SPX Pearpoint P330+ Series User manual

Pushrod cable re-termination guide

Re-teRmination of peaRpoint p330+/p340 and GatoRCam3+/GatoRCam4 pushRods

90/pp_ReteRm/04 issue 4 02/2012 Read and undeRstand this Guide in full befoRe pRoCeedinG

seRviCe Guide

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 2 of 59

P330+/P340, GC3/GC4 Pushrod Cable

Retermination guide

This guide defines when and how to re-terminate the camera end of the following pushrods:-

Pearpoint P341 Plumbers Reel (30m/100’) GatorCam4 Plumbers Reel

Pearpoint P341 Plumbers Reel (60m/200’) GatorCam4 Plumbers Reel

Pearpoint P331 and P341 Reel (35m/115’) GatorCam3+ and GatorCam4 Mini Reel

Pearpoint P332 and P342 Reel (60m/200’) GatorCam3+ and GatorCam4 Std Reel

Pearpoint P332 and P342 Reel (120m/400’) GatorCam3+ & GatorCam4 Std Reel

Pearpoint P333 and P343 Reel (150m/500’) GatorCam3+ & GatorCam4 Std Reel

Note: onwards we shall refer to the current Sales brands Gatorcam 4 and P340 throughout this

manual. The above table is a reference to the equivalent P330 and Gator3 ranges.

Table of Contents

1. Before you begin.............................................................................................3

2. Tools & Equipment..........................................................................................4

3. Slipring Replacement –All Versions .............................................................7

4. P341 Plumbers or GC4 Plumbers Reel (7mm dia.) 93/RP3144Z10..8

4.1. 93/RP3144Z10 Rod-end Re-termination Procedure .........................................................8

4.2. Typical Reel Resistances................................................................................................18

4.3. Pressure Testing.............................................................................................................23

4.4. Bill of Materials / Assembly Drawing...............................................................................24

5. P341 or Gatorcam 4 Mini Reel (35M/115’, 12mm dia.) 10/RP3181 .....26

5.1. RP3181 Rod-End Re-termination Procedure..................................................................27

5.2. Typical Reel Resistances................................................................................................33

5.3. Pressure Testing.............................................................................................................34

5.4. Bill Of Materials / Assembly Drawing ..............................................................................35

6. P342 or Gatorcam 4 Midi Reel (60M/200’ or 120M/400’) 10/RP2809 ....37

6.1. 10/RP2809 Rod-end Retermination Procedure...............................................................38

6.2. Typical Reel Resistances................................................................................................43

6.3. Pressure Testing.............................................................................................................44

6.4. Bill Of Materials / Assembly Drawing ..............................................................................45

7. P343 or Gatorcam 4 Specialist Reel (150M/500’) 93/RP2861 .47

7.1. 93/RP2861 Re-termination Procedure...........................................................................48

7.2 Typical Reel Resistances.................................................................................................54

7.3 Pressure Test ..................................................................................................................54

7.4 Bill of Materials / Assembly Drawing................................................................................56

PLEASE BE CERTAIN TO HEED THE SAFETY WARNINGS ON PAGE 3

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 3 of 59

1. Before you begin

Re-terminations should be performed by a competent technician.

We cannot guarantee or warrant any repairs made by any employee outside of our business,

including other unaffiliated service centres.

It is possible to cause further damage to systems, consequential damage caused by poor

worksmanship will not be covered and the warranty will be considered void. This document is

intended as a guide for customers wishing to re-terminate the reels, however we cannot accept

responsibility for any damages resulting from poor application of our guide.

Due to continuous development of our product details may change. We only offer this guide to

support those customers who agree to assume responsibility for maintaining their own product.

We can offer training and support packages for customers on how to perform this competently.

Enquire with Sales or Service.

Before any re-termination ensure the system is disconnected from the power supply and

mains to ensure safe working. The cameras can become hot, do not look directly into

the camera due to the bright lights, they may cause temporary blindness or longer-term issues.

Potentially hazardous current and voltage sources contained within system when live.

Gloves and other appropriate PPE are strongly advised based on your risk assessment

due to various mechanical, hygienic, electronic and other hazards. If the system is being re-

terminated in a clean area ensure it has been suitably cleaned for the purpose.

Before you attempt any re-termination it is worth checking the video settings are correct for your

reel. For each different length of reel a different amplifier is used to boost the video signal. If this

is set incorrectly it will give a poor signal that may be misinterpreted as a cable fault.

You will need a colour copy of this guide due to colour coded wires and information.

Be aware of and take precautions against ESD. It is advised as part of your risk assessment you

consider the MSDS sheets available online from the 3rd party products required for some repair

operations. Consider PPE as part of this review.

Warning

Use extreme caution when using tools or industrial products or preparations.

When using the junior hacksaw, avoid inhaling or ingesting the glass fibre dust. Consider PPE.

When using the epoxy potting compound, avoid contact with skin.

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 4 of 59

2. Tools & Equipment

Some or all of the following tools will be required depending on which re-termination is being done :-

Junior Hacksaw (150mm / 6”)

Fine wire cutters / Adjustable precision wire stripper, 0.25-0.80mm.

(such as RS®Stock No. 622-721)

Triple-action cable stripping tool, 4.5-29mm strip

{such as Tavismanor ROT29RTGRS01/001 (RS Stock No. 262-0151)}

Scalpel / craft knife

Heatgun appropriate for small heatshrink applications (see pictures)

Scotchweld®DP100 needle applicator

Digital Volt Meter

Soldering iron \ Solder

Pressure test Jig Part: 09/RP3210Z2 with regulated airline or foot pump with

pressure gauge

15mm & 16mm open-ended spanners

Open-ended torque spanner with 15mm/16mm heads

Internal circlip pliers

“C” Spanner

Special Tools:-

Dual Size “C” Spanner,

- Available from Pearpoint / Radiodetection, part number 70/GC2011N14

Torque wrench

Typical wire stripper

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 5 of 59

Typical multi-purpose cable

stripper

Scotchweld DP100 two-part

quick-set epoxy structural

adhesive (50ml cartridge).

Adhesive dispenser gun, 50ml

cartridge.

Warning

Use extreme caution when using sharp tools.

When using the junior hacksaw, avoid inhaling or ingesting the glass fibre dust.

When using the epoxy potting compound, avoid contact with skin.

Additional materials to be obtained locally:-

Loctite®222 as required (Farnell / Element14 Stock No.1370113)

Loctite 243 as required (Farnell / Element14 Stock No.1370152)

PTFE grease (e.g. Super Lube) (Farnell / Element14 Stock No.537159)

1.6mm Heatshrink

(Farnell / Element 14 stock no. Allied Electronics stock no)

Scotchweld DP100 two-part quick-set epoxy structural adhesive (50ml cartridge)

(Farnell / Element14 stock No. 1702758 / Allied Electronics stock no. 617-7001)

Adhesive dispenser gun, 50ml cartridge

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 6 of 59

(Farnell®/ Element14®stock no. 1711526/ Allied Electronics stock no. 365-7000)

DP8005 mixer nozzle

(Farnell / Element14 Stock No. 1691657 / Allied Electronics stock no. 365-7005)

Additional needle applicators

(Farnell / Element14 stock no. 3975575 / Allied Electronics stock no.984-3187 / 984-3190)

Third party part numbers are quoted for reference only. Any third-party products mentioned in this

manual are for instructional purposes only and are not an endorsement by Radiodetection Ltd and

SPX Corporation.

Radiodetection Ltd does not accept any liability for loss or damage to equipment or materials

when using any third-party products.

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 7 of 59

3. Slipring Replacement –All Versions

There are two types of slipring PCB, they are not interchangeable and should never be mixed.

Poor video quality will result.

The 10/RP2809-4 ROD-END slipring PCB is at the end of the ROD and has a 6-way connector.

Kit Contains: Rod termination Slipring PCB, O-ring, Circlip

The SONDE-END Slipring PCB goes at the end of the SONDE, it has a different PCB and a 4-way

connector to prevent accidental use (the PCB is visually similar - beware).

Order: 09/RP2816ZBD-V0 (PCB), 04/XVH62S02 (circlip), 07/B01204016 (o-ring).

Slide back the shroud nut and carefully secure

the connector in a vice.

Using a 2mm –3mm screw-driver or similar,

carefully prise out the circlip that secures the

slip-ring PCB. One end of the circlip is tapered

to facilitate this.

Using a craft knife or similar, lift out the slip-

ring PCB and remove the mini-Molex®

connector from the back of the PCB.

Plug the mini-Molex connector into the rear of the new slip-ring PCB then push the wires and the

PCB down into the connector being careful not to squash or damage any wires.

Secure the PCB in position with the new circlip, ensuring the circlip is properly seated in its

groove.

Remove the old O-ring. Lightly grease the new O-ring with PTFE grease and fit to the connector.

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 8 of 59

4. P341 Plumbers or GC4 Plumbers Reel (7mm dia.) 93/RP3144Z10

Rod Camera-End Retermination

Materials required:-

Rod Re-termination Kit 93/RP3144Z10

These instructions detail the re-termination procedures for both the P341 30m / 60m Plumbers

reels and GatorCam4 30m / 60m Plumbers reels. Ensure that you read and understand these

instructions in full before proceeding.

4.1. 93/RP3144Z10 Rod-end Re-termination Procedure

Remove the camera from the sonde spring, place out of the way.

Ensure that all damaged rod is removed from the reel. Cut off the damaged rod with the junior

hacksaw.

Pull out sufficient rod from the reel to facilitate the repair and lock the brake.

Remove the M3 x 4 grub screw

from the side of the rod cover,

using the 1.5mm AF Allen key.

This screw is secured with

Loctite 222.

Insert the M3 x 25mm caphead

screw into the grub screw socket

until it is hand-tight.

r

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 9 of 59

Using the “C” spanner to hold

the spring body, loosen the rod

cover from the spring body by

using the caphead screw as

leverage.

Undo the rod cover and slide it

away from the sonde spring.

Remove and discard the 6mm

and 15mm O-rings.

Ease the termination nut out the

spring body, taking care not to

damage the four wires.

Using a scalpel or craft knife

carefully slit the heat shrink that

covers the four solder posts and

the ends of the wires, cutting

from the base of the posts. De-

solder the wires and discard the

heatshrink.

Warning: If the insulation on any of

the wires is damaged, they will have to

be cut back, stripped of 4-5mm of

insulation and tinned. If too much of

any wire is removed, the sonde

cableform assembly will have to be

replaced.

Remove and discard

any damaged rod

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 10 of 59

Cut the end of the rod squarely with the

junior hacksaw.

Slide the rear cover over the end of the

Rod followed by the new 6mm O-ring.

Push back out of the way.

Score through full thickness of the outer

sheath at 60mm from the end of the rod,

taking care not to cut into the inner foil

layer.

Use suitable rotary cable stripping tools.

(NOTE: we have found scalpels to be

unsuitable and dangerous for this task.

Do not use them)

New 6mm O-ring

Rear

Cover

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 11 of 59

Typical multi-purpose cable stripper

Strip off the 60mm of the outer sheath, using a

suitable Multi-purpose Cable Stripping tool to

avoid damage to the inner foil and wires.

Ensure that the cutting depth of the stripping

tool is correctly set to cut the outer sheath

through without damaging the inner foil

wrapping layer. Several attempts may be

necessary to set the tool to the correct depth.

Uncoil and remove the foil layer.

Cut away the 6 x plastic filler strands back to

the end of the outer sheath.

Remove Foil

Remove 6 x filler

strands

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 12 of 59

15mm

Cut the fibreglass core to 15mm from the outer

sheath of the rod, using the junior hacksaw.

Cut the brown, green, yellow, red, blue and

drain wires back to 50mm long.

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 13 of 59

Strip the insulation of the green, brown, red,

blue and yellow wires back to 10mm from the

outer sheath of the rod, using the precision wire

stripper or small wire cutters.

Twist the bare strands of each wire to ease the

fit into the PCB.

Slide a 10mm length of 1.6mm heatshrink over

the drain wire, push down until it touches the

cable outer sheath and apply heat to shrink.

10mm

10mm

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 14 of 59

Check that the termination PCB fits

snugly into the termination nut. If

necessary, carefully trim the edge of

the board with a fine file or craft

knife.

Note: using cutting tools by hand

can be dangerous. Consider gloves,

PPE or the file as a safer alternative.

Screw the threaded termination nut

squarely onto the end of the rod until

the outer sheath is flush with the

inside rear of the metalwork.

4

3

2

1

Tin the four pins of the terminal

PCB.

Termination Nut

Outer Sheath

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 15 of 59

BLUE

VID 0V

BROWN

PWR+

DRAIN

YELLOW

0V

GREEN

VID-

RED

VID+

Feed the correct colour wires

through the rear of the termination

PCB, as shown

Feed the correct colour wires

through the rear of the termination

PCB.

PCB

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 16 of 59

Push the PCB down over the

fibreglass core, keeping the wires

taut, onto the termination nut until it

is flush with the top of the

metalwork.

With the termination PCB in position

check that none of the wires are

shorting out either to each other, or

the metalwork, by connecting a DVM

between each individual wire and all

the other wires in turn, as well as to

the case.

Keeping the PCB flush with the top

of the metalwork, solder the wires to

the PCB and crop all of the wires to

2mm from the board.

Disconnect the reel connector from

the hub assembly by turning the

round, ridged plug connector

through 90° anti-clockwise.

Termination nut

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 17 of 59

Using the DVM, check for continuity

from the reel connector to the

termination PCB.

Reel Connector Termination PCB

7 WAY

REEL PLUG

ROD WIRE

PCB

1

2

3

RED

VID+ ONLY

4

BLUE / DRAIN / YELLOW

VID 0V/ DRAIN / 0V

5

GREEN

VID- ONLY

6

DRAIN / YELLOW / BLUE

DRAIN / 0V / VID0V

7

BROWN

PWR+ ONLY

NOTE: Positions 1 and 2 at the seven way plug are wired to the reel counter reed switches,

therefore pins 1 and 2 will alternate from open to closed circuit relative to pin 4 as you rotate

the reel.

Reel Connector

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 18 of 59

P341

Plumbers

& GC4

Plumbers

Termination PCB

VID+

VID-

PWR+

GND

Reel connector

1

2

3

< 10Ω

∞

∞

∞

4

∞

< 10Ω

> 10kΩ

< 10Ω

5

∞

45 to 60Ω

> 10kΩ

45 to 60Ω

6

∞

< 10Ω

> 10kΩ

< 10Ω

7

∞

> 10kΩ

< 10Ω

>10kΩ

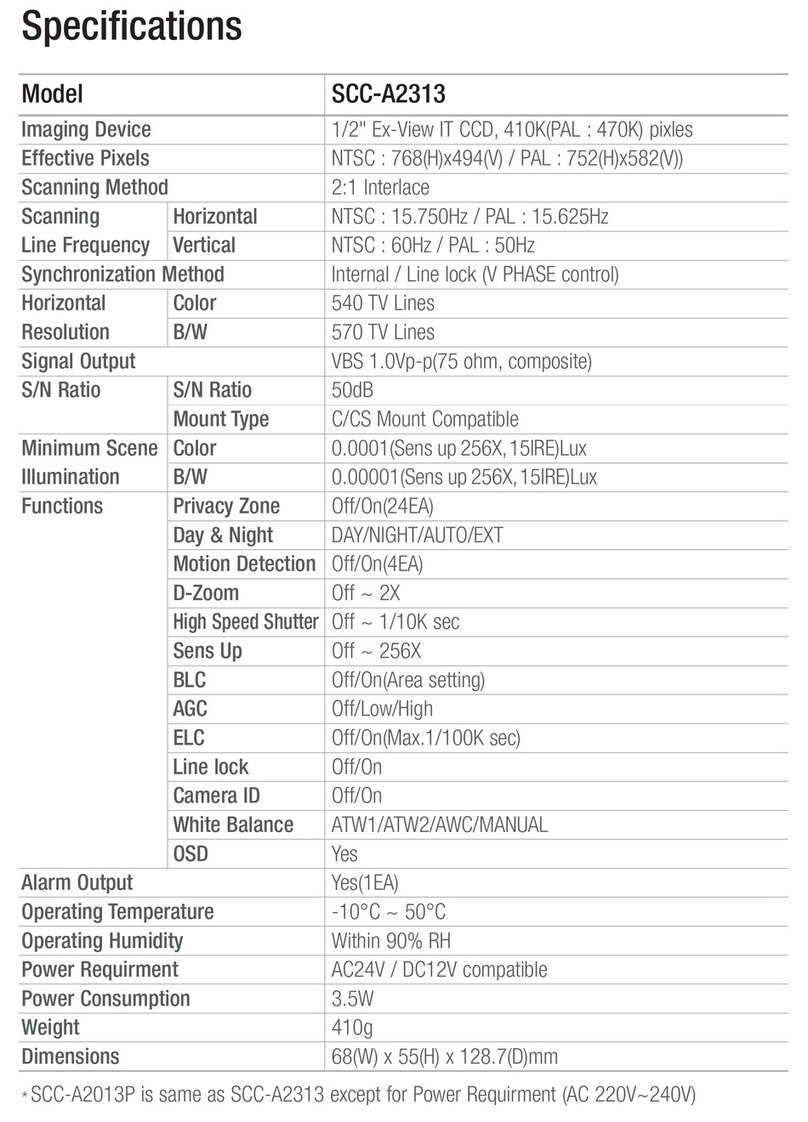

4.2. Typical Reel Resistances

7-Way reel plug

Signal

Slipring PCB

30m/100’ Reel

Resistance (Ω)

60m/200’ Reel

Resistance (Ω)

1

Not Connected

2

3

Vid +

Ring 1 (centre)

2.9

5.4

4

Gnd

Ring 4 (outer)

2.9

5.4

5

Vid -

Ring 2

50.1

52.3

6

Gnd

Ring 4 (outer)

1.1

1.9

7

Power +

Ring 3

2.8

5.4

Be aware that these values may change if the reel length has been significantly changed or cut

back during service operations!

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 19 of 59

Load a tube of two-part quick set epoxy

resin into an application gun.

Use a needle applicator to pot the

termination PCB into the termination

nut.

Insert the resin into the runner hole in

the PCB until it appears out of the riser

hole.

Ensure that the PCB is level and flush

with the top edge of the termination nut.

Keep the assembly level and allow the

epoxy to settle for 3-5 minutes and top

up if necessary.

Leave epoxy to set for at least 15

minutes, it will cure fully in 24 hours.

Runner

hole

Riser hole

Copyright 2012 Radiodetection Ltd.–SPX Corporation. All rights reserved. Radiodetection is a subsidiary of SPX Corporation.

This document may not be copied, reproduced, transmitted, modified or used, in whole or in part, without the prior written consent of Radiodetection

Ltd. We reserve the right to alter or amend any published specification without notice. Page 20 of 59

Lightly coat the new 15mm O-ring with

PTFE grease and fit onto the terminal

nut.

If the sonde wires have had to be cut

back, strip the insulation on the four

wires back to 4-5mm and twist and tin

the ends.

Slide a 5mm length of the 1.6mm

heatshrink over each of the four wires

from the rod end of the sonde.

Solder the four wires from the rod end

of the sonde to the termination PCB as

shown in the chart above.

NOTE: Solder the wires on the inside of

the pins to minimise the chance of

shorting to the

metal-work.

Slide the heatshrink over the joints and

apply the heat gun to shrink.

Slide the 6mm O-ring along the rod up

to the rear of the terminal nut.

6mm O-ring

Rod

end

This manual suits for next models

14

Table of contents

Other SPX Digital Camera manuals

Popular Digital Camera manuals by other brands

Bell and Howell

Bell and Howell Electric Eye 8mm Camera How to use

Ricoh

Ricoh GR DIGITAL M instruction manual

ROBOTIQ

ROBOTIQ RWC-UR-KIT instruction manual

Kodak

Kodak EASYSHARE C1505 Extended user guide

Aberg Best

Aberg Best ABcam 218 user manual

Insignia

Insignia NS-DSC10B - Digital Camera - Compact user guide