3

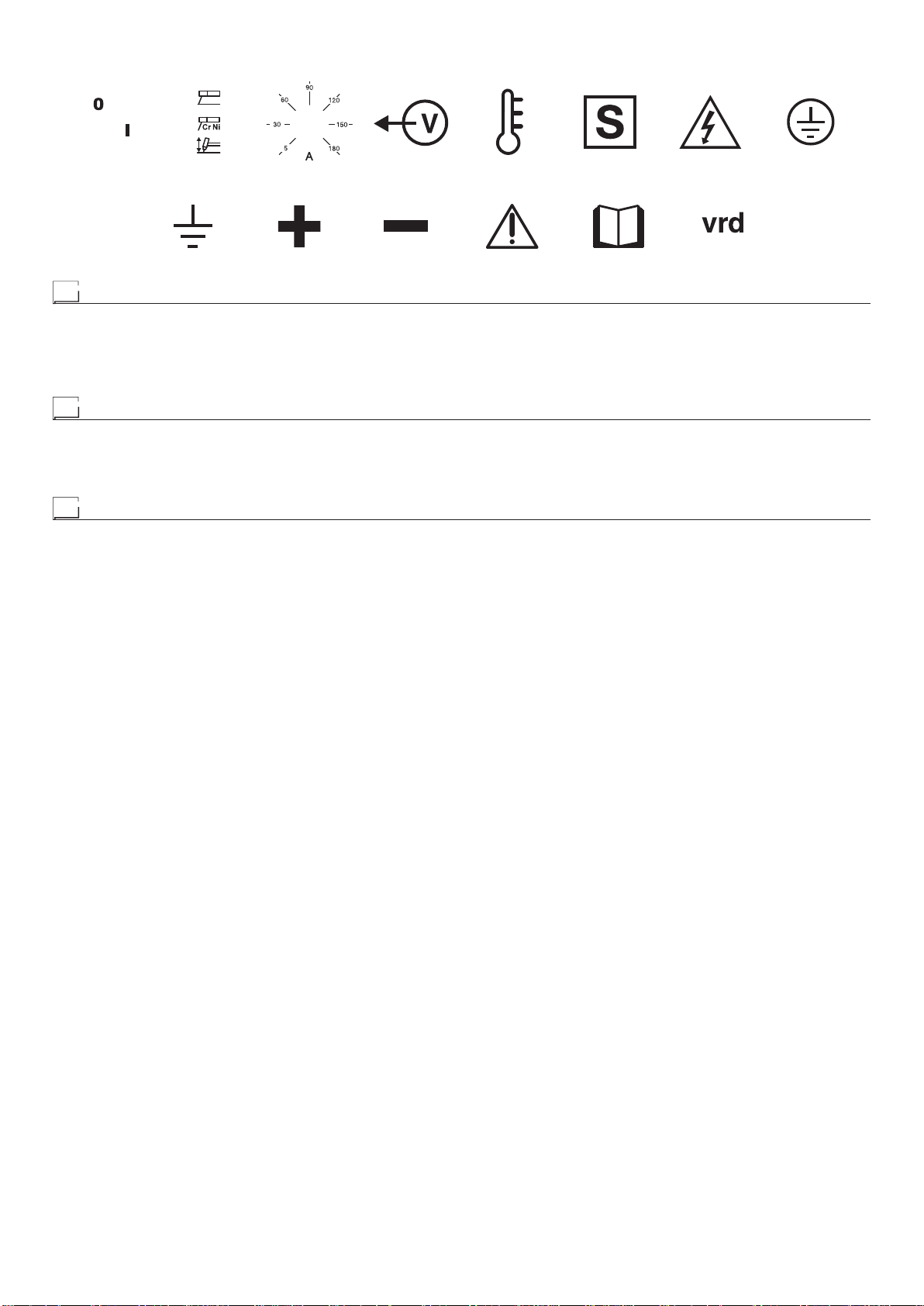

Usage limits (IEC 60974-1)

The use of a welding power source is typically discontinuous, in

that it is made up of effective work periods (welding) and rest pe-

riods (for the positioning of parts, the replacement of wire and

underflushing operations etc. This welding power source is di-

mensioned to supply a I2max nominal current in complete safety

for a period of work of 20% of the total usage time. The regula-

tions in force establish the total usage time to be 10 minutes. The

work cycle is considered to be 20% of this period of time. If the

permitted work cycle time is exceeded, an overheat cut-off occurs

to protect the components around the welding power source from

dangerous overheating. Intervention of the overheat cut-off is in-

dicated by the lighting up of yellow thermostat LED. After several

minutes the overheat cut-off rearms automatically (and the yellow

LED turns itself off) and the welding power source is ready for use

again. This generator is constructed in compliance with the IP23 S

protection level, meaning:

• That it is protected against the penetration of solid foreign bod-

ies with diameters in excess of Ø 12 mm.

•

That it is protected against water spray hitting the surface with

an angle of incidence up to 60°.

•

That the welding power source has been tested for withstanding

harmful effects due to water getting in when the moving parts on

the equipment are moving.

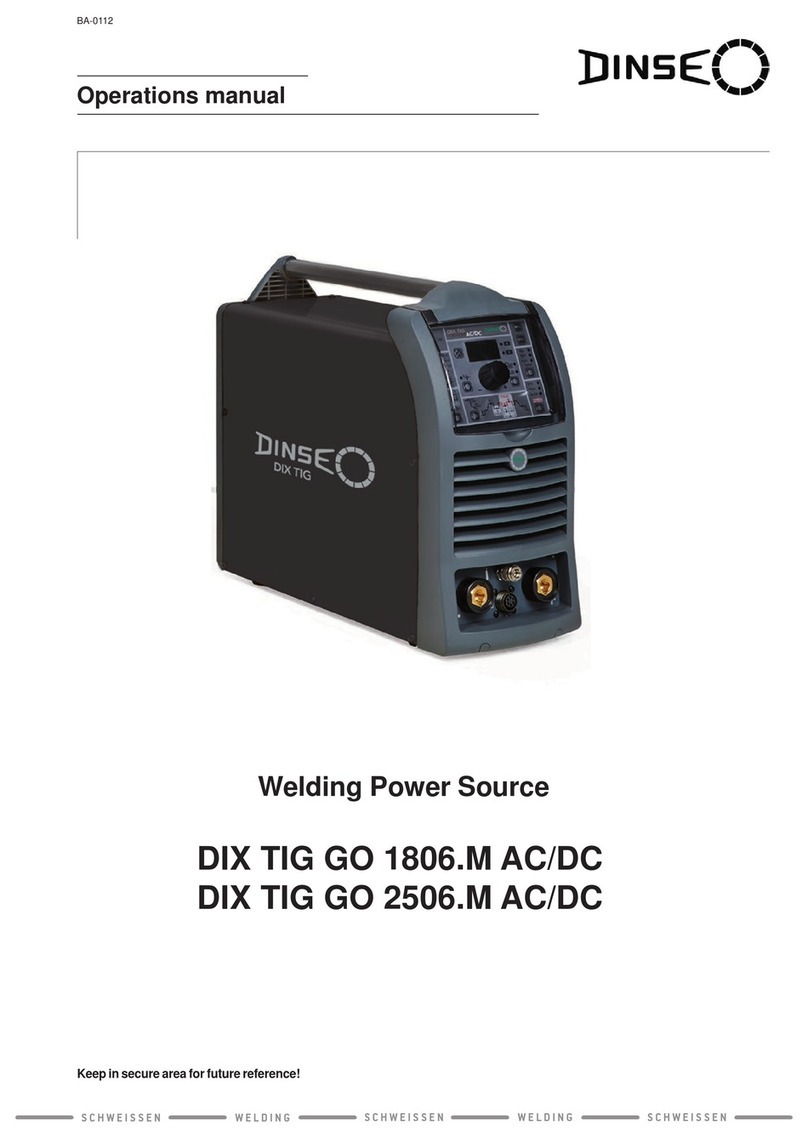

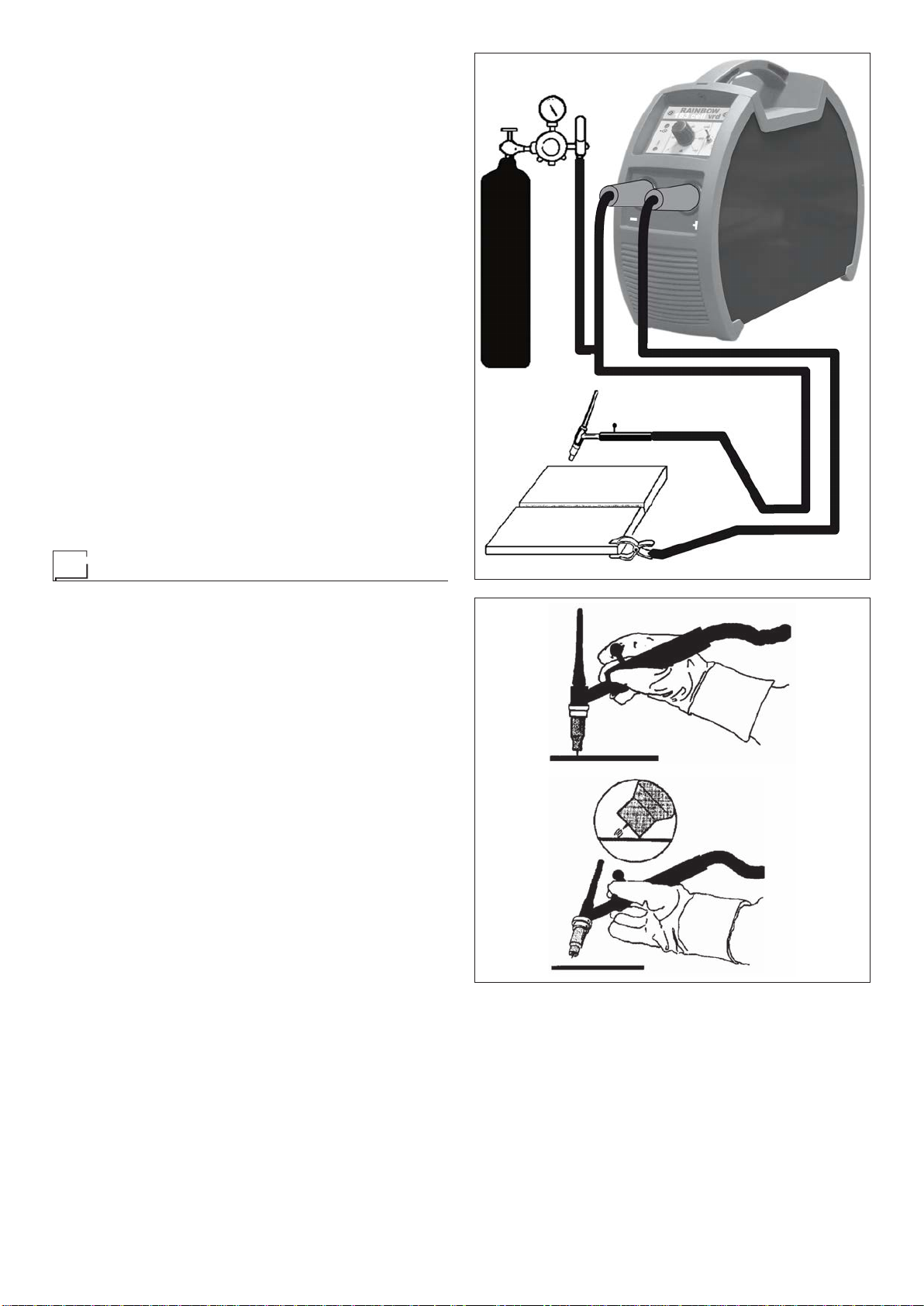

How to lift up the machine

This welding power source has a handle for picking it up and car-

rying it by hand.

NOTE: These hoisting and transportation devices conform to Eu-

ropean standards. Do not use other hoisting and transportation

systems.

Open the packaging

The system essentially consists of:

• DIX GO 1206.M C

• weld unit.

Upon receiving the system:

• Remove the welding generator and all relative accessories and

components from the packaging.

•

Check that the weld machine is in good condition, if not report

any problems immediately to the seller-distributor.

•

Make sure all ventilation grilles are open and that no foreign bod-

ies are blocking the air circulation.

Installation

The installation site for the system must be carefully chosen in or-

der to ensure its satisfactory and safe use.

The user is responsible for the installation and use of the system

in accordance with the producer’s instructions contained in this

manual.

Before installing the system the user must take into consideration

the potential electromagnetic problems in the work area. In particu-

lar, we suggest that you should avoid installing the system close to:

• Signalling, control and telephone cables.

• Radio and television transmitters and receivers.

• Computers and control and measurement instruments.

• Security and protection instruments.

Persons fitted with pace makers, hearing aids and similar equip-

ment must consult their doctor before going near a machine in

operation. The equipment’s installation environment must comply

to the protection level of the frame i.e. IP 23 S (IEC 60529 publi-

cation). The system is capable of working in environments where

working conditions are particularly hard. This system is cooled by

means of the forced circulation of air, and must therefore be placed

in such a way that the air may be easily sucked in and expelled

through the apertures made in the frame.

Connection to the electrical supply

Before connecting the welding power source to the electrical

supply, check that the machine’s plate rating corresponds to

the supply voltage and frequency and that the line switch of

the welding power source is in the “O” position.

This system has been designed for nominal voltage 230 V - 50/60

Hz. It can however work at 220 V and 240 V - 50/60 Hz without

any problem. Connection to the power supply must be carried out

using the tripolar cable supplied with the system, of which:

•

2 conducting wires are needed for connecting the machine to

the supply.

• The third, which is YELLOW GREEN in colour is used for mak-

ing the “EARTH” connection.

Connect a suitable load of normalised plug (2p + e) to the

power cable and provide for an electrical socket complete

with fuses or an automatic switch. The earth terminal must

be connected to the earth conducting wire (YELLOW-GREEN)

of the supply.

Table 2 shows the capacity values that are recommended for fus-

es in the line with delays.

NOTE 1: Any extensions to the power cable must be of a suitable

diameter, and absolutely not of a smaller diameter than the spe-

cial cable supplied with the machine.

NOTE 2: It is not advisable to plug up the welding power source

to motor-driven generators, as they are known to supply an un-

stable voltage.

Table 1

Model DIX

GO 1206.M C

Single-phase power supply 50/60 Hz V230

Mains supply: Zmax (*) Ω0,26

Power input @ I2Max kVA 11,3

Delayed fuse (I2@ 100%) A20

Power factor / cosφ 0,55 / 0,99

Maximum efficiency degree η0,74

Open circuit voltage (max) V105

Open circuit voltage (resting) V≤12

vrd - Intervention time at end of welding s≤0,3

vrd - LST LED indication

green

red V

VU2 > 35

U2≤35

Current range A5 ÷ 180

Duty cycle @ 100% (40°C) A100

Duty cycle @ 60% (40°C) A120

Duty cycle @ 20% (40°C) A180

Usable electrodes Ø mm 1,6 ÷ 4

Standards IEC 60974-1

IEC 60974-10

Insulation class IP 23 S

Protection class F

Dimensions mm 390-300-135

Weight kg 6,5

(*) Mains supply Zmax: maximum impedance value allowed for the grid

according to the EN/IEC 61000-3-11 standard.

WARNING: This equipment does not comply with EN/IEC 61000-3-12.

If it is connected to a public low voltage system, it is the responsibil-

ity of the installer or user of the equipment to ensure, by consultation

with the distribution network operator if necessary, that the equipment

may be connected.