SPX FLOW Power Team PTPH-100T User manual

Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

Original Instructions:

SPX FLOW US, LLC

5885 11th Street

Rockford, IL 61109-3699 USA

powerteam.com

Tech Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

* PTPH-100T

* PTPH-100T-50-220

* PTPH-100TDA

* PTPH-100TDA-50-220

PTPH-100TDA-E110

PTPH-100TDA-E220

PTPH-100T-E110

PTPH-100T-E220

* PTPH-102DATV

PTPH-102DATV-E110

PTPH-102DATV-E220

* PTPH-102T

* PTPH-102T-50-220

* PTPH-102TDA

* PTPH-102TDA-50-220

PTPH-102TDA-E110

PTPH-102TDA-E220

PTPH-102T-E110

PTPH-102T-E220

* PTPH-102TV

PTPH-102TV-E110

PTPH-102TV-E220

* PTPH-123T

* PTPH-123TDA

PTPH-123TDA-E110

PTPH-123TDA-E220

PTPH-123T-E110

PTPH-123T-E220

* PTPH-200T

PTPH-200T-E220

PTPH-200T-E110

Operating Instructions For:

100-TON AND 200-TON HYDRAULIC PULLER SYSTEMS

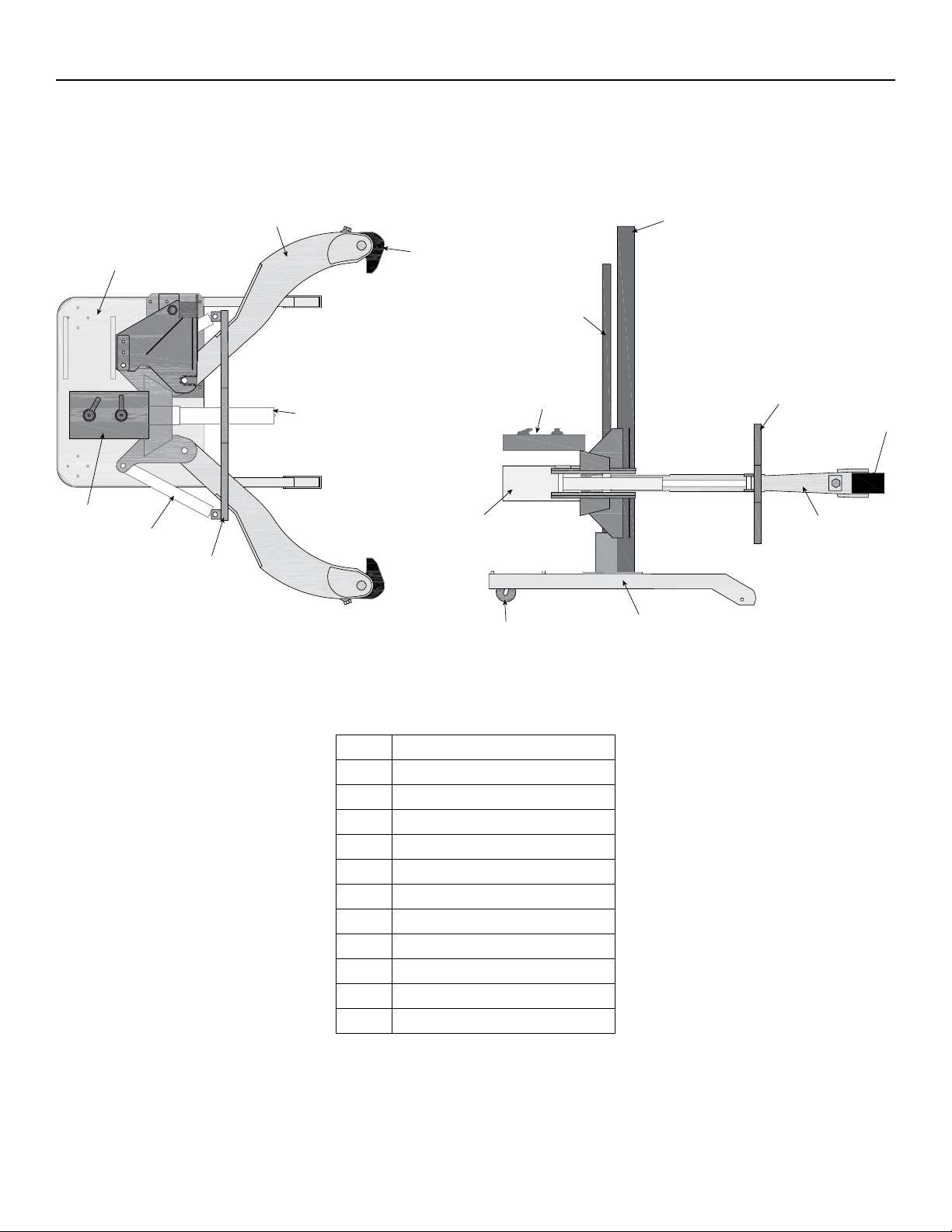

Model shown for PTPH-100TDA

* NON-CE and NON-UKCA certied.

1Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

TABLE OF CONTENTS

SAFETY SYMBOLS AND DEFINITIONS ������������������������������������������������������������������������������������������������������������ 2

SAFETY PRECAUTIONS ������������������������������������������������������������������������������������������������������������������������������������ 2

PRODUCT DATA ������������������������������������������������������������������������������������������������������������������������������������������������� 4

OVERVIEW ���������������������������������������������������������������������������������������������������������������������������������������������������������� 6

1� Major Components��������������������������������������������������������������������������������������������������������������������������������� 6

2� Pushers ������������������������������������������������������������������������������������������������������������������������������������������������� 7

3� Jaw Tips ������������������������������������������������������������������������������������������������������������������������������������������������ 8

ASSEMBLY���������������������������������������������������������������������������������������������������������������������������������������������������������� 8

ADJUSTMENTS��������������������������������������������������������������������������������������������������������������������������������������������������� 9

1� Raising the Puller ���������������������������������������������������������������������������������������������������������������������������������� 9

2� Lowering the Puller ������������������������������������������������������������������������������������������������������������������������������ 9

3� Hoist Travel Speed��������������������������������������������������������������������������������������������������������������������������������� 9

4� Changing the Jaw Spread ��������������������������������������������������������������������������������������������������������������������� 9

5� Adjusting Jaw Tips�������������������������������������������������������������������������������������������������������������������������������� 10

6� Adjusting Slide Rollers ������������������������������������������������������������������������������������������������������������������������ 10

7� Removing Puller From The Cart ���������������������������������������������������������������������������������������������������������� 11

OPERATION ����������������������������������������������������������������������������������������������������������������������������������������������������� 11

1� Setup ��������������������������������������������������������������������������������������������������������������������������������������������������� 12

2� Pulling an Object �������������������������������������������������������������������������������������������������������������������������������� 12

PTPH-123T TRANSFORMATION ��������������������������������������������������������������������������������������������������������������������� 13

SPREAD RANGE DIAGRAM ��������������������������������������������������������������������������������������������������������������������������� 15

POWER TEAM FACILITIES AND CONTACT �������������������������������������������������������������������������������������������������� 16

EC DECLARATION OF INCORPORATION ���������������������������������������������������������������������������������������������������� 17

UKCA DECLARATION OF INCORPORATION ����������������������������������������������������������������������������������������������� 18

2Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

SAFETY SYMBOLS AND DEFINITIONS

SAFETY PRECAUTIONS

It is impossible to predict the exact force needed for every pulling situation. The amount of press-t and

force of removal can vary greatly between jobs. The set-up requirements along with the size, shape and

condition of the parts being pulled are all variables which must be considered. Remember that a signicant

amount of force can be exerted with a puller. Respect this force and always observe safety precautions.

Failure to comply with the following cautions and warnings could cause equipment damage or personal

injury.

IMPORTANT

: Visually inspect all components for shipping damage. Shipping damage is not covered

by warranty. If shipping damage is found, notify the carrier at once. The carrier is

responsible for all repair and replacement costs resulting from damage in shipment.

Safety symbols are used to identify any action or lack of action that can cause personal injury.

Your reading and understanding of these safety symbols is very important.

WARNING

: Danger is used only when your action or lack of action will cause serious human injury

or death

: Warning is used to describe any action or lack of action where a serious injury can

occur.

: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

IMPORTANT

: Important is used when action or lack of action can cause equipment failure, either

immediate or over a long period of time.

CAUTION : Used without the safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

• The following procedures must be performed by qualied, trained personnel who are

familiar with this equipment. Operators must read and understand all safety precautions

and operating instructions included with the device. If the operator cannot read these

instructions, operating instructions and safety precautions must be read and discussed in

the operator's native language.

• Make sure all system components are protected from external sources of damage, such as

excessive heat, ame, moving machine parts, sharp edges and corrosive chemicals.

• Safety glasses must be worn at all time by the operator and anyone within sight of the unit.

Additional personal protection equipment may include: face shield, goggles, gloves, apron,

hard hat, safety shoes, and hearing protection.

• The owner of this tool must verify that safety-related decals are installed, maintained, and

replaced if they become hard to read.

• Keep hands away from possible pinching points.

• Use only genuine POWER TEAM replacement parts and endorsed hydraulic components.

General:

WARNING

:To prevent personal injury,

3Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

• DO NOT touch or handle hydraulic hoses or ttings with pressure in the system. Escaping

oil under pressure may cause serious injury. If oil is injected under the skin see a doctor

immediately.

• DO NOT make any electrical adjustments with electrical power active in the system.

• DO NOT make or break any hydraulic connections with pressure in the system.

• DO NOT overload the equipment. Use the right size puller.

• DO NOT stand on, under or near the puller while in use. Keep hands, feet and clothing

away from moving parts.

• To avoid personal injury and equipment damage, make sure all hydraulic components

withstand the maximum hydraulic pressure of 700 bar (10,000 psi).

• Always check to ensure that all cylinders and components are securely fastened.

• Inspect puller for dents, cracks, or excessive wear before each use. Immediately replace

worn or damaged parts.

• It is recommended to use 3-jaw puller whenever possible for a more secure grip, a more

even pulling force and better stability.

• Cover application with a protective blanket before applying force. Since high force is

applied on the part being pulled, breakage may occur and user may be exposed to ying

debris.

• Use hydraulic gauges in each hydraulic system to indicate safe operating loads.

• Apply force gradually. Be sure the puller is square with the component to be pulled.

• Always make sure the puller is aligned with the shaft.

• Select the appropriate ram extender for each application.

• Always place the puller in the lowest position and remove ram extenders while

transporting.

• Keep slide rollers and mast clean and lubricated.

• Always keep puller hoist vertical and the control valve closed when not adjusting vertical

position.

• A small amount of oil seepage is normal from breather vent on hoist cylinder.

• Make sure that all items being pulled are supported by a means other than the puller.

When using a puller in excess of 50 pounds, support puller by other means than a single

person. Do not use the puller for lifting or supporting objects.

• Avoid sharp bends and kinks in hoses as they may lead to premature hose failure.

Inspect hoses and ttings for leaks or damaged areas. Immediately discard and replace

damaged components.

Safety Precautions Continued

Hydraulic Puller Systems:

WARNING

:To prevent personal injury,

4Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

PRODUCT DATA

Portable 100-TON Hydraulic Puller Systems

Model

Number

Capacity

Tons (kN)

Number

of Jaws

Dimensions

Spread Overall

Length Reach Jaw Length Jaw Tip

Width

Tip Clear-

ance Tip Depth Weight

A B C D E F G

Single Acting

PTPH-102T-

XXX

100 tons

(890 kN) 27�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

1700 lbs�

(771 kg)

PTPH-100T-

XXX

100 tons

(890 kN) 37�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in

(89 mm)

1950 lbs�

(885 kg)

PTPH-123T-

XXX

100 tons

(890 kN) 2/3 7�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in

(89 mm)

3�5 in�

(89 mm)

2000 lbs�

(907 kg)

Single Acting Vertical

PTPH-

102TV-XXX

100 tons

(890 kN) 27�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

1800 lbs�

(816 kg)

Double Acting

PTPH-

102TDA-XXX

100 tons

(890 kN) 27�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

1800 lbs�

(816 kg)

PTPH-

100TDA-XXX

100 tons

(890 kN) 37�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

2050 lbs�

(930 kg)

PTPH-

123TDA-XXX

100 tons

(890 kN) 2/3 7�5 to 70 in�

(191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

2100 lbs�

(953 kg)

Double Acting Vertical

PTPH-

102DATV-

XXX

100 tons

(890 kN) 27�5 to 70 in�

191 to 1778 mm)

77 in�

(1956 mm)

50 in�

(1270 mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

1800 lbs�

(816 kg)

200-TON Hydraulic Puller System

PTPH-200T-

XXX

200 tons

(1779 kN) 46�5 to 70 in�

(203 to 1778 mm)

78�5 in�

(1994 mm)

48 in� (1219

mm)

53 in�

(1346 mm)

1�25 in�

(32 mm)

3�5 in�

(89 mm)

3�5 in�

(89 mm)

4150 lbs�

(1882 kg)

5Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

Product Data Continued

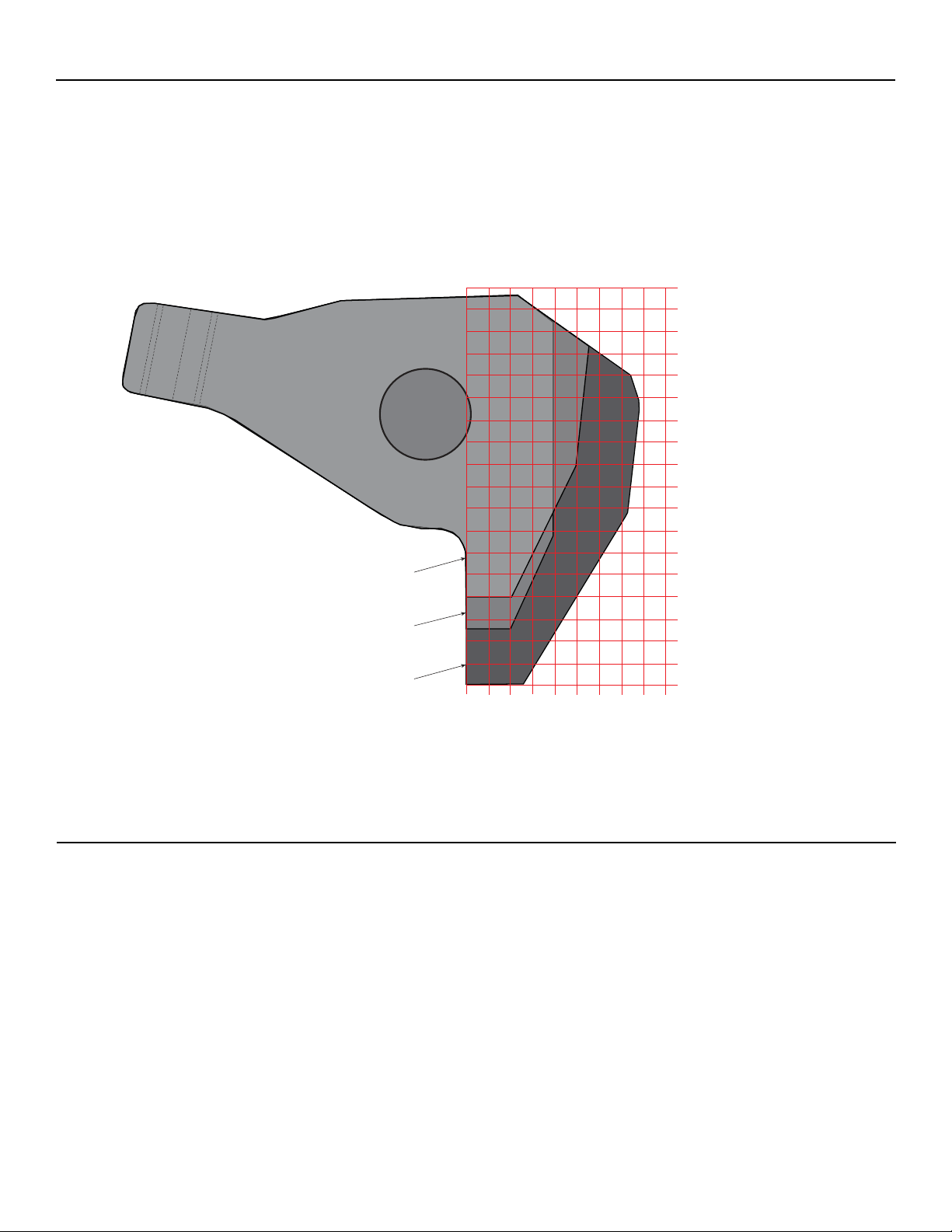

max. 66.54 in

[1690 mm]

min. 26.50 in

[673 mm]

77.95 in

[1980 mm]

40.98 in. [1041 mm]

Top View

B

D

C

A

E

F

G

(Figure shown for model PTPH-102T)

6Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

(Diagram shown for PTPH-102T, Some models have 3 Jaws)

ITEM DESCRIPTION

AJAW

BJAW TIP

C CAGE

DPUSHING ADAPTOR

E CAGE CYLINDER

F PUSHING CYLINDER

G CONTROL VALVES

H HOIST CYLINDER

I MAST

J BASE

K CASTERS

A

D

B

C

C

G

G

E

FA

B

I

H

J

K

J

Top view Side view

OVERVIEW

1. Major Components

7Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

2. Pushers

Included with the 100-TON pullers are THREE pushers and a coupler� String 2 pushers together to increase

the reach of the ram� Using a variety of combinations may be necessary to complete the pull of a deeply set

gear or bearing�

Included with the 200-TON puller are FOUR pushers� The diameters are 4 inches� The 200-TON does not include

coupler�

[229]

[483]

[89]

[89]

[102]

[19]

[10]

[19]

(89)PTHT-1162

(737)

(483)

(89)

PTHT-1163

(229)

(89)

(102)

(19)

(10)

(19)

PTHT-1164

Coupler

[89]

[89]

(203)

8.00

(102)

4.00

[102]

[89]

3.52 (89)

4 (102)

*Included with

200 TON only.

(102)

39.00

(991)

4

29.00

3.50

3.50

19.00

9.00

3.50

4.00

0.75

0.375

0.75

Note: Dimensions in Inches (mm)

Overview Continued

8Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

Overview Continued

PTHT-1180S

PTHT-1180A

PTHT-1180*

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

*Tip widths are 3 inches thick.

(0.0)

(12.7)

(25.4)

(38.1)

(50.8)

(63.5)

(76.2)

(88.9)

(101.6)

(114.3)

(127.0)

(139.7)

(152.4)

(165.1)

(177.8)

(190.5)

(203.2)

(215.9)

(228.6)

(0.0)

(12.7)

(25.4)

(38.1)

(50.8)

(63.5)

(76.2)

(88.9)

(101.6)

(114.3)

(mm) Inch

(mm)Inch

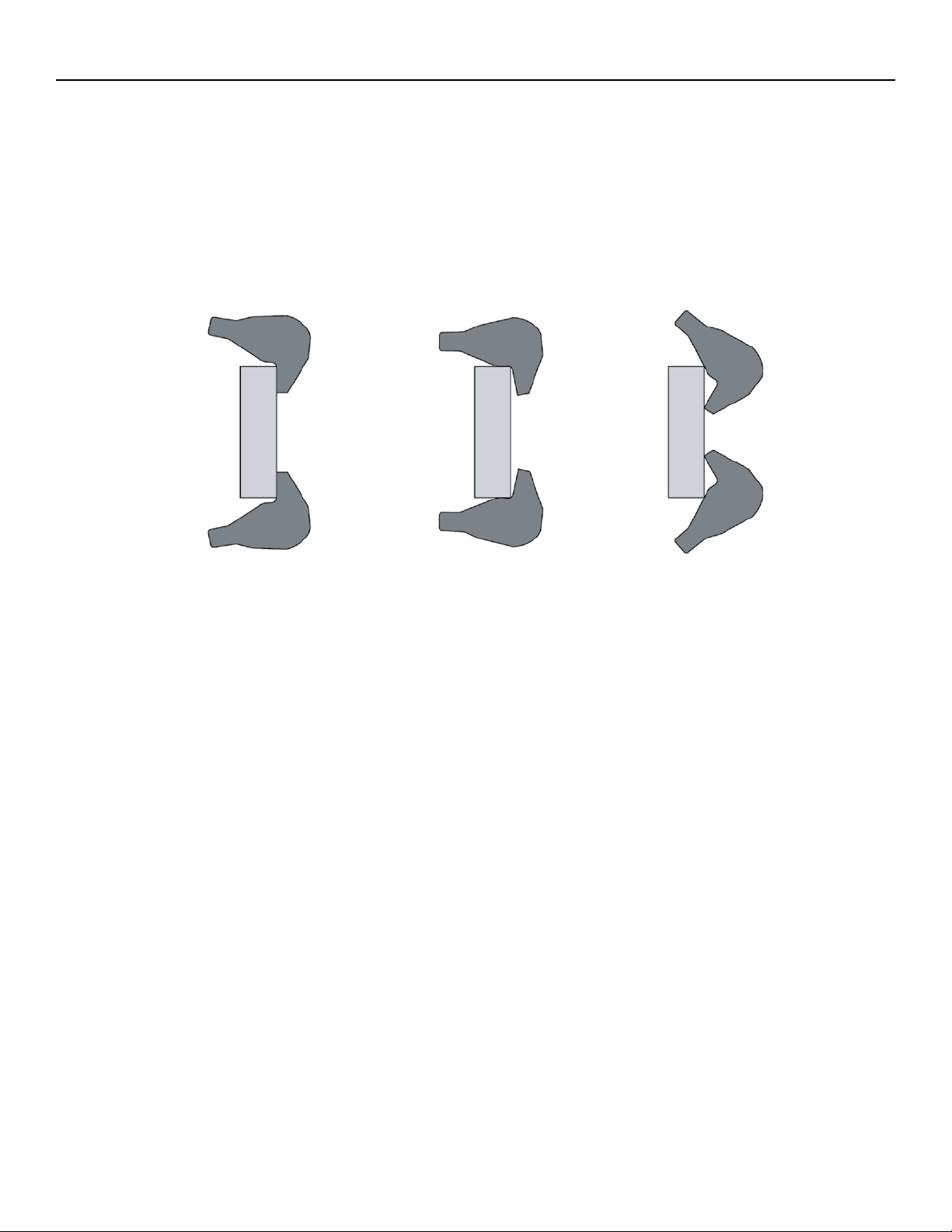

3. Jaw Tips

3 jaw tip sizes are available for 100 and 200 Ton puller models�

• PTHT-1180: standard with all models�

• PTHT-1180A: optional, for operations with limited space constraints�

• PTHT-1180S: optional, for operations with limited space constraints

ASSEMBLY

A� Ensure that shipping crate firmly rests on level ground in upright position.

B� Open small side panel and confirm that puller is resting firmly in upright position in the crate�

C� Remove remainder of plywood�

D� Inspect puller for any damage that may have been caused by shipping�

E� Save bolts that were used to brace the cart� These will be used for securing the included cart wheels to the

cart�

F� Inspect hoses for proper ratings� Connect the 10,000 psi hose to the port marked “10,000 psi only” on the

puller and the pressurized port on the pump� Connect hose with the lower pressure rating to the return port

on puller and pump�

G� Fill reservoir of pump with pump manufacturer specified oil� See pump or cylinder manual for details�

9Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

ADJUSTMENTS

1. Raising the Puller

A� Place cylinder control valve lever in “Hoist Oil Supply” position.

B� Raise puller by placing remote jog switch in “On” position and opening the puller hoist vertical control

valve�

C� Release remote jog switch� Close vertical control valve after reaching desired height�

2. Lowering the Puller

A� Place cylinder control valve lever in “Hoist Lower” position�

B� Lower puller by turning puller hoist vertical control valve counterclockwise�

C� Close vertical control valve after reaching desired height�

3. Hoist Travel Speed

NOTE: The restrictor valve, located at the top of the hoist cylinder, is used to control the rate of puller descent�

This valve should be set at the desired rate and locked in place using the nut on the valve shaft�

An appropriate starting point is one full turn from the closed position� This valve is a one-way restrictor only and

does not affect the rate at which the puller is raised�

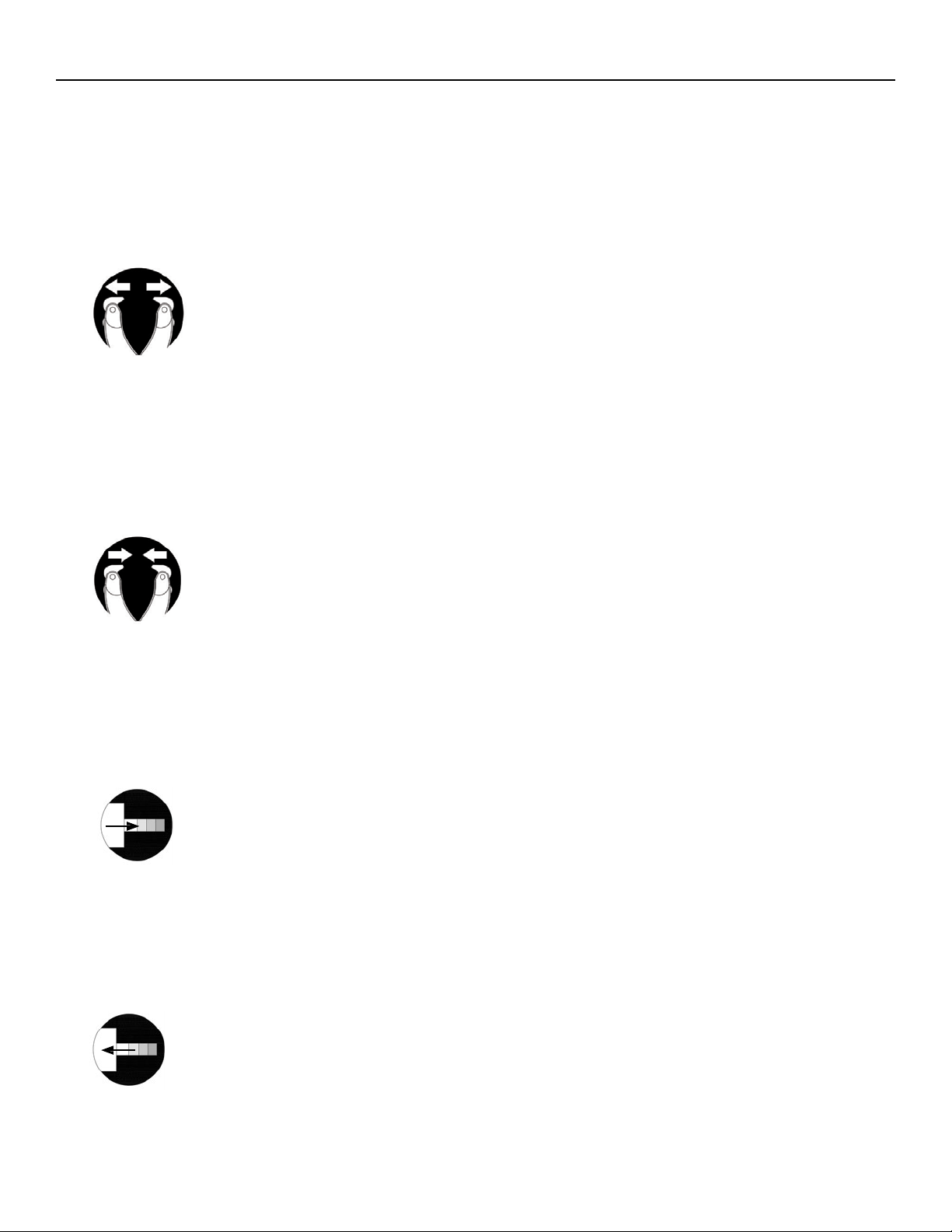

4. Changing the Jaw Spread

If opening/closing the jaws using the standard cage setting does not provide enough spread or does not

provide enough closure, use the following adjustments to achieve the maximum and minimum spreads�

A� Support the jaws�

B� Remove 6 cap screws, lock washers and nuts on 1 jaw guide at a time�

C� Slide jaw guide inward/outward on cage 1 bolt hole�

D� Replace 4 cap screws, lock washer, and nuts and tighten appropriately�

E� Reverse this process to return to standard jaw spread�

Jaw guide moved 1 bolt hole

OUT to increase spread.

Jaw guide moved 1 bolt hole

IN to decrease spread.

Default jaw guide position

when puller is shipped.

10 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

Adjustments Continued

5. Adjusting Jaw Tips

A� Adjust jaw tips by turning 1-1/4” cap screw�

NOTE: Always use maximum pulling surface of jaw. To angle tip inward, turn cap screw clockwise.

To angle tip outward, turn cap screw counterclockwise. Before pulling, always make certain

machined caps are properly tted to curved surface.

IncorrectIncorrect

Correct Alignment

6. Adjusting Slide Rollers

A� Lower slide and puller assembly until it rests solidly on base�

B� Loosen 5/8” hex bolt�

C� Move roller using eye bolts on each side of roller�

D� Adjust roller until equal spacing is obtained between mast and slide tube on both roller side and

opposite side�

E� Tighten locking nut on eye bolt�

F� Tighten 5/8” hex bolt�

11 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

Adjustments Continued

OPERATION

OPERATION IMPORTANT

: Hydraulic power is one of the safest methods for applying force

when used correctly. Be sure to read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal injury or property damage during system operation.

Power Team cannot be responsible for damage or injury resulting from unsafe use of product, lack

of maintenance or incorrect product and/or system operation.

It is important that the operator has a full understanding of all the instructions, warnings, cautions

and safety regulations before starting to operate equipment. When in doubt contact Power Team.

7. Removing Puller From The Cart

100-TON:

A� Support puller weight using lifting brackets provided�

B� Close puller hoist vertical control valve�

C� Disconnect puller hoist hose coupler at control panel�

D� Remove 2 of the 1/2” bolts which fasten locking plate to the puller lift bracket�

E� Remove puller from cart by rotating cart while keeping puller stationary�

200-TON:

A� Support puller weight using lifting brackets provided�

B� Close puller hoist vertical control valve�

C� Disconnect puller hoist hose coupler at control panel�

D� On each slide, remove the top and bottom 1/2” bolts� Do this on both the left and right slide, removing a

total of 4 bolts�

E� While keeping the puller supported and balanced, remove from the cart by moving the puller forward�

WARNING

MAINTENANCE

:

Always clean the puller after use and store in a clean, dry place.

12 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

1. Setup

A� Transport the puller by use of the puller cart of forklift�

B� Line the puller up to the workpiece�

C� Open the jaws�

Opening The Jaws:

i� Place cylinder control valve lever in “Oil Supply” position�

ii� Place cage control lever in “Jaw Open” position and activate pump by pushing remote

switch to the “On” position to open jaws to the desired spread�

C� Position the workpiece to be removed in between the jaws�

D� Continue to adjust the height until the workpiece and extending cylinder are aligned� See RAISING THE

PULLER on page 9�

E� Close the jaws�

Closing The Jaws:

i� Place cylinder control valve lever in “Oil Supply” position�

ii� Place cage control lever in “Jaw Closed” position and activate pump by pushing

remote switch to the “On” position to close jaws to the desired spread or for clamping�

C� Adjust the jaw tips appropriately� See ADJUSTING JAW TIPS on page 10�

2. Pulling An Object:

A� Extend the cylinder ram towards the workpiece until there is contact�

Extending Cylinder:

i� Place cylinder control valve in “Extend” position�

ii� Activate pump with jog switch�

C� Continue to extend the ram� The workpiece will begin to move gradually off the shaft�

D� Retract the cylinder�

E� Completely remove the workpiece�

Retracting Cylinder:

i� Place cylinder control valve in the “Retract” position�

ii� Activate pump with jog switch�

NOTE: On a single acting cylinder the cylinder ram will retract without activating the pump.

Operation Continued

13 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

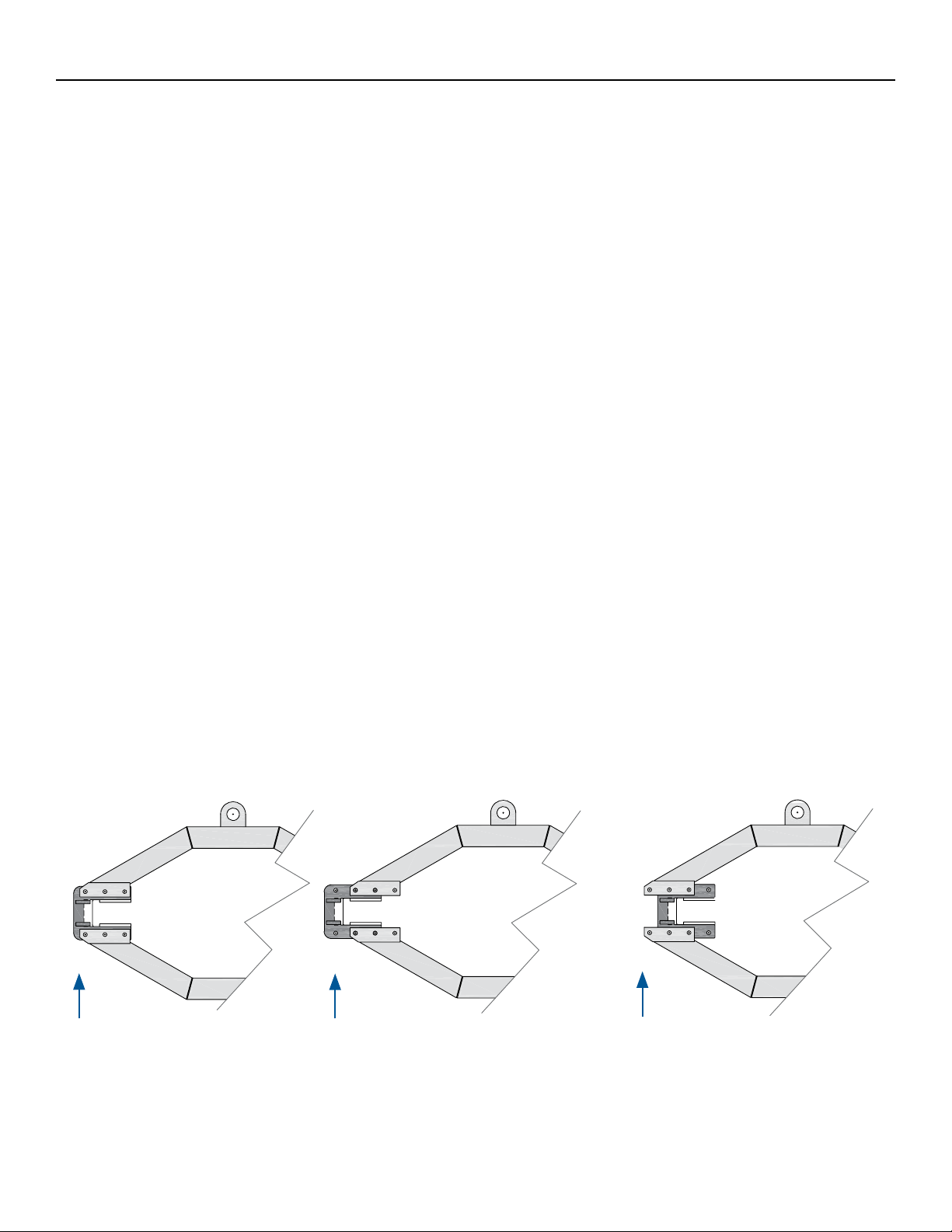

PTPH-123T TRANSFORMATION

A� Starting in a 2-jaw conguration, move the cage cylinder from the 2-jaw position to the 3-jaw position.

B� Remove the jaw on the left from the 2-jaw position�

14 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

PTPH-123T Transformation Continued

C� Place the jaw into the lower 3-jaw position�

D� Place jaw from the left 2-jaw position into upper 3-jaw position to complete the transformation�

15 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

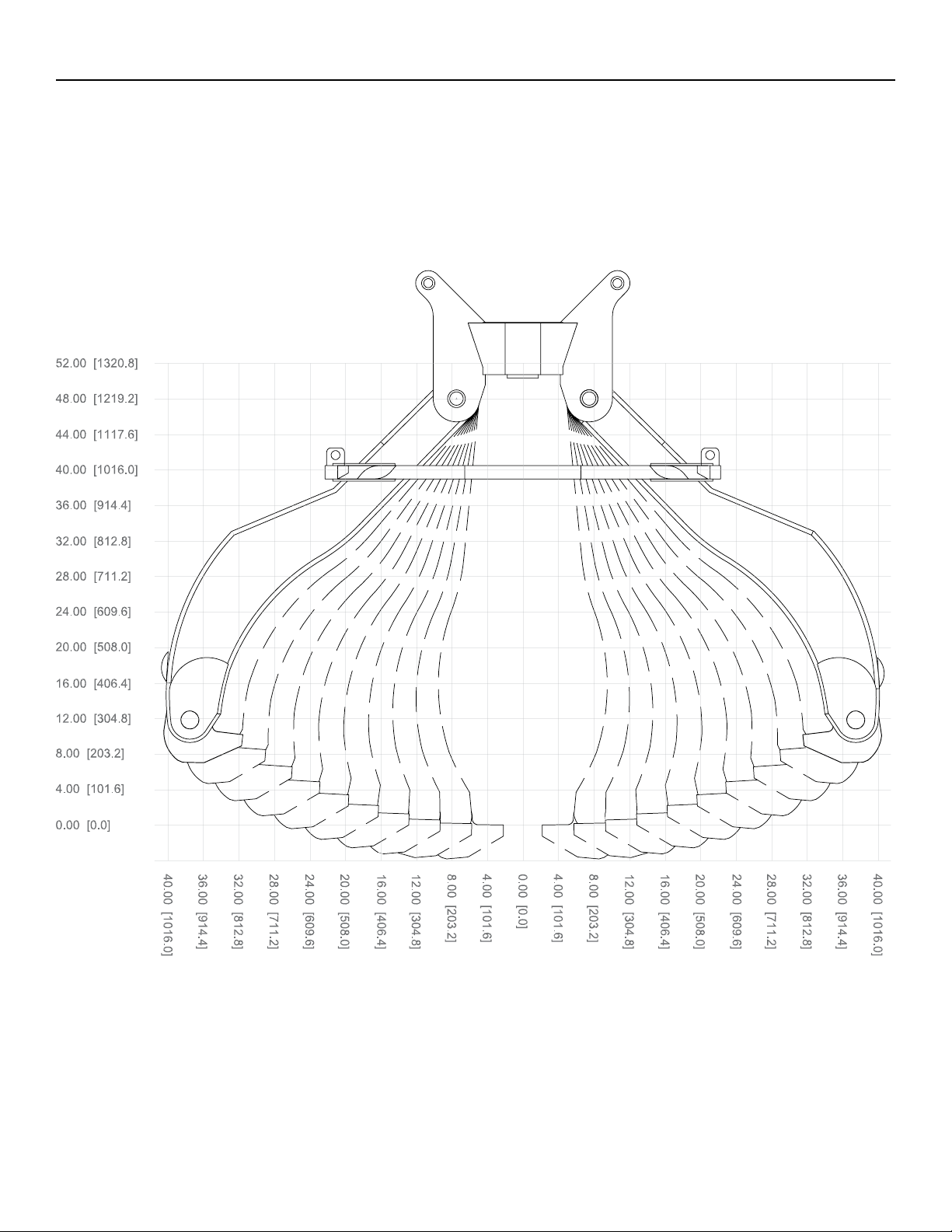

SPREAD RANGE

Use the diagram to determine the limitations of the jaw-opening� Spread ranges apply to all POWER TEAM

100-TON and 200-TON hydraulic puller systems. Gears, pulleys, wheels, sleeves, and other press t parts must t

within these limitations�

Spread Range Diagram

inch [mm]

inch [mm]

16 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

POWER TEAM FACILITIES AND CONTACT

Rockford, Illinois USA

Customer Service/Order Entry

Tel: +1 800 541 1418

Fax: +1 800 288 7031

European Headquarters

Tel: +31 45 567 8877

Fax: +31 45 567 8878

Asia Pacific Headquarters

Tel: +65 6265 3343

Fax: +65 6265 6646

Technical Services

Tel: + 1 800 477 8326

Fax: + 1 800 765 8326

Shanghai, China

Tel: +86 21 2208 5888

Fax: +86 21 2208 5682

17 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

English Original

SPX FLOW US LLC

5885 11th Street

Rockford, IL 61109-3699

United States of America

SPX FLOW Europe Ltd. -

Netherlands

SPX Hydraulic Technologies

Albert Thijsstraat 12

NL-6471 WX Eygelshoven

The Netherlands

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that our Hydraulic Puller Models:

*

PTPH-100T-E110, PTPH-100T-E220

PTPH-100TDA-E110, PTPH-100TDA-E220

PTPH-102T-E110, PTPH-102T-E220

PTPH-102TDA-E110, PTPH-102TDA-E220

PTPH-102TV-E110, PTPH-102TV-E220

PTPH-102DATV-E110, PTPH-102DATV-E220

PTPH-123T-E110, PTPH-123T-E220

PTPH-123TDA-E110, PTPH-123TDA-E220

PTPH-200T-E110, PTPH-200T-E220

to which this declaration relates are in conformity with the following:

EN, EN-ISO, ISO standards Title

Per the provisions of the Machinery Safety Directive 2006/42 EC

EN_ISO 12100 Safety of machinery, basic concepts, general principles for

design, risk assessment & risk reduction

EN 4413 Hydraulic Fluid Power –general rules and safety

requirements for systems & their components

Per the provisions of the EMC Directive 2014/30 EU

EN_61000-4-2 Electromagnetic Discharge Immunity test

EN_61000-4-3 Radiated, Radio Frequency, Electromagnetic Field

Immunity test

EN_61000-4-4 Electrical Fast Transient / Burst Immunity test

EN_61000-4-5 Surge immunity test

EN_61000-4-6 Immunity to Conducted Disturbances, Induced by Radio-

Frequency Fields

EN_61000-4-11 Voltage Dip and Interrupt test

EN 55011 Industrial, Scientific and Medical (ISM) Radio Frequency

Equipment-Electromagnetic Disturbance Characteristics-

Limits and Methods of Measurement

Per the provisions of the Low Voltage Directive 2014/35 EU

EN_60204-1 Safety of Machinery –Electrical equipment of machines –

Part 1 General requirements

Per the provisions of the RoHS Directive 2015/863 EU

Restriction of the use of certain hazardous substances in

electrical and electronic equipment

We hereby declare that the equipment specified under * conforms to the above quoted

European Community Directive(s) and Standard(s) as per the currently valid revision.

SPX Hydraulic Technologies is certified and registered to ISO 9001: 2015.

The Netherlands December 08th, 2022

------------------------------------------

Andreas J. Klemm, PhD

18 Form No. 1001292

Rev. 0 Dec. 21, 2022

© SPX FLOW, Inc.

English original

SPX FLOW US, LLC

5885 11th Street

Rockford, IL 61109-3699

United States of America

SPX FLOW Europe Ltd.

Ocean House, Wilmslow Road

Manchester, M20 2LY, UK

Andreas J. Klemm

SPX Flow Europe Ltd. –Netherl.

Albert Thijsstraat 12

NL-6471 WX Eygelshoven

UKCA DECLARATION OF CONFORMITY

We declare under our sole responsibility that our Hydraulic Puller Model:

*

PTPH-100T-E110, PTPH-100T-E220, PTPH-100TDA-E110,

PTPH-100TDA-E220, PTPH-102T-E110, PTPH-102T-E220

PTPH-102TDA-E110, PTPH-102TDA-E220, PTPH-102TV-E110,

PTPH-102TV-E220, PTPH-102DATV-E110, PTPH-102DATV-E220

PTPH-123T-E110, PTPH-123T-E220, PTPH-123TDA-E110,

PTPH-123TDA-E220

PTPH-200T-E110, PTPH-200T-E220

to which this declaration relates are in conformity with the following:

Legislation & standards Title

The Supply of Machinery (Safety) Regulations 2008 No. 1597 and amendments

EN_ISO 12100 Safety of machinery, basic concepts, general principles for

design, risk assessment & risk reduction

EN 4413 Hydraulic Fluid Power –general rules and safety requirements

for systems & their components

The Electromagnetic Compatibility Regulations 2016 No. 1091

EN_61000-4-2 Electromagnetic Discharge Immunity test

EN_61000-4-3 Radiated, Radio Frequency, Electromagnetic Field Immunity

test

EN_61000-4-4 Electrical Fast Transient / Burst Immunity test

EN_61000-4-5 Surge immunity test

EN_61000-4-6 Immunity to Conducted Disturbances, Induced by Radio-

Frequency Fields

EN_61000-4-11 Voltage Dip and Interrupt test

EN 55011 Industrial, Scientific and Medical (ISM) Radio Frequency

Equipment-Electromagnetic Disturbance Characteristics-

Limits and Methods of Measurement

The Electrical Equipment (Safety) Regulations 2016 No. 1101

EN_60204-1 Safety of Machinery –Electrical equipment of machines –

Part 1 General requirements

The Noise Emissions in the Environment by Equipment

for use Outdoors Regulation 2001 No. 1701

EN_3200L0014 Noise emission in the environment for use outdoors

ISO 3744 Sound Power Level Measurements

The Restriction of the Use of Certain Hazardous Substances in Electrical and

Electronic Equipment Regulations 2012 No. 3032

Restriction of the use of certain hazardous substances in

electrical and electronic equipment

We hereby declare that the equipment specified under * conforms to the above quoted

UK Legislation and international Standard(s) as per the currently valid revision.

SPX FLOW Europe Ltd. - Netherlands is certified and registered to ISO 9001: 2015.

The Netherlands December 15th, 2022

------------------------------------------

Andreas J. Klemm, PhD

This manual suits for next models

30

Table of contents

Other SPX FLOW Power Tools manuals

Popular Power Tools manuals by other brands

Baier

Baier BMF 501 Translation of the original instruction manual

Windsor

Windsor DOUBLE DRY DDH 86000000 operating instructions

Rongpeng

Rongpeng MCN90 operating instructions

Eastwood

Eastwood 13630 instruction manual

HAZET-WERK

HAZET-WERK 9035 VH operating instructions

MULTIQUIP

MULTIQUIP Mikasa MTX-80 Operation and parts manual

BGS technic

BGS technic 62506 instruction manual

Viega

Viega Picco 6 Instructions for use

Everwin

Everwin FCN90B Operation and maintenance manual

Parkside

Parkside PHLG 2000-2 Operation and safety notes

Clarke

Clarke CAT108 (1/2) Operating and maintenance instructions

Universal Tool

Universal Tool UT8726 operating instructions