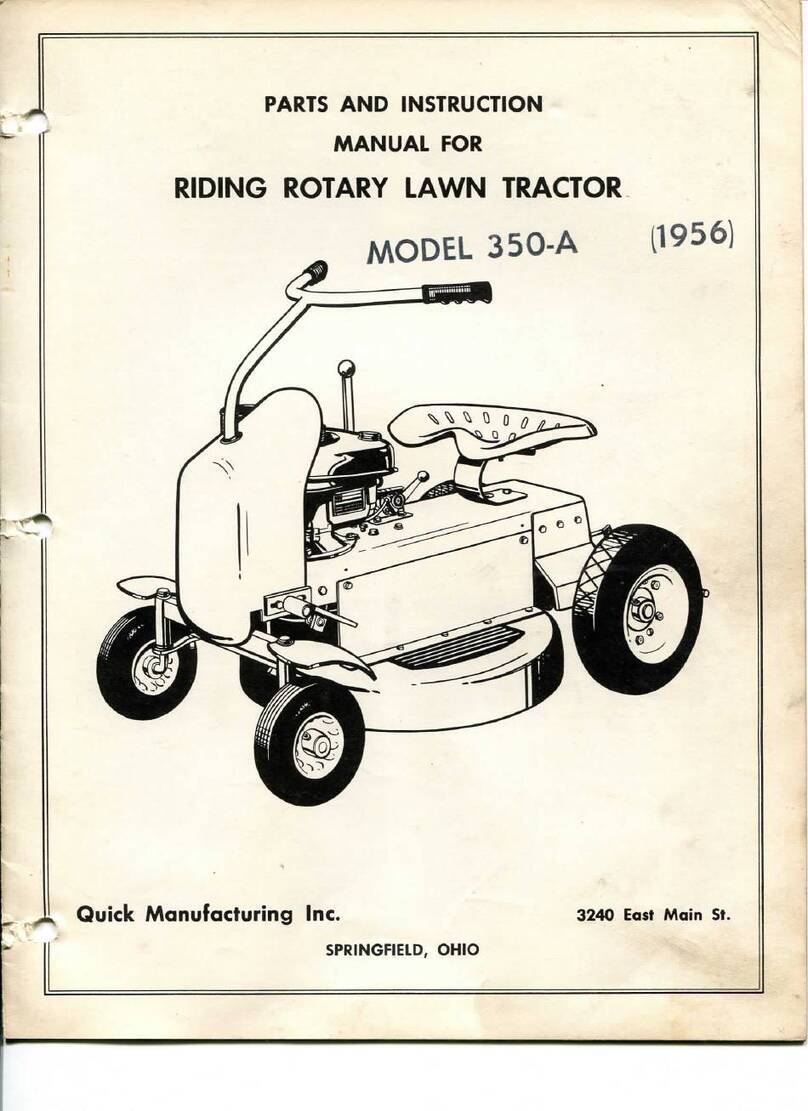

Beforethemowerisdeliveredtothecustomer,the

dealer

should

prepareitforoperationand

should

be

surethattheownerunderstandstheinstructionscon-

tained

in

theOperator's

Manual

foroperatingandcar-

ing

forhismower.See

figure

1.

PREPARING

FOROPERATION

1.

Install

thehandlebarby

sliding

it

down

into

the

top

ofthesteering

column

andattaching

with

twobolts

and

nuts.

2.Checkthe

chassis

tobesurethatithasbeen

lub-

ricated.

3.Checkthelevelofthe

lubricant

inthetransmis-

sion

assemblyby

removing

thetransmissioninspection

plug.

Lubricant

should

belevel

with

bottom

ofinspec-

tion

plug

hole,

when

tractorisonlevel

ground

or

floor.

4.

Fill

thecrankcase

with

oilaccordingtotheen-

gine

manufacturer'sinstructions.

CAUTION

Do

not

over-fill

thetransmissionorthecrank-

case.

Todoso

will

cause

overheatingand

blown

oil

seals.

5.

Fill

thegasolinetank

with

anyregulargasoline.

Do

notmixoil

with

thegasoline.

6.Squirta

drop

ortwoofoilonthetopofthe

ball

in

the

shift

leverhousing.

BREAKESIGIN

Tobreakintheengineandtransmission,setthe

rearofthetractorona blocktoraisetherearwheels

a

little

abovethe

floor,

andoperatetheengine

until

it

hasusedupone-halftankormoreofgasoline.Shift

the

transmission

into

thevarious

speeds

during

the

break-in

run,toassurebreakingitin

properly

for

the

owner.

GET

ACQUAINTED

WITH

YOUR

NEW

LAWN

MOWER

Beforeyourdealerdeliveredthemower toyou,hecheckedthe

transmission,

putoilintheenginecrankcase,

filled

thetankwiththe

proper

grade

ofgasoline,andattachedthehandlebars.Asyouare

gettingacquaintedwithyourmower,checktobesure

that

thesehave

beendone.

Become familiarwithyourmower beforeyouputit towork.Read

theseinstructionsandtheenginemanufacturer'sbooklet. Besureyou

know

whatthecontrolsarefor,andhowthey

operate.

Operateit for

awhileona drivewayorsidewalk,togetthefeelofthecontrols.

The

amountof

care

themower requiresissmallbutimportant.

Keep

it cleanand

well

lubricated.Keepthebladesharpand

bal-

anced.Learnitscapabilitiesandlimitations.Itiscapableofgivingyou

theyearsofdependableserviceyou

expect

fromanyfinepieceof

machinery.

LEARN

WHAT

THE

CONTROLS

AREFOR

These

simplecontrolsmakeyourmowerhandyto

operate.

1.Theenginespeedcontrolleverhasa

START

position(usedfor

choking

theengine),a RUNpositionwhichgivesyoucontroloverthe

engine'sspeed,anda

STOP

positionwhichstopstheengine.

2.

Pull

the

starter

ropeto

start

theengine.(Ifyourmowerhasan

electric

starter,

turntheignitionkey.)

3.Thebladeclutch

starts

andstopstheoperationoftheblade.

4.The

tractor

clutchpedalalso

operates

the

tractor

brake.

5.The

geaf

shiftleverprovidesreverseorthreespeedsforward.

6.Youcanchangethecuttingheightbymeansofthebladeheight

adjustmentcontrols,withoutstoppingtheengineorremovinganybolts.

HOWTO

START

THE

ENGINE

1.

Turn

onthevalveunderthefueltank.

2.Besurethegearshiftleverisinneutralandthebladeclutchis

disengaged.

3.Movetheenginespeedknobtothe

START

or

CHOKE

position.

4.

Pull

the

starter

handleswiftly.Donotletgoofthehandleas

theroperewinds.

This

helpspreventbacklashintherewindmechanism.

5.Ifa coldenginedoesnot

start

onthefirst

pull,

movethespeed

knobbacktothe

START

positionandtryagain.

6.Whenrestartinga hotengine,setthespeedknobaboutinthe

middle

oftheRUNmarking.

HOWTO

STOP

THE

ENGINE

Stopping

theengineissimple.Justmovethespeedknobtothe

STOP

position.Itisbestalwaystodisengagethebladeclutchandput

thetransmissioninneutralbeforestoppingtheengine.Whenfinished

with

themower fortheday,turnoffthevalveunderthefueltank.

CHOKE

AND

COLD

START-

HIGH

SPEED

WARM

START

LOW

SPEED

IDLE

STOP

Positions

of

Engine

Speed

Control

Lever

2

THINK

OF

SAFETY

BEFORE

YOUMOW

The

mower bladeusesmorethanthreehorsepower;thereforeit

is

a powerful cuttingtool.Treatit

with

therespectyouwould

treat

a

buzz-saw.

Beforeyouusethemower,besureyouknowthesesafety

rules.

1.Neverallowchildrenoryoung

teen-agers

to

operate

themower.

Keep

childrenandpetsawayfromtheareaofthemoweratalltimes

while

it isworking.

2.Always keephandsandfeetoutfromunderthemowerdeck

while

theengineisrunning,and

until

youare

SURE

that

thebladehas

stoppedturning

after

theengineisshutofforthebladeclutchdisen-

gaged.It

will

coast

forseveralseconds.

3.Beforeyou

start

mowing,walkovertheareayou'regoingto

cutandpickupalldebris

which

couldbepickedupandthrownby

theblade.Sticks,stonesandpiecesofmetal area hazardtothemower,

and

whenchoppedtobitsbytheheavyblade,canbedangeroustopets

and

people.

4.

Know

howto

stop

themowerandtheengineinstantly.

5.Whenmovingthe

tractor

alongpathsand

walks,

andatall

timeswhennotactuallycuttinggrass,keep thebladeclutch

disengaged.

6.Don't

attempt

any serviceoperations

while

theengineis

run-

ning.

Disconnectthesparkplugwiretopreventaccidentalstarting.

7.Whenmowinghighgrass,

start

with

thebladeatitshighest

position.

This

lessensthedangerofstrikiftghiddenobjects.

Then

take

asecondcut

after

first checkingtobesuretherearenoobstructions.

8.

Fill

thegasolinetankoutdoors.

Avoid

spilling

gasoline.Don't

smoke while filling the tank.

9. Stoptheengineanddisengagethebladeclutchwheneveryou

leavethe

tractor.

PUT

YOUR

MOWER

TO

WORK

CHOOSE

THE

RIGHTCUTTING

HEIGHT

1.Ingeneral,usethesamecuttingheightyouhaveusedbefore.

You

knowwhatheightisbestforyourown

lawn.

2.Whenfirst usingyourmower,cutthegrassa littlelongerthan

you

didbefore,

until

you'resure

that

the

greater

cuttingwidth

will

not

causescalpingduetoirregularitiesinthe

lawn.

3.Ifthegrassishigh,orifit containslotsofmoisture,takea first

cut

with

thebladesethigh.

Then

finish

cutting

with

a lowerbladeset-

ting.

This

gives

better

distributionoftheclippingsandprovidesa

cleanersecondcut.

4.Itispossible,byusingcare,tocutgrass

that

isextremelyhigh

orwet.Setthebladeatitshighestposition,andusethelowestdrive

speed.

Moveintotheareacautiously.Takea cutonlyhalfthewidth

ofthemowerateachpass.Wetclippingsmayclogthemowerhousing,

causing

thebladeto

stall.

5.Itmaybenecessarytoremovetheshrubbarfromthemower

housing

todischargecuttingsevenly.

HOWTOSETTHE

CUTTING

HEIGHT

1.A pointerundertheheightadjustmenthandleindicatesthe

height oftheblade.TheblademaybesetatII/2,2,21/2,3 or31/2

inches.

2.Toraisetheblade,pressdownonthe

foot

lever

with

yourheel.

3.Tolowertheblade,placeyourleftthumbontopofthe

tractor

chassis

andyourfingers underthehandle.

Lift

uponthehandle.The

entiremower housing

will

dropslightly.Returnthehandletothe

"down"

posRion.Theblade

will

dropfurther.Eachtimeyouraise

and

lowerthehandle,thebladedropsone-half

inch.

USETHE

RIGHT

SPEED

1.Uselow

gear

for

pulling

heavyloads,formowinginhighgrass,

and

formowing

while

climbing

hills.

This

allowsthebladetomaintain

aconstantRPM,anddeliversmostofthehorsepowertotheblade.

Low

gear

alsogivesyoumaximumcontrol

while

trimming.

2.Usesecond

gear

formowinglevelareasandforclimbing

hills

when

youarenotusingtheblade.Ifsecond

gear

resultsinuneven

mowing

duetotheconditionofthegrass,shifttolow

gear.

3.

High

gear

givesa speedofabout five milesperhourona

level,

hard

surface.Useit fortransportingthe

tractor

toandfromwork.

Mowing

inhigh

gear

is

likely

tobeuneven,becauseatthisspeedthe

bladedoesnothavetimeto

lift

eachbladeofgrassinto cuttingposition.

In

addition,somuchoftheengine'shorsepowerisabsorbedinforward

motion

that

itiscomparativelyeasytostalltheblade.

4.Slowdownonturnstoavoid

sliding

sideways.

5.Reverseisjusta littleslowerthansecond

gear.

Themower

will

cutequally

well

ineitherforwardorreverse.

SAVE

MOWING

TIME

WITH

PLANNING

1.Changingdirectionwastes time.Plantokeepthemower mov-

ing

forwardasmuchaspossible.

2.Planforthelongeststraightrunspossible.

3.Saveclose trimmingforthecleanup.

4.Trytowork

with

theclippingsdischarging

onto

thealready-cut

areas,topreventbuildupofclippingsintheuncutarea.Ifthegrassis

unusually

longor

full

ofmoisture,theclippingscouldimposean

extra

load

ontheblade,orcauseunevenmowingbecausetheypreventthe

grassfrom

rising

into thecuttingpathoftheblade.

Normal

'Round-and-'Round

methodforlarge,easyareas.

Divide

largerorirregularareasintotwosections

Efficient

Planning

of

Your

Mowing

Saves

Cuffing

Time

5.Sometimesit'seasiertodividea largeorirregular-shaped

areainto smallersectionstokeepthemowerworkingmoresteadily,

3

ortokeepfrombacking,turningorrepeatingtoooften.

6.Ina smallarea,wheretight turnswouldcauselosttimeinthe

center ifthenormal'round-and-'roundmethodswereused,trythe

cuttingmethodshownintheillustration.Makethesecondpassdown

the

center

ofthearea,ratherthandowntheoppositesidefromthefirst

pass.

This

allowsyouto

swing

wideattheendofeachpass,and

still

cut

all

ofthegrasswithouttoomuchreversing.

7.Trytoavoidsteep

hills.

Themower

will

normallycarrya 200-

pound

operatorupa

307f

grade

while

cuttinggrass.Ifyoucan,angle

yourcutsacrossa

hill,

toreducetheeffectofthegrade.Onsteepgrades,

uselowgear.

THE

TRACTOR

AND

MOWER

HAVE

LIMITS

Observing

thelimitsofthe

tractor

will

helpitserveyoulonger.

Overloading

andmistreatmentcanshortenitslifeorimpairitsuseful-

ness,

justastheycan

with

anytoolormachine.

1.Theengineisnotguaranteedona slopeofmorethan45degrees

in

anydirection,asit

will

notreceiveproperlubricationbeyondthis

angle.

2.Keepthemower clean,especiallyaroundtheblade.

A/buil3up

ofgrassclippingsinthebladehousingcanimpairtheefficiencyofthe

mowerandcauseunevencutting.

3.Ifthe

tractor

stallsduetoanoverload,buttheenginecontinues

torun.shift immediately to neutral andstartoutslowly.Failuretodo

this

will

causeexcessivebeltwearorbreaka*».

4.Donot

operate

themower

with

thebladeoutofbalance.

5.

Avoid

pulling

loads thataresoheavytheycausethedrivebelt

to

slip.

6.Iftheenginestallsduetooverload,disengagethebladeclutch

and

shifttoneutralbeforerestarting.

Then,

find

outwhatcausedthe

overload,andavoidittomakeit easierwhenstartingoutagain.

HOWTO

KEEP

YOUR

MOWER

WORKING

FORYOU

The

simpleservicerequiredforyourmower

will

resultinlonger

life

anddependableoperation.

KEEPIT

PROPERLY

LUBRICATED

1.Whenlubricatingthechassis,standthe

tractor

onitsfront end,

and

applya droportwoofoiltoallpivotpointsinthesteering,brake

and

clutchlinkages.Lubricatethefrontandrearwheelbearings

with

afewdropsofoil.(Standingthe

tractor

onthebackwheels

will

cause

oil

toenterthecylinder,resultinginextremelyhardstartingorin

damagetotheengine.)

2.Useanautomotive-typegrease guntolubricatethefrontaxle

kingpins.

3.Observetheenginemanufacturer'soilrequirementscarefully.

Failure

todoso

will

notonlyvoidthewarranty,butit couldalsoresult

in

enginefailure.Keeptheoillevel in

Clinton

engineshighenoughto

bevisibleintheoildrainteewhenthe

filler

plugisremoved.

4.Aftereach25hoursofoperation,squirta coupleofdropsofoil

on

theshiftlevertolubricatethetopoftheshifting

ball

assembly.

5.Ifitisnecessarytoaddoiltothetransmission((heckevery10

hoursofoperation

with

the

tractor

sittinglevel onitsfourwheels),use

agoodgradeofNo.90hypoid

gear

lubricant.Donot

fill

abovethe

level

oftheinspectionplug,asthis

will

causeblownoilseals,continual

leakage,and'possibleconsequent damagetothetransmission.

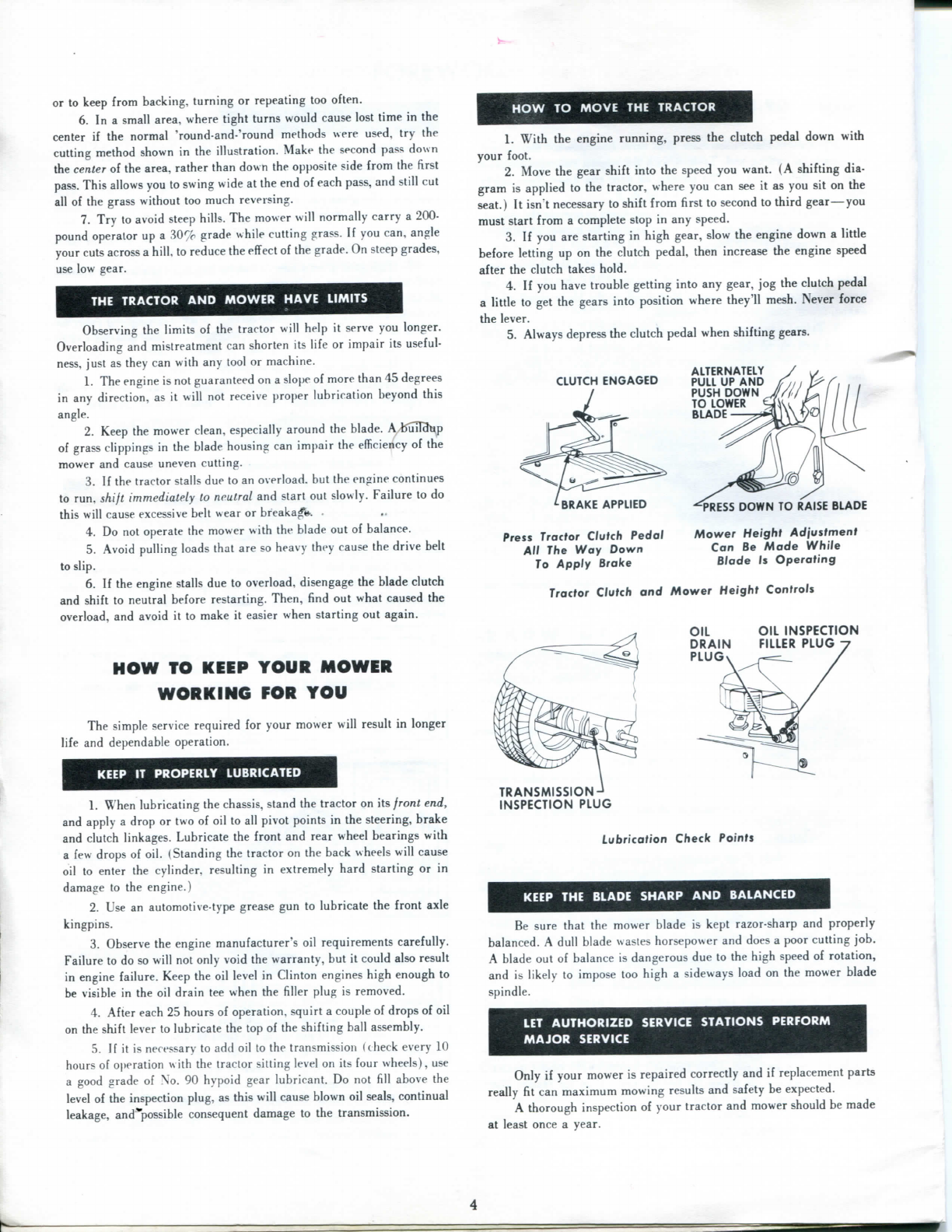

HOWTO

MOVE

THE

TRACTOR

1.Withtheenginerunning,presstheclutchpedaldown

with

your

foot.

2.Movethe

gear

shiftintothespeedyouwant.(Ashifting

dia-

gramisappliedtothe

tractor,

whereyoucanseeit asyousitonthe

seat.)

Itisn'tnecessarytoshiftfromfirsttosecondtothirdgear—you

muststartfroma complete stopinanyspeed.

3.Ifyouarestartinginhighgear,slowtheenginedowna little

beforelettingupontheclutchpedal,thenincreasetheenginespeed

aftertheclutchtakeshold.

4.Ifyouhavetroublegettingintoanygear,jogtheclutchpedal

alittletogetthegearsintopositionwherethey'llmesh.Neverforce

thelever.

5.

Always

depresstheclutchpedalwhenshiftinggears.

CLUTCH

ENGAGED

ALTERNATELY

PULL

UPAND

PUSH

DOWN

TO

LOWER

BLADE

BRAKE

APPLIED

Press

Tractor

Clutch

Pedal

All The Way

Down

To

Apply

Broke

"^PRESS

DOWN

TO

RAISE

BLADE

Mower

Heighf

Adjustmertt

Can Be

Made

While

Blade

Is

Operating

Tractor

Clutch

andMower

Height

Controls

OIL

DRAIN

PLUG

OIL

INSPECTION

FILLER

PLUG

TRANSMISSION-

INSPECTION

PLUG

Lubrication

Check

Points

KEEPTHE

BLADE

SHARP

AND

BALANCED

Besurethatthemower bladeiskeptrazor-sharpandproperly

balanced.

A

dull

bladewasteshorsepoweranddoesa poorcuttingjob.

A

bladeoutofbalanceisdangerousduetothehighspeedofrotation,

and

is

likely

toimposetoohigha sidewaysloadonthemower blade

spindle.

LET

AUTHORIZED

SERVICE

STATIONS

PERFORM

MAJOR

SERVICE

Only

ifyourmowerisrepairedcorrectlyandifreplacementparts

really

fitcanmaximummowingresultsandsafetybeexpected.

A

thoroughinspectionofyour

tractor

andmower shouldbemade

atleastoncea year.

4

HOWTO

OPERATE

AND

MAINTAIN

YOUR

ELECTRIC

START

LAWN

MOWER

It

isnecessary tofollowtheseadditionalinstructions,ifyour

lawn

mowerisequipped

with

electricstarting.Followingtheseinstructions

will

assureyouofthebestcontinuedbenefitsofelectricstarting.

PREPARING

FOR

OPERATION

The

"dry-charged"batteryanditscontainerofelectrolyteare

shipped

inseparatecartonsinsidethemower carton.Yourdealer

should

haveactivated,connectedandinstalledthebattery.Incasethis

was

notdonebeforeyoureceivedthemower,activatethebatteryand

install

itasfollows:

1.Removethebatteryfromitscarton.Activateit bypouring

theelectrolyteintothecells.

Fill

each

cell

tothelevelofthecirclein-

dicatorinthe

fill

tube.Afterreplacingthe

cell

caps,removethepipe-

cleanerplugsfromthevents.

2.Setthebatteryonthefloor beside themower.Attachthered

cabletothered(positive)terminalofthebatteryandtheyellowcable

totheyellow(negative)terminal.Usethehardwarefurnished.

3.

Slide

thebatteryinto thebracketprovidedatthefrontofthe

mower,andtightenthehold-downclamp.

4.Checkthecharge

with

a

^attery

hydrometer.Ifthespecific

gravityisbelow1.265to

1.285,

havethebatteryslow-chargedata

2-amp.maximum

rate

until

the

full

chargeisreached.This is particu-

larly important for cold weather starting.

Careful

preparationoftheengine

will

preventoverloadingofthe

electricstartingequipment,and

will

provide

better

servicefromyour

mower.

1.Keepthecrankcase

filled

totheproper

level.

Iftemperature

is

above40°F,useNo.30weightregulargradeautomobileengineoil.

2.Ifthetemperatureisbelow40°F,disregardthenameplate

instructionsand

fill

thecrankcasetotheproperlevel

with

No.10

weight

regulargradeautomobileengineoil.

3.Usea regulargradeof

FRESH

gasoline.Keepthegasoline

tank

full

whenthemowerisnotinuse, tohelppreventwaterconden-

sation.

4.Besurethecarburetorisadjustedforeasiest starting.

STARTING

WITH

THE

ELECTRIC

STARTER

Becauseofsizerequirements,thestarterhascertainoperating

limits

andcoldweatherlimitations.Intemperaturesbelow20°F it

maybenecessary tostarttheengine

with

therecoilstarter.Seethe

special

instructionsforcoldweatherstarting.Innormaltemperatures,

startthemowerasfollows:

1.Besurethetransmissionisinneutralandthebladeclutchis

disengaged.

This

relievesthestarterofextraload.

2.Besuretheenginespeedcontrolleverissetproperlyforstart-

ing.

3.Iftheengineisagainstthecompression,

pull

itpastthecom-

pression

stroke

with

therecoilstarterrope.

4.

Turn

thekeytostartcrankingtheengine.

5.A self-resettingcutoutswitchpreventsdamagetothestarter

motor

fromover-heating.Continuouscranking

will

causethisswitch

toopen,stoppingthestarter.Ifthishappens,allow thestartertocool

until

theswitch

contacts

close.

COLD

WEATHER

STARTING

In

coldweather,followtheseinstructionsforstartingtheengine

ofyour

lawn

mower.

1.Followthe"PreparingforOperation"instructionscarefully.

2.Besurethebatteryisat

full

chargeandallconnections are

tight.

3.Asthetemperaturedrops,batteryefficiencyalsodrops,even

thoughthebatteryis

fully

charged.

This

increasestheamperagedraw

ofthestarter,andmaycausethecutoutswitchtoopenafteronlya

momentarycrankingperiod.

(This

isbecauseanelectric

motor

heats

rapidly

underabnormalamperageconditions.)Ifthishappensincold

weather,it usuallymeansthatthestarterhasreacheditscoldweather

limitations,

anddoesnotnecessarilyindicatea defectivestartermotor.

4.Inmoderatelycoldweather(about20°F),besuretheengine

speedcontrolleverissetproperly,andallloadisremovedfromthe

engine.Itmayalsobenecessarytoturntheenginethroughtwoor

threerevolutions

with

therecoilstartertobreaktheoil

film

sealsand

reducethefriction.

5.Iftheenginehasstoodidlefora prolongedperiodincold

weather,it

will

usuallyhavetobestarted

with

therecoilstarter.

PROTECT

THE

STARTER

THROUGH

PROPER

USE

To

preventdamagetothestarter

motor

andbattery,usethestarter

carefully,

accordingtothefollowingcautions.Thewarrantyisvoid

if

thetimelimitsaredisregarded.

1.Neverrunthestarterformorethantensecondscontinuously.

2.

Allow

one

full

minutebetweenten-secondcrankingperiods.

3.Donotrepeattheten-second crankingperiodmorethanfive

times.Iftheenginedoesnotstart

within

fivecrankingandwaiting

periods,

thereisa mechanicalreason.Checkandcorrect.

4.

Allow

fifteen minutesbeforetryingtostarttheengine,after

using

upthefive 10-second crankingintervals.Failuretoobservethese

timelimitscausesexpensivepermanentdamagetothestartermotor.

TAKE

GOOD

CARE

OFTHE

ELECTRICAL

SYSTEM

Proper

care

oftheelectricalsystem

will

resultinlonglifeofthe

partsandgoodservicefromtheelectricstarter.

1.Checkthebatteryoncea monthfor

state

ofcharge.Recharge

thebatteryifthespecificgravityofthecellsfallsbelow

1.225,

orif

theopencircuitvoltageofthecellsdropsbelow2.04volts.Usea maxi-

mum

charging

rate

of2 amps.Keepbatteriesatornear

full

charge

forbestperformance.

2.Whilethebatteryisinuse, checkit oncea weekforelectro-

lyte

level.

Keeptheelectrolyteabovetheseparators,but

fill

onlyto

thecircleindicator,notinto thevent tube.Useonlydistilledorap-

provedwaterfor

filling.

3.Donotaddbatterydopes,additives,oracid.Suchadditions

void

thebatteryguarantee.

4.Keepthebatterycleanbybrushingoffdirt,dustandgrass

clippings

afteruse.Ifcorrosiondevelopsontopofthebattery,clean

it

with

waterandbakingsoda.Besuretokeepthevent plugsinthe

cells

while

cleaning.Coatthecleanedterminals

with

petroleum

jelly

(Vaseline)

topreventfurthercorrosion.

5.Batteriesmaybestoredwithoutdamageiftheyarefully

5

ATTACHMENTS

INCREASE

YOUR

MOWER'S

USEFULNESS

charged

whenplacedinstorage.Storeina dryplace,wherethetem-

peratureisbetween32°F and60°F.Keepthebatteryawayfrom

extreme

heatorcold.Rechargethebatterybeforeplacingit inservice.

6.Checkstoredbatteries everytwomonthsduringstorage.Re-

chargeimmediately,iftheopencircuitvoltagedropsbelow2.04volts,

orthespecificgravitydropsbelow

1.225.

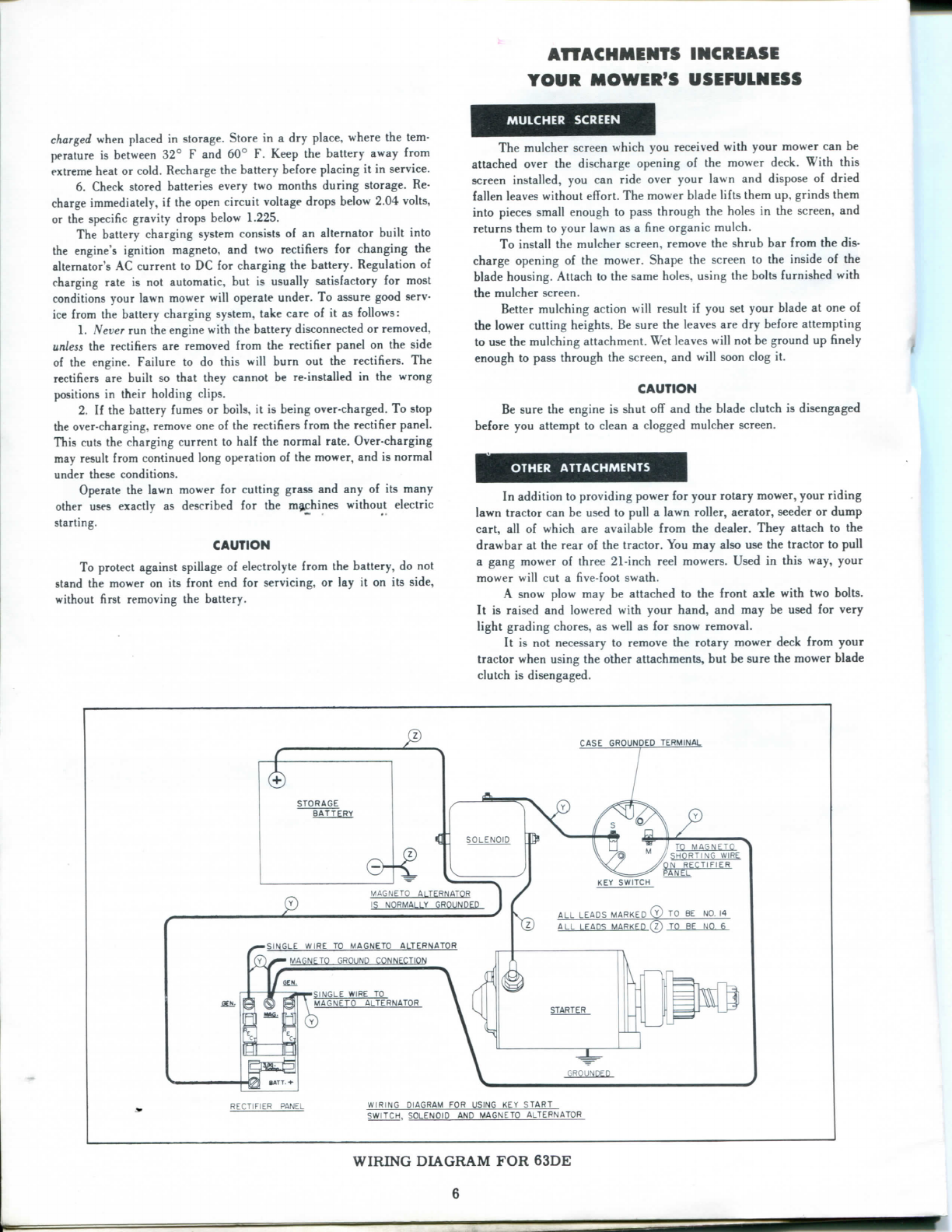

The

batterychargingsystemconsistsofanalternatorbuiltinto

theengine'signitionmagneto,andtworectifiersforchangingthe

alternator'sACcurrenttoDCforchargingthebattery.Regulationof

charging

rate

isnotautomatic,butisusuallysatisfactoryformost

conditionsyour

lawn

mower

will

operate

under.Toassuregoodserv-

icefromthebatterychargingsystem,take

care

ofit asfollows:

1.Never runtheengine

with

thebatterydisconnectedorremoved,

unless therectifiersareremovedfromtherectifierpanelontheside

oftheengine.Failuretodothis

will

burnouttherectifiers.The

rectifiersarebuiltsothattheycannotbere-installedinthewrong

positionsintheirholding

clips.

2.Ifthebatteryfumesorboils,itisbeingover-charged.Tostop

theover-charging,removeoneoftherectifiersfromtherectifierpanel.

This

cutsthechargingcurrenttohalfthenormalrate.Over-charging

mayresultfromcontinuedlong operationofthemower,andisnormal

undertheseconditions.

Operatethe

lawn

mowerforcuttinggrassandanyofitsmany

otherusesexactlyasdescribedforthemachineswithoutelectric

starting.

CAUTION

To

protect

againstspillageofelectrolyte fromthebattery,donot

standthemoweronitsfront endforservicing,orlayit onitsside,

without

firstremovingthebattery.

MULCHER

SCREEN

The

mulcherscreen

which

youreceived

with

yourmower canbe

attachedoverthedischargeopeningofthemowerdeck.Withthis

screeninstalled,youcanrideoveryour

lawn

anddisposeofdried

fallen

leaveswithouteffort.Themower bladeliftsthemup,grindsthem

into piecessmallenoughtopassthroughtheholesinthescreen,and

returnsthemtoyour

lawn

asa fineorganicmulch.

To

install

themulcherscreen,removetheshrubbarfromthe

dis-

chargeopeningofthemower.Shapethescreentotheinsideofthe

bladehousing.Attachtothesameholes,usingtheboltsfurnished

with

themulcherscreen.

Bettermulchingaction

will

resultifyousetyourbladeatoneof

thelowercuttingheights.Besuretheleavesaredrybeforeattempting

tousethemulchingattachment.Wetleaves

will

notbeground upfinely

enoughtopassthroughthescreen,and

will

soonclogit.

CAUTION

Besuretheengineisshutoffandthebladeclutchisdisengaged

beforeyouattempttocleana cloggedmulcherscreen.

OTHER

ATTACHMENTS

In

additiontoprovidingpowerforyourrotarymower,yourriding

lawn

tractor

canbeusedto

pull

a

lawn

roller,

aerator,

seederordump

cart,allof

which

areavailablefromthedealer.Theyattachtothe

drawbarattherearofthe

tractor.

Youmayalsousethe

tractor

to

pull

agangmowerofthree21-inchreelmowers.Usedinthisway,your

mower

will

cuta five-footswath.

A

snowplowmaybeattachedtothefrontaxle

with

twobolts.

It

israisedandlowered

with

yourhand,andmaybeusedforvery

light

gradingchores,as

well

asforsnowremoval.

It

isnotnecessarytoremovetherotarymowerdeckfromyour

tractor

whenusingtheotherattachments,butbesurethemowerblade

clutch

isdisengaged.

CASE

eWOUNDED

TERMINAL

STORAGE

BATTERY

4c <[

SOLENOID

//

TQ

MASNETQ

SHORTING

WIRE

®

MAGNETO

AlTERNATOR

15

NORMALLY

GROUNDED

•SINGLE

WIRE

TO

MAGNETO

ALTERNATOR

[Y)^MAgNETO

GROUND

CONNECTION

-SINGLE

WIRE

TO

MAGNETO

ALTERNATOR

GROUNDED

RECTIFIER

PANEL

WIRING

DIAGRAM

FOR

USING

KEY

START

SWITCH.

SOLENOID

AND

MAGNETO

ALTERNATOR

WIRING

DIAGRAM

FOR63DE

6

MAINTENANCE

TIRE

PRESSURE

Themowers

use

pneumatictires

and

tubes

onthe

back

wheels.

The

32-inchmower

alsouses

pneumatic

tires

and

tubes

onthe

frontwheels.Keep

the

rear

pneumatictiresinflated

toa

maximum

of30

pounds

pressure.Maximumpressure

forthe

fronttires

is

45

pounds.

(The

25-inchmower

uses

semi-pneumatic

tiresonthefrontwheels.

These

tires

will

not

require

inflation.)

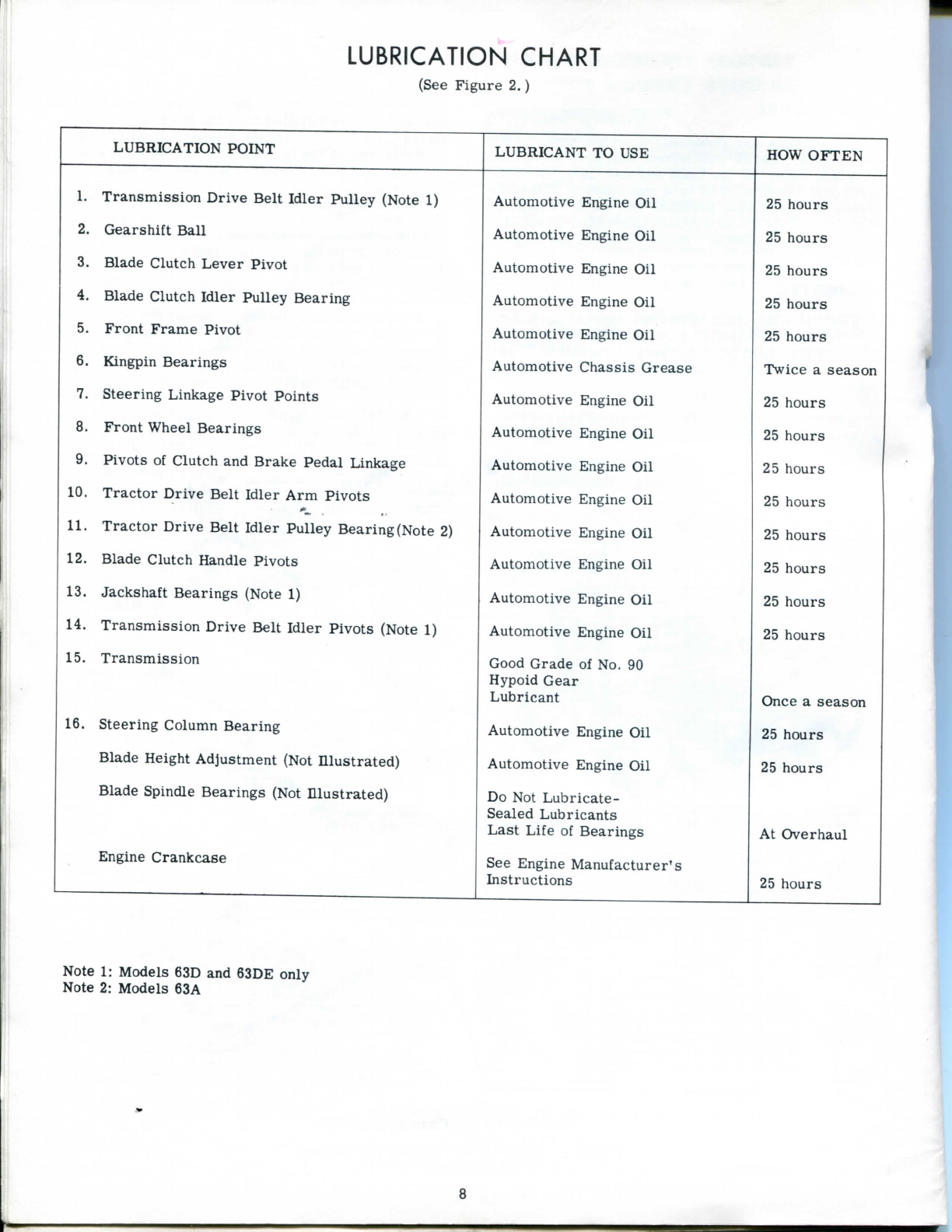

LUBRICATION

The

following

chartshows

all

lubricationpoints,

with

thetype

of

lubricant

touseoneach.

Lubrication

times

inthe

chartrefer

to

hours

of

operation.Lub-

ricatemoreoften

ifthe

mower

is

used

in

exceptionally

dusty

areas.

Note

that

the

ClintonEngineused

onsome

models

ofthemower

has

no

dip

stickforcheckingoil.Instead,

to

checktheoil,

remove

the

plug

from

thetopofthe

pipe

tee

which

is

installed

nearthe

front

ofthe

engine,

on

the

right

handside

ofthe

tractor.

Ifoilis

visible

in

the

bottom

ofthetee

when

the

tractor

isona

level

surface,there

is

sufficient

oilinthecrankcase.

In

addition

to

thelubricationproceduresdescribed,

it

isa

goodidea

to

clean

all

lubricationpoints

ofthe

tractorandmoweroccasionally,

to

prevent

build-up

of

dust

and

foreignmatter

onthe

parts.

ADJUSTMENTS

Adjustmentsrequiredforthemower

are

simple

and

infrequent.

Spring-loadedidlers

onthe

mainblade

drive

belt

(andonthe

bladedrivebelts

ofthe

32-lnch

mowerattachment)maintainpropertension

forthese

belts

so

thatadjustment

isnot

required

for

them.

Adjust

the

brakebandbytightening

or

loosening

the

lock

nutonthe

rear

endofthe

brake

rod.

STEERINGHANDLEBARS

GEARSHIFTLEVER

STARTER

ROPE

HANDLE

ENGINESPEED

CONTROLLEVER

LEVELING

WHEELS •ELECTRIC

STARTKEY

STEERING

HANDLEBARS

FUEL

TANK

VALVE

TRACTORCLUTCH

ANDBRAKEPEDAL

STARTER ROPEHANDLE

GEARSHIFTHANDLE

BLADECLUTCH

LEVER

BLADE

CLUTCH

LEVER

*ElectricStartModelsOnly

BLADE

HEIGHT

ADJUSTMENT

GEARSHIFTLEVER

ENGINESPEED

CONTROLLEVER

kPosifionsof

Engine Speed

Control

Lever

Figure

1.

Controls

for

Tractor

and

Mower

7

LUBRICATIONCHART

(See

Figure

2.)

LUBRICATION

POINT

LUBRICANT

TOUSE

HOW

OFTEN

1.

TransmissionDriveBeltIdlerPulley(Note

1)

Automotive

Engine

Oil

25hours

2. GearshiftBall

Automotive

EngineOil 25hours

3. BladeClutchLeverPivot

Automotive

Engine

Oil

25hours

4. BladeClutchIdlerPulleyBearing

Automotive

Engine

Oil

25hours

5.

Front

FramePivot

Automotive

Engine

Oil

25hours

6.

Kingpin

Bearings

Automotive

Chassis

Grease

Twice

a

season

7. SteeringLinkagePivotPoints

Automotive

Engine

Oil

25hours

8.

Front

Wheel

Bearings

Automotive

EngineOil 25hours

9. Pivots

of

ClutchandBrakePedalLinkage

Automotive

Engine

Oil

25hours

10. TractorDriveBeltIdlerArmPivots

Automotive

Engine

Oil

25hours

11.

TractorDriveBeltIdlerPulleyBearing(Note

2)

Automotive

Engine

Oil

25hours

12. BladeClutchHandlePivots

Automotive

Engine

Oil

25hours

13.

Jackshaft

Bearings

(Note

1)

Automotive

EngineOil 25hours

14. TransmissionDriveBeltIdlerPivots(Note

1)

Automotive

Engine

Oil

25hours

15. Transmission GoodGrade

of

No.

90

Hypoid

Gear

Lubricant

Once

a

season

16. SteeringColumnBearing

Automotive

Engine

Oil

25hours

BladeHeightAdjustment(NotIllustrated)

Automotive

Engine

Oil

25hours

BladeSpindle

Bearings

(NotIllustrated)

Do

NotLubricate-

Sealed

Lubricants

LastLife

of

Bearings

At

Overhaul

Engine

Crankcase

See

EngineManufacturer's

Instructions

25hours

Note

1:

Models

63Dand

63DE

only

Note

2:

Models

63A

8

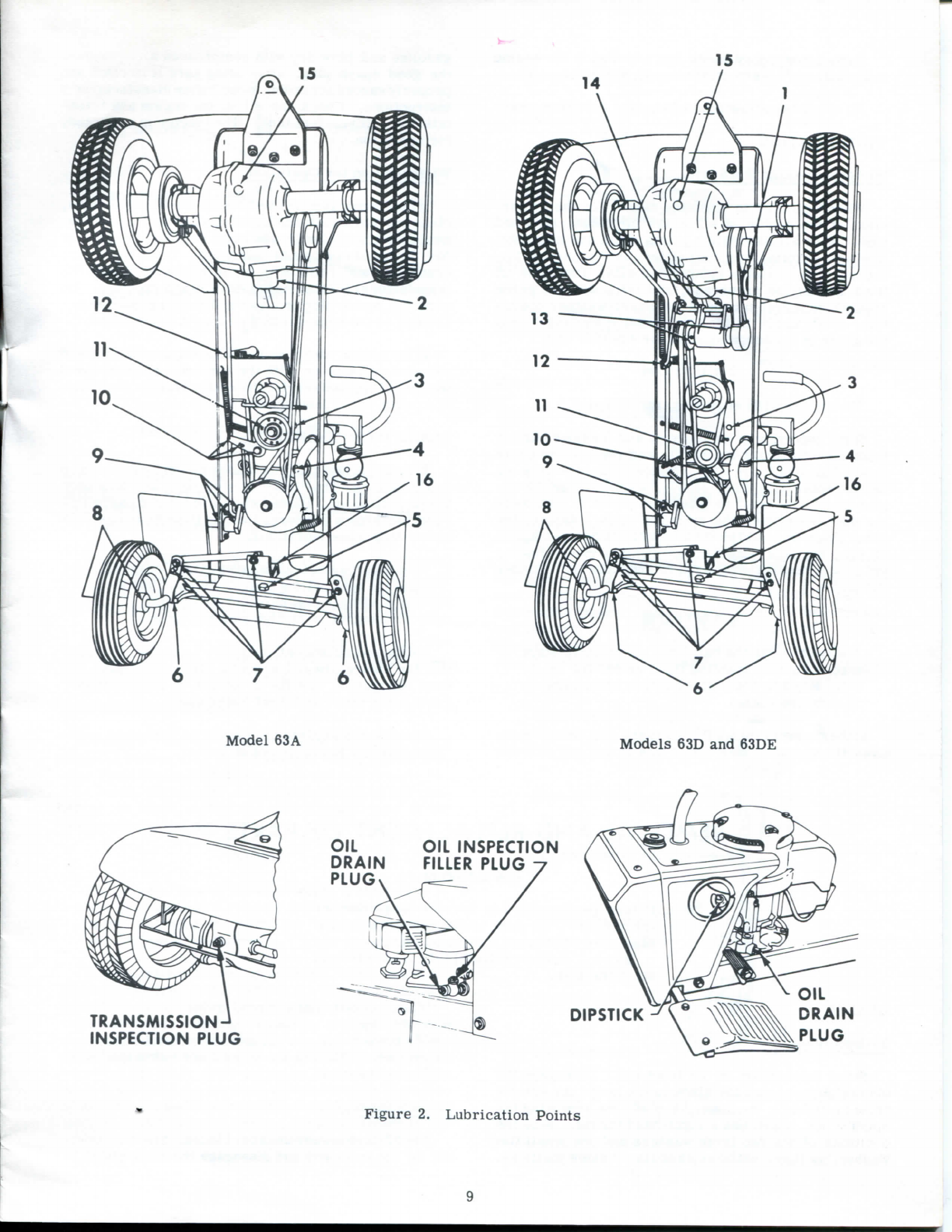

Model

63A

Models

63D

and

63DE

9

Carburetoradjustments

are

covered

inthe

engine

manufacturer's

instruction

manual,

which

is

furnished.

No

otheradjustments

are

required

forthe

mower.

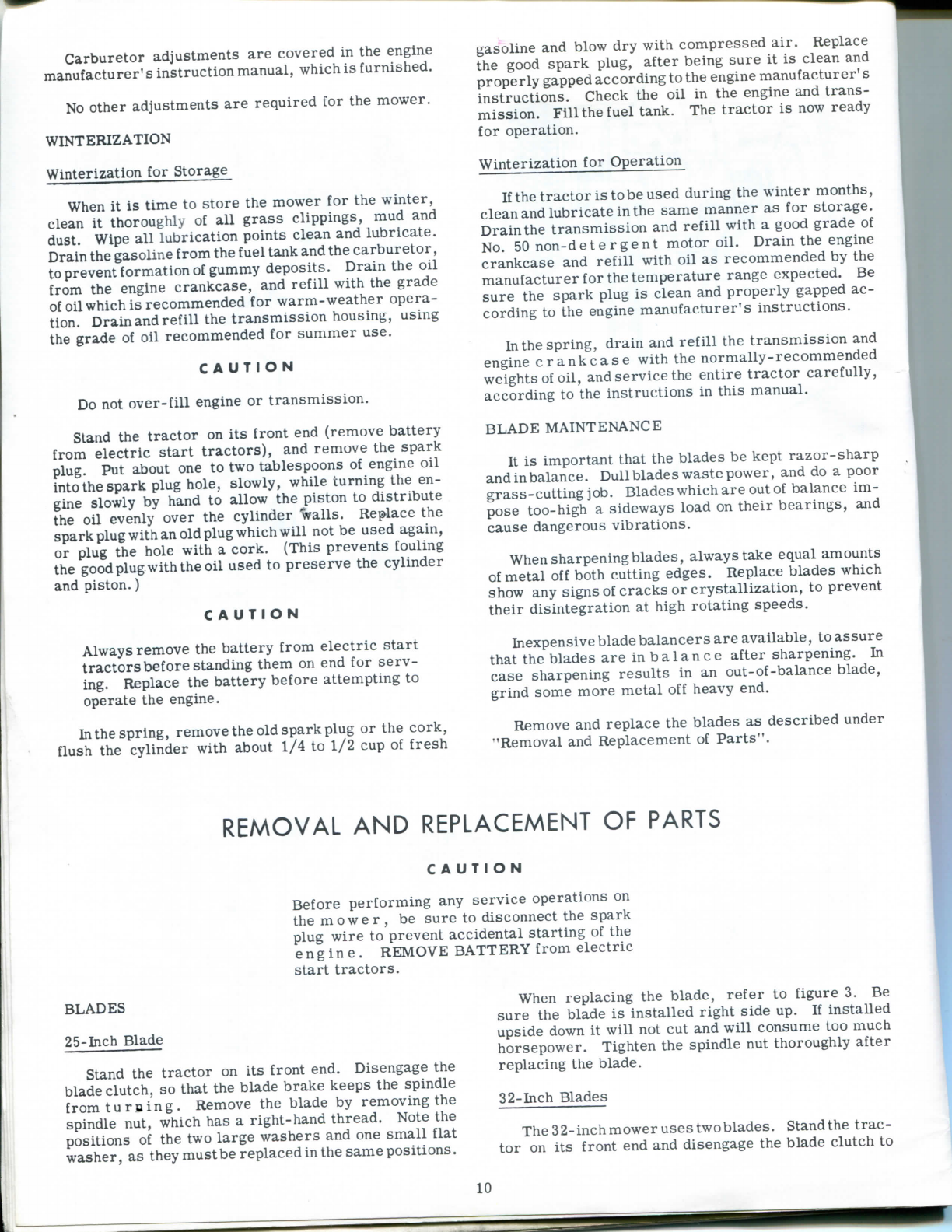

WINTERIZATION

Winterization

for

Storage

When

itis

time

to

store

the

mower

forthe

winter,

clean

it

thoroughly

ofall

grass

clippings,

mudand

dust.

Wipe

all

lubricationpointsclean

and

lubricate.

Drain

thegasoline

from

the

fuel

tankandthecarburetor,

to

prevent

formation

of

gummydeposits.

Drain

theoil

from

the

engine

crankcase,

and

refill

with

the

grade

of

oil

which

is

recommended

for

warm-weatheropera-

tion.

Drain

and

refill

the

transmissionhousing,using

thegrade

ofoil

recommended

for

summer

use.

CAUTION

Do

not

over-fill

engine

or

transmission.

Stand

the

tractor

onits

front

end

(removebattery

from

electricstarttractors),

and

remove

the

spark

plug.

Put

about

oneto

twotablespoons

of

engine

oil

into

thespark

plug

hole,

slowly,

while

turning

theen-

gineslowly

by

hand

to

allow

the

piston

to

distribute

the

oil

evenlyover

the

cylinderwalls.

Replace

the

spark

plug

with

an

old

plug

which

will

notbe

usedagain,

or

plug

the

hole

with

a

cork.(Thisprevents

fouling

thegood

plug

with

theoilused

to

preserve

the

cylinder

and

piston.)

CAUTION

Always

remove

the

battery

from

electricstart

tractorsbeforestandingthem

onendfor

serv-

ing.

Replace

the

batterybeforeattempting

to

operate

the

engine.

In

thespring,removetheoldspark

plug

orthe

cork,

flush

the

cylinder

with

about

1/4to1/2cupof

fresh

gasoline

and

blowdry

with

compressed

air.

Replace

thegoodspark

plug,

afterbeingsure

itis

clean

and

properly

gappedaccordingtotheenginemanufacturer's

instructions.

Check

theoilinthe

engine

and

trans-

mission.

Fill

the

fuel

tank.

The

tractor

is

nowready

for

operation.

Winterization

for

Operation

If

thetractor

is

to

be

used

during

the

wintermonths,

cleanandlubricateinthe

same

manner

asfor

storage.

Drain

thetransmission

and

refill

with

a

goodgrade

of

No.

50

non-detergentmotoroil.

Drain

the

engine

crankcase

and

refill

with

oilas

recommended

bythe

manufacturerforthetemperaturerangeexpected.

Be

sure

the

spark

plug

is

clean

and

properlygapped

ac-

cording

tothe

enginemanufacturer'sinstructions.

In

thespring,

drain

and

refill

the

transmission

and

engine

crankcase

with

the

normally-recommended

weights

of

oil,

andservicetheentiretractorcarefully,

according

tothe

instructions

in

thismanual.

BLADE

MAINTENANCE

It

is

importantthat

the

blades

be

keptrazor-sharp

andin

balance.

Dull

bladeswastepower,

anddoa

poor

grass-cuttingjob.

Blades

which

are

out

of

balance

im-

pose

too-high

a

sidewaysload

on

theirbearings,

and

cause

dangerousvibrations.

When

sharpeningblades,alwaystakeequalamounts

ofmetal

off

both

cutting

edges.

Replace

blades

which

show

any

signs

of

cracks

or

crystallization,

to

prevent

their

disintegration

at

high

rotating

speeds.

Inexpensiveblade

balancers

are

available,to

assure

that

the

blades

arein

balance

aftersharpening.

In

case

sharpeningresults

inan

out-of-balanceblade,

grind

some

moremetal

off

heavy

end.

Remove

and

replace

the

blades

as

describedunder

"Removal

and

Replacement

of

Parts".

REMOVALANDREPLACEMENTOFPARTS

CAUTION

Beforeperforming

any

serviceoperations

on

themower

, be

sure

to

disconnect

the

spark

plug

wire

to

preventaccidentalstarting

ofthe

engine.REMOVEBATTERY

from

electric

starttractors.

BLADES

25-InchBlade

Stand

the

tractor

onits

front

end.

Disengage

the

bladeclutch,

so

that

the

bladebrake

keeps

the

spindle

from

turning.

Remove

the

blade

by

removing

the

spindle

nut,

which

hasa

right-handthread.Note

the

positions

ofthe

twolargewashers

andone

small

flat

washer,

as

theymustbereplacedinthe

same

positions.

When

replacing

the

blade,refer

to

figure

3.Be

sure

the

blade

is

installed

right

sideup.

If

installed

upside

down

it

will

notcut

and

will

consume

too

much

horsepower.Tighten

the

spindle

nut

thoroughlyafter

replacing

the

blade.

32-Inch

Blades

The

3

2-inchmower

uses

two

blades.Standthetrac-

tor

onits

front

endand

disengage

the

bladeclutch

to

10

Figure3.Installationof

Blades

apply

thebraketothebladedrivespindle.Inserta

drift

pinorotherblockingdeviceintotheholeinthe

mowerdeck,

adjacent

to

each

oftheblades,toprevent

the

blades

from

turning.

(Seefigure4.)

Remove

the

blades

bytakingofftheright-hand

threadedspindlenuts.Notethepositionsofthelarge

and

smallflatwashers,as

these

mustbereplacedin

the

same

positionswhenthebladeisreinstalled.

Besurethe

blades

areinstalled

right

sideup.See

Figures.Usetheblockingpinsto

keep

the

blades

from

turning

whenretighteningthespindlenuts.

MOWERATTACHMENT

Usea 1/2-inchwrenchtoloosenthefourbolts

which

hold

themowerdecktothe

sides

ofthetractor

chas-

sis.Standthetractoronitsfrontendandremovethe

four

bolts.Graspthemowerattachmentbythe

cen-

teroftheblade,andbytherear

cross-bar

ofthe

heightadjustmentmechanism,toremoveit.

NOTE

Toprevent

loss

ofthefourbolts,ifthetrac-

tor

istobeused

without

themowerattach-

ment,reinstallthemintothe

holes

and

tight-

en.Donotover-tighten.

Toreinstallthemowerattachment,againstandthe

tractoronitsfrontend.Loosenthefourbolts

holding

thebladedrivepulleytothe

chassis.

Graspthemow-

erattachmentbytherear

cross-bar

andthe

center

of

theblade.

Turn

thebladeslightlyto

engage

thehex-

agonaltopofthespindleintothehexagonalholeinthe

bottom

ofthebladedrivepulleyonthe

chassis.

Slide

thesideplatesofthemowerattachmentoverthe

sides

ofthe

chassis,

andattach

with

thefour5/16-inchbolts.

Retightenthefourbolts

holding

thedrivepulleytothe

Figure4.LockingBladePulleytoLoosenBladeNut

chassis.

This

centers

thepulley

with

respect

tothe

mowerattachment.

Themowerattachmentmaybeleftin

place

forall

attachmentsbutthesnowblade.

TRACTORDRIVE

BELTS

NOTE

It

is

necessary

toremovethemowerattach-

mentbeforereplacinganyofthebelts.

TractorDriveBelt(Model63A)

With

thetractorstandingonitsfrontend,

depress

theclutchpedalasfarasit

will

go.This

takes

the

tensionoffthetractordrivebelt.

Wring

thebeltoff

theenginepulley,

disengage

it

from

thebeltguides,

and

removeit

from

thetransmissionpulley.(Notice

thedirectionof

twist

ofthebelt,9othatyoucanrein-

stall

itmoreeasilyinthe

same

pcJSition.)

Seefigure5.

Figure5 InstallationofTractorDriveBelt

(Model

63A)

11

TRANSMISSION

DRIVE

BELT

JACKSHAFT

DRIVEN

PULLEY

TRACTOR

DRIVE

BELT

IDLER

PULLEY

TENSION

SPRING

TRANSMISSION

DRIVE

PULLEY

CLUTCH

IDLER

PULLEY

JACKSHAFT

DRIVE

PULLEY

BELT

GUARD

TRACTORDRIVE

BELT

IDLER

PULLEY

ENGINE

PULLEY

LEFT

HAND

BLADE

RIGHT

HAND

BLADE

DRIVE

BELT

ANDDRIVE

BELT

PULLEY

ANDPULLEY

SHAFTADAPTERAND

MAIN

BLADEDRIVE

PULLEY

SPRING-LOADEDIDLERS

Figure

7.

BladeDrive

Belts

on

32-InchMowerAttachments

Figure

6

Installation

of

TractorDrive

Belts

(Models

63Dand

63DE

)

To

replace

the

tractordrivebelt,

place

it

over

the

transmissionpulley

first,

thenthrough

the

rearbelt

guide.

Twistthebelt

which

leads

offthe

bottom

ofthe

transmissionpulleyone-half

turn

tothe

left

and

place

it

onthe

outside

ofthe

middlebeltguide.Twist

the

belt

which

leads

offthetopofthe

transmissionpulley

one-half

turn

totheleft,

and

place

it

behind

the

middle

beltguide(between

the

beltguide

andthe

bladeclutch

mechanism).

Wring

thebeltaround

the

enginepulley.

The

veeofthe

beltshould

fit

into

the

groove

ofthe

enginepulley.

Engage

the

belt

onthe

clutchidler

pulley,

so

thattheidlerpulleyrides

onthe

rear

ofthe

belt.

(Notethat

the

clutchidlerpulley

is

mounted

onits

bracket

with

a

slight

tilt,

in

order

to

properlyguide

and

engage

thebelt.This

tilt

is

intentional,

and

should

not

be

disturbed.

See

figure

5.)

TractorDriveBelt(Models

63Dand63DE)

Disconnect

the

spring

which

appliestension

tothe

idler

pulley

forthe

tractordrivebelt.

Wring

the

belt

off

theenginepulley.Whenremoving

the

belt,notice

thedirection

of

twist,

so

that

the

belt

canbe

replaced

in

thesame

manner.

Replace

the

belt

by

installing

it

over

the

jackshaft

driven

pulley

first,

then

twisting

thetop

side

ofthe

beltone-quarter

turn

tothe

left

so

that

theveeofthe

belt

will

runintothegroove

ofthe

enginepulley,

atthe

right.

Wrfng

the

beltinto

the

groove

ofthe

engine

pulley.

Thebeltshouldrun

offthe

leftside

oftheen-

ginepulley

tothe

bottomside

ofthe

jackshaft

driven

pulley.

See

figure

6.

TransmissionDriveBelt(Models

63Dand

63DE)

Remove

the

beltguard

which

partiallysurrounds

thejackshaftdrive

pulley.

Donotmisplacethisguard,

asitis

essential

that

itbe

replacedafterreplacing

thebelt.

Depress

theclutchpedal,

to

take

the

tension

off

the

transmissiondrivebelt.

Wring

the

belt

off

either

the

jackshaftdrivepulley

orthe

transmission

pulley,

to

remove

it

from

the

tractor.

Reinstallation

ofthe

transmissiondrivebelt

isthe

reverse

of

removal.

Be

sure

to

replace

the

beltguard,

to

keep

the

belt

in

place

during

timeswhen

the

clutch

pedal

is

depressed.

Mower

DriveBelt(AllModels)

Remove

the

tractordrivebelt

as

describedabove,

for

access

tothe

mowerdrivebelt,thenremove

the

5/16

inchbolt

which

holds

the

bladeclutchidler

arm

to

the

tractor

chassis.

Wring

the

mowerdrivebelt

overthemowerdrivepulley

and

remove

from

theen-

ginepulley.

Replace

thebelt

first

ontheengine

pulley,

then

wring

it

onto

the

mowerdriveadapterpulley.

Replace

the

linkageandsprings

which

weredisconnected.

Replace

thetractordrivebelt

as

describedabove.

Blade

Belts

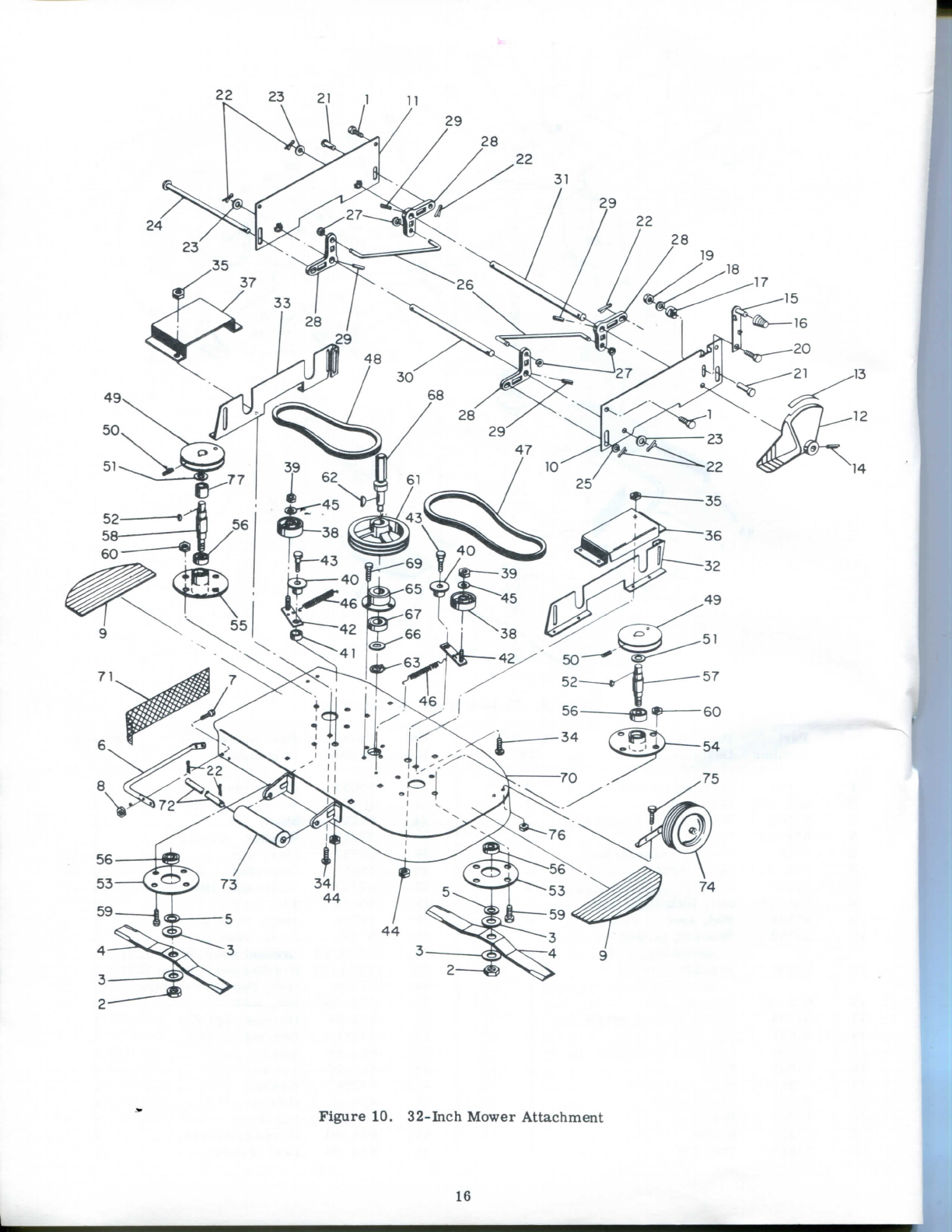

(32-lnchMowerAttachment)

Remove

the

right-hand

and

left-handpulley

covers

for

access

tothebladedrivebelts.

See

figure

7.Un-

12

hook

thesprings

from

theidlers.

Wring

thebeltsoff

theoutsidepulleys

first,

thenremovethem

from

the

center

pulley.

Replace

inthereverseorder.Besure

to

hookthesprings

into

theidlerarms.

Replace

the

pulley

coversafterthebeltshavebeenreinstalled.

BEARINGS

Rear

AxleBearings

Rear

axlebearingsoftheModels63A,63Dand

63DE

arecontainedinextensionsofthetransmis-

sion

housing.Theyarelubricated

from

within

bythe

transmissionlubricant,andcanbereplacedonlyon

completedisassemblyofthetransmission.

BearingsofBladeDriveSystem

Thebearingsoftheblade

drive

systemaremount-

edinhousings

which

areboltedtothetractor

drive

chassis

orthemowerhousing.

These

arelocatedas

describedbelowforthetwo

sizes

ofmowers.Ifre-

placementofthebearingsoftheblade

drive

systemis

required,

removethebelts

from

aroundtheaffected

pulleys,

andremovethebladeifa bladespindle

bear-

ing

istobereplaced.

Refer

totheexplodedviews

which

illustratetheparts

list,

fordisassembly.

Locationsofthebearingsofthe-blade

drive

system

areas

follows:

Both

models:Blade

drive

adapter,locatedin

center

of

chassis,

underneath.

25-Inch

Model:

Bladespindle,locatedin

center

of

mower

housing.

32-InchModel: Twobladespindles,locatedon

mower

housing

toward

outside

from

center.Blade

pulley

spindle,locatedin

center

ofmowerhousing.

If

itis

necessary

to

drive

thebearingsoutoftheir

housings,applyforceonlyonthe

races

which

are

tight

in

thehousingsorontheshafts.Donottransmit

removing

orinstalling

forces

throughtheballsor

rollers.

Usea soft-headed(leather,rubberorplastic)

mallet

to

drive

bearings

into

oroutofposition.

TRANSMISSIONANDENGINE

If

thetransmissionshouldrequirerepair,contact

the

closest

authorizedservicestation,orthe

nearest

centraldistributoraslistedon

page

24ofthisbook.

Toremovethetransmission

from

thetractor

chas-

sis,

first

removethetransmission

drive

beltanddis-

connectthebrakerod

from

thebrakeband.Remove

thenuts

from

thetwoU-bolts

which

fastentheaxle

housingstothewheelsupportbrackets.Takeoutthe

four

bolts

which

attachthetransmissionhousingtothe

tractor

chassis.

Thisallowsthetransmission,com-

plete

with

rearaxlehousingsandwheels,tobere-

moved

from

thetractor.

Toremovetheengine,takeoffthehood,handle

bars,and

drive

belts.(The

fuel

tanktorLausonen-

ginemodels

will

come

off

with

thehood.)Removethe

enginepulleybytakingoutthe3/8-inchbolt

which

is

threaded

into

thebottomoftheenginecrankshaft.Do

not

lose

ordamagethekey

which

locksthepulleytothe

enginecranksahft.Disconnecttheexhaustpipecou-

pling

nut.

Removethefour5/16-inchbolts

which

fasten

theenginetotheenginemountingplate,and

lift

the

engine,

with

carburetorand

fuel

system,offthetopof

the

chassis.

Donot

lose

thebeltguide

which

isattached

by

twooftheengine

mounting

bolts.Itisnot

necessary

to

removetheexhaustpipe

from

the

chassis.

Repairoftheengineshouldbeaccomplishedbyone

oftheenginemanufacturer'sauthorizedservice

sta-

tions.

MISCELLANEOUSPARTS

Follow

theexplodedviews

which

accompanythere-

placementparts

list

ifanyotherpartsaretobere-

placed.Orderallreplacementparts

from

the

closest

Quick

Mfg.,Inc.centralparts

distributor

showninthe

list

insidethebackcoverofthisbook.Givecomplete

information,

including

themodelnumberofthemower,

and

thepartnameandcorrectpartnumberofthere-

placementparts

list

andaccompanyingexplodedviews.

Figures8 through14showallofthereplaceable

partsofthetractors,explodedfor

easy

identification.

REPAIRPARTSLIST

The

illustrations

and

partslists

which

follow

show

all

ofthereplaceablepartsofyour

riding

rotary

lawn

tractor.

The

illustrations

showthetractordismantled

into

itsmajorcomponents,

with

each

partindexed.

If

youshould

find

it

necessary

toreplacea part,

find

the

illustration

which

showsthesectionofthe

mower

which

containsthepartyouneed;then

find

the

part

inthe

illustration

andnoteits

reference

number.

Turn

tothe

listing

ofpartsforthe

illustration,

and

find

the

reference

numberassignedtothepartyou

need.

Read

across

thelinetodeterminethenameand

part

numberofthepart.

Order

thepartsyouneedby

NAME

ANDPART

NUMBER

ONLY.Donotusethe

reference

numbers.

13

REPAIR

PARTS

LIST

Figure

8.FrontEndAssembly(AllModels)

Ref. Part PartNameor

Quantity

Ref. Part PartNameor

Quantity

No.

Number Description

25" 32"

No.

Number Description

25"32"

1

57155

Fender

front

2 2 8

57985

Nut,

Hex 22

2

57102

Bolt,

Sems

unit

. , , . 4 4 9 1806 Lockwasher.... 22

3

55033

PotterDin 5 5 10

57971

Pin

22

w

4 1018 Washer 6 6 11 60A-39

Rod,

Tie

1

1

5

57150

WheelAssy,

front

. . 2 12 Y60A-44

Axle

assy,

front,

R.H.

1

1

57150-1

2 -13 Y60A-43

Axle

assy,

front,

L.H.

1

1

6 Y60D-22 Wheel

assy,

front,incl.

-2 14

57137

Housing,front

axle

1

1

60D-23

-2 15 57116

Grease

fitting

. . . 22

60D-24

Tube. . _ 2 16

57961

Screw

1

1

60D-25

_ 2 17 1022 Washer,

flat

....

1

1

«0D-21 -2 18

57962

Nut,

castellated. .

1

1

7 59A-70

Ball

joint

(steering

link)

19 57980 22

1 1

14

Figure

9.

25-Inch

Mower

Attachment

Ref.

No.

Part

Number

Part

Name

or

Description

Quantity

25" Ref.

No.

Part

Number

Part

Name

or

Description

Quantity

25"

1

57101

Bolt,

Sems

unit

....4

259A-153

Nut,

lock

1

3

57206

Washer,blade,special

2

4

60F-43

Blade

1

5

1018

Washer,special

flat.

. 1

660A-41

Bar,

shrub

1

7

59074

Bolt

4

859A-149

Nut,

lock

4

9

57222Pad,

foot

2

1057252

Bracket,mower

mounting,

L.

H.

. . 1

11

57250

Bracket,mower

mounting

R.

H.

• •

1

1260A-30Ratchet,

lift

1

1357284

Decal,

cutting

height

. 1

1455024Pin,

lock

1

1557266

Lift

pawl

assembly..

. 1

1657145

Knob

1

17

57267Nut,

pawl

slide

1

1857294

Lockwasher

1

19572^5Nut1

2057010

Screw

1

21

57912Pin,

lift

2

22

55033

Cotter

pin6

231018

Washer,special

flat.

3

2457256

Shaft,

lift

1

2557282

Washer,special

...1

2657257

Link,

lift

2

27

55054

Snap

ring

4

2857258

Bellcrank,

lift

4

2955024Pin,

lock

4

3057254

Shaft,

front

pivot

...1

31

57255

Shaft,rear

pivot

...1

32Y60A-18Bracket

assy,

lower

L.

H.

1

33

Y60A-17Bracket

assy,

lower

R.

H.

1

34 57228

Bolt,Specialcarriage

10

35

59A-150

Nut,

lock

10

36

62A-54

Housing,

spindle

...1

37

57281

Bearing

2

38

62A-55Spindle

1

39

62A-56

Spacer1

40 57276

Washer

1

41

63A-3Bolt

4

4259A150

Nut,

lock

4

43

60A-40

Housing,

mower.

...1

44

60A-36Leaf

Mulcher

1

15

Parts

Listing

for32-Inch

Mower

Attachment

Ref.PartPartNameor

Quantity

No.

NumberDescription32"

1

57101Bolt,

Sems

unit

4

259A-153Nut,lock2

3

57206

Washer,blade,special4

460D-50Blade2

51018Washer,special

flat

. . 2

660D-42Bar,shrub1

7

59074

Bolt4

859A-149Nut,lock4

960D-13Pad,

foot

2

1060D-41Bracket,mower

mounting,

L.

H.

. . 1

11

60D-34Bracket,mower

mounting,

R.

H.

. . 1

1260A-30Ratchet,

lift

1

13

57284

Decal,

cutting

height.. 1

14

55024

Pin,lock1

15

57266

Pawl

assembly,

lift

. . 1

16

57145

Knob1

17

57267

Nut,

pawl

slide1

18

57294

Lockwasher1

19

57295

Nut1

20

57010

Screw1

21

57912

Pin,

lift

' 2

22

55033

Cotterpin8

231018Washer,special

flat.

. 4

24

57256

Shaft,

lift

1

25

57282

Washer,special....1

26

57257

Link,

lift

2

27

55054

Snap

ring

4

28

57258

Bellcrank,

lift

4

29

55024

Pin,lock4

30

57254

Shaft,

front

pivot

....1

31

57255

Shaft,rear

pivot

....1

32Y61D-11Bracket

assy,

lower

L.

H.

1

33Y61D-12Bracket

assy,

lower

R.

H.

1

34

57228

Bolt,Specialcarriage.10

3559A-150Nut,lock10

3660D-31Pulleycover,L.

H.

. . 1

3760D-32Pulleycover,R.H...1

38

59049

Pulley,

idler

2

39

57247

Nut2

40

59050-2

Bushing2

41

60D-58

Spacer

1

42Y60D-61Bracket,

idler

2

43

59076

Bolt2

4459A-150Nut,lock2

45

55057

Washer,

flat

2

4661D-40Spring2

47

61TR-83

Belt,L.H 1

Ref.

Part Part

Nameor

Quantity

No.

Number Description

32"

48 61D-35

1

49 60D-48

Pulley

2

50 2111 Screw,Set 2

51

1018 Washer,special

flat

3

52 57011 2

53

57276

Washer,special. . 2

54 62D-13

Spindle

housing

1

55 62D-13

Spindle

housing X

56

57281

4

57 60D-38 Bladeshaft,L.

H..

.

1

58 62D-15 Bladeshaft,R.

H..

.

1

59 63A-3

60 59A-150

61

61D-34

1

62

61TR-129

Woodruff

key....

1

63 1020

1

64

57980

Cotter

Pin

65

57264

Housing,

bearing. .

1

66 1217 Washer

1

67

57263

1

68 Y61D-10

Spindle,

center. . .

(Universal

joint).

1

69

57960

Screw,self-tapping,

Sems

4

70 Y61D-8

Housing

assembly..

1

71

60D-20 LeafMulcher. . . .

1

72

61TR-82

Shaft,

roller

1

73 61TR-81

Roller

1

74 Y60D-105Wheelassembly,L.

H.,

1

Consistsof:

Y60D-106. Bracket,L.H.. .

56004

.

Axle

56014

. Wheel

59A-151. Nut

Y60D-103Wheelassembly,R.

H.,

Consistsof:

Y60D-104. Bracket,R.

H.

. .

56004

.

Axle

56014

. Wheel

59A-151. Nut

751046Bolt

7659A-149. Nut

NR

Y60D-44CompleteSpindle

Assy,

L.H

NR

Y60D-45CompleteSpindle

Assy,

R.H

NR

61TR-244

Plug,

Button

7762D-14

Spacer

17

Figure11.ExplodedViewof

Chassis

Assembly

(Model63A)

18

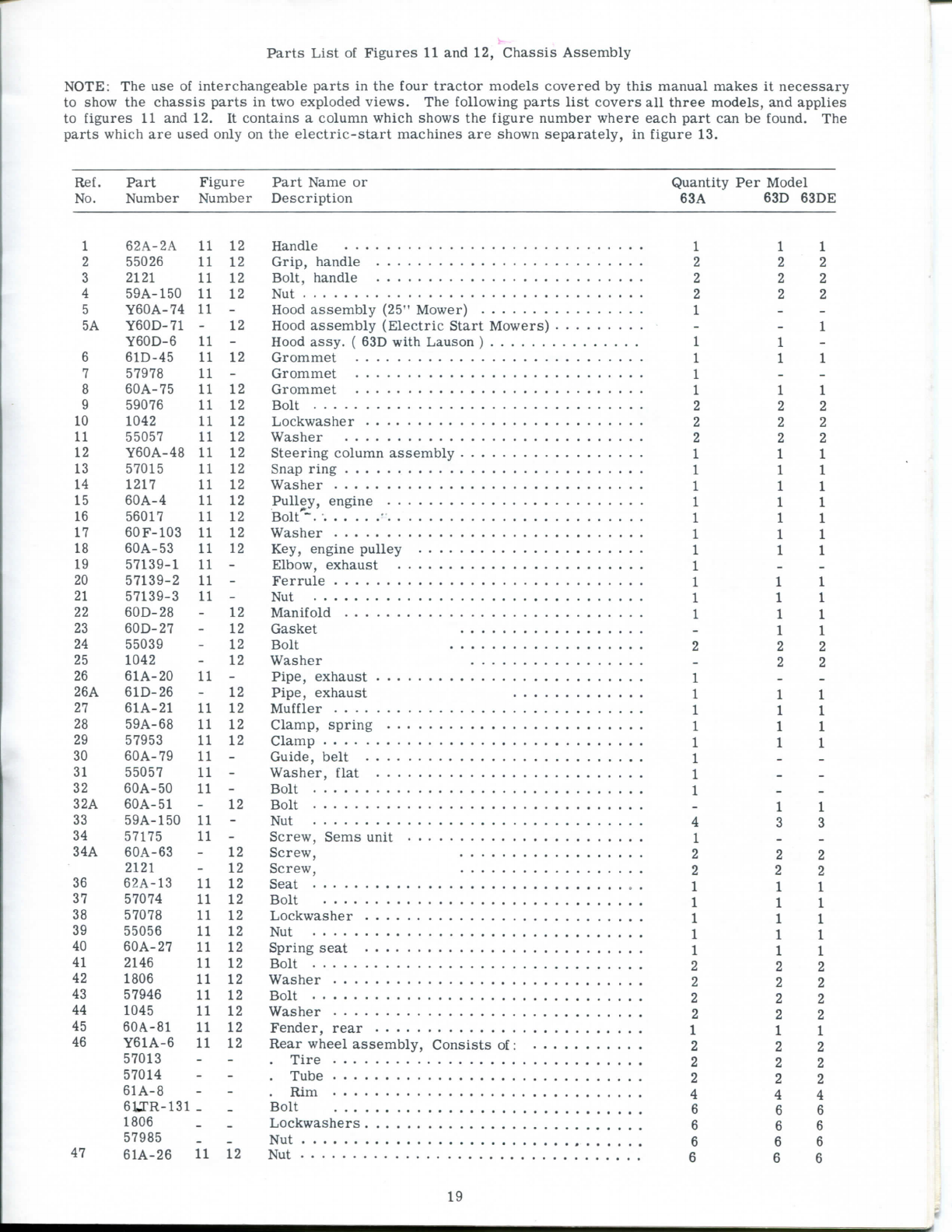

Parts

List

of

Figures

11and12,Chassis

Assembly

NOTE:

Theuse of

interchangeableparts

inthe

four

tractormodelscovered

by

this

manualmakes

itnecessary

to

show

thechassis

parts

in

twoexploded

views.

The

following

parts

list

coversallthreemodels,andapplies

to

figures

11and12.It

contains

a

column

which

shows

the

figure

numberwhereeach

part

can be

found.

The

parts

which

are

used

only

onthe

electric-startmachines

are

shown

separately,

in

figure

13.

Ref.PartFigurePartName

or

Quantity

Per

Model

No.

NumberNumberDescription

63A63D

63DE

1

62A-2A

11

12

1 1

2

55026

11

12 2 2

3 2121

11

12 2 2

4 59A-150

11

12 2 2

5 Y60A-74

11

-

1

- -

5A

Y60D-71 12

-

1

Y60D-6

11

-

1 1

-

6

61D-45

11

12

1 1

7

57978

11

---

8 60A-75

11

12

1 1

9

59076

11

12 2 2

10 1042

11

12 2 2

11

55057

11

12 2 2

12 Y60A-48

11

12

1 1

13

57015

11

12

1 1

14

1217

11

12

1 1

15

60A-4

11

12

1 1

16

56017

11

12

1 1

17

60F-103

11

12

1 1

18

60A-53

11

12

1 1 1

19

57139-1

11

-

1

--

20 57139-2

11

-

1 1

21

57139-3

11

-

Nut

1 1 1

22

60D-28

-

12

1 1

23

60D-27

-

12 Gasket

1 1

24

55039

-

12 2 2

25 1042

-

12 2 2

26

61A-20

11

-

1

- -

26A

61D-26

-

12

1 1 1

27

61A-21

11

12

Muffler

1 1 1

28

59A-68

11

12

1 1 1

29

57953

11

12

1 1 1

30 60

A-79

11

-

Guide,

belt

1

--

31

55057

11

-

Washer,

flat

1

--

32 60A-50

11

-

Bolt

1

--

32A

60A-51

12

Bolt

1 1

33

59A-150

11

-

Nut

4 3 3

34

57175

11

-

1

- -

34A 60A-63 12 2 2 2

2121 12 2 2 2

36

62A-13

11

12

1 1

37

57074

11

12

1 1

38

57078

11

12

1 1 1

39

55056

11

12

Nut

1 1 1

40

60A-27

11

12

1 1

41

2146

11

12

Bolt

2 2 2

42

1806

11

12 2 2

43

57946

11

12 2 2

44 1045

11

12 Washer 2 2 2

45

60A-81

11

12

1 1

46

Y61A-6

11

12 2 2 2

57013

- -

2 2

57014

- -

2 2

61A-8

- -

4 4

euR-isi

_ _

Bolt

6 6

1806

_

6 6

57985

_

6 6

47 61A-26

11

12 6 6

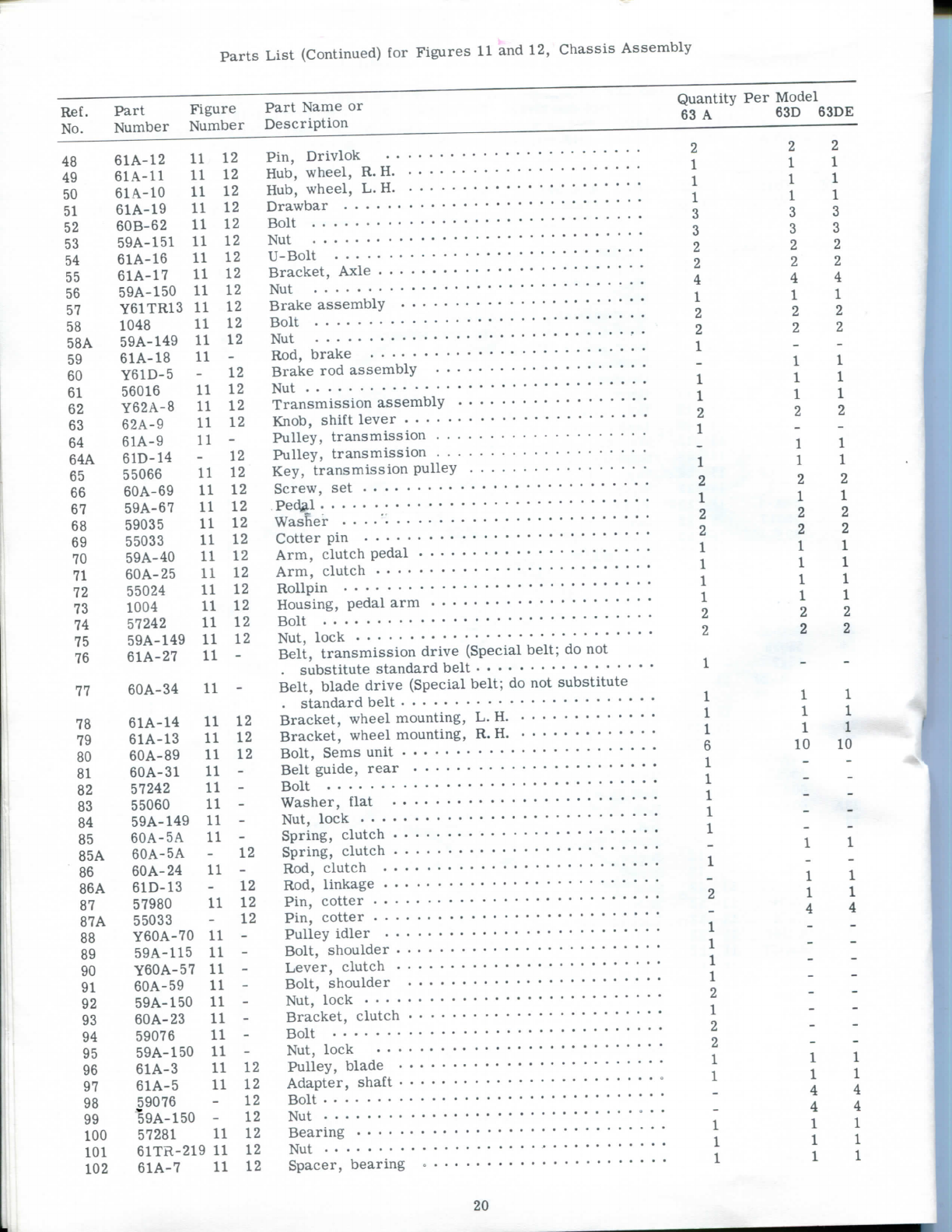

19

Parts

List(Continued)

for

Figures

11and12,Chassis

Assembly

Ref. Part Figure

No.

Number Number

48

61A-12

11 12

49

61A-11 11 12

50

61A-10

11 12

51

61A-19

11 12

52

60B-62

11 12

53

59A-151 11 12

54

61A-16

11 12

55

61A-17

11 12

56

59A-150

11 12

57

Y61TR13

11 12

58 1048

11 12

58A

59A-149

11 12

59

61A-18

11 -

60

Y61D-5

-12

61

56016

11 12

62 Y62A-8 11 12

63

62A-9 11 12

64

61A-9 11 -

64A

61D-14

-12

65

55066

11 12

66

60A-69

11 12

67

59A-67

11 12

68

59035

11 12

69

55033

11 12

70

59A-40

11 12

71

60A-25

11 12

72

55024

11 12

73 1004

11 12

74 57242

11 12

75

59A-149

11 12

76

61A-27

11 -

77

60A-34

11 -

78

61A-14

11 12

79

61A-13

11 12

80

60A-89

11 12

81 60A-31 11 -

82

57242

11 -

83

55060

11 -

84

59A-149

11 -

85

60A-5A 11 -

85A 60A-5A -12

86

60A-24

11 -

86A

61D-13

-12

87

57980

11 12

87A

55033

-12

88

Y60A-70

11 -

89

59A-115

11 -

90

Y60A-57 11 -

91

60A-59

11 -

92

59A-150

11 -

93 60

A-23 11 -

94

59076

11 -

95

59A-150

11 -

96

61A-3 11 12

97 61A-5 11 12

98

59076

-12

99

59A-150

-12

100

57281

11 12

101

61TR-219

11

12

102 61A-7 11 12

PartName

or

Description

Quantity

Per

Model

63A 63D

63DE

Pin,

Drivlok

Hub,

wheel,

R.H

Hub,

wheel,

L.H

Drawbar

Bolt

Nut

U-Bolt

Bracket,Axle

Nut

Brake

assembly

Bolt

Nut

Rod,brake

Brake

rod

assembly

Nut

Transmission

assembly

Knob,

shiftlever

Pulley,

transmission

Pulley,

transmission

Key,transmissionpulley

Screw,

set

Pec|3,l

Washer

Cotter

pin

Arm,

clutchpedal

Arm,

clutch

RoUpin

Housing,

pedal

arm

Bolt

Nut,

lock

Belt,transmissiondrive

(Special

belt;

donot

.substitutestandardbelt

Belt,bladedrive

(Special

belt;

donot

substitute

.standardbelt

Bracket,wheelmounting,

L.

H.

Bracket,wheelmounting,

R.

H

Bolt,

Sems

unit

Beltguide,rear

Bolt

Washer,flat

Nut,

lock

Spring,

clutch

Spring,

clutch

Rod,clutch

Rod,linkage

Pin,

cotter

Pin,

cotter

Pulleyidler

Bolt,shoulder

Lever,clutch

Bolt,shoulder

Nut,

lock

Bracket,clutch

Bolt

Nut,

lock

Pulley,

blade

Adapter,

shaft

Bolt

Nut

Bearing

Nut

Spacer,

bearing

2

1

1

1

3

3

2

2

4

1

2

2

1

1

1

2

1

1

2

1

2

2

1

1

1

1

2

2

1

1

1

6

1

1

1

1

1

1

2

1

1

1

1

2

1

2

2

1

1

2

1

1

1

3

3

2

2

4

1

2

2

1

1

1

2

1

1

2

1

2

2

1

1

1

1

2

2

1

1

1

10

1

1

4

2

1

1

1

3

3

2

2

4

1

2

2

1

1

1

2

1

1

2

1

2

2

1

1

1

1

2

2

1

1

1

10

20

This manual suits for next models

2

Other Springfield Lawn Mower manuals