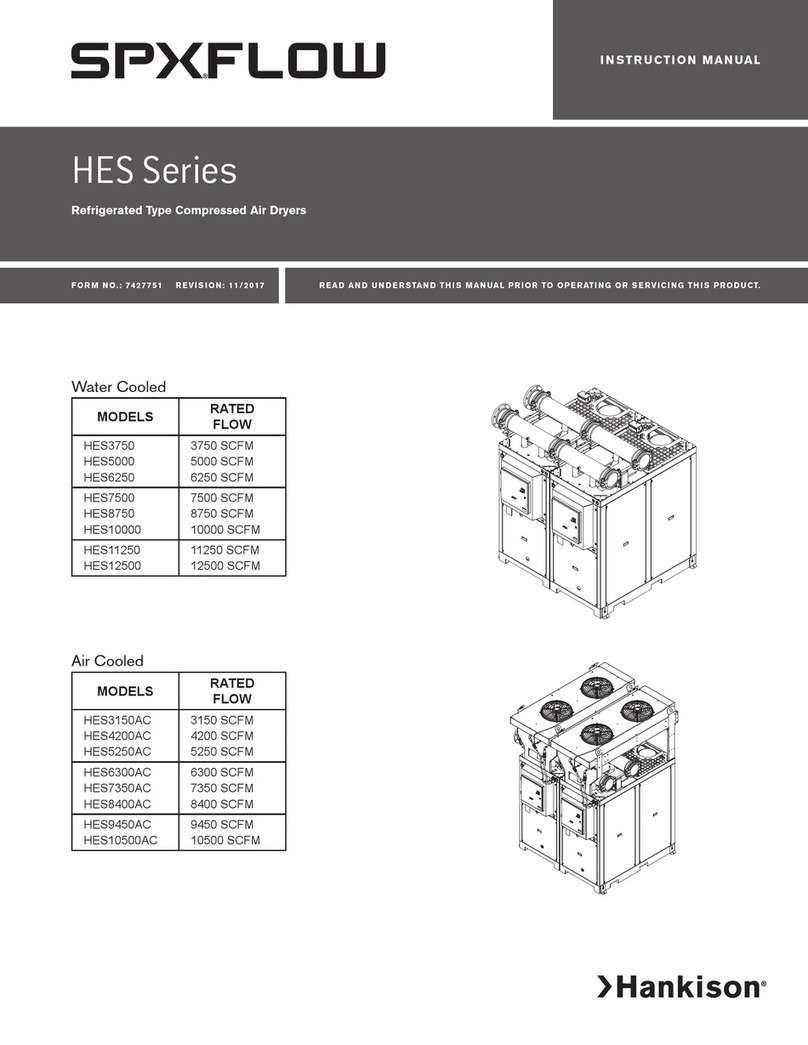

SPX FLOW Hankison DH Series User manual

1

PRESSURE-SWING

DESICCANT TYPE

COMPRESSED

AIR DRYERS

7610.479.9 1/22/97

IMPORTANT:

READ PRIOR TO STARTING THIS

EQUIPMENT

A.

UNPACKING

This shipment has been thoroughly checked,

packed and inspected before leaving our plant.

It was received in good condition by the

carrier and was so acknowledged.

1. Check for Visible Loss or Damage. If this

shipment shows evidence of loss or damage

at time of delivery to you, insist that a notation

of this loss or damage be made on the delivery

receipt by the carrier’s agent.

2. Check for Concealed Loss or Damage. When a

shipment has been delivered to you in

apparent good order, but concealed damage is

found upon unpacking, notify the carrier

immediately and insist on his agent inspecting

the shipment. Fifteen days from receipt of

shipment is the maximum time limit for

requesting such inspection. Concealed

damage claims are not our responsibility as

our terms are F.O.B. point of shipment.

B.

MOVING CAUTION:

Do not lift by piping. Use lifting lugs or fork lift.

1. Pressurized devices: This equipment is

a pressure containing device. Do not

exceed maximum operating pressure as

shown on equipment serial number tag.

Make sure equipment is depressurized

before working on or disassembling it

for service.

2. Electrical: This equipment requires

electricity to operate. Install equipment

in compliance with national and local

electrical codes. Standard equipment is

supplied with NEMA 4, 4x electrical

enclosures and is not intended for

installation in hazardous environments.

Disconnect power supply to equipment

when performing any electrical service

work.

3. Breathing Air: Air treated by this

equipment may not be suitable for

breathing without further purification.

Refer to OSHA standard 1910.134 for

the requirements for breathing quality

air.

GENERAL SAFETY

INFORMATION

MODEL RATEDFLOW DESIGNATEDASMODELS

DH-25 25 SCFM 25

DH-45 45 SCFM 45

DH-6000 60 SCFM 60

DH-80 80 SCFM 80

DH-115 115 SCFM 115

DH-165 165 SCFM 165

DH-260 260 SCFM 260

DH-370 370 SCFM 370

DH-450 450 SCFM 450

DH-590 590 SCFM 590

DH-750 750 SCFM 750

DH-930 930 SCFM 930

DH-1130 1130 SCFM 1130

DH-1350 1350 SCFM 1350

DH-1550 1550 SCFM 1550

DH-2100 2100 SCFM 2100

DH-3000 3000 SCFM 3000

DH-4100 4100 SCFM 4100

DH-5400 5400 SCFM 5400

®

Instruction Manual

DH Series

SERVICE DEPARTMENT (724) 746-1100

2

CONTENTS

1.0 DESCRIPTION ............................................................................................................................ 4

1.1 Function...................................................................................................................................... 4

1.2 Description of Operation.......................................................................................................... 5

2.0 INSTALLATION .......................................................................................................................... 6

2.1 Location in a compressed air system...................................................................................... 6

2.2 Minimum & Maximum Operating Conditions .......................................................................... 6

2.3 Mounting..................................................................................................................................... 6

2.4 Piping.......................................................................................................................................... 6

2.5 Electrical connections..............................................................................................................10

2.6 Provisions for purge exhaust ..................................................................................................10

2.7 Initial Desiccant Charge ...........................................................................................................10

3.0 OPERATION ..............................................................................................................................12

3.1 Start-up ......................................................................................................................................12

3.2 Operational check points.........................................................................................................14

3.3 Shut-down ................................................................................................................................ 15

3.4 Loss of power ...........................................................................................................................15

3.5 Design parameters ..................................................................................................................16

3.6 Determining purge and outlet flows .......................................................................................16

3.7 Outlet dew points vs. inlet temperatures ...............................................................................16

4.0 MAINTENANCE .........................................................................................................................18

4.1 Desiccant replacement.............................................................................................................18

4.2 Pilot air filter cartridge replacement (models 370 & larger only) ........................................18

4.3 Fuse Replacement (automatic purge models only)...............................................................19

4.4 Battery replacement (automatic purge models only)...........................................................19

4.5 Test Mode ..................................................................................................................................19

5.0 TROUBLESHOOTING ...............................................................................................................21

NOTE

Supplemental instructions for units supplied with the

optional Automatic Purge Saving System are shown in italics.

3

MINI INSTRUCTIONS

For complete instructions on installation, operation, and maintenance, consult manual.

I . INSTALLATION

1. Install on level surface.

2. Ambient temperature range: 35 to 120°F (1.7 to 49°C) [ if low ambient package supplied: -10 to 120°F (-23 to 49°C) ]

3. Install purge mufflers if shipped separately.

4. Connect air from compressor to inlet.

• Maximum compressed air temperature: 120°F (49°C)

• Maximum compressed air pressure: Refer to serial number tag.

• Minimum compressed air pressure: See section 2.2.1.2 .

5. Connect outlet to air system.

6. Refer to serial number tag for correct voltage. Make electrical connection to terminal strip in electrical enclosure. Standard units: connect

line to position 5, neutral to position 6 and ground to position 7.

Automatic purge saving system: connect wires to positions 2 and 3; ground to position 1.

7. Set controller for 120V or 240V using selector switch.

I I. START UP

1. Set or verify controller settings. See section 3.1.1.

2. SLOWLY pressurize unit.

3. Energize dryer by turning on/off switch on. ("I" is on; "O" is off)

4. Adjust purge air flow rate. Turn purge rate valve until Purge Pressure Gauge reads as shown in the following table.

NOTE: One tower must be purging when setting purge pressure.

III . OPERATIONAL CHECKPOINTS

1. Check that dryer is energized (indicating lights are illuminated)

2. MOISTURE INDICATOR - Indicator should be green (Allow 4 hours after start up for indicator to turn green).

3. TOWER PRESSURE GAUGES -

• Tower on line should read line pressure

• Tower off line should read 2 psig or less while purging. If pressure exceeds 2 psig replace purge muffler elements.

NOTE: An extra set of elements is shipped with dryer.

4. PURGE PRESSURE GAUGE - Verify proper setting.

5. CHECK FOR ALARM CONDITION.

IV . DEPRESSURIZATION

Isolate dryer. Run timer until both tower pressure gauges read 0 psig.

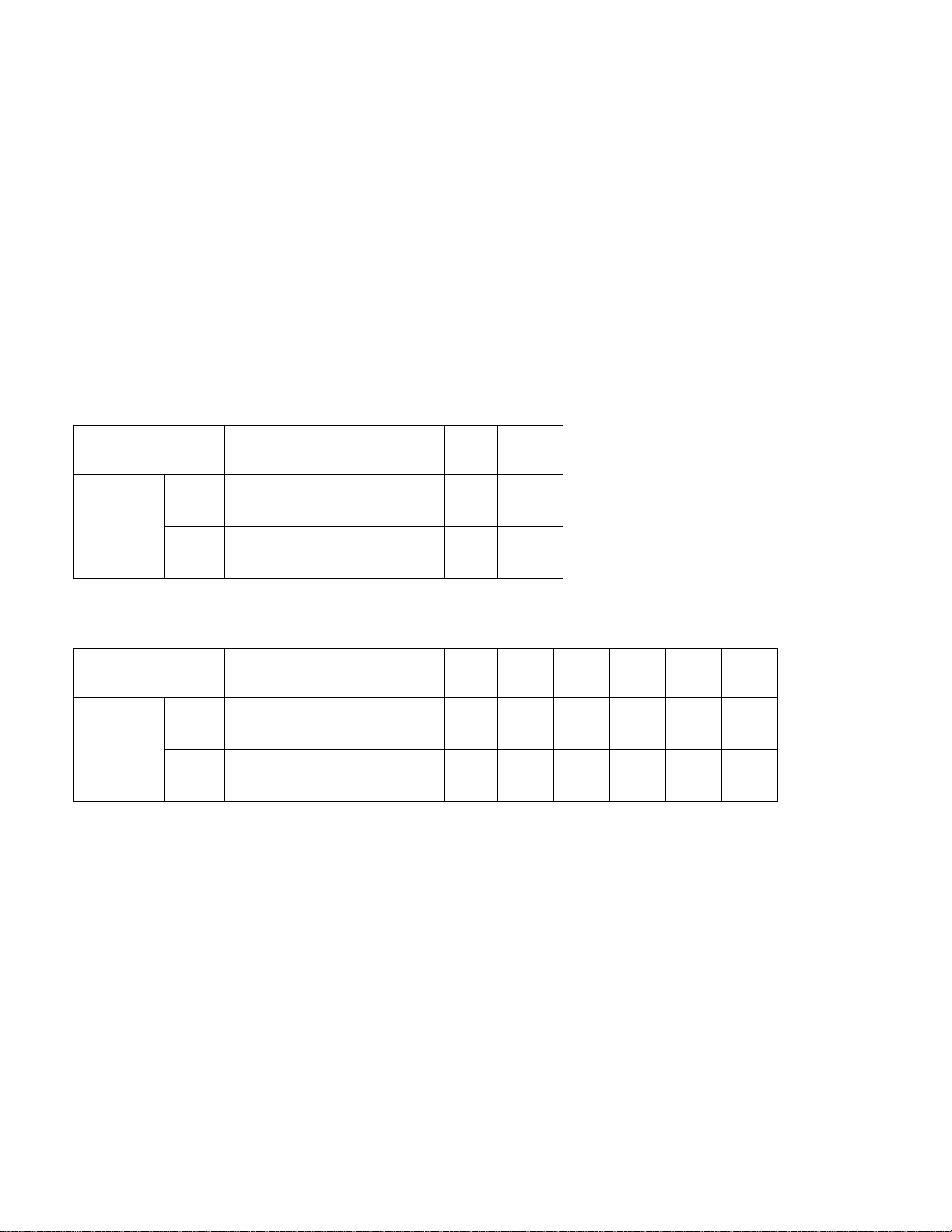

150 psig M.W.P. models

4

Min.

10

Min.

250 psig M.W.P. models

CYCLE

TIME

SETTING

80 79 78 77 76 75 70 64 60 57

4

Min.

10

Min.

—————132123115108102

INLET PRESSURE 60-100 110 120 130 140 150

(psig)

CYCLE

TIME

SETTING

45 43 41 39 37 36

70 66 63 60 58 56

INLET PRESSURE 125 130 135 140 145 150 175 200 225 250

(psig)

4

1.0 DESCRIPTION

1.1 Function

1.1.1 Dryer Dual tower regenerative desiccant dryers are an economical

and reliable way to dry compressed air to dew points below the freezing

point of water (dew points as low as -150°F [1 ppb @ 100 psig, 7.0 kgf/

cm2] are possible) or reduce the moisture content of compressed air when

used in critical process applications.

These dryers continuously dry compressed air by using two identical

towers, each containing a desiccant bed. While one tower is on-stream

drying the compressed air, the other tower is off-stream being regenerated

(reactivated, i.e., dried out). The towers are alternated on- and off-stream

so that dry desiccant is always in contact with the wet compressed air. In

this way a continuous supply of dry air downstream is possible.

Desiccant dryers lower the dew point of compressed air by adsorbing the

water vapor present in the compressed air onto the surface of the

desiccant. Desiccant is a highly porous solid containing extensive surface

area.

Adsorption occurs until the partial pressure of the water vapor in the air

and that on the surface of the desiccant come into equilibrium. As

adsorption occurs, heat is released (referred to as the heat of adsorption)

and is stored in the bed for use during regeneration.

Desiccant is regenerated by driving off (desorbing) the water collected on

its surface. Pressure-swing (also called heatless or heaterless because no

outside heat is added) dryers regenerate by expanding a portion (approxi-

mately 14 - 15% at 100 psig, 7 kgf/cm2) of the dried air to atmospheric

pressure. This “swing in pressure” causes the expanded air to become

very dry (have a very low vapor pressure). This very dry air (called purge

air) plus the stored heat of adsorption allows the moisture to desorb from

the desiccant. The purge air then carries the desorbed water out of the

dryer.

1.1.2 Optional Automatic Purge Saving System

The Automatic Purge Saving System is designed to save energy (purge

air) when pressure-swing dryers are operated at reduced loads.

The patented Purge Saving System operates by monitoring the changes

in temperature within the desiccant beds. These changes in temperature

are the result of heat (thermal energy) that is released when a bed is on-

line drying (heat of adsorption), and the heat that is used when a bed is

off-line being regenerated (heat of desorption).

Themagnitudeofthesechangesintemperatureisanindirectmeasureof

thewatervaporcontentin theairbeingdried.This informationisusedto

determine the time a tower stays on line during the drying cycle.

5

8

1

5C 5D 8

72

61

5A

10A 9A 3A 3B 9B 10B

5B

11

INLET

FIGURE 1A

88

5C 5D

72

6

11

5A 5B

11

10A 9A 3A 10B

9B

3B

INLET

LEGEND

Process Stream

Purge Stream

TOWER4ADRYING: TOWER4BREGENERATING

FIGURE1C

7. Purge Orifice

8. Pressure Relief Valves

9. Purge / Repressurization Valves

10. Purge Mufflers

11. Moisture Indicator

1. Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Check Valves

6. Adjustable Purge Rate Valve

FIGURE1B

TOWER4BDRYING: TOWER4AREGENERATING

1.2 Description of Operation

1.2.1 Dryer

(Refer to Figure 1A.)

Compressed air flows through inlet switching valve (3A) to tower

(4A) where the air is dried. After the air is dried it flows through check

valve (5A) and then to the dryer outlet.

A portion of the dry air, the purge stream, branches off from the

main air stream prior to the outlet. The purge stream flow rate is controlled

by the adjustable purge rate valve (6) and the purge orifice (7).

The purge flow, which has been throttled to near atmospheric

pressure, is directed through check valve (5D) to tower (4B). As the purge

flow passes over the desiccant in tower (4B), it removes the water vapor

which was deposited there while the tower was on-line drying. The purge

air then passes through purge and repressurization valve (9B) and purge

muffler (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) closes

allowing tower (4B) to repressurize slowly. Adequate repressurization time

is allowed so that tower 4B is fully repressurized before switchover. After a

controlled time period, air inlet switching valve (3B) opens and inlet

switching valve (3A) closes, purge and repressurization valve (9A) then

opens.

(Refer to Figure 1B.)

Tower (4B) is now drying the main air

stream while tower (4A) is being regenerated by the purge air stream. The

operation of the inlet switching and purge and repressurization valves is

sequenced by the control system located in the electrical box.

1.2.2 Optional Automatic Purge Saving System (Refer to Figure 1C)

AssumeTowerAison-linedryingtheairwhiletowerBhasjust

goneoff-linetobe regenerated. Atthe beginningoftower B’s regenera-

tion cycle a temperature measurement is made at position B1. After the

tower has been regenerated, another measurement is made at B1. The

drop in temperature sensed during regeneration is an indirect measure

of the water vapor content of the inlet air. The Purge Saving System’s

microprocessor then uses this information to calculate an allowable

temperature rise in the bed during the drying cycle.

When tower B goes back on-line, a temperature probe at

position B2 measures the initial bed temperature at this point and then

monitors the bed until the calculated temperature rise occurs. The

temperature rise occurs as heat of adsorption is released during the

drying process. The time for the temperature rise to occur depends on

flow rate. At 100% flow the temperature rise takes five minutes, at 50%

flow it takes 10 minutes.

When the calculated temperature rise is reached, the towers

switchwith towerA nowdrying andtower Bbeing regenerated.TowerB

regenerates for 3.9 minutes, repressurizes, and remains idle until it is

called upon for the next drying cycle.

TOWER

4B

TOWER

4A

OUTLET

OUTLET

TOWER

4A TOWER

4B

OUTLET

INLET

A2 B2

TOWER

A TOWER

B

B1

A1

6

Compressor Aftercooler Receiver

Separator Desiccant

Dryer

FIGURE2A

(B & C) PREFILTERS - Adequate filtration is required upstream of the

dryer in order to protect the desiccant bed from contamination. The

following filtration are recommended:

B - Particulate/Gross Liquid Removal

- On heavily contaminated systems

use a gross contaminant filter to remove solids and high inlet liquid

concentrations.

C - Oil Aerosol Removal

-On systems with lubricated compressors, use

an oil removal filter to remove oil aerosols and protect desiccant bed from

oil contamination.

(D) DESICCANT DRYER

(E) AFTERFILTER - To ensure downstream air purity (prevent desiccant

dust from traveling downstream) adequate filtration downstream of the

dryer is required. Typically 1 micron filtration is specified although finer

filtration is available.

OR

Oil Vapor Adsorber

- Use as an afterfilter to remove oil vapor and its

subsequent taste and odor and to protect down-stream components from

solid particles 0.01 micron and larger.

NOTE

By-pass lines and isolation valves are recommended so that maintenance

work can be performed without shutting off the air supply.

2.1 Location in the compressed air system.

NOTE

Air Compressor should be adequately sized to handle air system demands

as well as purge loss. Failure to take this into account could result in

overloading air compressors and/or insufficient air supply downstream.

NOTE

It is desirable to install dryer where compressed air is at the lowest

possible temperature (downstream of aftercoolers) and the highest

possible pressure (upstream of pressure reducing valves) without

exceeding the maximum working pressure.

(Refer to Figure 2A)

(A) AFTERCOOLER/SEPARATOR - Compressed air entering dryer must be

cooled to at least 120°F (49°C). Use aftercooler and separator if higher

temperatures are present.

NOTE

Installation of a refrigerated dryer ahead of a pressure-swing desiccant

dryer does not increase desiccant dryer capacity or reduce purge flow

requirements. However a cooling unit installed ahead of the desiccant

dryer reduces the inlet air temperature and outlet air dew point.

2.0 INSTALLATION

2.2 Minimum & Maximum Operating Conditions

The compressed air supply inlet should be checked periodically to ensure

that equipment design specifications are not exceeded. Normally the

compressor installation includes intercoolers, aftercoolers, separators,

receivers, or similar equipment which adequately pretreat the compressed

air supply in order to avoid excessively high air temperatures and liquid

slugging of downstream equipment.

2.2.1 Compressed air conditions

2.2.1.1 Maximum working pressure:

Refer to dryer Serial Number Tag.

WARNING

Do not operate the dryer at pressures above the maximum

pressure shown on the tag.

2.2.1.2 Minimum working pressures:

150 psig (10.5 kgf/cm2) MWP models -

60 psig (4.2 kgf/cm2) for dryers operated on a 10 minute cycle

80 psig (5.6 kgf/cm2) for dryers operated on a 4 minute cycle

250 psig (17.6 kgf/cm2)MWP models -

125 psig (8.8 kgf/cm2) for dryers operated on a 10 minute cycle

150 psig (10.5kgf/cm2)for dryersoperatedon a4minute cycle.

If lower inlet pressures are encountered, consult factory.

2.2.1.3 Maximum inlet compressed air temperature:

120°F (49°C)

NOTE

If inlet air is higher than 120°F (49°C) the air must be precooled

with an aftercooler.

2.2.2 Ambient temperatures:

Minimum:

Standard units: 35°F (1.7°C)

Units with optional low ambient package: - 10°F (-23°C)

Maximum: 120°F (49°C)

NOTE

If dryer is installed in ambients below 35°F (1.7°C) heat tracing of

the prefilters and inlet piping and valves is necessary to prevent

condensate from freezing. If installing heat tracing, observe electrical

class code requirements for type of duty specified.

2.3 Mounting

Install dryer on a level pad on floor. Holes are provided in the

floor stand base angles for floor anchors if desired.

NOTE

Floor anchors must be used if area is subject to vibrations.

2.4 Piping

2.4.1 Inlet and Outlet connections

Observe location of inlet and outlet connections as indicated in

Figure 2B, 2C, or 2D and connect inlet and outlet piping.

NOTE

All piping must be supported so as not to bear on the dryers or

filters.

2.4.2 Isolation valves

If isolation valves are installed, it is recommended that gate

valves be used to ensure that dryer is pressurized slowly. This is

particularly true if isolation valves are placed before and after pre-

and afterfilters where rapid pressurization could cause excessive

pressure drop across filter cartridges.

Prefilter(s) Afterfilter

7

Desiccant Drain Port

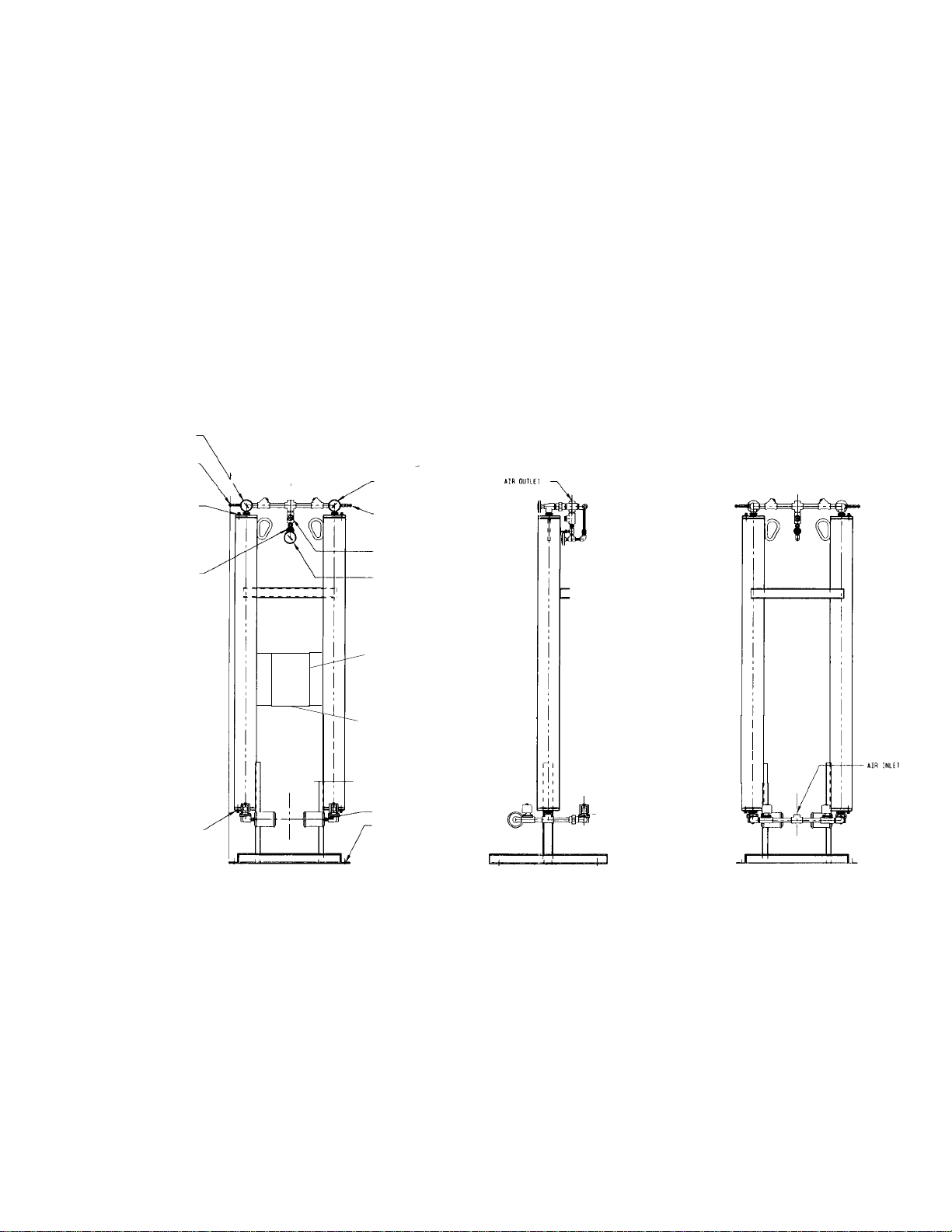

FRONT VIEW RIGHT SIDE VIEW REAR VIEW

Purge Muffler

3/4" Dia.

Mounting Holes

Desiccant Fill Port

Left Tower Pressure

Gauge

Purge Pressure

Adjustment Valve

Left Tower Pressure

Relief Valve Right Tower Pressure

Gauge

Right Tower

Pressure Relief Valve

Moisture

Indicator

Purge Pressure

Gauge

FIGURE 2B Models 25 through 80

Electrical Entry

(7/8")

Control Panel

8

FIGURE 2C Models 115 through 2100

"G" Air Inlet

Left Tower Pressure

Relief Valve AB

CD

E

L

2" (51mm)

Desiccant Drain Port

"G" Air Outlet K

F

J

H

Right Tower Pressure Relief Valve

3/4" (19mm) Dia. Mounting Holes

Pilot Air Filter (Models 370 & larger)

Moisture Indicator

Right Tower

Pressure Gauge

Control Panel

Electrical Entry

(7/8")

Purge Muffler

Left Tower Pressure Gauge

Purge Pressure Adjustment Valve

Desiccant Fill Port

Purge Pressure Gauge

*

*Models 115 through 260 use solenoid valves. Models 370 and larger use air operated butterfly valves.

**

*

Lifting Lugs

9

FIGURE 2D Models 3000 thru 5400

PA

BM

DC

NE

Right Tower Pressure

Relief Valve

K

FL

J

H

Desiccant Fill Port

Lifting Lugs

Moisture Indicator

Right Tower Pressure

Gauge

Control Panel

Electrical Entry

(7/8")

Purge Mufflers

Desiccant Drain Port

7/8" Dia. Mounting Holes

Lifting Lugs

Left Tower

Pressure Gauge

Purge Pressure

Gauge

Purge Pressure

Adjustment Valve

Pressure

Relief Valve

Left Tower

Air Inlet

Pilot Air Filter

Air Outlet

10

2.5.2.2Automatic PurgeSaving System

Dry contacts for a remote alarm are supplied at terminals 6 and 7.

Maximum contact rating is:

230 VAC - 4.3 amp

115 VAC - 8.7 amp

200 VDC - 0.15 amp

100 VDC - 0.35 amp

50 VDC - 1.2 amp

30 VDC - 4.5 amp

25 VDC - 10 amp

10 VDC - 10 amp

2.5.1.2 Automatic Purge Saving System (Refer to Figure 2F)

Connect wires to terminal strip. Connect line to position 3,

neutraltoposition2andgroundtoposition1. Donotmakeconnections

to terminals labeled with grouding symbol or labeled with RS.

Set the voltage selection switch located at the lower edge of

the control board for the proper supply voltage.

Electricalentryis7/8"dia.holefor1/2"nominalconduitentry.

2.5 Electrical Connections

2.5.1 Power to Unit

NOTE

Check Serial Number Tag for correct voltage.

2.5.1.1 Standard Unit

2.6 Provisions for Purge Exhaust -Purge exhaust must be routed through

the factory supplied mufflers or piped to a remote location.

2.6.1 Purge mufflers - If shipped separately, install purge exhaust

mufflers in the locations shown in Figure 2B, 2C or 2D.

2.6.2 If purge exhaust is piped to a remote location, choose a pipe size

large enough so that back pressure through the piping is not created.

WARNING

Do not operate dryer without one of the above measures. Exhausting air will

result in noise levels above OSHA permissible levels and exhausting gas

could potentially cause harm to persons or property.

2.7 Initial Desiccant Charge -The dryer is shipped complete with desiccant

and ready to operate after piping and electrical connections are made.

POWER REQUIREMENTS

STANDARD CONTROL BOARD

25 THRU 60 120V - 60 Hz, 110V - 50 Hz 34.2 0.53 1.28

240V - 60 Hz, 220V - 50 Hz 34.2 0.27 0.64

80 120V - 60 Hz, 110V - 50 Hz 44.1 0.68 2.70

240V - 60 Hz, 220V - 50 Hz 44.1 0.34 1.35

115 THRU 260 120V - 60 Hz, 110V - 50 Hz 49.4 0.70 3.45

240V - 60 Hz, 220V - 50 Hz 49.4 0.35 1.73

370 THRU 5400 120V - 60 Hz, 110V - 50 Hz 34.6 0.53 1.24

240V - 60 Hz, 220V - 50 Hz 34.6 0.26 0.62

AUTOMATIC PURGE SAVING SYSTEM

25 THRU 60 120V - 60 Hz, 110V - 50 Hz 44.2 0.62 1.37

240V - 60 Hz, 220V - 50 Hz 44.2 0.31 0.68

80 120V - 60 Hz, 110V - 50 Hz 54.1 0.77 2.78

240V - 60 Hz, 220V - 50 Hz 54.1 0.38 1.39

115 THRU 260 120V - 60 Hz, 110V - 50 Hz 59.4 0.78 3.53

240V - 60 Hz, 220V - 50 Hz 59.4 0.39 1.77

370 THRU 5400 120V - 60 Hz, 110V - 50 Hz 44.6 0.61 1.33

240V - 60 Hz, 220V - 50 Hz 44.6 0.30 0.66

AMPS

MODEL WATTS HOLDING INRUSH

2.5.2 Connections for external alarm

2.5.2.1 Standard Unit

Dry contacts for a remote alarm are supplied at terminals 20, 21, 22.

When the unit is energized and no alarms are in effect, continuity should

exist between terminals 20 and 21, with no continuity between terminals

21 and 22. Alarm contact is common for switching failure alarm and

optional high humidity alarm.

Maximum contact rating is:

240 VAC - 5.0 amps

50 VDC - 1.0 amps

Connect wires to terminal strip. Connect line to position 5, neutral

to position 6, and ground to position 7.

Set the voltage selection switch located at the lower edge of the

control board for the proper supply voltage.

Electrical entry is 7/8" dia. hole for 1/2" nominal conduit entry.

11

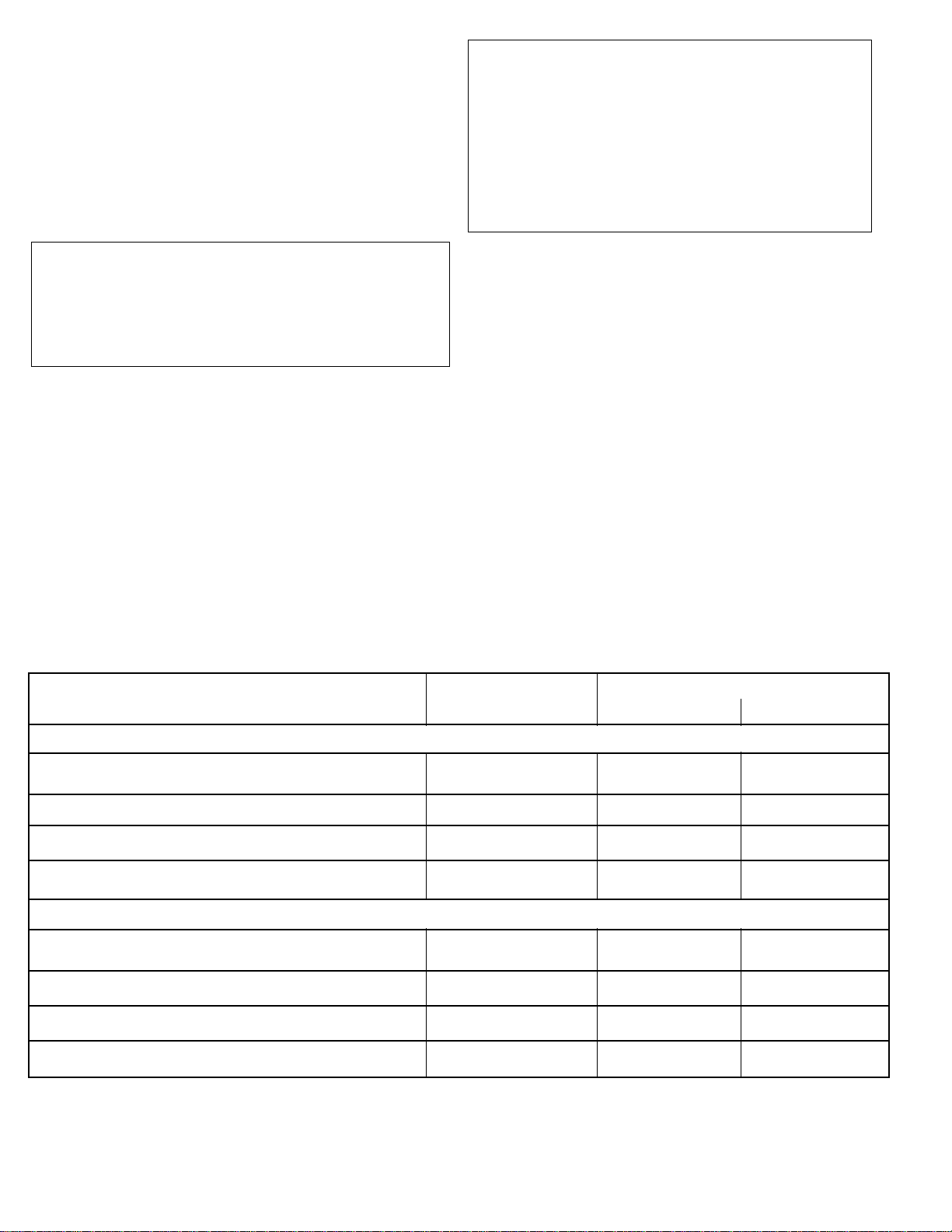

FIGURE 2F ELECTRICALSCHEMATIC (DRYERSWITHAUTOMATICPURGESAVINGSYSTEM)

Line

Neutral

GND.

Left Tower Lower Thermistor

Left Tower Upper Thermistor

Right Tower Lower Thermistor

Left Tower Pressure Switch

Right Tower Pressure Switch

Right Tower Upper Thermistor

Left Tower Purge & Repressurization Solenoid

Left Tower Switching Solenoid

Right Tower Switching Solenoid

Right Tower Purge & Repressurization Solenoid

FIGURE2E ElectricalSchematic(StandardDryers)

1SOL Energized Indicator (Green)

2SOL Energized Indicator (Green)

3SOL Energized Indicator (Green)

4SOL Energized Indicator (Green)

Left Tower Drying Indicator (Green)

Left Tower Regenerating Indicator (Green)

Right Tower Drying Indicator (Green)

Right Tower Regenerating Indicator (Green)

4 Minute Cycle Mode Indicator (Yellow)

10 Minute Cycle Mode Indicator (Yellow)

Test Mode Indicator (Yellow)

Switching Failure Alarm Indicator (Red)

High Humidity Alarm Indicator (Red)

Purge Economizer 100% Setting Indicator (Yellow)

Purge Economizer 90% Setting Indicator (Yellow)

Purge Economizer 80% Setting Indicator (Yellow)

Purge Economizer 70% Setting Indicator (Yellow)

Purge Economizer 60% Setting Indicator (Yellow)

Purge Economizer 50% Setting Indicator (Yellow)

Purge Economizer 40% Setting Indicator (Yellow)

Purge Economizer 30% Setting Indicator (Yellow)

Alarm-Reset/Selection Mode Switch

Purge

Economizer

DIP Switches

To Solid

State

Timer

and

Control

Circuits

To Solid

State

Timer

and

Control

Circuits

To Solid

State

Timer

and

Control

Circuits

Power Off/On

Switch

Spare Load Connections

Control Circuit Fuse

Solid State Timer and

Control Circuit Step

Down Transformer

120/240 VAC Control

Board Inlet Voltage

Selector Switch

Solenoid Circuit Fuse

Right Tower Inlet

Switching Solenoid

Left Tower Purge/

Repressurization

Solenoid

Right Tower Purge/

Repressurization

Solenoid

Left Tower Inlet

Switching Solenoid

Spare Ground

Connections

Common

Alarm Relay

Common Alarm (See section 2.5.2.1)

Contacts

Right Tower Switching Failure Alarm

Pressure Switch

Left Tower Switching Failure Alarm Pressure

Switch

To Solid State

Timer

and

Control

Circuits

To

Solid

State

Timer

and

Control

Circuits

Customer

Common

Alarm

Connections

Customer

Power

Connections

LEGEND

CR ...................................... CONTROL RELAY

DS ............................................... DIP SWITCH

FU ........................................................... FUSE

L ............................................................. LIGHT

PB .......................................... PUSH-BUTTON

PS ................................. PRESSURE SWITCH

Q ..................TRIAC (SOLID-STATE SWTICH)

SOL ................................... SOLENOID VALVE

SS .................................. SELECTOR SWITCH

SST ................. SOLID-STATE TIMER BOARD

T ............................................ TRANSFORMER

TB ..................................... TERMINAL BLOCK

SW ................................. SELECTOR SWITCH

}Customer Power

Connection

12

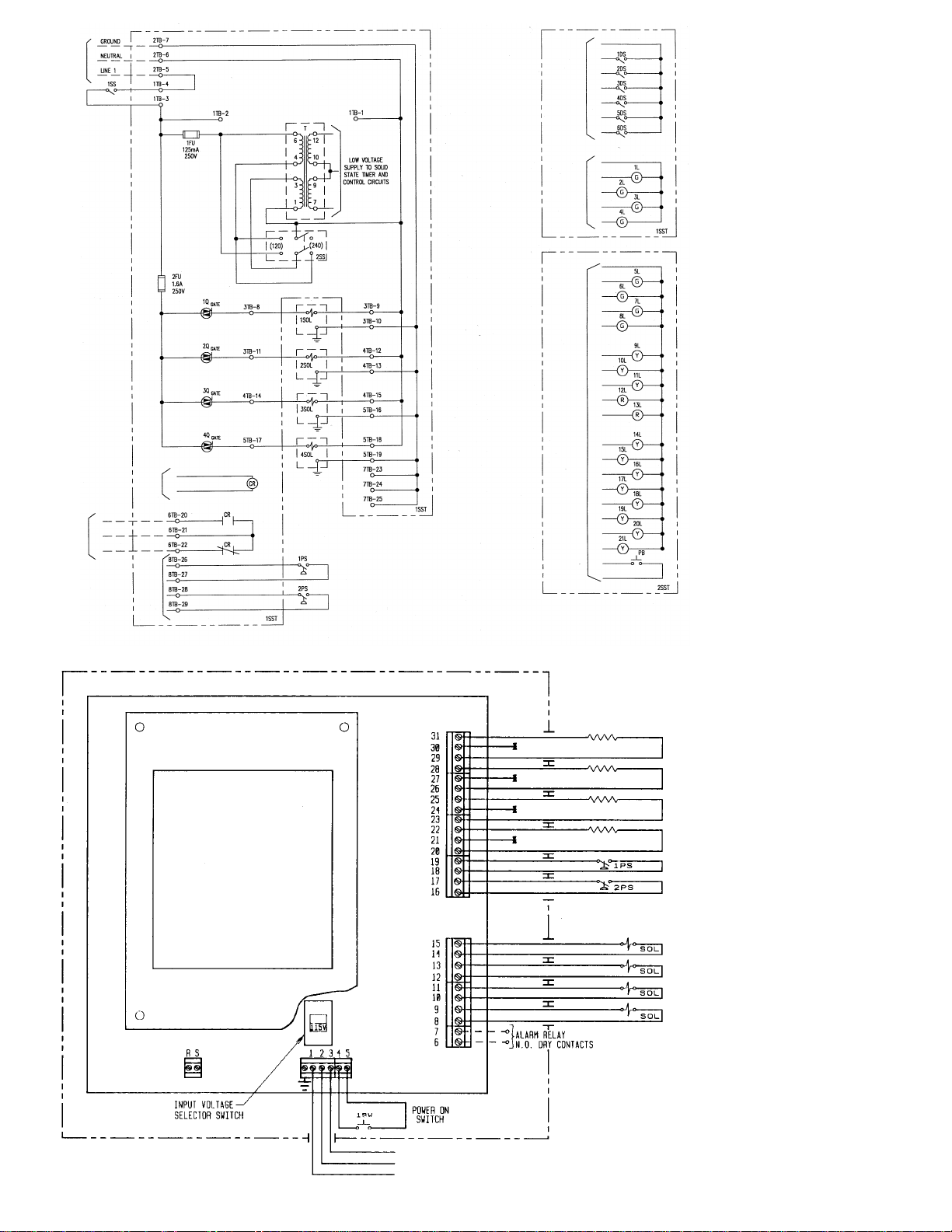

FIGURE 3A

StandardControlPanel

3.0 OPERATION

3.1 Start-up

3.1.1 Controller Settings- Set or verify settings on controller

3.1.1.1 Standard Unit Control Board - NOTE: Make settings with dryer

de-energized.

3.1.1.1.1 Voltage Selection - Set the voltage selection switch located

at the lower edge of the power board for the proper voltage.

3.1.1.1.2 Dip Switch Settings - NOTE: For ON DIP switch is up; OFF

DIP switch is down

1. Select setting for Standard (150 psig, 10.5 kgf/cm2MWP) or

High Pressure (250 psig, 17.6 kgf/cm2MWP) unit (See Serial

Number Tag)

A. Standard - place switch 4 in OFF position

B. High Pressure - place switch 4 in ON position

2. Select Operating Cycle (4 or 10 minute)

A. 10 minute cycle - place switch 5 in OFF position,

switch 6 in ON position

B. 4 minute cycle - place switch 5 in ON position,

switch 6 in OFF position

3. To select Test Mode - place switch 5 and 6 in ON position

4. Purge Economizer Switch Setting - If dryer is operated at less than

maximum flow capacity a reduction in purge air usage may be possible.

Refer to Section 3.5.4 to determine maximum inlet flow capacity at

operating pressure. Divide your actual flow by Maximum Flow to get % of

Maximum Flow. Set switches 1 through 3 as shown

EXAMPLE:

A 60 scfm unit has a Maximum Rated Inlet Flow of 60 scfm @

100 psig. Currently only 30 scfm is used. 30/60 = .50 = 50%. To save

purge air, set Purge Economizer Switch for 50%: switches 1 and 3 are ON,

switch 2 is OFF.

Purge Economizer Setting Standard or High Cycle/Mode Selection

Pressure Selection

Switch No. 1 2 3 4 5 6

Standard 10 minute cycle OFF ON

150 psig OFF

MWP 4 minute cycle ON OFF

High

pressure ON Test mode ON ON

250 psig

MWP

% of

Max.

Flow

100 OFF OFF OFF

90 ON OFF OFF

80 OFF ON OFF

70 ON ON OFF

60 OFF OFF ON

50 ON OFF ON

40 OFF ON ON

30 ON ON ON

NOTE

If full flow is restored, Purge Economizer Switch must be reset for 100%.

• CYCLE MODE • MODO DE CICLO

• MODE CYCLIQUE

Outlet

Salida

Sortie

Inlet

Entrada

Entrée

Drying

Secando

Séchage

Drying

Secando

Séchage

4 Min.

Test Mode

High

Humidity Alarm

Reset/

Selection Mode

• ECONOMIZER SETTING

• DEMANDA PROMEDIO

• REGLAGE POUR MODE ECONOMIQUE

Switching

Failure Alarm

10 Min.

Regenerating

Regenerando

Régénération

Regenerating

Regenerando

Régénération

• TOWER STATUS • ESTADO DE LA TORRE • ETAT DES TOURS

Alarma por Falla en el

Cambio de Torres

Alarme de Non-

Alternance des Tours

Restablecer/

Selector de Ciclo

Commande de Remise/

Sélection de Mode

Alarma por Alta Humedad

Alarme de Haute Humidité

Modo de Prueba

Mode d' Essai

I

O

60 %

50 %

40 %

30 %

100 %

90 %

80 %

70 % 60 %

50 %

40 %

30 %

100 %

90 %

80 %

70 %

Right Inlet Solenoid Energized

Left Purge/Repressurization Solenoid Energized

Right Purge/Repressurization Solenoid Energized

Left Inlet Solenoid Energized

DIP Switches for Economizer Setting,

Standard or HP selection,

Cycle/Mode selection

Alarm Hook-up

Power Hook-up

Voltage Selection

Switch

Soleniod circuit fuse

1.6A 250V

Littlefuse #21701.6

Control circuit fuse

125m A 250V

Littlefuse #218.125

StandardControlPanel

TABLE 3A

13

80 79 78 77 76 75 70 64 60 57

___ ___ ___ ___ ___ 132 123 115 108 102

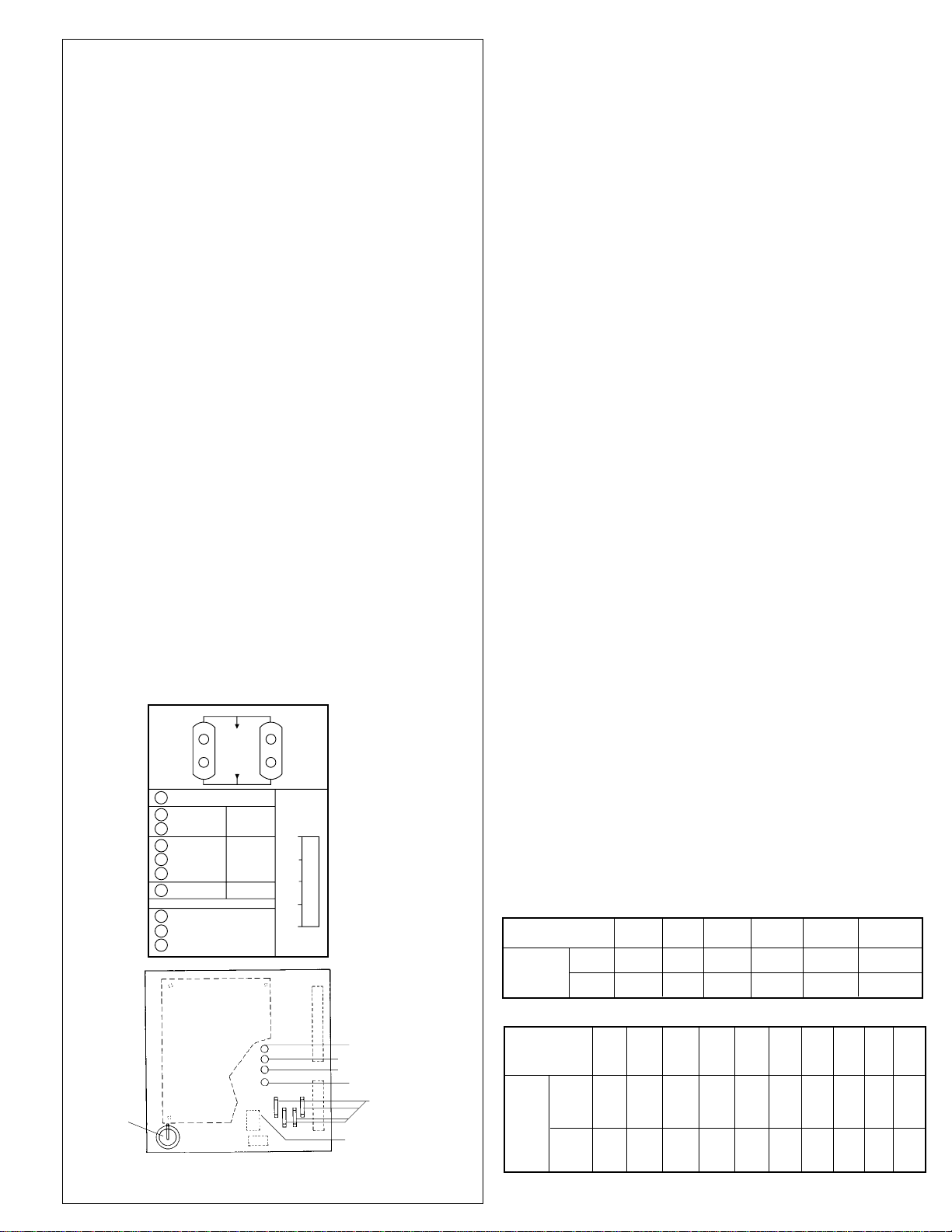

3.1.1.2

Automatic Purge Saving System Control Board

3.1.1.2.1 Voltage selection - Set the voltage selection

switch located at the lower edge of the power board for the

proper voltage.NOTE:

Make certain that paper insulation in front of battery has been

removed.

3.1.1.2.2

Cycle selection

A cycle selector allows two choices in the fixed cycle mode and

three in the demand cycle mode. Cycle selection is accom-

plished by depressing the cycle selector switch repeatedly until

the light indicating the desired cycle mode illuminates.

1) Fixed cycle mode

10 minute - in this mode the dryer switches towers every 5

minutes. With 100

°

F (38

°

C) inlet air, a -40

°

F (-40

°

C) pres-

sure dew point is produced.

4 minute - In this mode the dryer switches towers every 2

minutes. With 100

°

F (38

°

C) inlet air, a -100

°

F (-73

°

C)

pressure dew point is produced.

(2) Demand Cycle Mode

In this mode the dryer switches when the desiccant bed is

loaded as signalled by a calculated temperature rise. Unit can

be set to produce three outlet dew points, -40

°

F (-40

°

C), 0

°

F

(-17.8

°

C) and 40

°

F (4.4

°

C). NOTE:

Automatic control will begin 1/2 cycle after start-up.

NOTE:

If a cycle change is made while dryer is operating, dryer will

finish previous cycle (right tower drying terminates) before

changing. Indicating light of newly selected mode will blink until

changeover is complete. If it is necessary to begin a new

selection immediately, shut unit off and on. (This is not

recommended if either tower is in the regeneration mode since

rapid repressurization could result.)

NOTE:

If switching to a cycle mode producing a lower dew point (e.g.

0

°

F to -40

°

F [ -17.8 to -40

°

C] ) while dryer is operating, one or

two days of operation may possibly be needed before the new

dew point is achieved.

3.1.2 SLOWLY pressurize dryer to full line pressure (open

inlet valve, outlet valve remains closed).

NOTE

During initial start-up check entire system for leaks. If neces-

sary, depressurize and correct any leaks.

3.1.3 Energize dryer using the power switch located on the

control panel.

NOTE

Standard controller - Switching failure alarm: alarm (light) may

be activated if unit is energized before it is pressurized. To

deactivate alarm, allow dryer to cycle to next step and press

the reset button.

3.1.4 Adjust the purge rate valve.

3.1.4.1 Determine:

1)Maximum working pressure (MWP) of dryer from the dryer

serial number tag

2) Air pressure at inlet to dryer

3) Cycle time setting (4 or 10 minutes)

For units with optional

Automatic Purge Saving System in the demand cycle mode

use the 10 minute setting.

3.1.4.2 Refer to

Table 3B

for proper purge rate pressure

setting at the conditions found in 3.1.4.1

3.1.4.3 Adjust purge rate valve until purge flow indicator

reads required pressure setting.

NOTE

Adjustment must be made while a tower is purging (air

exhausting from muffler).

IMPORTANT

INSUFFICIENT PURGE AIR WILL EVENTUALLY RESULT IN

SATURATION OF DESICCANT BED AND WET AIR DOWN-

STREAM. MAKE CERTAIN THAT CYCLE TIME, PURGE

ECONOMIZER SWITCH, AND PURGE PRESSURE ARE

CORRECTLY SET.

3.1.5 Establish normal flow through dryer (open outlet

isolation valve). Close air by-pass valve if present.

NOTE

When dew points below -40°F (-40°C) are required, the dryer

must be run with an inlet flow rate of less than 50% of maxi-

mum until the desired dew point is attained. Depending on the

initial dryness of the desiccant, this can take as long as 2 to 3

days. This stabilization period is required on initial startup,

after dryer has been shutdown for extended periods of time, or

after dryer maintenance (desiccant change, etc.).

3.1.6 With the inlet pressure to the dryer at its minimum

level, readjust the purge pressure as determined in 3.1.4.

150 psig, 10.5 kgf/cm2M.W.P. models

INLET PRESSURE 60-100 110 120 130 140 150

(psig) 45 43 41 39 37 36

70 66 63 60 58 56

10 Min.

4 Min.

CYCLE

250 psig, 17.6 kgf/cm2M.W.P. models

INLET PRESSURE 125 130 135 140 145 150 175 200 225 250

(psig)

10 Min.

4 Min.

CYCLE

Battery

FIGURE3B

AUTOMATICPURGESAVINGPANEL

LFT. P&R

LFT. INLET SW.

RT. P&R

RT. INLET SW.

Fuses

Voltage Selection

Switch

TOWER STATUS

OUTLET

INLET

DRYING

REGENERATING

DRYING

REGENERATING

4 MINUTES

10MINUTES

40°F/+5°C DEW POINT

0°F/-18°C DEW POINT

-40°F/-40°C DEW POINT

TEST MODE

SWITCHING FAILURE

TEMPERATURE PROBE

RESET

CYCLE SELECTOR AVERAGE

DEMAND

FIXED

CYCLE

DEMAND

CYCLE

MANUAL

CYCLE

ALARMS

100%

75%

50%

25%

0%

TABLE3B- PurgeRatePressureSettings(psig)

14

3.2.1.3 Purge Flow Indicator -Every four hours check the

purgepressure andadjust asrequired.Adjustmentshouldbemade

when the inlet pressure to the dryer is at its minimum level.

NOTE

Adjustmentmustbemadewhileatowerispurging(airexhaust-

ing from muffler).

3.2.1.4 Alarms

Periodically check for flashing red alarm light. Alarm light will

flashifeithertowerfailstopressurizeordepressurizetotherequired

levels at the proper time or if optional high humidity alarm indicates

high exiting dewpoint. NOTE

Alarm will activate if dryer is energized without being pressur-

ized. If this occurs allow dryer to cycle to next step and press reset

button. NOTE

Alarm light will continue to flash even if fault clears. To clear

alarm, press reset button.

NOTE

If the tower being regenerated fails to repressurize, the dryer

will not switch towers. The switching failure alarm will be activated

and the dryer will remain in this mode until the tower repressurizes.

3.2.1.5TowerStatusLights-illuminated lightindicateswhich

tower is on-line (pressurized) or off-line regenerating (depressur-

ized)

3.2.1.6 Tower pressure gauges

3.2.1.6.1 Periodically check tower pressure gauges to verify

that tower pressure gauge of tower on-line reads line pressure and

tower pressure gauge of tower off-line reads below 2 psig.

NOTE

Readoff-linetowergaugewhentowerispurging(airexhausting

from muffler)

3.2.1.6.2 Check mufflers for back pressure

Excessivebackpressuremayresultduetotheaccumulationof

dustinthemuffler. Thissometimesoccursafterstart-upbecauseof

dusting of the desiccant during tower filling and dryer transport.

If the tower pressure gauge of the off-stream tower rises out of

the black area on the gauge dial, muffler elements should be

replaced. A set of purge exhaust muffler replacement elements is

supplied with the dryer.

3.2.2. Units with Automatic Purge Saving

System

3.2.21Powertounit-Checkperiodicallythatthereispower

to the unit (indicating lights illuminated).

3.2.2.2 Moisture Indicator - Every four hours check mois-

tureindicator.Indicatorshouldbe green.Outletrelative humidity

of the desiccant dryer is indicated by the color change humidity

indicator. Green indicates a R.H. below 3% and yellow indicates

a R.H. above 3%. Table 3J (page 17) indicates outlet dew point

whenmoistureindicatorchangesfromgreentoyellowatvarious

inlet temperatures. During start-up the indicator may be yellow,

however, it should begin to change to green within four hours.

3.2.2.3 Purge Flow Indicator -Every four hours check the

purge pressure and adjust as required. Adjustment should be

madewhentheinletpressuretothedryerisatitsminimumlevel.

NOTE

Adjustment must be made while a tower is purging (air

exhausting from muffler).

3.2.2.4 Alarms

3.2.2.4.1 Switching Failure Alarm - The switching failure

alarm operates by sensing tower pressures after tower

changeover. If towers have failed to pressurize or depressurize

to the required levels, an alarm condition exists. The alarm light

blinks while the alarm condition exists. If the alarm condition

clears for two complete cycles, the light will switch to a steady

glow.Depressingtheresetswitchwillextinguishthelight,butwill

not interrupt the drying cycle.

Ifthetowerbeingregeneratedfailstorepressurize,thedryer

will not switch towers. The switching failure alarm will be

activated and the dryer will remain in this mode until the tower

repressurizes.

3.2.2.4.2

Temperature Probe Alarm - (operates in a

demand cycle mode only) This alarm is actuated by a short

circuit, an open circuit, or temperatures below 40

°

F (4.4

°

C) or

above 150

°

F (65.5

°

C). The alarm light blinks while the alarm

conditionexists.Afterthealarmconditionclearsforonecomplete

cycle, the light will switch to a steady glow. Depressing the reset

switch will extinguish the light, but will not interrupt the drying

cycle.

3.2.2.4.3 Dryer Cycle (operates in demand cycle mode

only) Eitheralarmwillcausethecontrollertoautomaticallyswitch

toafixed10minute cycle(cycle modelightwillnotindicate this).

After the alarm condition clears and the light stops blinking,

thecontrollerwillcleartheinternalinformationandswitchbackto

a demand mode. It is not necessary to push the alarm reset for

thedryertoreturntotheselecteddemandcyclemode. However,

to extinguish the alarm light, press the alarm reset button.

NOTE

After an alarm condition clears, the dryer will not return to a

demand cycle mode until the dryer completes two cycles if a

switching failure alarm is experienced or one cycle if a tempera-

ture probe alarm is experienced. This occurs even if the alarm

reset is depressed and the alarm light is extinguished.

3.2.2.4.4

Relay for Remote Alarm

Theremotealarmrelaywillclosewhenanalarmoccursand

remaincloseduntil thealarmclearsand isreset.Therelay does

not cycle as the lights blink.

3. 2 Operational Check Points

3.2.1 Standard Unit

3.2.1.1 Power to unit - Check periodically that there is power to the

unit (indicating lights illuminated).

3.2.1.2 Moisture Indicator - Every four hours check moisture

indicator. Indicator should be green. Outlet relative humidity of the

desiccant dryer is indicated by the color change humidity indicator. Green

indicates a R.H. below 3% and yellow indicates a R.H. above 3%.

Table 3J(page 17) indicates outlet dew point when moisture indicator

changes from green to yellow at various inlet temperatures.

NOTE

During start-up the indicator may be yellow, however, it

should begin to change to green within four hours.

15

150 psig MWP 100% 234 sec.

90% 211 sec.

80% 187 sec.

70% 164 sec.

60% 140 sec.

50% 117 sec.

40% 94 sec.

30% 70 sec.

250 psig MWP 100% 174 sec.

90% 157 sec.

80% 139 sec.

70% 122 sec.

60% 104 sec.

50% 87 sec.

40% 70 sec.

30% 52 sec.

9B Cl OPEN CLOSED CLOSED

6" (2)

ECONOMIZER SWITCH PURGE TIME

SETTING

TIME (Min.)

0 1 2 3 4 5 6 7 8 9 10

3A OPEN CLOSED

3B CLOSED OPEN

9B Cl 6" OPEN (1) Cl CLOSED

9A CLOSED Cl OPEN CLOSED

6" (1)

3.2.2.5 Towerstatuslights- indicatewhenleftandright

towers are drying and regenerating.

3.2.2.6 Valve energized lights

FourLEDsarefurnishedoncontrollertoindicatewhichair

control valves are energized at any particular time

3.2.2.7 Average Demand Meter

The demand meter displays the average demand on the

dryerforthelast 4 cycles.Itisdetermined by dividing 40(time

tocomplete4cyclesatfullflow)bytheactualtimetocomplete

the last 4 cycles.

3.2.2.8 Tower pressure gauges

3.2.2.8.1 Periodically check tower pressure gauges to

verify that tower pressure gauge of tower on-line reads line

pressure and tower pressure gauge of tower off-line reads

below 2 psig. NOTE

Read off-line tower gauge when tower is purging (air

exhausting from muffler)

3.2.2.8.2 Check mufflers for back pressure

Excessive back pressure may result due to the accumu-

lationofdustinthemuffler. Thissometimesoccursafterstart-

upbecauseofdustingof thedesiccantduring towerfillingand

dryer transport.

If the tower pressure gauge of the off-stream tower rises

out of the black area on the gauge dial, muffler elements

should be replaced. A set of purge exhaust muffler replace-

ment elements is supplied with the dryer.

3.2.3 All MODELS - Determine if air control valves are

operating and sequencing correctly.

Refer to Section 1.2 and Figure 1A and 1B for a general

description of operating sequence.

3.2.3.1 Inlet switching and purge/repressurization valves.

1) Tower pressure gauge of tower on-line should read line

pressure. No air should be leaking from purge/repressurization

valve of the on-line tower.

2)Towerpressure gauge oftoweroff-line shouldreadbelow 2

psig while tower is purging. If excessive purge air is exhausting

during purge cycle, inlet valve may have failed to close or a check

valve may be sticking.

3.2.3.2 Check valves

Check valve sticking will result in excessive air discharge

throughamuffler.Ifexcessiveairis dischargedthroughthemuffler

on the left, check if valve 5a or 5d is sticking. If excessive air is

discharged through the muffler on the right, check if valve 5b or 5c

is sticking.

3.2.3.3 Operating Sequence

For dryers with standard controller and dryers with automatic

purge saving system operating on a fixed time cycle-

Figure 3C

and

Table 3C

show valve sequence times when

dryer is operating on a 10 minute cycle.

Figure 3D

and

Table 3D

show sequence times when dryer is operating on a four minute

cycle.

TIME (MIN)

0 1 2 3 4

3A OPEN CLOSED

3B CLOSED OPEN

(1) See table 3C for open times.

VALVE

PRESSURE

9A CLOSED CI OPEN CLOSED

6" (2)

(2) See table 3D for open times.

3.3 Shut Down

3.3.1 Depressurize dryer

3.3.1.1 Open by-pass valve (if one is installed) and close inlet

and outlet isolation valves.

3.3.1.2 Run timer through a tower change cycle until pressure

gauges on both towers read 0 psig.

3.3.2 De-energize dryer

Turn dryer off using on-off switch (indicating lights extin-

guished).

3.4 Loss of Power

Control valves are designed so that upon loss of power the air

dryer is capable of drying air until the desiccant exposed to the air

flow is saturated.

TABLE 3D Purge valve open times for dryers operating on a 4 minute cycle.

VALVE

FIGURE 3D For dryers operating on a 4 minute cycle

TABLE 3C Purge valve open times for dryers operating on a 10 minute cycle.

FIGURE 3C For dryers operating on a 10 minute cycle

150 psig MWP 100% 66 sec.

90% 59 sec.

80% 53 sec.

70% 46 sec.

60% 40 sec.

50% 33 sec.

40% 26 sec.

30% 20 sec.

250 psig MWP 100% 42 sec.

90% 38 sec.

80% 34 sec.

70% 29 sec.

60% 25 sec.

50% 21 sec.

40% 17 sec.

30% 13 sec.

PRESSURE ECONOMIZER SWITCH PURGE TIME

SETTING

16

Determine average outlet flow available by subtracting Aver-

age Purge Flow (APF) found in 3.6.1.2 from the inlet flow to the

dryer. NOTE

Average outlet flow may be used to determine available down-

streamair supplyifastoragevessel(e.g.receivertank)of sufficient

volumeisavailablebetweendryerandpointofairusage.Otherwise

use minimum outlet flow to determine downstream air available.

EXAMPLE

Find maximum inlet flow, maximum and average purge flows,

andminimumandaverageoutletflowsfora60scfmunitwithaMWP

of 150 psig operated at 120 psig on a 10 minute cycle. Dryer will

operate with an inlet air flow of 46 scfm.

Step 1: Find Maximum Inlet Flow @120 psig by multiplying

Maximum Inlet Flow at Rated Conditions from

Table 3E

by Inlet

Pressure Correction Factor for 120 psig from

Table 3F

: 60 x 1.08 =

64.8 scfm.

Step 2: Find Maximum Purge Flow by multiplying Maximum

Inlet Flow at Rated Conditions from

Table 3E

by Maximum Purge

Flow Factor from

Table 3G

: 60 x .162 = 9.7 scfm.

Step 3: Find Average Purge Flow by multiplying Maximum

Inlet Flow at rated conditions from

Table 3E

by Average Purge/

RepressurizationFlowFactorfrom

Table3H:

60x0.097=5.8scfm.

NOTE

At 46scfminletflow,dryerisoperatingat70%ofmaximumflow

found in Step 1: (46/64.8 = 70%.) Average purge flow is based on

Economizer Switch setting of 70%.

Step 4: Find Minimum Outlet Flow available by subtracting

Maximum Purge Flow (Step 2) from inlet flow: 46 - 9.7 = 36.3 scfm.

Step 5: Find Average Outlet Flow available by subtracting

Average Purge Flow (Step 3) from inlet flow: 46 - 5.8 = 40.2 scfm.

3.7 Determining outlet pressure dew point at

various inlet compressed air temperatures:

Theoutletpressuredewpointisdeterminedbythecompressed

air temperature at the inlet to the dryer and cycle time selected ( 4

or 10 minutes). Use

Table 3I

to determine outlet dew points at var-

ious inlet compressed air temperatures and cycle times.

3.5 Verify that dryer is operating within design

parameters

3.5.1 Maximum working pressure:

Refer to Serial Number Tag to determine maximum working

pressure of dryer.

WARNING

Do not operate dryer at pressures above the maximum pres-

sure shown on the tag.

3.5.2 Minimum working pressures:

150 psig, 10.5 kgf/cm

2

MWP models

-

60 psig (4.2 kgf/cm2) for dryers operated on a 10 minute cycle

80 psig (5.6 kgf/cm2) for dryers operated on a 4 minute cycle

250 psig, 17.6 kgf/cm

2

MWP models

125psig(8.8kgf/cm2) for dryersoperatedona 10 minute cycle

150psig(10.5kgf/cm2)fordryersoperatedona4minutecycle.

If lower inlet pressures are encountered, consult factory.

3.5.3 Maximum operating temperature: 120°F (49°C).

3.5.4 Maximum Inlet Flow Capacity

3.5.4.1At100psig(7.0kgf/cm2):Formaximuminletflowat100

psig (7.0 kgf/cm2) refer to

Table 3E.

3.5.4.2Atpressuresotherthan100psig (7.0kgf/cm2):Multiply

inletflowfrom

Table3E

bymultiplierfrom

Table3F

thatcorresponds

to system pressure at inlet to dryer.

3.6 Determining Purge and Outlet Flows:

3.6.1 Purge Flows

3.6.1.1 Maximum Purge Flow.- Maximum Purge Flow (MFP) is

the amount of purge air flowing through the off-stream tower when

the purge/repressurization valve is open. After the purge/

repressurizationvalvecloses,thepurgeflowwillgraduallydecrease

as the off-stream tower repressurizes to line pressure.

For maximum purge flow multiply inlet flow at rated conditions

from

Table 3E

by Maximum Purge Flow Factor from

Table 3G

that

correspondstothedryerMWP,CycleTimeSetting,andairpressure

at inlet to dryer. For dryers supplied with the optional Automatic

PurgeSavingSystemoperatingintheDemandCycleMode,use10

minutes as the cycle time.

3.6.1.2 Average Purge Flow - For dryers with the standard

control board and dryers with the Automatic Purge Saving System

operating in the fixed cycle mode:

The Average Purge Flow (APF) is the actual amount of flow

used during the entire purge/repressurization cycle. It includes the

maximumpurgeflow(MFP)foraportionofthepurge/repressurization

time and the volume of air used for repressurization, averaged over

the cycle time.

To determine average purge flow, multiply maximum inlet flow

atratedconditionsfrom

Table3E

byAveragePurge/Repressurization

Flow Factor from

Table 3H

that corresponds to the dryer Maximum

Working Pressure, Inlet Pressure, Cycle Time Setting, and Econo-

mizer Switch Setting.

3.6.2 Outlet Air Flow

3.6.2.1 Minimum Outlet Flow

Determine minimum outlet flow available from dryer by sub-

tractingMaximum PurgeFlow(MFP)foundin3.6.1.1frominletflow

to the dryer.

3.6.2.2 Average Outlet Flow - For dryers with the standard

control board and dryers with the Automatic Purge Saving System

operating in the fixed cycle mode:

17

4.2 4.9 5.6 6.3 7.0 7.7 8.4 8.8 9.1 9.8 10.5 12.3 14.1 15.8 17.6

0.65 0.74 0.83 0.91 1.00 1.04 1.08 1.10 1.12 1.16 1.20 1.29 1.37 1.45 1.52

60 70 80 90 100 110 120 130 140 150 125 150 175 200 225 250

100% 0.141 0.142 0.143 0.143 0.144 0.139 0.135 0.131 0.128 0.125 0.133 0.125 0.119 0.114 0.111 0.108

90% 0.127 0.128 0.129 0.130 0.130 0.126 0.122 0.119 0.116 0.113 0.120 0.113 0.108 0.104 0.101 0.099

80% 0.114 0.114 0.115 0.116 0.117 0.113 0.110 0.107 0.104 0.102 0.108 0.102 0.098 0.094 0.092 0.090

70% 0.100 0.101 0.101 0.102 0.103 0.100 0.097 0.095 0.092 0.091 0.096 0.091 0.087 0.084 0.082 0.081

60% 0.086 0.087 0.088 0.088 0.089 0.087 0.084 0.082 0.081 0.079 0.083 0.079 0.076 0.074 0.073 0.072

50% 0.073 0.073 0.074 0.075 0.076 0.073 0.072 0.070 0.069 0.068 0.071 0.068 0.066 0.064 0.063 0.063

40% 0.059 0.060 0.060 0.061 0.062 0.060 0.059 0.058 0.057 0.056 0.058 0.056 0.055 0.054 0.054 0.054

30% 0.045 0.046 0.047 0.047 0.048 0.047 0.046 0.046 0.045 0.045 0.046 0.045 0.044 0.044 0.044 0.045

100% 0.147 0.149 0.151 0.153 0.155 0.151 0.148 0.145 0.143 0.141 - 0.141 0.137 0.135 0.134 0.134

90% 0.134 0.136 0.137 0.139 0.141 0.138 0.135 0.133 0.131 0.129 - 0.129 0.127 0.125 0.125 0.125

80% 0.120 0.122 0.124 0.125 0.127 0.124 0.122 0.120 0.119 0.118 - 0.118 0.116 0.115 0.116 0.116

70% 0.106 0.108 0.110 0.112 0.114 0.111 0.110 0.108 0.107 0.106 - 0.106 0.105 0.105 0.106 0.107

60% 0.093 0.095 0.096 0.098 0.100 0.098 0.097 0.096 0.095 0.095 - 0.095 0.095 0.095 0.097 0.098

50% 0.079 0.081 0.083 0.084 0.086 0.085 0.084 0.084 0.084 0.084 - 0.084 0.084 0.085 0.087 0.089

40% 0.065 0.067 0.069 0.071 0.072 0.072 0.072 0.072 0.072 0.072 - 0.072 0.074 0.075 0.078 0.080

30% 0.052 0.053 0.055 0.057 0.059 0.059 0.059 0.060 0.060 0.061 - 0.061 0.063 0.065 0.068 0.071

INLET psig

PRESSURE kgf/cm2

MULTIPLIER

TABLE 3G Maximum Purge Flow Factor

DRYER MWP 150 psig 250 psig

INLET PRESSURE (psig) 60-100 110 120 130 140 150 125 150 175 200 225 250

0.175 0.168 0.162 0.156 0.151 0.146 0.214 0.196 0.184 0.172 0.163 0.155

0.249 0.239 0.230 0.221 0.215 0.207 - 0.326 0.304 0.286 0.270 0.257

CYCLE

TIME 10 minute

4 minute

10

MINUTE

CYCLE

INLET TEMP. °F 35 40 50 60 70 80 90 100 110 120

°C 1.7 4.4 10.1 15.6 21.1 26.7 32.2 37.8 43.3 48.9

°F -34 -28 -22 -16 -10 -4 3 9 15 21

OUTLET P.D.P. °C -36.7 -33.4 -30.0 -26.7 -23.4 -20.0 -16.1 -12.8 -9.5 -6.1

INLET TEMP. °F 35 40 50 60 70 80 90 100 110 120

°C 1.7 4.4 10.1 15.6 21.1 26.7 32.2 37.8 43.3 48.9

. OUTLET P.D.P. °F -75 -70 -65 -60 -55 -50 -45 -40 -35 -30

10 MIN. CYCLE °C -59.4 -56.7 -53.9 -51.1 -48.3 -45.6 -42.8 -40.0 -37.2 -34.4

OUTLET P.D.P. °F -149 -145 -138 -130 -122 -115 -108 -100 -92 -85

4 MIN. CYCLE °C -100.6 -98.3 -94.4 -90.0 -85.6 -81.7 -77.8 -73.3 -68.9 -65.0

TABLE 3J Outlet pressure dew points at moisture indicator color

change

250 psig

ECONOMIZER

SWITCH

SETTING

ECONOMIZER

SWITCH

SETTING

DRYER MWP 150 psig

4

MINUTE

CYCLE

TABLE 3H Average Purge/Repressurization Flow

Factor

TABLE 3I Outlet pressure dew points for dryers supplied with Activated Alumina Desiccant

60 70 80 90 100 110 120 125 130 140 150 175 200 225 250

TABLE 3F Inlet Pressure Correction Factor

MODEL 25 45 60 80 115 165 260 370 450 590 750 930 1130 1350 1550 2100 3000 4100 5400

Inlet @ 100 psig

(7.0 kgf/cm2) 25 45 60 80 115 165 260 370 450 590 750 930 1130 1350 1550 2100 3000 4100 5400

(scfm) (1) (2)

(1) Convert scfm to metric units as follows: 1 scfm = 1.717m3n/h.

(2) "Performance data obtained and presented in accordance with CAGI standard ADF200 - Methods for rating and testing."

Conditions for rating air dryers are: 100 psig (7.0 kgf/cm2) and 100oF (37.8oC)saturated inlet air, and a maximum 5 psi (.4 kgf/cm2) pressure drop. Actual pressure drop for

all units is less than 3 psi at rated conditions.

TABLE 3E Maximum Inlet Flow at Rated Conditions

INLET PRESSURE (psig)

18

FILL

PLUG

DRAIN

PLUGS

FIGURE4A

TABLE 4A Amount of desiccant required for complete change (lb)

MODEL 25 40 60 80 115 165 260 370 450 590

ACTIVATED ALUMINA 48 48 72 106 182 182 316 452 528 710

MODEL 750 930 1130 1350 1550 2100 3000 4100 5400

ACTIVATED ALUMINA 926 1172 1468 1766 2064 2592 3930 4920 7750

4.0 MAINTENANCE

WARNING

The heatless desiccant dryer is a pressure containing device.

Depressurize before servicing. (See Section 3.3)

4.1 Desiccant Replacement

NOTE

The use of the correct replacement desiccant is necessary for

proper dryer operation. Never use hygroscopic salts of the type

commonly used in “deliquescent” type dryers.

4.1.1 Frequency of desiccant replacement

Desiccantshouldbereplacedwhenevertherequired dewpoint

cannot be maintained while the dryer is being operated within its

design conditions and there are no mechanical malfunctions. Refer

to section 5.0 for troubleshooting hints.

NOTE

Desiccantlifeisdeterminedbythequalityoftheinletair.Proper

filtering of the inlet air will extend the life of the desiccant.

Typically desiccant life is 3 to 5 years.

4.1.2 Procedure for Desiccant Charge Replacement

4.1.2.1 Depressurize and de-energize the dryer. (See section

3.3) 4.1.2.2Removethefillanddrain

plugsfromdesiccanttoweranddrain

the spent desiccant. Place a con-

tainer at the base of the vessel to

collect the desiccant. If necessary

tap the sides of the vessels with a

rubber mallet to loosen desiccant.

4.1.2.3 Replace the drain plug

usingteflontapesealantor equiva-

lent.4.1.2.4 Fill the desiccant drying

tower as full as possible with dry

desiccant. Do not tamp desiccant.

4.1.2.5 Replace the fill plug us-

ingteflon tapesealant orequivalent.

4.1.2.6 Repeat this procedure

for the other drying tower.

4.1.3 Insuring desiccant dryness

4.1.3.1 Replacement desiccant is shipped in air tight contain-

ers. Keep the covers on these containers tightly closed until use to

avoidmoisturecontamination.Ifdesiccantisexposedtoairitcanbe

heatedinan oven at400°F(204°C) forfourhours before use,orthe

procedure in 4.1.3.2 can be used.

4.1.3.2 If the dryer is not refilled with dry desiccant, it will be

necessarytooperatethedryerwithaninletflowrateoflessthan50%

of maximum to dry the desiccant. To do this, set the Economizer

Switch for 100%, and the purge pressure for 45 psig. (3.2 kgf/cm2)

NOTE

4.2.2.1 Remove the filter bowl.

4.2.2.2 Clean the filter bowl.

4.2.2.3 Remove the old filter element and discard. Also discard

the small O-ring that seals the filter to the filter assembly head.

4.2.2.4 Insert small replacement O-ring on top of replacement

filter element and replace filter element.

4.2.2.5 After making sure large O-ring in filter head is in place,

reassemble filter bowl to filter head.

4.3 Fuse Replacement

4.3.1 Standard Units Only:

4.3.1.1 Fusesarelocatedonboardinelectricalenclosure. See

Figure 3A or 3B.

FIGURE4B

HEAD

HEAD "O" RING

CARTRIDGE "O" RING

CARTRIDGE

BOWL

4.2 Pilot Air Filter - Element Replacement -

Models 370 scfm and larger

4.2.1Frequencyofreplacement-Pilotairfiltercontainsafilter

elementwhichshouldbechanged yearlyor soonerifpressure drop

across cartridge prevents valves from actuating. Pilot air pressure

must not drop below 60 psig (4.2 kgf/cm2).

4.2.2 Procedure for cartridge replacement.

WARNING

THE FILTER IS A PRESSURE CONTAINING DEVICE. DE-

PRESSURIZE DRYER BEFORE SERVICING. (SEE SECTION

3.3)

19

4.3.2 Fuse Replacement

Only one of the "Valve Power" and one of the "Control

Power" fuses should be installed at any time.

4.3.2.1 Use 1/8 amp fuse in positions 1 & 2

4.3.2.2 Use 1.6 amp fuse in positions 3 & 4.

4.3.2.3 Positions 1 & 4 take 5 mm x 20 mm size.

4.3.2.4 Positions 2 & 3 take 1/4" x 1 1/4" size.

4.3.2.5 Place fuses in positions 2 & 3 or 1 & 4 only. Do not

place fuses in all four positions.

STEP WHAT

NUMBER OCCURS L L R R L P/R L IN R P/R R IN T T B B

LT RT LT RT P/R IN P/R IN L R L R

Start D D LP LP C O C O

1 R IN closes D - LP LP C O C C E X

2 (1) R P/R opens D R LP <2 C O O C E E X

3 No change D R LP <2 C O O C E E X

4 (2) (3) R P/R closes D - LP REP C O C C E X

5 R IN opens D D LP LP C O C O

6 L IN closes - D LP LP C C C O E X

7 (1) L P/R opens R D <2 LP O C C O E E X

8 No change R D <2 LP O C C O E E X

9 (2) (3) L P/R closes - D REP LP C C C O E X

POS. 1 POS.4

POS.2 POS. 3

4.5.2 Test Mode - Automatic Purge Saving System

4.5.2.1 Press cycle selector switch until Test Mode Light

illuminates. This change will not be acknowledged by the controller

until the present cycle is completed (right tower drying terminates)

oruntilthecontroller is de-energizedandre-energized. NOTE: Do

not de-energize dryer unless both towers are at line pressure.

4.5.2.2 Use the alarm reset switch to step through cycle in the

order shown in 4B.

4.5.2.3 Theaveragedemandmeterwillfunctionasavoltmeter

monitoring the voltage from the thermistors. The thermistor being

monitored is indicated in Table 4B. A 0% reading indicates a short

circuit and a 100% reading indicates an open circuit. A curve

relating the demand meter reading to thermistor temperature is

shown in Figure 4C, page 20.

SOLENOID/TERMINALS THERMISTOR

TOWER STATUS VALVE POSITION ENERGIZED BEING CHECKED

(light illuminated) (automatic purge

saving system)

MODE PRESSURE

4.4 Battery replacement

Controller contains a battery which requires replacement

every3to4years. If thebatteryisdeadandthepoweristurned

off and back on, a 10 minute fixed cycle will be selected by

default.

4.5.2.4 After troubleshooting is completed, reset the cycle

selector to the desired position. Use the reset switch to manually

stepthroughthedryeroperatingsequenceuntiltheleft towerdrying

light is illuminated and the reset switch cannot be used to step

through the cycle. At this point, the dryer is on automatic control.

Verify that the right tower depressurizes and repressurizes auto-

matically before leaving the dryer.

If the dryer is switched from the test mode and the cycle is not

completed using the reset switch, the controller will automatically

step through the test mode at a rate of one step every 50 seconds

until the cycle is completed. Normal operation will then resume.

NOTE

Changesinthecycleselectorareonlyacknowledgedwhenthe

present cycle is completed. If in the test mode, continue to step

through dryer operating sequence until left tower drying begins.

NOTES:

(1)Closepurgerate valve during thissteptocheck for any valve leaks. Noairshouldexhaust through the muffler. Ifairisexhausting through the muffler,

check all valves for leaks. After testing for leaks or fixing any leaks, be sure to open the purge pressure valve and reset the purge pressure.

(2) Do not go to the next step until the tower is repressurized.

(3) Switching failure alarm circuit is energized during this step (alarm light should flash until pressure exceeds 40 psig).

CODES:

R IN

- Right inlet valve D - Drying E - Energized

R P/R - Right purge/repressurization valve R - Regenerating TL -Top left

L IN - Left inlet valve LP - Line Pressure TR - Top right

L P/R - Left purge/repressurization valve <2 - Less than 2 psig BL - Bottom left

LT - Left tower REP - Repressurizing BR - Bottom right

RT - Right tower C - Closed

O - Open

Test Mode

4.5 Test Mode

4.5.1 Test Mode - Standard Control Panel

4.5.1.1 To select test mode, de-energize dryer and place DIP

switches 5 and 6 in ON position.

4.5.1.2 Use Reset/Selection Mode switch to step through

cycle in the order shown in Table 4B.

4.5.1.3 When finished (it is recommended that all 9 steps are

completed) de-energize dryer, reset DIP switches 5 and 6 to the

cycle time (4 or 10 minutes) desired, and re-energize.

NOTE

Do not de-energize dryer unless both towers are at line

pressure.

TABLE 4B

20

160

140

120

100

80

60

40

20

0 10 20 30 40 50 60 70 80 90 100

TEMPERATURE RANGE VERSUS AVERAGE DEMAND

THERMISTOR TEMPERATURE RANGE (F)

AVERAGE DEMAND READING

FIGURE4C

This manual suits for next models

19

Table of contents

Other SPX FLOW Dehumidifier manuals

SPX FLOW

SPX FLOW HBP Series User manual

SPX FLOW

SPX FLOW FLEX Series User manual

SPX FLOW

SPX FLOW Hankison HPR Series User manual

SPX FLOW

SPX FLOW Deltech ZP Series User manual

SPX FLOW

SPX FLOW Deltech FLEX Series User manual

SPX FLOW

SPX FLOW DFX 1.1 User manual

SPX FLOW

SPX FLOW Delair EtsilineCommPact User manual

SPX FLOW

SPX FLOW HES Series User manual

SPX FLOW

SPX FLOW Pneumatic Products SHA Series User manual