Spudnik 8400 Owner's manual

OWNER’S / OPERATOR’S MANUAL

Part # 290092 UP TO 2004

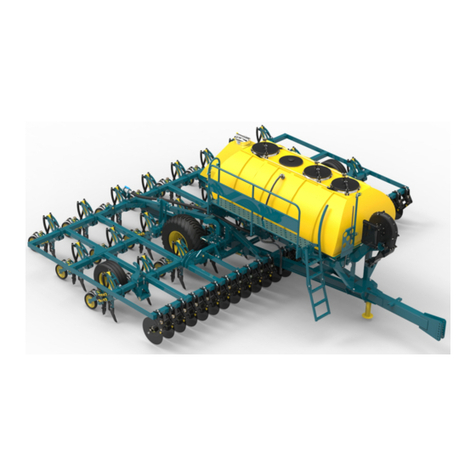

MODEL 8400/8600

PLANTER

Service Centers

Phone:(208)785-0480-Fax: (208)785-1497

E-Mail: [email protected]

Web Site:www.spudnik.com

BLACKFOOT PASCO GRAFTON

584 West 100 North 5802 North Industrial Way 1410 12th St. West

P.O. Box 1045 Pasco, Wa. 99301 Grafton, Nd. 58237

Blackfoot, ID 83221 Phone (509) 543-7166 Phone (701) 352-9603

Phone (208)785-0480 Fax (509) 543-7169 Fax (701) 352-9610

Fax (208)785-1497

HEYBURN PRESQUE ISLE

300 Centennial Dr. 110 Airport Dr.

Heyburn, ID 83336 Presque Isle, Me. 04769

Phone (208)436-8052 Phone (207) 764-4686

Fax (208) 436-9170 Fax (207) 764-4674

02/11/04 2

TABLE OF CONTENTS

PAGE

Introduction……………………………………………………………………………….. 3

Warranty…………………………………………………………………………………... 4

Reporting Safety Defects ..…………………………………………………………….. 5

Safety……………………………………………………………………………………… 6,7

Planter Speed & Seed Spacing Setup..……………………………………………… 9,10

Lubrication & Maintenance..……………………………………………………………. 11

Machine Parts Breakdown

Table of Contents ………………………………………………………………………..

12

Electrical Schematics …………………………………………………………………… 46

02/11/04 3

INTRODUCTION

Welcome to the SPUDNIK line of potato handling equipment. We appreciate

your decision to make our equipment a part of your operation, and look forward to a

long-term partnership. We strive to put the best quality and workmanship into each of

our machines, and hope as you use your MODEL 8400 or 8600 SCOOP/CUP

PLANTER, that you will find this to be true. This owner’s / operator’s manual has been

prepared to aid you in the safe operation and service of your Planter.

Read this manual carefully to learn how to operate your machine safely and

within the design limits of this machine. Failure to do so could result in personal injury

and/or damage to the machine.

This manual is to be considered an important part of this machine and should

accompany it when moved from location to location.

Warranty is provided, as a part of the SPUDNIK EQUIPMENT COMPANY LLC

service program, for customers who operate and maintain their equipment as outlined in

this manual.

OWNER REGISTRATION

Name _____________________________________________

Address ___________________________________________

City ______________________________________________

State / Province _____________________________________

Country ___________________________________________

Model Number ____________ Serial Number _____________

Purchase Date ______________________________________

P.O. Box 1045 - 584 West 100 North - Blackfoot, Idaho 83221

Phone: 208-785-0480 - Fax: 208-785-1497 - www.spudnik.com - E-mail: [email protected]

WARRANTY FOR NEW AGRICULTURAL MACHINERY

A. GENERAL PROVISIONS –The warranties described below are provided by Spudnik Equipment Company LLC.

to the original purchasers of the Agricultural Machinery from Spudnik or authorized Spudnik dealers. These

warranties apply only to equipment intended for sale in the U.S. Under these warranties, Spudnik Equipment

Company LLC will repair or replace, at its option, any covered part which is found to be defective in material or

workmanship during the applicable warranty term. Warranty service must be performed by Spudnik or an authorized

Spudnik dealer which will use only new or remanufactured parts or components furnished by Spudnik. Warranty

service will be performed without charge to the purchaser for parts and labor. The purchaser will be charged for any

premium charged for overtime labor requested by the purchaser, and for any service and/or maintenance not directly

related to any defect covered under the warranties below

B. WHAT IS WARRANTED – All new Spudnik Equipment Company LLC products are warranted for the

number of months or operating hours specified below.

PRODUCT WARRANTY TERM

Rollers, sprockets, roller chain, belt lacing,

bearings

183 days or 720 hrs whichever comes first

All paint to include: Insufficient coverage,

failure of paint, excessive runs and

imperfections. Excessive runs not to exceed

more than 15% of the paint ed surface on the

machine.

12 months from date of purchase

All other materials and workmanship 12 months from date of purchase

C. WHAT IS NOT WARRANTED –(1) Electrical motors or electrical components unless approved by

vendor. (2) Used products. (3) Rock chip damage and other abuse to painted surfaces. (4) Any product

that has been altered or modified in ways not approved by Spudnik Equipment Company LLC.

(5) Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure

to follow the product’s Operator Manual recommendations. (6) Using machine for other than normal

moving of agricultural products during planting, harvest, and processing seasons. Agricultural products

to include: Potatoes, beets, onions, carrots, grains, etc. (7) Changes to sales orders that have been

approved by customer that are incorrect and have the customers’ signature.

D. SECURING WARRANY SERVICE –To secure warranty service, purchaser must (1) report the product

defect to Spudnik and/or authorized dealer and request repair within the applicable warranty term. (2)

Present evidence of the warranty start date. (3) Make the product available to Spudnik or the dealer

within a reasonable period of time and (4) return all faulty parts to Spudnik.

E. WARRANTY SERVICE – All warranty request must (1) be approved by Spudnik Equipment Company

LLC. (2) All warranty must be completed within one year of purchase unless an agreement is made with

Spudnik Equipment Company LLC, to do otherwise, prior to the end of the year. (3) Spudnik Equipment

Company LLC must approve all exceptions to this policy.

(Effective 5/04/2004)

02/11/04 5

SAFETY

You are responsible for the safe operation and maintenance of your SPUDNIK

PLANTER. All operators and anyone doing work or maintenance on Planter must be

trained in the operation, maintenance procedures and related SAFETY information

contained in this manual. All operators and maintenance personnel must receive this

training at least annually to be in compliance with OSHA regulation 1928.57. This

manual is a guide to good safety practices that should be followed while operating

Planter.

The operator is the most important safety device on the Planter. It is the operator’s

responsibility to read and understand ALL operating and safety instructions in this

manual.

ANY UNAUTHORIZED MODIFICATIONS TO MACHINE IS CONSIDERED A

BREACH OF CONTRACT AND REMOVES ALL LIABILITY FROM THE

MANUFACTURER. Unauthorized modification may impair function of machine and/or

safety and could affect the life and warranty of the Planter.

THINK SAFETY! WORK SAFELY!

THE LIFE YOU SAVE MAY BE YOUR OWN!

02/11/04 6

SAFETY

SAFETY ALERT SYMBOL

THE SAFETY ALERT SYMBOL MEANS:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The SAFETY ALERT SYMBOL identifies important safety information on the safety

decals and in this manual. When you see this symbol be alert to the possibility of

personal injury or death.

SIGNAL WORDS:

DANGER, WARNING, and CAUTION are signal words with messages:

DANGER: An immediate and specific hazard, which WILL result in

severe injury or death if proper precautions are not taken.

WARNING: A specific hazard or unsafe practice, which COULD result in

severe injury or death.

CAUTION: Unsafe practices, which COULD result in personal injury if

proper precautions are not taken.

02/11/04 7

SAFETY

GENERAL SAFETY PRACTICES

• The primary responsibility for safe operation of the Spudnik Planter with the

owner/operator.

• OSHA (Occupational Safety and Health Administration) requires that all operators be

trained at the time of initial assignment, and annually thereafter by the employer, in

the safe operation of the Planter.

• Read and understand the operator manual before operating, maintaining, or

adjusting Planter.

• Untrained individuals and children should not be allowed on or around the Planter at

anytime.

• Keep hands, feet, long hair, and clothing away from moving and/or rotating parts.

• Never wear ill-fitting baggy or frayed clothing when working around or on any drive

system component.

• Do not attempt to service, lubricate, clean or adjust Planter while it is running.

• Inspect all mechanisms before starting Planter and replace all worn or damaged

parts.

• Make sure all guards and shields are properly installed and secured before

operating Planter.

• Replace all worn or missing bolts with SAE Grade 5 or better unless specifically

stated otherwise.

• When working on machine parts supported by hydraulic cylinders, ALWAYS support

structure by some other means than cylinders.

• Before applying pressure to the hydraulic system make sure all components, fittings,

steel lines, and hoses are tight and undamaged.

• Do not attempt to ride or mount while the Planter is moving.

02/11/04 8

Planter Setup

Row Spacing – 32”, 34”, 36”, 38”

Requires changing the length of the hopper top tube and the drive shaft

couplings.

Unbolt the hopper, move the hopper feed chain trays, row units, and

wheels to the correct spacing, and then reassemble with the new parts.

Seed Spacing – (Mechanical Drive) The seed spacing sprocket on the jack shaft

behind the drive wheel is generally a tooth count of 2 times the desired spacing

in inches (example: a 10” spacing requires a 20 tooth sprocket). However, the

amount of wheel slip which depends on soil type, will usually require the use of a

sprocket at least one or two teeth smaller than the nominal.

Part # Description

881287 SPRCKT,60A12x1-1/4" BORE 2003 MDL

881288 SPRCKT,60A13x1-1/4" BORE 2003 MDL

881289 SPRCKT,60A14x1-1/4" BORE 2003 MDL

881290 SPRCKT,60A15x1-1/4" BORE 2003 MDL

881291 SPRCKT,60A16x1-1/4" BORE 2003 MDL

881292 SPRCKT,60A17x1-1/4" BORE 2003 MDL

881293 SPRCKT,60A18x1-1/4" BORE 2003 MDL

881294 SPRCKT,60A19x1-1/4" BORE 2003 MDL

881295 SPRCKT,60A20x1-1/4" BORE 2003 MDL

881296 SPRCKT,60A21x1-1/4" BORE 2003 MDL

881297 SPRCKT,60A22x1-1/4" BORE 2003 MDL

881298 SPRCKT,60A23x1-1/4" BORE 2003 MDL

881299 SPRCKT,60A24x1-1/4" BORE 2003 MDL

881300 SPRCKT,60A25x1-1/4" BORE 2003 MDL

881301 SPRCKT,60A26x1-1/4" BORE 2003 MDL

881302 SPRCKT,60A27x1-1/4" BORE 2003 MDL

881303 SPRCKT,60A28x1-1/4" BORE 2003 MDL

Planting Depth - is adjusted with the gage wheel on each row unit.

Seed Switch Gate – the switches which turn the feed chains on and off must be

adjusted so that they are clear of the target when the gate is down, and fully

actuated when up. Also the weights on the gate can be increased or moved out

to keep the gate moving up positively when it empties.

Covering Discs – are adjustable for angle, depth, and width.

Tighten idlers – on row unit drive chain, mechanical drive wheel, hopper chain,

and chemical box drives.

02/11/04 9

Singulation sprocket – controls the ability of the cup chain to eliminate extra

seed pieces.

The size of the sprocket, and the speed of the chain are interrelated. The

singulation sprocket can be made smaller for slower chain speeds (lower ground

speeds, and wider seed spacing), and larger for faster chain speeds (higher

ground speeds and smaller seed spacing).

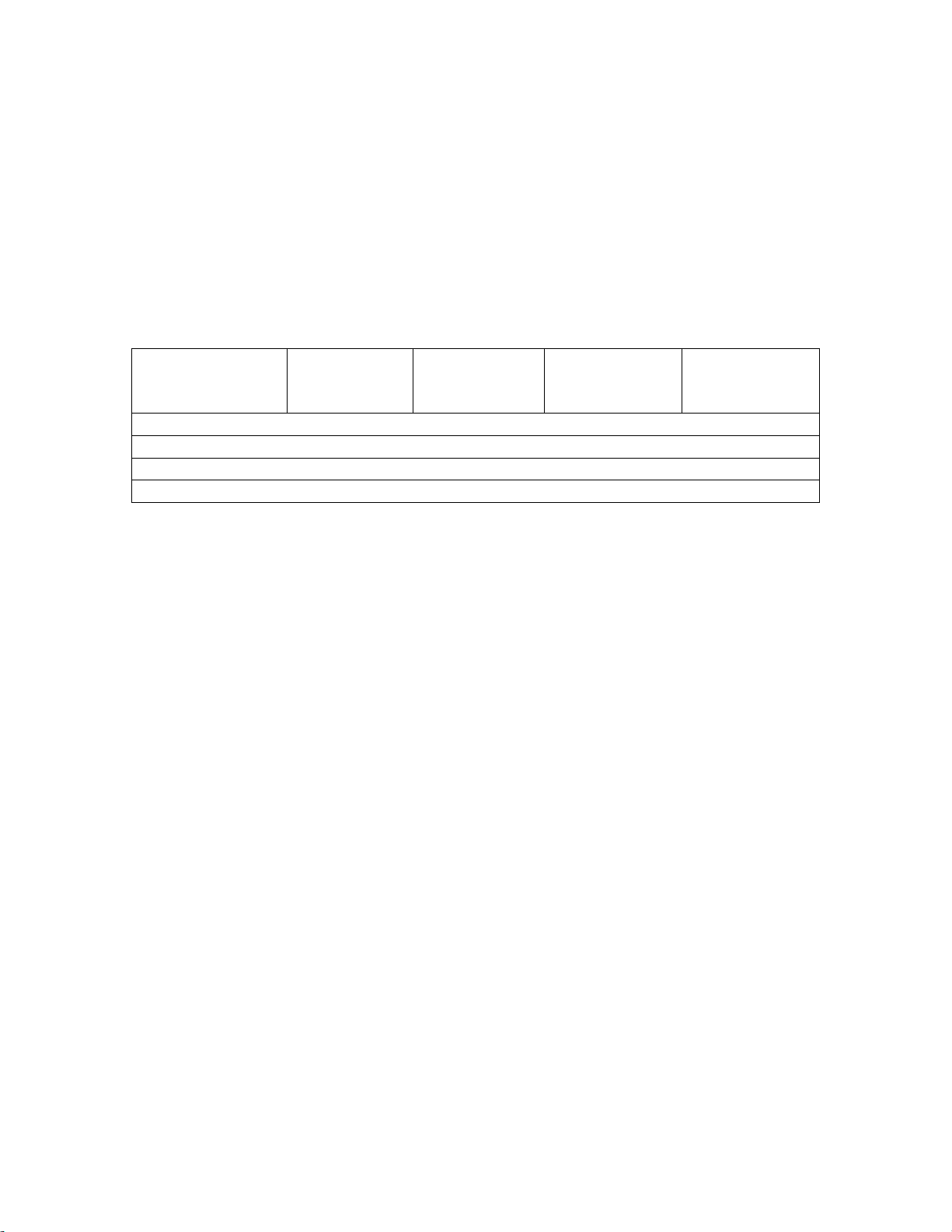

Singulator sprocket choice:

Choose the preferred planting speed and seed spacing. From the chart below,

choose the singulator sprocket size that corresponds with speed and seed

spacing. If the seed is large, a slightly slower speed, or a larger singulator

sprocket will be indicated on the chart. The opposite is true if the seed is smaller.

Operating

speed in

seeds / minute

Singulator

sprocket

size

M.P.H. @

12” seed

spacing

M.P.H. @

10” seed

spacing

M.P.H. @

8” seed

spacing

500 15 5.6 4.7 3.8

400 13-15 4.6 3.8 3.0

300 11-13 3.4 2.8 2.2

200 7-9 2.3 1.9 1.5

The singulator sprocket is located at the top rear of the row unit. There are five

sprocket choices. The 7-tooth sprocket mounts in the holes nearest to the outer

edge and the 15-tooth sprocket mounts in the holes farthest from the edge of the

center section of the row unit. The other sprockets mount in their respective

holes.

Part # Description

881211 SPRCKT,550A7x 1/2" BORE W/BRNG&BUSHING

881208 SPRCKT,550A9x 1/2" BORE W/BRNG&BUSHING

881212 SPRCKT,550A11x 1/2" BORE W/BRNG&BUSHING

881209 SPRCKT,550A13x 1/2" BORE W/BRNG&BUSHING

881213 SPRCKT,550A15x 1/2" BORE W/BRNG&BUSHING

Final adjustment:

The planter should now be run in the field to do the final adjustments. The field

should be essentially level where the setup is done.

Disengage the shakers by moving them in until the vibration is slight.

Start at the predetermined speed and observe the chain for skips and doubles.

Note: Adequate seed must be in the bowl to correctly set up the planting

unit. See the next section.

If there are essentially no skips, speed up until some skips are observed. If too

many skips are produced, slow down until very few skips. From this base speed,

slow down in increments of 0.1 mph until skips are within the acceptable range. If

this speed is very far from the desired planting speed a larger or smaller

singulator sprocket should be installed and process repeated.

Change the singulation sprocket only if skips cannot be eliminated (chain too

fast), or doubles cannot be reduced acceptably (chain too slow).

Once the singulator sprocket and planting speed is determined, raise the

secondary (top) vibrator to further reduce doubles. Take care too not unduly

increase the skips.

02/11/04 10

Seed level in bowl - If there is not adequate seed in the bowl, skips will result.

Adjust the weight on the seed door to keep adequate seed in the bowl. Adding

weights increases the bowl level.

The maximum seed level should be one inch below the top edge of the seed

weight door at the rear. The bowl level should be observed while planting

because the bowl may overfill when stopping or lifting the planter.

Speed of feed chains and lift cylinders – is adjusted with the tractor hydraulic

flows.

Specifications

Weight: 6-Row -12,500 lb.

4-Row -9,000 lb.

Hopper Capacity: 4-Row 7,000 to 8,000 lb.

6-Row 11,000 to 12,000 lb.

02/11/04 11

LUBRICATION AND MAINTENANCE

• All wheel bearings and wheel hubs should be greased and packed at least

once a year.

• Check wheel lug nuts daily.

• Check tire pressure daily (for 11.2-24/4 16 PLY tire - 54 P.S.I.)

(for 12.5L-16 12 PLY support wheel - 56 P.S.I.)

(for 18/8.50-8/4 gage wheel – 22 P.S.I.)

• To avoid contamination of product all hydraulic fittings must be checked daily

for leaks and replaced or tightened as necessary.

• All bearings are of sealed type and are lubricated by manufacturer. Bearings

will only need to be greased at start of season. Over greasing sealed

bearings will result in seal being broken and rapid failure of bearing. If seal is

broken, bearing should be greased daily until replaced. One pump of grease

at start of season is sufficient.

02/11/04 12

MACHINE PARTS BREAKDOWN

Table of Contents Page.

SAFETY LABELS & SHIELDS

MECHANICAL DRIVE SHIELD ASSEMBLY (OPTION) 17

SAFETY LABEL PLACEMENT 15, 16

SAFETY LABELS 13, 14

PLANTER ASSEMBLIES

CASTER, CRAZY WHEEL ASSEMBLY 27

GAGE WHEEL ASSEMBLY 20

HILLING COULTER ASSEMBLY 24

HILLING COULTER HUB ASSEMBLY 25

HOPPER ASSEMBLY 23

MAIN DRIVE TIRE ASSEMBLY 28

MAIN FRAME ASSEMBLY 26

ROW UNIT ASSEMBLY 18, 19

ROW UNIT COMPONENT ASSEMBLIES 21

ROW UNIT DRIVE ASSEMBLY 29

SEED CONVEYOR ASSEMBLY 22

PLANTER OPTIONS

END TOW HITCH ASSEMBLY (OPTION) 40

HOPPER EXTENSION AND CATWALK (OPTION) 37

MARKER ARMS, 4-ROW PLANTER (OPTION) 35

MARKER ARMS, 6-ROW PLANTER (OPTION) 36

MICROBAND CHEMICAL BOXES ASSEMBLY (OPTION) 33, 34

PLANTER FURROW SHOES (OPTION) 30

REAR TOOL BAR ASSEMBLY (OPTION) 39

ROW UNIT HYDRAULIC DRIVE ASSEMBLY (OPTION) 32

ROW UNIT MECHANICAL DRIVE ASSEMBLY (OPTION) 31

TARP ASSEMBLY (OPTION) 38

PLANTER HYDRAULIC

FOUR CASTERS, CRAZY WHEELS HYDRAULIC ASSEMBLY

(6-ROW PLANTER ONLY)

42

MARKER ARMS HYDRAULIC (OPTION) 45

SEED CONVEYOR HYDRAULIC DRIVE ASSEMBLY 41

THREE CASTERS, CRAZY WHEELS HYDRAULIC ASSEMBLY

(6-ROW PLANTER ONLY)

43

TWO CASTERS, CRAZY WHEELS HYDRAULIC ASSEMBLY

(4-ROW PLANTER ONLY)

44

ELECTRICAL

CLOSE-LOOP LEADER-FOLLOWER PLANTER CONTROL 47 – 52

ELECTRICAL ASSEMBLY 46

SAFETY LABELS

ITEM 1

ITEM 2

ITEM 3

ITEM 4

SAFETY LABELS

ITEM# PART# DESCRIPTION QTY

02/11/04 13

1 300087 LABEL,WARNING,EXPOSED,DRIVE,CAN CAUSE 4

2 300086 LABEL,CAUTION,MOVING,DRIVES,CAN CAUSE 5

3 300097 LABEL,WARNING,HIGH,PRESSURE,OIL,CAN 2

4 300094 LABEL,WARNING,MOVING,MACHINERY,CAN 2

SAFETY LABELS

ITEM 1

300089

ITEM 3

WARNING

CRUSHING HAZARD

KEEP HANDS AND

FEET AWAY FROM

MACHINERY WHILE

RUNNING.

300154

WARNING

MOVING MACHINE

Can cause severe

injury or death.

Do not mount or

dismount moving

machine.

300088

ITEM 2

SAFETY LABELS

ITEM# PART# DESCRIPTION QTY

02/11/04 14

1 300089 LABEL,CAUTION,LOW,SPEED,TIRE,CAN,CAUSE 2

2 300088 LABEL,WARNING,MOVING,MACHINE,CAN,CAUSE 2

3 300154 LABEL,WARNING,CRUSHING HAZARD 2

SAFETY LABEL PLACEMENT

BEHIND ALL SHIELDS

WARNING

CRUSHING HAZARD

CRUSHING HAZARD

KEEP HANDSAND

FEETAWAY FROM

MACHINERYW

HILE

RUNNING.

KEEP HANDS AND

FEETAWAY FROM

MACHINERYWHILE

RUNNING.

300154

300154

WARNING

CRUSHINGHAZARD

CRUSHINGHAZARD

KEEPHANDS AND

FEETAWAY FROM

MACHINERYWHILE

RUNNING.

KEEPHANDS AND

FEETAWAY FROM

MACHINERYWHILE

RUNNING.

300154

300154

.

WARNING

CRUSHING HAZARDCRUSHING HAZARD

KEEP HANDS AND

FEET AWAY FROM

MACHINERY WHILE

RUNNING.

KEEP HANDS AND

FEET AWAY FROM

MACHINERY WHILE

RUNNING.

300154300154

3

4

1

.

2

5

6

SAFETY LABEL PLACEMENT

ITEM# PART# DESCRIPTION QTY

02/11/04 15

1 300097 LABEL,WARNING HIGH PRESSURE OIL CAN CAUS 2

2 300154 LABLE,WARNING CRUSHING HAZARD 2

3 300094 LABEL,WARNING MOVING MACHINERY CAN CAU 2

4 300089 LABEL,CAUTION,LOW,SPEED,TIRE,CAN,CAUSE 2

5 300086 LABEL,WARNING MOVING DRIVES CAN CAUSE 3

6 300087 LABEL,WARNING EXPOSED DRIVE CAN CAUSE 3

SAFETY LABEL PLACEMENT

BEHIND ALL SHIELDS

4

3

2

1

4

WARNING

MOVING MACHINE

Can cause severe

injuryor death.

MOVING MACHINE

Can cause severe

injuryor death.

Donot mount or

dismountmoving

machine.

Donot mount or

dismountmoving

machine.

300088300088

WARNING

MOVING MACHINE

Can cause severe

injuryor death.

MOVING MACHINE

Can cause severe

injuryor death.

Donot mount or

dismountmoving

machine.

Donot mount or

dismountmoving

machine.

300088300088

WARNING

MOVING MACHINE

Can cause severe

injury or death.

MOVING MACHINE

Can cause severe

injury or death.

Do not mount or

dismount moving

machine.

Do not mount or

dismount moving

machine.

300088

55

This manual suits for next models

1

Table of contents

Popular Seeder manuals by other brands

GREAT PLAINS

GREAT PLAINS Turbo Max 2400TM Assembly manual

AerWay

AerWay AWATS-100-AG-4 Owner's/operator's manual

Equalizer

Equalizer Econo 4000E Operator's manual

GREAT PLAINS

GREAT PLAINS 3S-3000-3210 Operator's manual

Apex Digital

Apex Digital XA1200 Operation manual

John Shearer

John Shearer Pasture Renovation Drill Operator's manual