SPX FLOW HES Series User manual

HES Series

Refrigerated Type Compressed Air Dryers

FORM NO.: 7427751 REVISION: 11/2017 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

Water Cooled

MODELS RATED

FLOW

HES3750

HES5000

HES6250

3750 SCFM

5000 SCFM

6250 SCFM

HES7500

HES8750

HES10000

7500 SCFM

8750 SCFM

10000 SCFM

HES11250

HES12500

11250 SCFM

12500 SCFM

Air Cooled

MODELS RATED

FLOW

HES3150AC

HES4200AC

HES5250AC

3150 SCFM

4200 SCFM

5250 SCFM

HES6300AC

HES7350AC

HES8400AC

6300 SCFM

7350 SCFM

8400 SCFM

HES9450AC

HES10500AC

9450 SCFM

10500 SCFM

CONTENTS

1.0 GENERAL SAFETY INFORMATION ........................................................ 1

2.0 RECEIVING, MOVING, AND UNPACKING .............................................. 1

3.0 INSTALLATION ......................................................................................... 6

4.0 OPERATION ............................................................................................ 9

5.0 MAINTENANCE ........................................................................................ 19

6.0 TROUBLESHOOTING GUIDE.................................................................. 21

7.0 REFERENCE

Sizing......................................................................................................... 24

Engineering Data Tables ........................................................................... 25-26

Dryer Set Point Tables............................................................................... 27-28

Dryer Alarm Tables .................................................................................... 29-30

Controller Screen Shots

Dryer Status Screens............................................................................. 31

Module Status Screens.......................................................................... 32

Alarm History Screens........................................................................... 33

Energy Savings Screens ....................................................................... 34

Dryer Scheduler Screens....................................................................... 35

Dryer Setting Screens............................................................................ 36-37

Network Setting Screens ....................................................................... 38

Factory Setting Screens ........................................................................ 39

8.0 DRAWINGS: WATER-COOLED UNITS

General Arrangement

Models 3750 and 5000 .......................................................................... 40

Models 6250 and 7500 .......................................................................... 41

Models 8750 and 10000 ........................................................................ 42

Models 11250 and 12500 ...................................................................... 43

Electrical Schematic

Refrigeration Dryer ................................................................................ 44-47

Instrumentation Option .......................................................................... 48-50

575V option............................................................................................ 51

9.0 DRAWINGS: AIR-COOLED UNITS

General Arrangement

Models 3150 and 4200 .......................................................................... 52

Models 5250 and 6300 .......................................................................... 53

Models 7350 and 8400 .......................................................................... 54

Models 9450 and 10500 ........................................................................ 55

Electrical Schematic

Refrigeration Dryer ................................................................................ 56-60

Instrumentation Option .......................................................................... 61-63

575V option............................................................................................ 64

10.0 REPLACEMENT PARTS

Cabinet Panels.......................................................................................... 65

Water-Cooled Units ................................................................................... 66-67

Air-Cooled Units ........................................................................................ 68-69

NOTES:................................................................................................................ 70

WARRANTY......................................................................................................... 71

1

2.0 RECEIVING, MOVING, AND UNPACKING

2.1 RECEIVING

This shipment has been thoroughly checked, packed and

inspected before leaving our plant. It was received in good

condition by the carrier and was so acknowledged.

Check for Visible Loss or Damage. If this shipment shows

evidence of loss or damage at time of delivery to you,

insist that a notation of this loss or damage be made on

the delivery receipt by the carrier’s agent.

2.2 UNPACKING

Check for Concealed Loss or Damage. When a shipment

has been delivered to you in apparent good order, but

concealed damage is found upon unpacking, notify the

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

2.3 MOVING

In moving or transporting dryer, do not tip dryer onto its

side.

2.4 STORAGE/SHUT DOWN

The dryer should not be stored outside (either

packaged or unpackaged) or exposed to the weather. Damage

to the electrical and control components may result.

IMPORTANT: If the dryer is shut down in below freezing

temperatures, the water-cooled condenser may freeze and

cause permanent damage. The condenser must be drained

when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above 130°F

(54°C).

1.0 GENERAL SAFETY INFORMATION

1.1 PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Do not exceed maximum operating

pressure as shown on equipment

serial number tag.

• Make sure equipment is depressurized before working

on or disassembling it for service.

1.2 ELECTRICAL:

This equipment requires electricity to

operate.

• Install equipment in compliance with all

applicable electrical codes.

• Standard equipment is supplied with electrical

enclosures not intended for installation in hazardous

environments.

• Disconnect the power supply to the equipment when

performing any electrical service work.

1.3 BREATHING AIR:

• Air treated by this equipment may

not be suitable for breathing without

further purication.

Refer to applicable standards and

specications for the requirements

for breathing quality air.

2

FEATURES AT A GLANCE:

WATER-COOLED UNITS

DETAIL A

MASTER CONTROL ELECTRICAL ENCLOSURE

WITH CUSTOMER INTERFACE

MASTER CONTROL KEYPAD

QUARTER TURN LATCH

MASTER ENCLOSURE POWER

DISCONNECT SWITCH

LED TEXT DISPLAY

A

RIGID GROOVE COUPLINGS

CONDENSATE DRAIN

CONNECTION 3/8-FPT

SEPARATOR ACCESS

(NO PANEL REMOVAL REQUIRED)

3

DETAIL C

SWING PANEL ACCESS

(PANEL HINGES LOCK OPEN @115°)

DETAIL B

MODULE POWER

DISCONNECT SWITCH

QUARTER TURN LATCH FOR

ELECTRICAL ENCLOSURE ACCESS

POWER ON LED (GREEN)

ALARM LED (RED)

WARNING LED (YELLOW)

QUARTER TURN LATCHES FOR

SWING PANEL ACCESS

B

MODULE ELECTRICAL ENCLOSURE

MOUNTED ON SWING PANEL

FLOOR MOUNT BRACKET

GROOVED FLANGE ADAPTERS

4

FEATURES AT A GLANCE:

AIR-COOLED UNITS

DETAIL A

MASTER CONTROL ELECTRICAL ENCLOSURE

WITH CUSTOMER INTERFACE

MASTER CONTROL KEYPAD

QUARTER TURN LATCH

MASTER ENCLOSURE POWER

DISCONNECT SWITCH

LED TEXT DISPLAY

A

SEPARATOR ACCESS

(NO PANEL REMOVAL REQUIRED)

GROOVED FLANGE ADAPTERS

AIR COOLED CONDENSER

(ONE PER MODULE)

VARIABLE SPEED FANS

QUICK DISCONNECT NO-LOSS

REFRIGERATION FITTINGS

CONDENSATE DRAIN

CONNECTION 3/8-FPT

5

DETAIL C

SWING PANEL ACCESS

(PANEL HINGES LOCK OPEN @115°)

DETAIL B

MODULE POWER

DISCONNECT SWITCH

QUARTER TURN LATCH FOR

ELECTRICAL ENCLOSURE ACCESS

POWER ON LED (GREEN)

ALARM LED (RED)

WARNING LED (YELLOW)

QUARTER TURN LATCHES FOR

SWING PANEL ACCESS

FLOOR MOUNT BRACKET

RIGID GROOVE COUPLINGS

MODULE ELECTRICAL ENCLOSURE

MOUNTED ON SWING PANEL

6

3.3 ADDITIONAL INSTALLATION PROCEDURE FOR AIR

COOLED CONDENSER OPTION

A. Air Condenser – Locate air condenser and set condenser

with brackets on top of unit. Locate brackets per drawing

on following page and bolt to frame using Qty (4) 3/8-16

Bolt’s supplied.

B. Install discharge and liquid refrigerant piping per drawing.

Turn until nut bottoms using quick links. Please note piping

is charged with refrigerant.

C. Wire junction box per wiring schematic reference drawing

for air cooled units in manual.

3.4 MODULE INSTALLATION

A. Identify customer-to-dryer connection requirements.

NOTE: Inlet and outlet headers on the dryer offer dual

installation capability. Either end of the header (inlet or

outlet) may be equipped with an adaptor ange or blind

ange for the customer connection.

B. Install a grooved adapter ange to the inlet header of the

module which is to be connected to the customer inlet con-

nection. (Refer to the General Arrangement drawing for

the specic model in Section 8 or 9 of this manual for the

correct Inlet location.)

C. Install a grooved adapter ange to the outlet header of the

module which is to be connected to the customer outlet

connection. (Refer to the General Arrangement drawing

for the specic model in Section 8 or 9 of this manual for

the correct Outlet location.)

D. NOTE: Be sure that the leveling feet are seated completely

against the bottom of the cabinet prior to setting the module.

This will allow the greatest range of adjustment.

Utilizing a standard oor jack and the fork channels con-

structed in the base pan of each module, align the module

with the grooved adapter ange on the inlet connection

with the customer’s inlet connection.

Level and plumb the module by adjusting the leveling feet

at the bottom of each module.

IMPORTANT: READ PRIOR TO STARTING THIS EQUIPMENT

3.0 INSTALLATION

3.1 LOCATION

A. For typical placement in a compressed air system, see

drawing.

B. Air compressor intake – Locate the air compressor so that

contaminants potentially harmful to the dryer (e.g. ammo-

nia) are not drawn into the air system.

C. The dryer should be installed in a moderately heated, well

ventilated area. Avoid locations immediately adjacent to

cold exterior windows or walls, or adjacent to high tem-

perature ovens or boilers.

D. The dryer should be installed in the air system at the high-

est air pressure possible (e.g. before pressure reducing

valves).

E. The dryer should be installed in the air system at the cool-

est compressed air temperature possible.

F. Clearances:

Service clearance should be a minimum of 48 inches

(1220 mm) on all sides to allow adequate space for access

and maintenance. Recommended overhead clearance is

36 inches (914mm) from top of cabinet for water cooled

unit and top of condenser for air cooled unit.

G. Standard units are designed to operate in ambient:

Water-cooled: 40 to 130°F (4 to 54°C)

Air-cooled: 40 to 110°F (4 to 43°C).

H. Dryer is designed to operate at all altitudes - no adjust-

ment for altitude is required.

I. The installation of a exible connection prior to the dryer is

recommended to prevent possible damage from vibration.

NOTE: Outdoor installation – Standard units are designed for

indoor installation. Contact manufacturer if installing outdoors.

3.2 MOUNTING

Mount the dryer on a level solid surface.

Aftercooler

Separator

Dryer

Compressor

7

C

D

DETAIL C

CONDENSER INLET

(GAS LINE)

SEE NOTES!

CONDENSER OUTLET

(LIQUID LINE)

SEE NOTES!

DETAIL D

ATTACH SUPPORT STRUCTURE WITH

BOLT & WASHER UP THROUGH FROM

INSIDE AND WASHER & LOCKNUT ON

TOP, OUTSIDE UNIT (2 PLACES)

CONNECT CONDENSER

POWER HARNESS

TO CORRESPONDING

JUNCTION BOX

TERMINALS

ATTACH REAR SUPPORT STRUCTURE

W/ BOLT & WASHER DOWN THROUGH

FROM OUTSIDE AND WASHER &

LOCKNUT INSIDE UNIT. (2 PLACES)

MAIN POWER ENTRY IS

IN CONDENSER ENCLOSURE

AT BOTTOM CENTER

NOTES:

1. After installing the condenser unit assembly to the top

of the module, apply appropriate amount of approved

refrigerant tting lubricant to the condenser lines quick

connect ttings (Detail ‘C’).

2. Connect line assemblies between condenser and dryer

module (Detail ‘C’).

3. Use back up wrenches when tightening ttings to prevent

twisting lines, making sure the ttings are fully seated.

4. After the lines are connected, use a leak detection device

to assure there are no leaks at the connections.

INSTALLATION PROCEDURE FOR AIR COOLED CONDENSER

8

E. Connect the module to the customer’s inlet connection.

Tighten ange bolts.

NOTE: Tighten ange bolts to customer outlet connec-

tion if grooved adapter ange to the outlet header is also

installed on module.

F. CRITICAL ASSEMBLY NOTE! The permissible gap

range between the ends of the adjacent inlet and outlet

headers is 0 - 0.25 inches. Also, based on the tolerance

of the modules the module cabinets may either be ush or

will provide a gap. Check each module cabinet gap prior

to tightening the header couplings in place and set the gap

to be consistent if so desired.

Repeat step D for installing the remaining modules to the

dryer. Connect the modules together using couplings

provided. Tighten bolts.

NOTE: The modules are numbered and should be

installed in sequential order. If piping begins on the right

side, start with the highest numbered module rst and

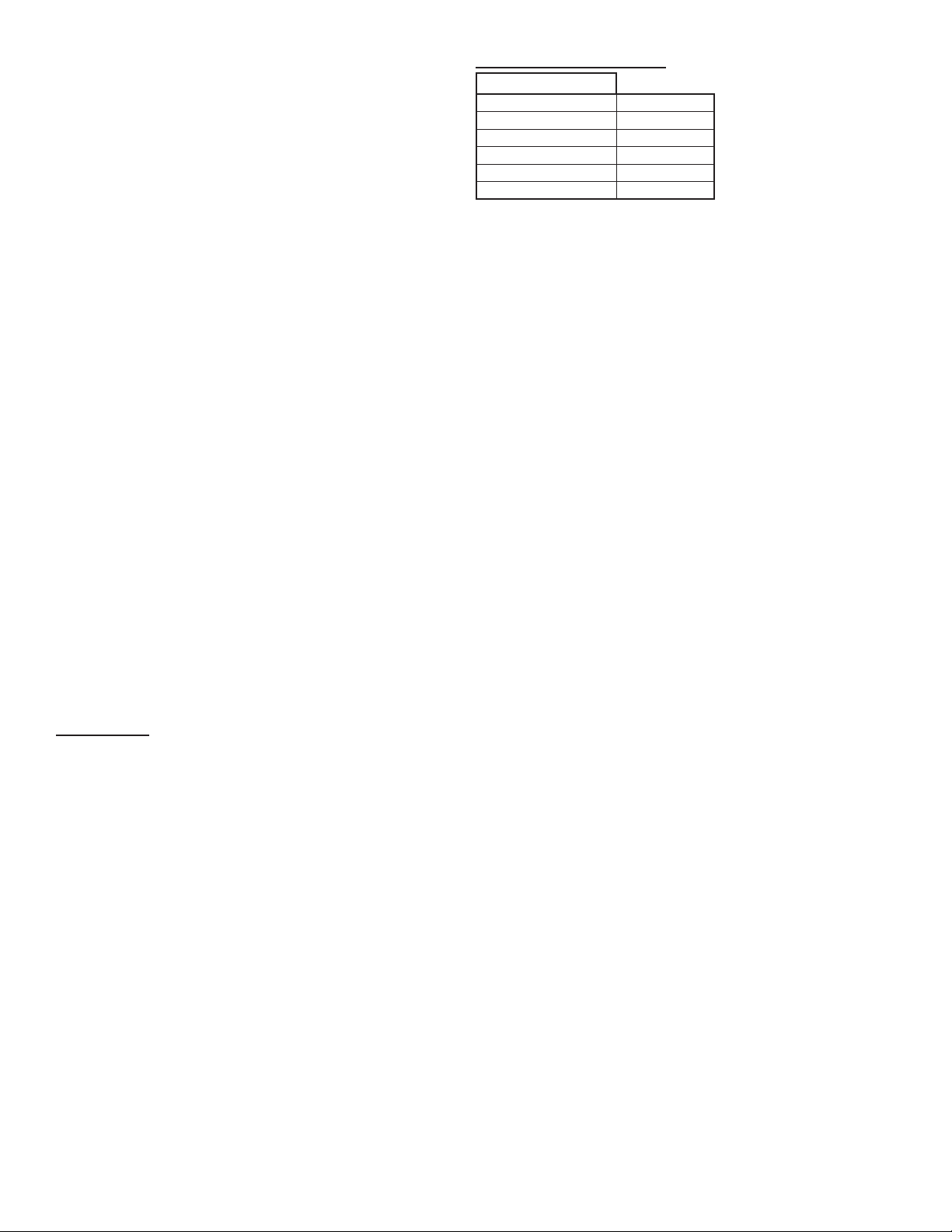

Cooling Water System – Hose Labeling Matrix

Flow Rate Module Position Module Tie Wrap Label Description

3750 - 5000 scfm

M2 Z

M2 Cooling Water Inlet Wrap - MI

Cooling Water Outlet Wrap - MO

ZCooling Water Inlet Wrap - ZI

Cooling Water Outlet Wrap - ZO

Flow Rate Module Position Module Tie Wrap Label Description

6250 - 7500 scfm

M3 Y Z

M3 Cooling Water Inlet Wrap - MI

Cooling Water Outlet Wrap - MO

YCooling Water Inlet Wrap - YI

Cooling Water Outlet Wrap - YO

ZCooling Water Inlet Wrap - ZI

Cooling Water Outlet Wrap - ZO

Flow Rate Module Position Module Tie Wrap Label Description

8750 - 10000 scfm

M4 X Y Z

M4 Cooling Water Inlet Wrap - MI

Cooling Water Outlet Wrap - MO

XCooling Water Inlet Wrap - XI

Cooling Water Outlet Wrap - XO

YCooling Water Inlet Wrap - YI

Cooling Water Outlet Wrap - YO

ZCooling Water Inlet Wrap - ZI

Cooling Water Outlet Wrap - ZO

Flow Rate Module Position Module Tie Wrap Label Description

11250 - 12500 scfm

M5 W X Y Z

M5 Cooling Water Inlet Wrap - MI

Cooling Water Outlet Wrap - MO

WCooling Water Inlet Wrap - WI

Cooling Water Outlet Wrap - WO

XCooling Water Inlet Wrap - XI

Cooling Water Outlet Wrap - XO

YCooling Water Inlet Wrap - YI

Cooling Water Outlet Wrap - YO

ZCooling Water Inlet Wrap - ZI

Cooling Water Outlet Wrap - ZO

work down. Piping that begins on the left side will start

with the lowest numbered module and work up. Interior

modules can be identied by their open framework on

each side of the module.

G. Install blind anges on module headers not previously

tted with grooved adapter anges.

H. Secure the dryer to the oor with the oor mounting

brackets provided on the Master Module and the end

Dryer Module.

3.5 WATER CONNECTIONS (Standard Water Cooled Unit)

A. Connect the cooling water supply to the cooling water inlet

connection of the dryer.

B. Connect the cooling water return line to the cooling water

outlet connection of the dryer.

NOTE: It is recommended to add water inlet and outlet

temperature and pressure gauges to the water piping at

the dryer inlet and outlet connections.

9

4.0 OPERATION

Basic theory of operation: The dryer uses digital scroll technol-

ogy to achieve energy savings. The refrigeration compres-

sor has a unique mechanism that allows it to be completely

“unloaded”.

This is accomplished internally, using a piston to “pull” the

upper scroll apart from the lower scroll. This stops the com-

pression of the refrigerant and dramatically reduces energy

consumption. The compressor motor continues to spin, provid-

ing lubrication to the mechanism.

At the rated compressed air ow rate, the compressor runs

fully loaded. At reduced ow rates, the control system

determines the amount of unloading required to maintain a

constant outlet dew point.

NOTE: The compressor sound changes noticeably between

the loaded and unloaded state, this occurs every ten to forty

seconds.

4.1 MINIMUM/MAXIMUM OPERATING CONDITIONS

A. Inlet air pressure: 30 / 232 psig (2 /16 barg)

B. Inlet air temperature: 40 / 130°F (4 / 54°C)

C. Ambient temperature:

Water Cooled: 40 / 130°F (4 / 54°C)

Air Cooled: 40 / 110°F (4 / 43°C)

4.2 START-UP

(Refer to the Control Panel illustration on the following page

and Controller Screen Shots in Section 8 for control panel as-

sistance)

A. Energize the dryer by turning on the red/yellow disconnect

switches at the main display control panel and at each

module. A green power on light will illuminate and blink on

each enclosure.

IMPORTANT: Energize for 24 hours before starting the

dryer! All disconnect switches must be turned on. Never

use the disconnect switches to shut down the dryer for

an extended period of time (except for repair). Failure to

follow these instructions may result in a non-warrantable

compressor failure.

B. Programming the Dryer Controller (MEM)

Select and press the keypad button associated with each

programming function. Use the Up and Down arrow buttons

to scroll through the list of sub-menu choices. Press the Enter

button to view the sub-menu that is displayed. Press ESC to

return to the Main Menu.

1. Setting Date & Time

a. Press the Clock keypad button to display the Date/

Time Set-up Menu.

NOTE: This menu can also be displayed by pressing

the Set-up Menu keypad button.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set year (10

to 99 representing 2010 to 2099). Press ‘Enter’ to

accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set month (01

to 12). Press ‘Enter’ to accept new value.

NOTE: Each module is shipped from the factory with the

necessary water piping included. A strainer and water

regulating valve is supplied on each dryer module.

C. Open the swing panels that hold the module electrical

enclosures.

D. Connect the labeled water lines of each module to the

barbed ttings of the mating lines located on the module to

its left. See the table below for hose identication.

3.6 ELECTRICAL CONNECTIONS

IMPORTANT: Use copper supply wires

only.

A. The dryer is designed to operate on

the voltage, phase, and frequency

listed on the serial number tag.

B. Water Cooled Units: The electrical supply connection for

each dryer module is made in the junction box located at

the top of each module. Refer to the dryer serial tag or the

electrical data table for the maximum overcurrent protec-

tion to be used with each dryer module circuit.

NOTE: The dryer is designed to run continuously

and should NOT be wired to cycle on/off with the air

compressor.

C. Air Cooled Units: The electrical supply connection for

each dryer module is made in the junction box located at

the end of the air cooled condenser. Refer to the dryer

serial tag or the electrical data table for the maximum

overcurrent protection to be used with each dryer module

circuit.

NOTE: The dryer is designed to run continuously and should

NOT be wired to cycle on/off with the air compressor.

3.7 CONDENSATE AND ELECTRONIC

DEMAND DRAIN (EDD) CONNECTIONS

A. Connect customer supplied condensate

line to condensate drain connection lo-

cated at the bottom left of the dryer.

NOTE: Condensate may contain oil.

Comply with applicable laws concerning

proper disposal.

B. All dryer modules are supplied with one EDD as standard.

Modules with the additional (optional) oil removal lters

are supplied with two additional EDDs each.

C. From the back of each module, remove the panel and

connect each drain line to the adjacent module using the

push-to-connect drain connections.

3.8 COMMUNICATION CONNECTIONS

A. Open the swing panels that hold the module electrical

enclosures.

B. Locate the communications cable located at the top right

corner of the module.

C. Plug the cable in to the connector located on the back of

the swing panel of the module to its right.

10

d. Use the ‘Up’ and ‘Down’ arrow buttons to set day (01

to maximum for the month and year selected). Press

‘Enter’ to accept new value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set hours (00

to 23). Press ‘Enter’ to accept new value.

f. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00 to 59). Press ‘Enter’ to accept new value.

g. Use the ‘Up’ and ‘Down’ arrow buttons to set seconds

(00 to 59). Press ‘Enter’ to accept new value.

2. Setting Schedule

a. Press the Scheduler keypad button.

b. Use the ‘Up’ and ‘Down’ arrow buttons to select desired

“Day of week ”. Press ‘Enter’ to accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set hour (00

to 23). Press ‘Enter’ to accept new value.

NOTE: If the hour setting is ‘IGNORE’, Press ‘Enter’

again.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes.

Press ‘Enter’ to accept new value. Repeat steps a

through c as needed.

3. Setting Hours To Service

a. Press the Set-up Menu keypad button.

b. Use the Up and Down arrow buttons to scroll to the

Service Interval Set-Up menu. Press ‘Enter’ to view

the sub-menu.

c. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the range of permissible values (1000 to 8000) before

service reminder is initiated. Press ‘Enter’ to accept

new value. (Only hours that refrigeration compressor is

operating are counted).

NOTE: All dryers contain an integral 3 micron lter.

As the lter element accumulates solid contaminants,

differential pressure increases. Solid particulate

load in the compressed air supply will determine

frequency of service. Typically element change out is

recommended at least annually.

4. Energy Cost

a. Press the Set-up Menu keypad button.

b. Use the Up and Down arrow buttons to scroll to the

Energy Cost Set-Up menu. Press ‘Enter’ to view the

sub-menu.

c. Use the ‘Up’ and ‘Down’ arrow buttons to select the

desired currency ($ or €). Press ‘Enter’ to accept new

value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set the

energy cost. Press ‘Enter’ to accept new value.

5. Event or Alarm History

a. Press the Event keypad button.

b. Use the Event keypad button to scroll through the

Event (Alarm History) menu.

c. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the last twenty (20) alarms beginning with the most

recent alarm.

NOTE: The number at the end of the top line identies

which of the past twenty alarms is being displayed.

C. Starting the Dryer

IMPORTANT: The dryer must be energized 24 hours before

starting the refrigeration compressor.

NOTE: It is recommended that dryer be started 15 minutes

before compressed air ow begins.

1. Begin cooling water ow prior to starting water cooled

units. Turn air condenser disconnect on for air cooled

units.

NOTE: If a module must be shut down, refer to section

5.1 – “Procedure for Shutting Down a Single Module”

located on page 18.

2. Check for proper electrical voltage.

3. Conrm the module ball valves located behind the electri-

cal enclosure swing panel are open, unless the module is

intended to be off-line.

4. The dryer may be operated in either manual or scheduled

mode.

a. Manual mode - This mode is initiated by pushing the

On/Off button. The modules will run continuously and

will not be turned on and off by the controller. All of the

modules will be started when pushing the On/Off from

the home screen. Individual modules can be started

from the module screen. Push the module button and

push the On/Off button. Scroll to the next module by

using the module button then push the On/Off button.

Continue this until all the desired modules are started.

From the home screen, scroll down one screen to see

the status of each module.

Module Status Modes: S - standby, R - running,

A - alarm, D - disconnected

Once turned On, the dryer and modules will begin will

begin to register a load percentage value. The mod-

ules can also be turned off at the dryer home screen or

individually at the module screen.

b. Schedule mode - This mode allows the user to set a

weekly schedule for when the dryer will be on and off.

See 4.2.B.2 for setting the schedule. Each module can

be selected to operate on the preset schedule. Press

the module key and press Enter to select either Manual

Standby or Scheduled Standby.

NOTE: The dryer may be returned to the manual mode

at any time using the ‘On/Off’ button. MANUAL FIXED or

MANUAL STANDBY will appear on display panel. To reinstitute

Schedule, go to the module screen and push the Enter button.

NOTE: The dryer will not automatically restart in the event

of a power failure. Consult factory if it is desired to have the

equipment automatically restart after power interruption.

NOTE: The dryer will run in FIXED mode for a brief period

then switch over to PID control.

5. Slowly pressurize the unit air side by opening the inlet

isolation valve. Check for air leaks.

6. After 15 minutes, slowly open the outlet isolation valve and

close the air by-pass valve (if equipped).

11

RESET

I 2 3

ESC

$

RESET

I 2 3

ESC

$

1

2

3

4

5

CONTROL PANEL

1. Alarm / Service Light

2. Warning Light

3. Power-on Light

4. Operator Interface Display

5. Operator Keypad

6. Disconnect Switch

6

Operator Keypad

Dryer Status I 2 3 Module Status Setup Up Arrow

Scheduler Graph Event Down Arrow

$Energy Savings Mute Date/Time Setup Enter

Shift

ESC

Escape/Cancel

RESET

Reset On/Off

12

D. Operating Check Points

1. Check that no alarms or warnings exist. The green light

only should be illuminated on the module and master elec-

trical enclosures. A yellow light indicates a warning which

indicates an issue that needs to be addressed. The dryer

will continue to operate. A red light indicates an alarm and

will shut down the affected module. Refer to the Trouble-

shooting Guide for addressing Warnings and Alarms.

2. The home screen will indicate an operating load % value

for the dryer. Press the module button and scroll through

each module to conrm the status is NORMAL and a load

% value for the module is displayed.

3. Check the operating parameters of the modules by select-

ing the modules using the arrow keys to scroll through the

list.

4. If equipped with the optional instrumentation package, ad-

ditional parameters can be viewed on the home screen by

using the arrow keys.

E. Using the RS-485 Port Connector (J3)

This connector provides RS-485 compatible signals from the

internal master microprocessor. Using jumpers on the headers

supplied near the connector (J1 and J2), 120 ohm termination

resistors can be connected and the system can be connected

for either two-wire or four-wire operation (half or full duplex). To

connect the termination resistors, install jumpers on J1 in the

direction shown by the white bars printed above the connector.

If the jumpers are removed no termination of the RS-485 bus is

in effect. Usually, these jumpers must be in position for proper

operation of the bus.

J2 (located above J1) contains the two-wire/four-wire jumpers. If

the jumpers are in place, the circuit is set up for two-wire opera-

tion. If the jumpers are removed the circuit is set up for four-wire

operation. Selection of jumper settings must be determined by the

customer’s system. The jumpers are supplied as standard and

are installed as shown at the factory. Be sure to set the jumpers

properly for your system.

RS-485 Pinout

Following is the pinout for J3, the RS-485 communications

connector.

1 TX-

2 TX+

3 RX+

4 RX-

5 Data Enable - asserted high (+5 VDC) when transmitting

6 100 Ohms to Ground

7 TX- (spare)

8 TX+ (spare)

When connected in two-wire mode, the bus wires may be

connected to pins 1 & 2, Pins 3 & 4 or pins 7 & 8. Also note

that when in two-wire mode, one termination resistor jumper

should be removed to prevent the termination from being too

low in value. It may be stored on the top set of pins on J1.

Those pins are not connected. Please make sure that your

connections are properly made. This connector is an 8-pin

RJ45 connector. Mating connectors are not supplied. The

electrical signals supplied by this connector are TIA/EIA-485A

compliant. A good cable should be used to transmit signals

such as Belden 3109A or equivalent.

Communication Parameters:

RS-485 Parameters

Baud Rate 19200

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Slave ID 1

13

Modbus Registers

Page 1 of 3

Holding Register

Reference Address Name Units Description

40001 0x0000 DRYER_STATUS Status ID Status ID for the dryer

40002 0x0001 ALARM_STATUS Flag Bits Alarm ag bits

40003 0x0002 WARNING_STATUS Flag Bits Warning ag bits

40004 0x0003 SERVICE_STATUS Flag Bits Service ag bits

40005 0x0004 DRYER_LOAD Percent Dryer load as a percentage of full load

40006 0x0005 AVG_DAILY_LOAD Percent Average daily dryer load

40007 0x0006 AVG_MONTHLY_LOAD Percent Average monthly dryer load

40008 0x0007 INLET_AIR_TEMP Celsius Inlet air temperature

40009 0x0008 WATER_TEMP / AMBIENT_TEMP Celsius Water Cooled - Cooling water temperature / Air Cooled - Ambient air temperature

40010 0x0009 OUTLET_AIR_PRESSURE PSIG Outlet air pressure

40011 0x000A WATER_PRESS / RESERVED PSIG Water Cooled - Cooling water pressure / Air Cooled - Reserved

40012 0x000B ANNUAL_SAVINGS Integer Projected annual energy savings in dollars / euros

40013 0x000C CUMULATIVE_SAVINGS Integer Total cumulative energy savings in dollars / euros

40017 0x0010 MOD_1_STATUS Status ID Status ID for module #1

40018 0x0011 MOD_1_ALARMS Flag Bits Alarm ag bits

40019 0x0012 MOD_1_WARNING Flag Bits Warning ag bits

40020 0x0013 MOD_1_SERVICE Flag Bits Service ag bits

40021 0x0014 MOD_1_LOAD Percentage Module load as a percentage of full load

40022 0x0015 MOD_1_PV PSIG Process value

40023 0x0016 MOD_1_SUCTION_TEMP Celsius Suction temperature

40024 0x0017 MOD_1_SEPARATOR_TEMP Celsius Separator temperature

40025 0x0018 MOD_1_DISCHARGE_TEMP Celsius Discharge temperature

40026 0x0019 MOD_1_SUCTION_PRESS PSIG Suction pressure

40027 0x001A MOD_1_DISCHARGE_PRESS PSIG Discharge pressure

40028 0x001B MOD_1_SERVICE_TIMER Hours Module service timer

40029 0x001C MOD_1_TOTAL_TIMER Hours Module total operating timer

40030 0x001D MOD_1_ALARM_PHRASE1 Phrase ID Alarm phrase 1

40031 0x001E MOD_1_ALARM_PHRASE2 Phrase ID Alarm phrase 2

40032 0x001F MOD_1_ALARM_PHRASE3 Phrase ID Alarm phrase 3

40033 0x0020 MOD_2_STATUS Status ID Status ID for module #2

40034 0x0021 MOD_2_ALARMS Flag Bits Alarm ag bits

40035 0x0022 MOD_2_WARNING Flag Bits Warning ag bits

40036 0x0023 MOD_2_SERVICE Flag Bits Service ag bits

40037 0x0024 MOD_2_LOAD Percentage Module load as a percentage of full load

40038 0x0025 MOD_2_PV PSIG Process value

40039 0x0026 MOD_2_SUCTION_TEMP Celsius Suction temperature

40040 0x0027 MOD_2_SEPARATOR_TEMP Celsius Separator temperature

40041 0x0028 MOD_2_DISCHARGE_TEMP Celsius Discharge temperature

40042 0x0029 MOD_2_SUCTION_PRESS PSIG Suction pressure

40043 0x002A MOD_2_DISCHARGE_PRESS PSIG Discharge pressure

40044 0x002B MOD_2_SERVICE_TIMER Hours Module service timer

40045 0x002C MOD_2_TOTAL_TIMER Hours Module total operating timer

40046 0x002D MOD_2_ALARM_PHRASE1 Phrase ID Alarm phrase 1

40047 0x002E MOD_2_ALARM_PHRASE2 Phrase ID Alarm phrase 2

40048 0x002F MOD_2_ALARM_PHRASE3 Phrase ID Alarm phrase 3

14

Modbus Registers

Page 2 of 3

Holding Register

Reference Address Name Units Description

40049 0x0030 MOD_3_STATUS Status ID Status ID for module #3

40050 0x0031 MOD_3_ALARMS Flag Bits Alarm ag bits

40051 0x0032 MOD_3_WARNING Flag Bits Warning ag bits

40052 0x0033 MOD_3_SERVICE Flag Bits Service ag bits

40053 0x0034 MOD_3_LOAD Percentage Module load as a percentage of full load

40054 0x0035 MOD_3_PV PSIG Process value

40055 0x0036 MOD_3_SUCTION_TEMP Celsius Suction temperature

40056 0x0037 MOD_3_SEPARATOR_TEMP Celsius Separator temperature

40057 0x0038 MOD_3_DISCHARGE_TEMP Celsius Discharge temperature

40058 0x0039 MOD_3_SUCTION_PRESS PSIG Suction pressure

40059 0x003A MOD_3_DISCHARGE_PRESS PSIG Discharge pressure

40060 0x003B MOD_3_SERVICE_TIMER Hours Module service timer

40061 0x003C MOD_3_TOTAL_TIMER Hours Module total operating timer

40062 0x003D MOD_3_ALARM_PHRASE1 Phrase ID Alarm phrase 1

40063 0x003E MOD_3_ALARM_PHRASE2 Phrase ID Alarm phrase 2

40064 0x003F MOD_3_ALARM_PHRASE3 Phrase ID Alarm phrase 3

40065 0x0040 MOD_4_STATUS Status ID Status ID for module #4

40066 0x0041 MOD_4_ALARMS Flag Bits Alarm ag bits

40067 0x0042 MOD_4_WARNING Flag Bits Warning ag bits

40068 0x0043 MOD_4_SERVICE Flag Bits Service ag bits

40069 0x0044 MOD_4_LOAD Percentage Module load as a percentage of full load

40070 0x0045 MOD_4_PV PSIG Process value

40071 0x0046 MOD_4_SUCTION_TEMP Celsius Suction temperature

40072 0x0047 MOD_4_SEPARATOR_TEMP Celsius Separator temperature

40073 0x0048 MOD_4_DISCHARGE_TEMP Celsius Discharge temperature

40074 0x0049 MOD_4_SUCTION_PRESS PSIG Suction pressure

40075 0x004A MOD_4_DISCHARGE_PRESS PSIG Discharge pressure

40076 0x004B MOD_4_SERVICE_TIMER Hours Module service timer

40077 0x004C MOD_4_TOTAL_TIMER Hours Module total operating timer

40078 0x004D MOD_4_ALARM_PHRASE1 Phrase ID Alarm phrase 1

40079 0x004E MOD_4_ALARM_PHRASE2 Phrase ID Alarm phrase 2

40080 0x004F MOD_4_ALARM_PHRASE3 Phrase ID Alarm phrase 3

40081 0x0050 MOD_5_STATUS Status ID Status ID for module #5

40082 0x0051 MOD_5_ALARMS Flag Bits Alarm ag bits

40083 0x0052 MOD_5_WARNING Flag Bits Warning ag bits

40084 0x0053 MOD_5_SERVICE Flag Bits Service ag bits

40085 0x0054 MOD_5_LOAD Percentage Module load as a percentage of full load

40086 0x0055 MOD_5_PV PSIG Process value

40087 0x0056 MOD_5_SUCTION_TEMP Celsius Suction temperature

40088 0x0057 MOD_5_SEPARATOR_TEMP Celsius Separator temperature

40089 0x0058 MOD_5_DISCHARGE_TEMP Celsius Discharge temperature

40090 0x0059 MOD_5_SUCTION_PRESS PSIG Suction pressure

40091 0x005A MOD_5_DISCHARGE_PRESS PSIG Discharge pressure

40092 0x005B MOD_5_SERVICE_TIMER Hours Module service timer

40093 0x005C MOD_5_TOTAL_TIMER Hours Module total operating timer

40094 0x005D MOD_5_ALARM_PHRASE1 Phrase ID Alarm phrase 1

40095 0x005E MOD_5_ALARM_PHRASE2 Phrase ID Alarm phrase 2

40096 0x005F MOD_5_ALARM_PHRASE3 Phrase ID Alarm phrase 3

15

Modbus Registers

Page 3 of 3

Holding Register

Reference Address Name Units Description

40129 0x0080 NUM_MODULES Integer Number of installed modules

40130 0x0081 SERVICE_INTERVAL Hours Service interval

40131 0x0082 ENERGY_COST Integer Energy cost in 1/100th Dollars / Euros per kWh

40132 0x0083 CONDENSER_TYPE Integer Condenser type selection (0=Water Cooled, 1=Air Cooled)

40133 0x0084 MODBUS_ADDRESS Integer Modbus drop number

40134 0x0085 AUDIBLE_ALARM Boolean Audible alarm enabled

40135 0x0086 WATER_PRESSURE_SP PSIG Low cooling water pressure alarm set point

40136 0x0087 WATER_TEMPERATURE_SP Celsius High cooling water temperature alarm set point

40137 0x0088 INLET_TEMPERATURE_SP Celsius High inlet air temperature alarm set point

40138 0x0089 OUTLET_PRESSURE_SP PSIG Low outlet air pressure alarm set point

40139 0x008A AMBIENT_TEMPERATURE_SP Celsius High ambient air temperature alarm set point

40140 0x008B MOD_1_TYPE Integer Module type (0=None, 1=6HP, 2=10HP)

40141 0x008C MOD_2_TYPE Integer Module type (0=None, 1=6HP, 2=10HP)

40142 0x008D MOD_3_TYPE Integer Module type (0=None, 1=6HP, 2=10HP)

40143 0x008E MOD_4_TYPE Integer Module type (0=None, 1=6HP, 2=10HP)

40144 0x008F MOD_5_TYPE Integer Module type (0=None, 1=6HP, 2=10HP)

16

Modbus Register Details

Page 1 of 3

Dryer Status Flags

Register 40001

Bit Mask Description

0 0x0001 Module 1 status (0 = not installed, 1 = installed)

1 0x0002 Module 2 status (0 = not installed, 1 = installed)

2 0x0004 Module 3 status (0 = not installed, 1 = installed)

3 0x0008 Module 4 status (0 = not installed, 1 = installed)

4 0x0010 Module 5 status (0 = not installed, 1 = installed)

5 0x0020 Reserved

6 0x0040 Reserved

7 0x0080 Reserved

Dryer Alarm Flags

Register 40002

Bit Mask Description

0 0x0001 Reserved

1 0x0002 Reserved

2 0x0004 Reserved

3 0x0008 Reserved

4 0x0010 Reserved

5 0x0020 Reserved

6 0x0040 Reserved

7 0x0080 Reserved

Dryer Warning Flags

Register 40003

Bit Mask Description

0 0x0001 Inlet temperature sensor failure

1 0x0002 Cooling water temperature sensor failure

2 0x0004 Outlet pressure sensor failure

3 0x0008 High inlet air temperature

4 0x0010 High cooling water temperature

5 0x0020 Low cooling water pressure

6 0x0040 Low outlet air pressure

7 0x0080 Cooling water pressure sensor failure

8 0x0100 Ambient air temperature sensor failure

9 0x0200 High ambient air temperature

10 0x0400 Reserved

11 0x0800 Reserved

12 0x1000 Reserved

13 0x2000 Reserved

14 0x4000 Reserved

15 0x8000 Reserved

17

Modbus Register Details

Page 2 of 3

Dryer Service Flags

Register 40004

Bit Mask Description

0 0x0001 Service Module #1

1 0x0002 Service Module #2

2 0x0004 Service Module #3

3 0x0008 Service Module #4

4 0x0010 Service Module #5

5 0x0020 Reserved

6 0x0040 Reserved

7 0x0080 Reserved

Module Status

Register(s) 40017, 40033, 40049, 40065, 40081

Decimal Hex Description

0 0x0000 Standby

1 0x0001 Fixed Cycle

2 0x0002 PID Cycle

3 0x0003 Alarm

Module Alarm Flags

Register(s) 40018, 40034, 40050, 40066, 40082

Bit Mask Description

0 0x0001 Compressor failure

1 0x0002 Suction pressure sensor failure

2 0x0004 Discharge pressure sensor failure

3 0x0008 High discharge temperature

4 0x0010 High suction super heat

5 0x0020 Low refrigerant pressure alarm

6 0x0040 High refrigerant pressure alarm

7 0x0080 Compression alarm

8 0x0100 Discharge temperature sensor failure

9 0x0200 Suction temperature sensor failure

10 0x0400 Crank case heater failure

11 0x0800 Reserved

12 0x1000 Reserved

13 0x2000 Reserved

14 0x4000 Reserved

15 0x8000 Reserved

18

Modbus Register Details

Page 3 of 3

Module Warning Flags

Register(s) 40019, 40035, 40051, 40067, 40083

Bit Mask Description

0 0x0001 Separator temperature sensor failure

1 0x0002 Drain 1 alarm

2 0x0004 Drain 2 alarm

3 0x0008 Drain 3 alarm

4 0x0010 High separator temperature

5 0x0020 High refrigerant pressure warning

6 0x0040 Reserved

7 0x0080 Reserved

8 0x0100 Reserved

9 0x0200 Reserved

10 0x0400 Reserved

11 0x0800 Reserved

12 0x1000 Reserved

13 0x2000 Reserved

14 0x4000 Reserved

15 0x8000 Reserved

Module Service Flags

Register(s) 40020, 40036, 40052, 40068, 40084

Bit Mask Description

0 0x0001 Reserved

1 0x0002 Reserved

2 0x0004 Reserved

3 0x0008 Reserved

4 0x0010 Reserved

5 0x0020 Reserved

6 0x0040 Reserved

7 0x0080 Reserved

This manual suits for next models

32

Table of contents

Other SPX FLOW Dehumidifier manuals

SPX FLOW

SPX FLOW FLEX Series User manual

SPX FLOW

SPX FLOW Hankison DH Series User manual

SPX FLOW

SPX FLOW Delair EtsilineCommPact User manual

SPX FLOW

SPX FLOW DFX 1.1 User manual

SPX FLOW

SPX FLOW Deltech ZP Series User manual

SPX FLOW

SPX FLOW Hankison HPR Series User manual

SPX FLOW

SPX FLOW HBP Series User manual

SPX FLOW

SPX FLOW Deltech FLEX Series User manual

SPX FLOW

SPX FLOW Pneumatic Products SHA Series User manual