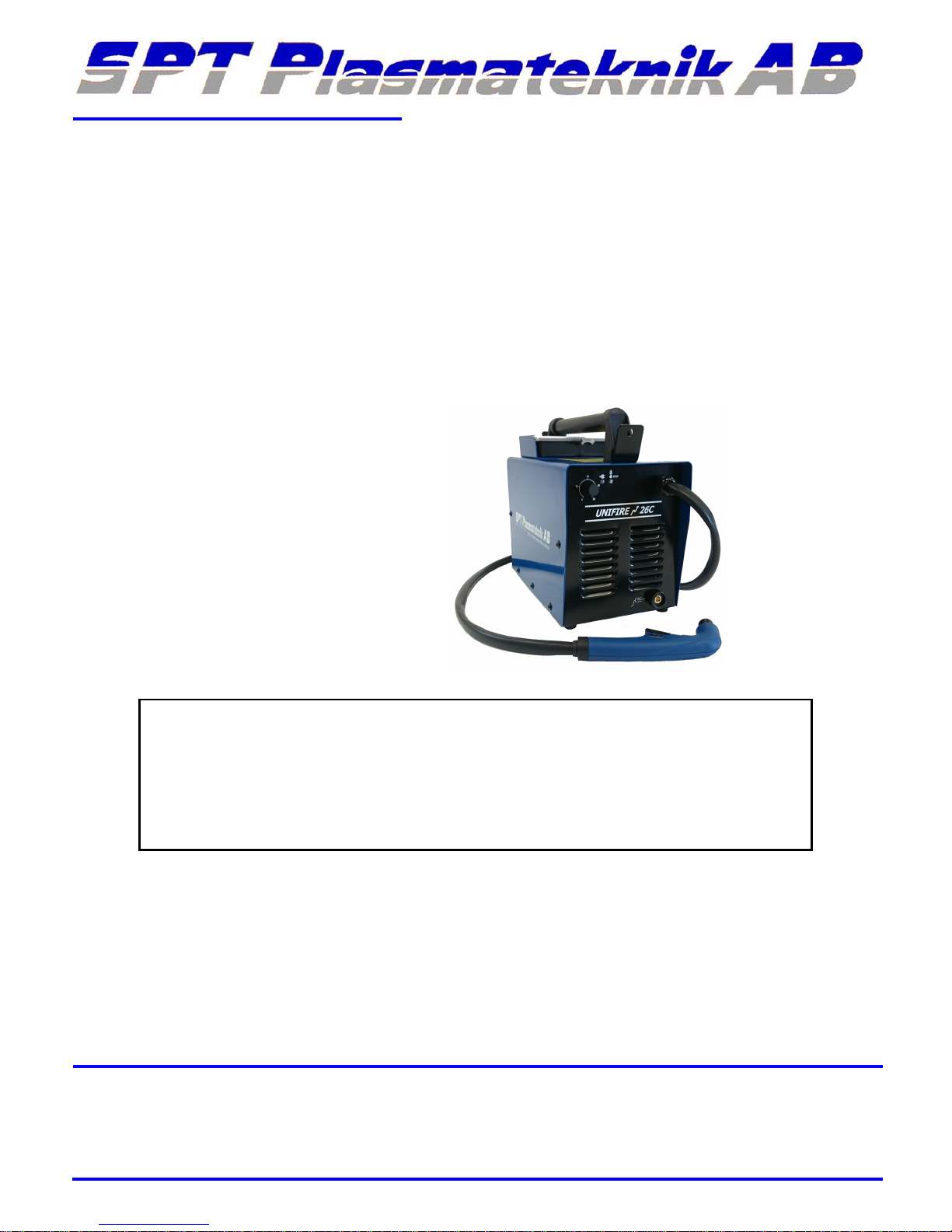

UNIFIRE

Therefore the power source is marked with the S-sign and operation under enhanced electrical

endangerment is allowed.

Attention! Always follow the local safety rules!

Endangerment through high voltage (HV)

A HV-igniter starts the pilot arc. The HV-supply is cut-off automatically after pilot arc has

struck.

Attention! Never touch nozzle or nozzle cap when power source is switched ON!

HV-ignition may establish electromagnetic fields and can influence:

-heart pace-makers

-electronic devices

Endangerment through electromagnetic interferences

The plasma cutting unit is in conformity with the conditions of the EN 50199

“Electromagnetic compatibility”. This standard is valid for arc welding and related processes

(plasma cutting) that come in use in commercial and private fields.

Warning!

Special precautions may be required if the plasma unit is used in private fields (for instance

screened cables etc.)

The user takes the full risk when installing and using the machine. He has to follow strictly the

instructions of the supplier. If electromagnetic interferences are noticed the user is to contact

the producer to solve the problem.

Recommendations to classify the environment (EN 50199):

Before the installation takes place the user has to value the environment for electromagnetic

problems and to take into consideration:

-Other mains supplies, control cables, signal and telecommunication lines along, above,

below or beside the installation

-Broadcasting or television installations

-Computers or other controls

-Safety devices, protection circuits

-The health of people in the area (heart pace makers, hearing aids etc.)

-Devices for measuring and calibrating

-The noise immunity of equipment around the installation, so that they are compatible

with electromagnetic interferences. Special measures may be required.

-The time of day that plasma cutting is performed

Recommendations to minimise interferences:

If interferences take place, the following should be done:

-Apply filter for mains connection

9