Sterling STT 110 User manual

Operating Instructions

Dehumidified air dryer

STT 110

STT 160

506-2MS

Sterling Material Processing

Technical service:

Service department

Telephone: (800) 423-3183

Edition: 04/02

506-2MS

STT 110 / STT 160

2

These operating instructions are for*:

(* Please fill in personally)

Serial number:

Year of manufacture:

Date of delivery:

Number of delivery:

Date of commissioning:

Location:

Group of machines:

Sterling Material Processing

5200 West Clinton Ave.

Milwaukee, WI 53223

Telephone: (414) 354-0970

Fax: (414) 354-6421

www.sterlco.com

Sterling Material Processing retains all rights to change the information in these

operating instructions at any time without notice.

We assume no liability for any errors or direct or indirect damage resulting in con-

text with these operating instructions.

Copying, translation or publication in any form except for personal use of purcha-

ser requires approval from Sterling Material Processing.

All rights reserved.

506-2MS

STT 110 / STT 160

3

Table of contents

1. General Information .......................................................1-1

1.1. Warnings and symbols.............................................1-2

1.2. Explanations and information .......................................1-4

1.3. Legal basis ......................................................1-4

1.4. Fields of applications ..............................................1-4

1.5. Notes on Usage ..................................................1-4

2. Safety instructions ........................................................2-1

2.1. For your safety ...................................................2-2

2.2. For the safety of the devices ........................................2-5

3. Start up ..................................................................3-1

3.1. Initial Operation ..................................................3-2

3.1.1. Switching on the Dryer ......................................3-2

3.2. Continuous Operation .............................................3-4

3.2.1. Switching the Dryer on ......................................3-4

3.2.2. Setting the Drying Temperature...............................3-5

3.3. Switching the Dryer off.............................................3-7

4. Error and error correction ..................................................4-1

5. Maintenance ..............................................................5-1

5.1. Maintenance schedule .............................................5-3

5.2. Cleaning or Replacing the Air Filter ..................................5-4

5.2.1. Cleaning or Replacing the Return Air Filter .....................5-5

5.3. Disposing of Drying Agents .........................................5-6

5.3.1. .........................................................5-6

5.3.2. .........................................................5-6

5.3.3. .........................................................5-6

5.3.4. .........................................................5-6

5.3.5. .........................................................5-6

5.3.6. .........................................................5-6

5.3.7. .........................................................5-6

5.3.8. .........................................................5-6

5.3.9. .........................................................5-6

5.4. Cleaning the Drying Hopper ........................................5-7

6. Functional description .....................................................6-1

506-2MS

STT 110 / STT 160

4

6.1. General Information ...............................................6-2

6.2. Drying Hopper (Optional) ...........................................6-5

6.2.1. Hopper Heater.............................................6-6

6.3. Connection to a Pneumatic Conveying System (Optional) ................6-7

6.4. Return Air Cooler (Optional) ........................................6-7

7. Transport, Assembly and Storage ...........................................7-1

7.1. Tansport and Packing .............................................7-2

7.2. Assembly........................................................7-3

7.3. Storage .........................................................7-3

8. Assembly instructions .....................................................8-1

8.1. Installation of the exhauster fan for regeneration of exhaust air............8-2

8.2. Grounding the equipment against electrostatic charging .................8-2

8.3. Electrical Connection ..............................................8-3

8.4. Connection of Return Air Cooler (Optional) ............................8-4

9. Technical Data ............................................................9-1

9.1. STT 110.........................................................9-1

9.2. STT 160.........................................................9-2

9.3. Dimension Sheet .................................................9-3

10. Spare parts list .........................................................10-1

11. Electrical manual........................................................11-1

oConnection diagram no.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

oCurrently not available; will be delivered at a later date !

12. Accessories ............................................................12-1

oBasic setting thermo regulator

oDigital timer

o_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

506-2MS

STT 110 / STT 160

5

1. General Information

»These operating instructions are addressed to all users of the device.

These operating instructions must be used by every person charged with

work on the unit.

506-2MS

STT 110 / STT 160

General Information 1-1

1.1. Warnings and symbols

The following warnings and symbols are used in these operating instructions:

»This symbol indicates danger to life! Fatal or serious injury is possible if the

corresponding instructions, regulations or warnings are not observed.

LThis symbol indicates that serious injury is possible if the corresponding

instructions, regulations or warnings are not observed.

FThis symbol indicates that extensive damage to equipment is possible if

the corresponding instructions, regulations or warnings are not obser-

ved.

&This symbol indicates information important for becoming familiar with

the equipment, i.e. technical correlations.

$This symbol indicates that a technical term is explained at this point.

506-2MS

STT 110 / STT 160

General Information 1-2

When disposing of drying agents / batteries / oil, observe all official rules.

Caution: High noise pollution !

For all work on the equipment, hearing protection should be worn.

Avoids impairment of hearing!

Caution: Danger of crushing !

Disconnect the equipment from mains supply before starting

mainenance procedures. All compressed air pipes on the equipment

should be depressurised before starting maintenance work.

Caution: Danger of hot surface !

Before starting any work wait until all parts have been cooled down suffi-

ciently. Avoid touching any of these parts!

Caution: Danger of skidding !

Remove any granules remaining on the ground.

Caution: Danger to life through electrical shock !

Observe that the control system is still under voltage even when the main

switch is switched off.

506-2MS

STT 110 / STT 160

General Information 1-3

1.2. Explanations and information

Various terms and designations are used in these operating instructions to ensure clarity. There-

fore please note that the terms used in the text stand for the corresponding explanations listed be-

low.

•Equipment

”Equipment” can mean an individual unit, a machine or an installation.

•Operating personnel

The ”operating personnel” are persons operating the equipment on their own responsibility or ac-

cording to instructions.

•Operator

The ”operator” of the equipment (production manager, foreman, etc.) is the person responsible for

all production sequences. The operator instructs the operating personnel of what is to be done.

•Operating instructions

The ”operating instructions” describe the interaction of the equipment, production sequences or

methods. The operating instructions must be compiled by the operator of the equipment.

•Equipment foreman

When several operating personnel work on one machine, the ”equipment foreman” coordinates

the sequences. The equipment foreman must be appointed by the operator.

•Trained personnel

”Trained personnel” are persons who, due to their training, are authorized to carry out the required

work.

1.3. Legal basis

See “Manufacturer’s Certificate” resp. “Certificate of Conformity”.

1.4. Fields of applications

For the drying of thermoplastic granules and regrind before processing in order to remove all re-

maining moisture from the granules both inside and out, independent of climate or ambient air

conditions.

1.5. Notes on Usage

•Experienced operators can begin directly with the chapter on “Start-up” if the unit has been pro-

perly installed.

•If the unit has not been installed yet, observe the instructions in the chapter on “Assembly Instruc-

tions” and “Transport, Assembly and Storage”.

506-2MS

CTT 110 / CTT 160

General Information 1-4

2. Safety instructions

»These safety instructions apply to all persons within the range of action of the

equipment.

Please inform all persons within the range of action of the equipment of the

direct and indirect hazards connected with the equipment.

These operating instructions are to be used by all persons assigned activi-

ties connected with the equipment.

Knowledge of the English language is prerequisite.

Ensure in each case that the operating personnel are familiar with the opera-

ting instructions and the function of the equipment.

506-2MS

STT 110 / STT 160

Safety instructions 2-1

2.1. For your safety

General

The operating personnel of this equipment must be at least 16 years old.

Please read these operating instructions carefully before taking into operation for the first time.

Contact us should questions arise. This avoids injury and damage to equipment!

These operating instructions must be kept available at all times at the place of operation of the

equipment. Improper operation results in danger of accidents!

Please note that, for reasons of clarity, not all conceivable cases regarding operation or mainten-

ance of the equipment can be covered in these operating instructions.

Please observe all safety instructions and warnings on the equipment. This avoids injury and da-

mage to equipment!

All work on the equipment is to be carried out by persons whose qualifications are specified in the

pertaining chapters of the operating instructions. Improper operation results in danger of acci-

dents!

The proper working clothes are to be worn during any work on the equipment. This avoids injury!

The local regulations and requirements pertaining to this equipment must be observed.

Disconnect electrical components from the mains supply before work is carried out on these com-

ponents Caution: Danger to life through electrical shock!

Compile detailed operating instructions based on these Operating instructions for the sequence

of procedures to be carried out on this equipment. Improper operation results in danger of acci-

dents!

Observe that the control system is still under voltage even when the main switch is switched off.

Caution: Danger to life through electrical shock!

506-2MS

STT 110 / STT 160

Safety instructions 2-2

Assembly

Compare the connected loads with those of the mains supply. Danger of injury through electrical

shock!

When using lifting gear, please observe the pertaining regulations. Caution: Danger of accidents!

Do not modify, add other equipment or change the design of the equipment without the approval

of the manufacturer. Caution: Danger of accidents!

Attachments not supplied by Sterling must be manufactured in accordance with safety regulation

EN 294. Danger of accidents!

The equipment may only be operated when all the associated components are properly connec-

ted up and in accordance with the relevant regulations. This avoids injury and damage to equip-

ment!

Operate the device only if all its components are grounded. Danger: accident through electrical

shock!

Please note for installation that the equipment is top-heavy. Danger exists that it may topple over!

Take care that the device is not standing on the mains cable. This will prevent danger to people

and material!

Operation

Appoint an equipment foreman to be responsible for the equipment.

Ensure that the operating personnel are provided detailed instruction in the operation of the

equipment. Improper operation results in danger of accidents!

When the main switch is switched off for reasons pertaining to safety, it must be secured against

unauthorized activation. Caution: Danger of accidents!

Repair work may be carried out by trained personnel only. Caution: Danger of accidents!

Never operate the equipment when partially dismantled! Danger! Limbs may be caught in machi-

nery! Electric shock!

In case of malfunction, shut down the equipment immediately. Have malfunctions corrected im-

mediately. Danger of accidents!

The machine is intended only for the drying of granulated plastics. Any other or additional use is

contrary to specifications.

This equipment is not suitable for food processing.

The safety instructions of the connected machines must be followed.

Please note that sound levels exceeding 85 db(A) may in the long term damage your health. Use

the appropriate ear muffs. This avoids impairment of hearing!

Please note that the drying cells, drying hoppers and air pipings grow hot during use. Avoid tou-

ching any of these parts! Danger: Injury through burns!

Never operate the dryer without side panels. Danger: Limbs may be caught in machinery! Injury

through burns!

506-2MS

STT 110 / STT 160

Safety instructions 2-3

Operate the dryer only if there is at least one drying hopper operating. This will prevent damage of

material!

When drying plastics which emit gases dangerous for human health, take care that the regenera-

tion exhaust air is disposed of without polluting the environment. This will prevent danger to peo-

ple and material!

Maintenance

Before starting maintenance work, appoint a supervisor.

Inform the responsible personnel before maintenance work on the system is started. Caution:

Danger of accidents!

Disconnect the equipment from mains supply before starting maintenance procedures to ensure

that it cannot be switched on unintentionally. Caution: Danger of accidents!

All pipes, hoses and screwed connections should be checked regularly for leaks and damage.

Any faults which arise should be corrected immediately. Danger of accidents!

Depressurize all compressed air piping before starting maintenance work. Danger of accidents!

The air filters should only be cleaned/replaced when the the main switch is off and the blower has

stopped. This avoids injury and damage to equipment!

Any maintenance work on the equipment should only be started when the the main switch is off

and the blower has stopped. This avoids injury and damage to equipment!

Check the v-belts of the blower only when the main switch is switched off and the blowers have

stopped. Caution: Danger of accidents!

Open drying hoppers only if they are completely empty. Danger of accidents!

Never open drying hoppers while the device is in operation. Danger: Injury through burns!

Open drying hoppers only if they have been cooled down sufficiently. Danger: Injury through

burns!

Before starting maintenance work wait until the drying cells, drying hoppers and air pipings have

been cooled down sufficiently. Avoid touching any of these parts! Danger: Injury through burns!

Remove any granules remaining on the ground. Danger of accidents!

Arrest the wheels after installation if the dryer is mounted on a movable frame. This will prevent

danger to people and material!

506-2MS

STT 110 / STT 160

Safety instructions 2-4

2.2. For the safety of the devices

Never change settings without carefully assessing the consequences.

Use only original Sterling spare parts.

Observe the maintenance instructions.

Keep a record of all maintenance works and repairs.

Please note that electronic components can be damaged by static discharge.

Before initial operation and in regular intervals, make sure that no electrical connections are loo-

se.

Never readjust sensors without exactly knowing their functions.

Please ensure that the permitted storage temperature lies between 0 and +55 °C

(32 to +131 °F).

Please ensure that the permitted operation temperature lies between 0 and +45 °C

(32 to +113 °F).

Check the direction of rotation of the blowers after the electrical connections have been made

(see rotational direction arrow).

Clean the drying hoppers before the first filling.

Note the instructions of the material manufacturer for the maximum drying temperature.

Note the drying instructions of the material manufacturer.

Take care that the drying hoppers are always completely filled and that the retention period is re-

spected if continual removal is taking place.

Note that too large amounts taken from the drying hopper lead to insufficient drying of the materi-

al.

Close the air stop valves of drying hoppers which are empty or have not been used.

Note down all data which you have entered into the control system.

The password is to be entrusted to authorised personnel only.

Please note that the temperature of the dryer heating system must always be set lower than that of

the supplementary heaters.

When you dispose of drying agents, observe all official rules.

Note that drying cells are replaced or refilled by Sterling only if they are empty.

The material level may not fall below 40 % in the drying hopper, when material is continuously re-

moved from the drying hopper, but no material is continuously fed into the drying hopper (batch

drying). Close the throttle valves.

Read the operating manuals of the connected devices.

506-2MS

STT 110 / STT 160

Safety instructions 2-5

3. Start up

»This chapter is addressed to the operators of the machine.

This chapter assumes general skills with drying equipment.

This chapter assumes that the functional description has been read and un-

derstood.

It must be ensured that the operators have the required experience.

FMake sure that the main switch is at “0" position.

Check the drying hopper for cleanliness.

Check to see whether the adhesive film on the drying hopper has be re-

moved.

If there is a return air cooler, switch on its coolant circuit.

If there is a timer clock (optional), adjust it. Read the operating manual of

the timer clock.

Check whether the release switch “Timer” and the release switches

“Hopper” (ST1 - ST6) are at ”0" position.

&The signal lamp “trouble” may flash shortly while the valve block is chan-

ged.

506-2MS

STT 110 / STT 160

Start up 3-1

3.1. Initial Operation

Check whether the inlet of the drying hopper is closed by a blind lid, or whether a conveyor unit

(optional) is installed.

If not, manufacture a suitable blind lid and install it on the inlet of the drying hopper or install the

conveyor unit (optional).

FAttachments which are not supplied by Sterling must be manufactured

according to the safety regulation European Standard 294.

Check whether the coolant circuit of the return air cooler is turned on (if a return air cooler is instal-

led).

3.1.1. Switching on the Dryer

Switch on the main switch of the dryer.

&The signal lamp “power” goes on.

For operation with timer clock (optional):

Turn the release switch “Timer” at position:

For operation without timer clock:

Turn the release switch “Timer” at position:

&The blower is running.

FIf the dryer has not been in use for several months it must be operated for

about 2 hours without material.

506-2MS

STT 110 / STT 160

Start up 3-2

Turn the release switches “Hopper” (ST1 - ST6) at “I” position.

Turn the thermo regulator to +80 °C (176°F) for the drying temperature.

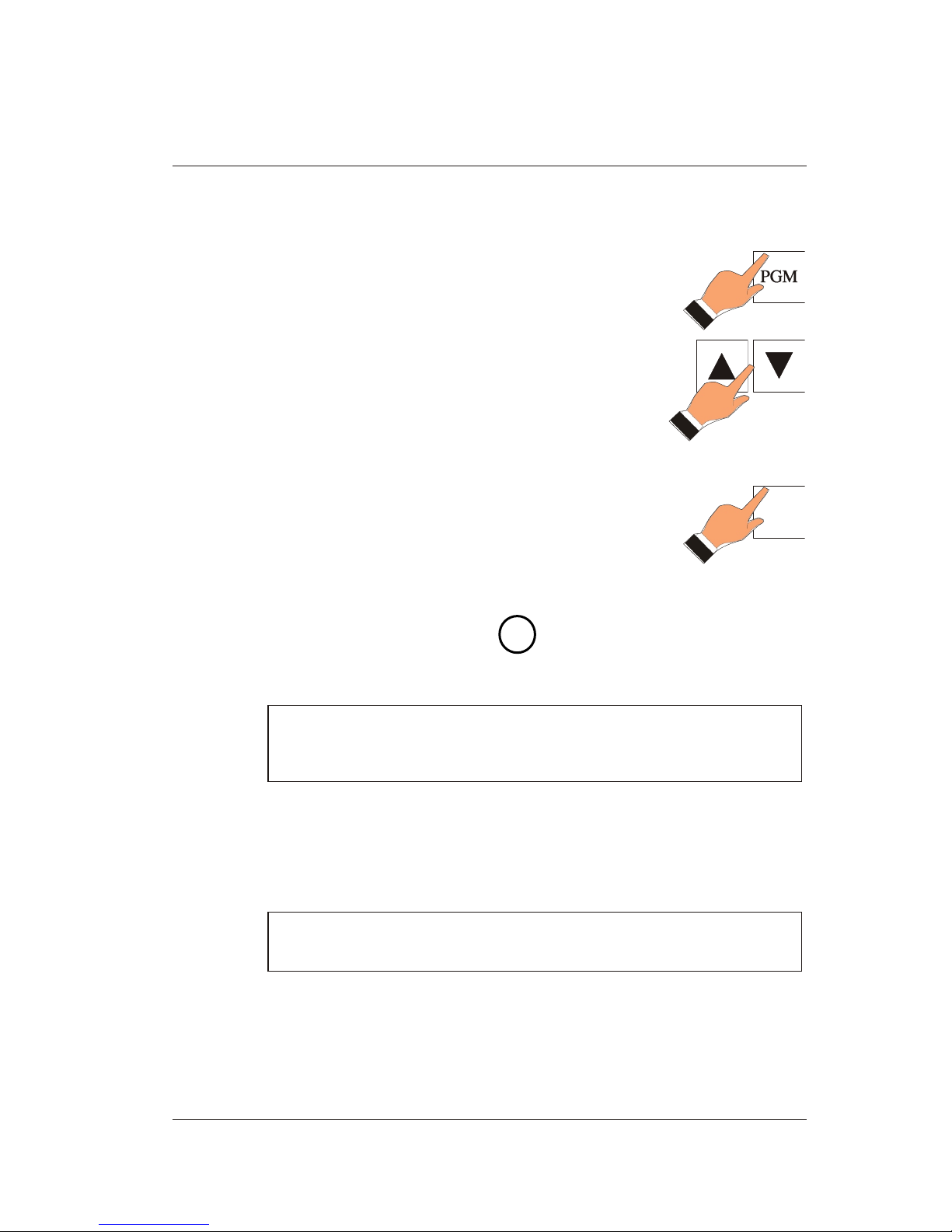

Press the “PGM” key.

Set by means of the arrow keys the drying temperature to “80".

After 2 seconds the display flashes and the value is stored.

Press the “EXIT” key (the setpoint value and the actual value

of the drying temperature are displayed).

After 2 hours turn the release switches “Hopper” (ST1 - ST6) at “0” position.

Turn the release switch “Timer” at position:

LWait until the blower has stopped.

The run on time of the blower is 10 minutes.

If there is a return air cooler installed, switch off its coolant circuit.

Switch off the main switch of the dryer.

&The signal lamp “power” goes off.

506-2MS

STT 110 / STT 160

Start up 3-3

EXIT

3.2. Continuous Operation

FFill at least half of the drying hopper with material.

3.2.1. Switching the Dryer on

Switch on the main switch of the dryer.

&The signal lamp “power” goes on.

For operation with timer clock (optional):

Turn the release switch “Timer” at position:

For operation without timer clock:

Turn the release switch “Timer” at position:

&The blower is running.

506-2MS

STT 110 / STT 160

Start up 3-4

3.2.2. Setting the Drying Temperature

Turn the release switches “Hopper” (ST1, ST2) at “I” position.

For each drying hopper, set the required drying temperature (= desired value) by means of the re-

spective thermo regulator.

Check whether the set drying temperature is appropriate for the materials which have been filled

in.

Observe the instructions of the material manufacturer.

After the first filling, process the material only after the retention period is over.

Observe the instructions of the material manufacturer.

Press the “PGM” key.

By means of the arrow keys select the desired value for

the drying temperature.

After 2 seconds the display flashes and the value is stored.

Press the “EXIT” key (the setpoint value and the actual value

of the drying temperature are displayed).

FAfter a change of materials, immediately check and correct the set drying

temperature.

506-2MS

STT 110 / STT 160

Start up 3-5

EXIT

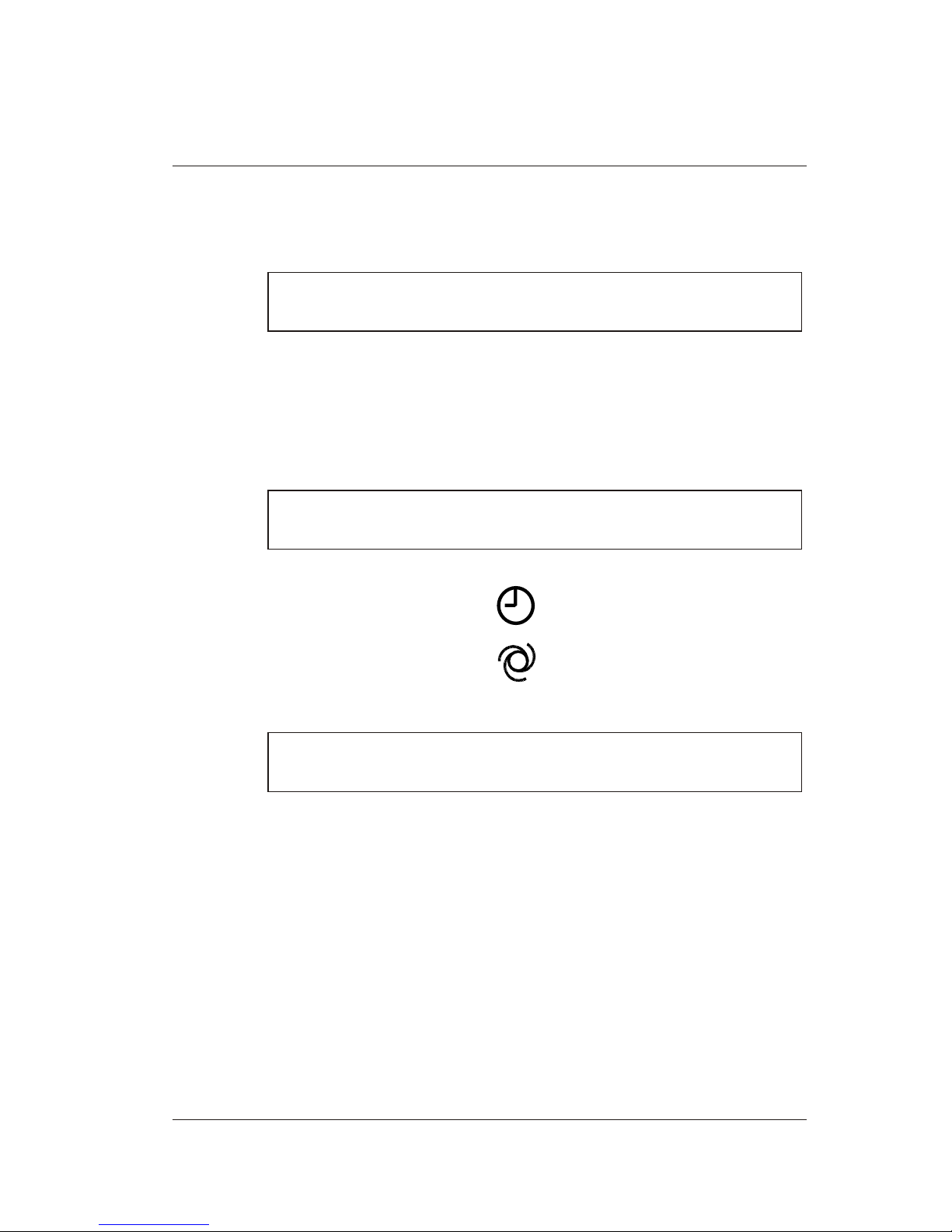

Optimizing the thermo regulator

Press the “EXIT” key for at least 2 seconds.

“tunE” flashes. The optimization can take several minutes.

If “tunE” stops flashing, the optimization is finished.

Press the “EXIT” key.

506-2MS

STT 110 / STT 160

Start up 3-6

EXIT

EXIT

PGM

K1K1 K2K2

K3K3

tunE

60

EXIT

EXIT

PGM

tunE

60

This manual suits for next models

1

Table of contents

Other Sterling Dehumidifier manuals