4

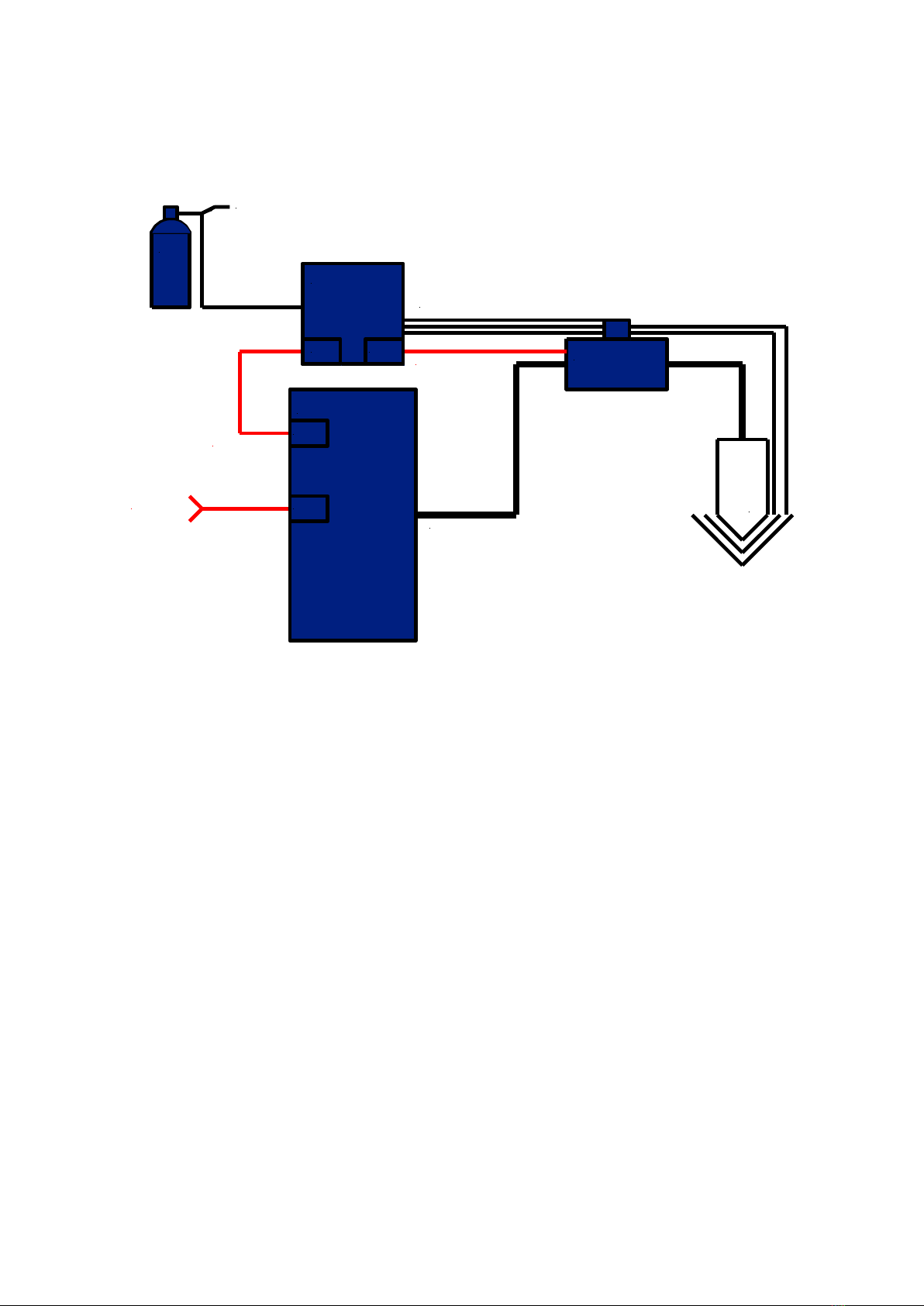

2. INSTALLATION

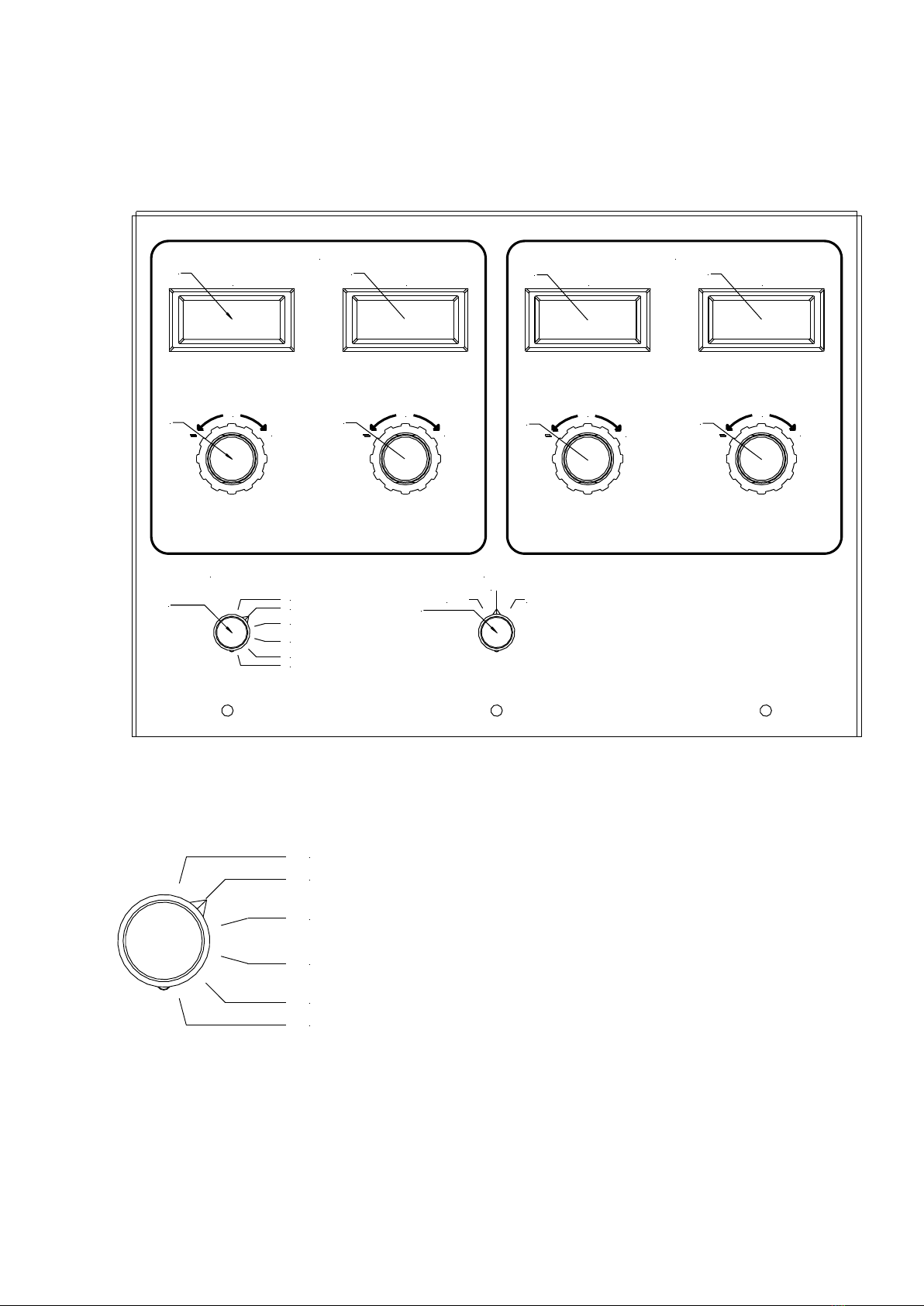

Below is a scheme over the principle of the system and its components. These instructions are

aimed at system builders with experience in mechanised plasma cutting. If such competence

is not available it is advised that SPT be contacted for guidance.

To obtain satisfactory cutting quality and economy it is vital that the CNC-machine be

equipped with a suitable height control device for plasma cutting. The plasma technology

requires a very well defined process control. The height control must be able to handle

different heights for ignition, piercing and cutting. Most robots can easily be programmed to

handle the process.

If a suitable height control system is not available one can be delivered by SPT. Contact us for

advice.

Electrical supply:

SPARCIN 4000: 3~50 Hz, 400V, 80A slow blow

Note that the SPARCIN 4000 is an inverter power source and it requires a stable power

supply. Make sure that the power supply is stable and within 400 V +6/-10 %. A circuit

breaker should be present at the wall socket.

Gas supply:

Connect the gases to the rear of the gas console. Use only 2-step pressure regulators of high

quality and adjust to 9-10 bar on each bottle. Also the compressed air shall be adjusted to 9-10

bar. The compressed air should be dry, oil free and free from particles.

Bear in mind that pressurized oxygen and oil is an explosive combination that can lead to loss

of life as well as destruction of property.

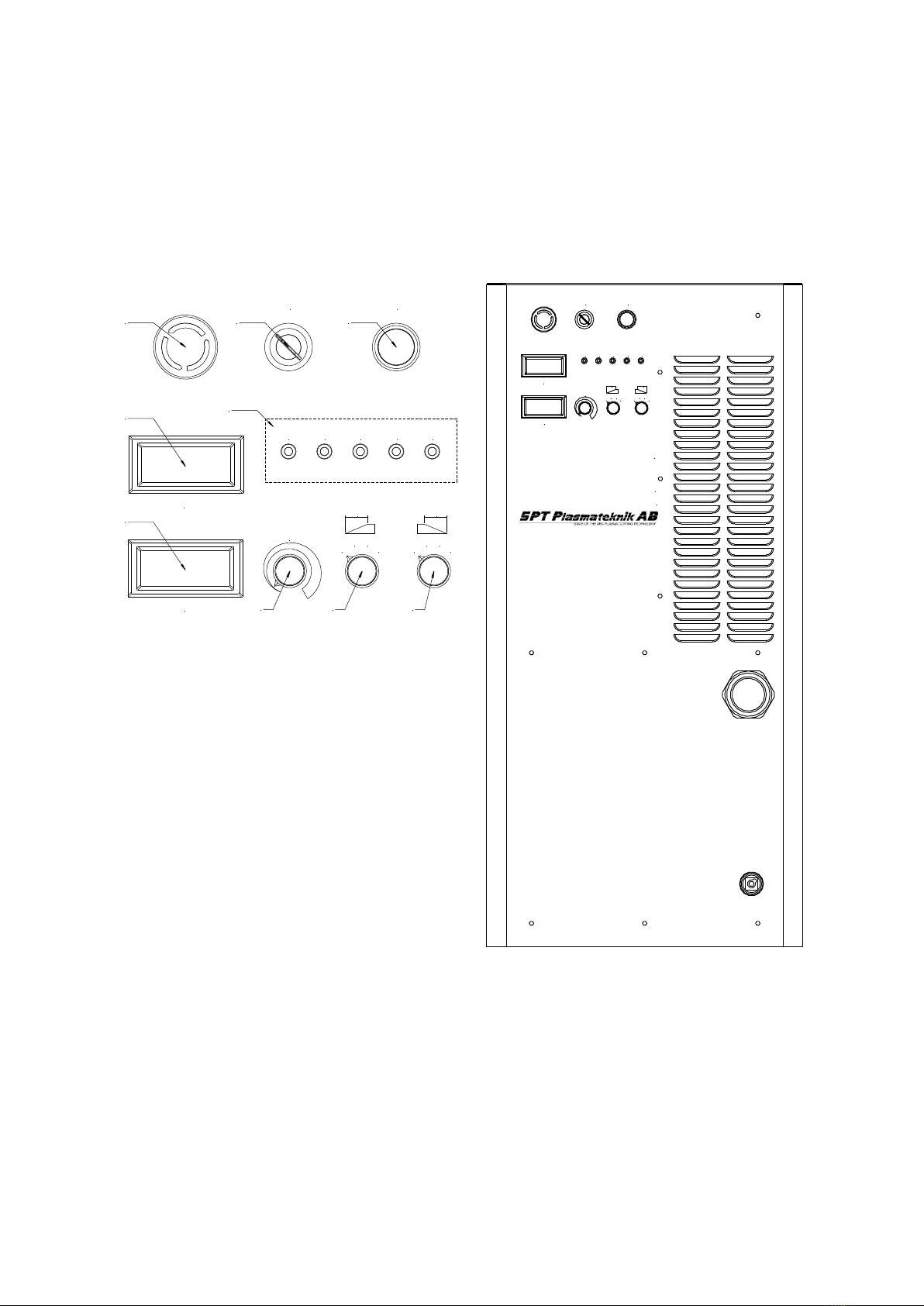

Remote control from robot or CNC

The plasma system is controlled via a multi-pole connector marked “CNC” on the rear panel

of the power source. This should be connected according to diagram further back in this

manual. The system is highly sensitive and it is therefore vital to connect it properly. Pins in

the connector that are not used by the remote control must be left unconnected. If they are

connected to a wire that is left unconnected in the other end this works as an antennae and this

will lead to unwanted behavior.

In some cases it may be necessary to screen the cables.

Safety

Only specially trained personnel should install the SPARCIN 4000 system. National law and

regulations must be followed. Note that parts of the system are electrically live when

connected even though the main power switch is off.