59

3.5 Heat sink temperature limit

For safety reasons the heat sink temperature is limited to 85 °C. At ambient tempera-

tures of more than 45 °C the heat sink temperature may reach 80 °C. In this event the

maximum inverter output is reduced temporarily. If the temperature rises above 85 °C the

device switches off automatically in order to prevent thermal overload.

3.6 Integrated overvoltage protection

On the DC side, the central inverter has a 750 V over-voltage arrestor from positive and

negative pole against ground in each case.

4 Installation

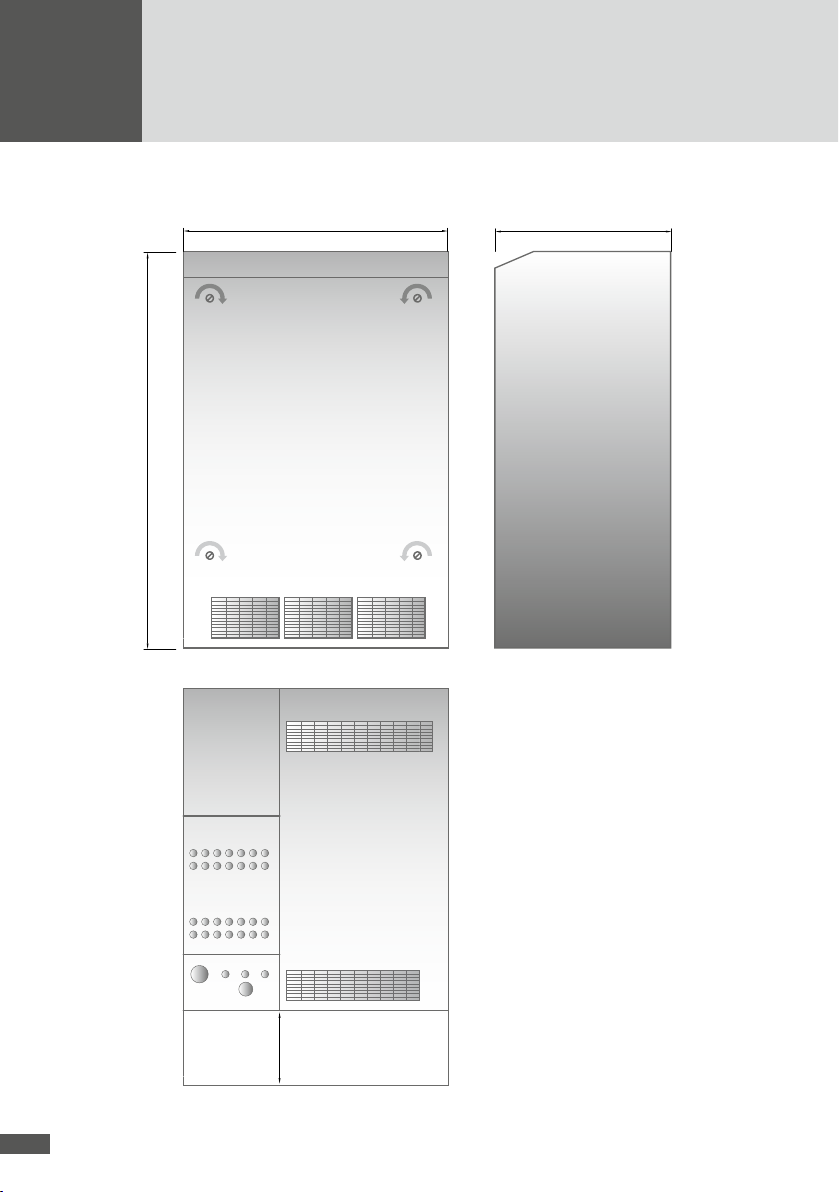

4.1 Siting

SolarMax central inverters must be sited properly in order to ensure maximum opera-

tional safety and efciency. The SolarMax inverter must be covered and protected from

ooding and direct sunlight. Due to the associated noise emissions, the inverter should

not be installed in the close vicinity of habitable rooms or ofces.

The transformation of DC voltage into AC voltage generates heat that has to be dissipated.

If required, the heat sinks are cooled with internal fans. The heated air is ejected at the

rear.

Please note the following during transportation and installation:

The SolarMax inverter should only be transported vertically (in normal position). Never

transport it on its side or upside down!

During transportation and intermediate storage the specied ambient conditions (tem-

perature and relative humidity) must be observed. Prolonged unattended outdoor stor-

age of the SolarMax inverter should be avoided.

The device must be protected from unauthorised access.

The ambient temperature should be between 0 and 30 °C. The maximum permissible

ambient temperature is 60 °C.

In order to ensure adequate cooling, the back of the unit should be kept free. The dis-

tance to the wall should be at least 30 cm.

If the device is installed in a small plantroom, additional ventilation must be provided

(800 m3/h for SolarMax 20S, 1.200 m3/h for SolarMax 35S). The additional ventilation

may be temperature-controlled. It should be activated when the air temperature in the

plant room exceeds 30 °C.