SPX Pearlpoint P374 User manual

Ðíéì

× Ò Ì Î × Ò Í × Ý ß Ô ÔÇ Í ß Ú Û Ý Ñ ÔÑ Ë Î Ýß Ó Û Î ß

Ø Ý í é ì Óß Ò ó ê × Í Í Ë Û ê ð ì ñ î ð ïí Î Û ß Ü ß Ò Ü Ë Ò Ü Û Î Í Ìß Ò Ü Ì Ø × Í Ó ß Ò Ëß Ô Ð Î × Ñ Î Ì Ñ Ñ Ð Û Î ßÌ × Ò Ù Ì Ø Û Í ÇÍ Ì Û Ó

Ë Í Û Î Ó ß Ò Ë ß Ô

P374 System User Manual Section 1

© Pearpoint Ltd 2-1

COPYRIGHT NOTICE

The information within this publication is authorised for distribution to

customers, authorised service centre personnel, and distributors of Pearpoint.

Every effort has been made to supply information within this publication which

is correct. However, Pearpoint assumes no responsibility for its use nor any

infringements of patents or other rights of third parties which would result. No

licence is granted by the manufacturer under any patent or patent rights. The

manufacturer reserves the right to modify and update the equipment at any time

without prior notice.

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means to a third party without the prior

consent of the copyright holder.

The manufacturer's warranty will be invalidated if the equipment is operated by

untrained personnel or if any attempt is made to service the equipment by

untrained personnel.

REVISION HISTORY

Revision Date Comments

1.0 November 2001 First Issue

2.0 July 2002 FM Approval

3.0 Nov 2003 New ATEX Information Added

4.0 Nov 2006 Minor corrections and additions

Radiodetection Ltd

Western Drive

Bristol

Telephone: +44(0)117 976 7776

Facsimile: +44(0) 0117 976 7775

http://www.radiodetection.com

Manual part number: HC374MAN-1

i

Section 1 P374 System User Manual

© Pearpoint Ltd

2-2

CONTENTS

Page

1. GENERAL INFORMATION 1-1

1.1 WARNINGS, CAUTIONS AND NOTES 1-1

1.2 SAFETY PRECAUTIONS 1-1

1.3 SIRA CERTIFICATION 1-2

1.4 FM CERTIFICATION 1-5

1.5 EMC COMPLIANCE STATEMENT 1-7

1.6 INTRINSICALLY SAFE CONSIDERATIONS 1-9

1.7 RETURNS PROCEDURE 1-11

2. SYSTEM PREPARATION AND CONNECTION 2-1

2.1 INTRODUCTION 2-1

2.2 OVERVIEW 2-1

2.3 CONNECTIONS 2-1

2.4 SET MONITOR DISPLAY 2-2

2.5 ROD COUNTER SYSTEM 2-2

2.6 ROD CALIBRATION 2-3

2.7 ZERO THE ROD COUNTER 2-3

3. P374 INTRINSICALLY SAFE FLEXIPROBE 3-1

3.1 SETTING MANUAL FOCUS 3-1

3.2 SKID SETS 3-3

3.3 FITTING 100MM (4”) BRUSH SKIDS 3-4

3.4 FITTING 100MM (4”) AXIS SKIDS 3-5

3.5 FITTING 100MM (4”) AXIS SKIDS LIVE GAS MAIN INSERTION 3-6

3.6 USER MAINTENANCE 3-7

3.7 USER REPAIRS 3-8

3.8 OPTIONS 3-10

4. TEXT EDITOR 4-1

4.1 KEYBOARD FUNCTIONS 4-1

4.2 SET CURRENT DATE - [SET] [DATE] 4-1

4.3 SET CURRENT TIME - [SET] [TIME] 4-2

4.4 SET ROD COUNTER - [SET] [COUNT] [SET] 4-2

4.5 SET LANGUAGE - [CONF] [LANG] 4-2

4.6 SET MEASUREMENT UNITS - [CONF] [UNITS] 4-2

4.7 SET DISPLAY COLOUR - [CONF] [DISP] 4-2

4.8 SYSTEM RESET [CONF] [FCLR] 4-2

4.9 USER TEXT PAGES - [SET] [USR] 4-2

4.10 CREATING TEXT ON A PAGE. 4-3

4.11 ENTERING FIELDS ONTO A PAGE 4-4

4.12 DELETING FIELDS FROM TEXT 4-4

ii

P374 System User Manual Section 1

© Pearpoint Ltd 2-3

4.13 DELETING A CHARACTER 4-4

4.14 DELETING A LINE 4-4

4.15 DELETING EVERYTHING ON A PAGE 4-4

4.16 DELETING EVERY PAGE 4-5

4.17 CORRECTING A CHARACTER 4-5

4.18 INSERTING A CHARACTER 4-5

4.19 INSERTING A LINE 4-5

5. SPECIFICATIONS AND TROUBLESHOOTING 5-1

5.1 GENERAL EQUIPMENT SPECIFICATION 5-1

5.2 TROUBLESHOOTING 5-1

iii

Section 1 P374 System User Manual

© Pearpoint Ltd

2-4

GENERAL INFORMATION

1.1 WARNINGS, CAUTIONS AND NOTES

Within this handbook, pay particular attention to Warnings, Cautions, and

Notes, examples of which are shown below.

INDICATES THE POSSIBILITY OF PERSONAL INJURY IF INSTRUCTIONS ARE

NOT FOLLOWED CAREFULLY.

C

Indicates a possibility of equipment damage if the instructions are not

followed carefully.

S

INDICATES SERVICEABLE PARTS

NNOTE. Gives added information that will make operation of the equipment

easier.

1.2 SAFETY PRECAUTIONS

C

The P374 Inspection System is designed to reduce hazards from electric

shock provided that proper operating procedures are followed. If it is

operated in an outdoor environment it is imperative that proper earthing

procedures are followed. Use of a Residual Current Detector (RCD) is

strongly recommended [USA - Ground Fault Interrupter (GFI)]

Ensure the system is not placed in or near surface water.

Always ensure that cabling is properly connected.

Always transport a generator with the minimum amount of fuel in the

tank.

Never connect or disconnect any part of the equipment when it is switched

on.

Always switch the system on and off using the mains supply switch.

Clean and sterilise equipment at regular intervals.

ALWAYS USE HEAVY DUTY INDUSTRIAL GLOVES WHEN HANDLING ROD OR

CABLE WHICH IS BEING WITHDRAWN FROM A SEWER.

TO AVOID RISK OF BURNS,DO NOT TOUCH THE CAMERA HEAD WHEN IT IS

SWITCHED ON OR IMMEDIATELY AFTER SWITCH OFF. LEAVE AMPLE TIME

FOR IT TO COOL BEFORE HANDLING.

ARISK ASSESSMENT SHOULD BE PERFORMED PRIOR TO COMMENCING

WORK AS IT MAY HIGHLIGHT ADDITIONAL SAFETY ISSUES SPECIFIC TO THE

APPLICATION

1-1

P374 System User Manual Section 1

© Pearpoint Ltd 2-5

1.3 SIRA CERTIFICATION

1-2

Section 1 P374 System User Manual

© Pearpoint Ltd

2-6

1-3

P374 System User Manual Section 1

© Pearpoint Ltd 2-7

1-4

Section 1 P374 System User Manual

© Pearpoint Ltd

2-8

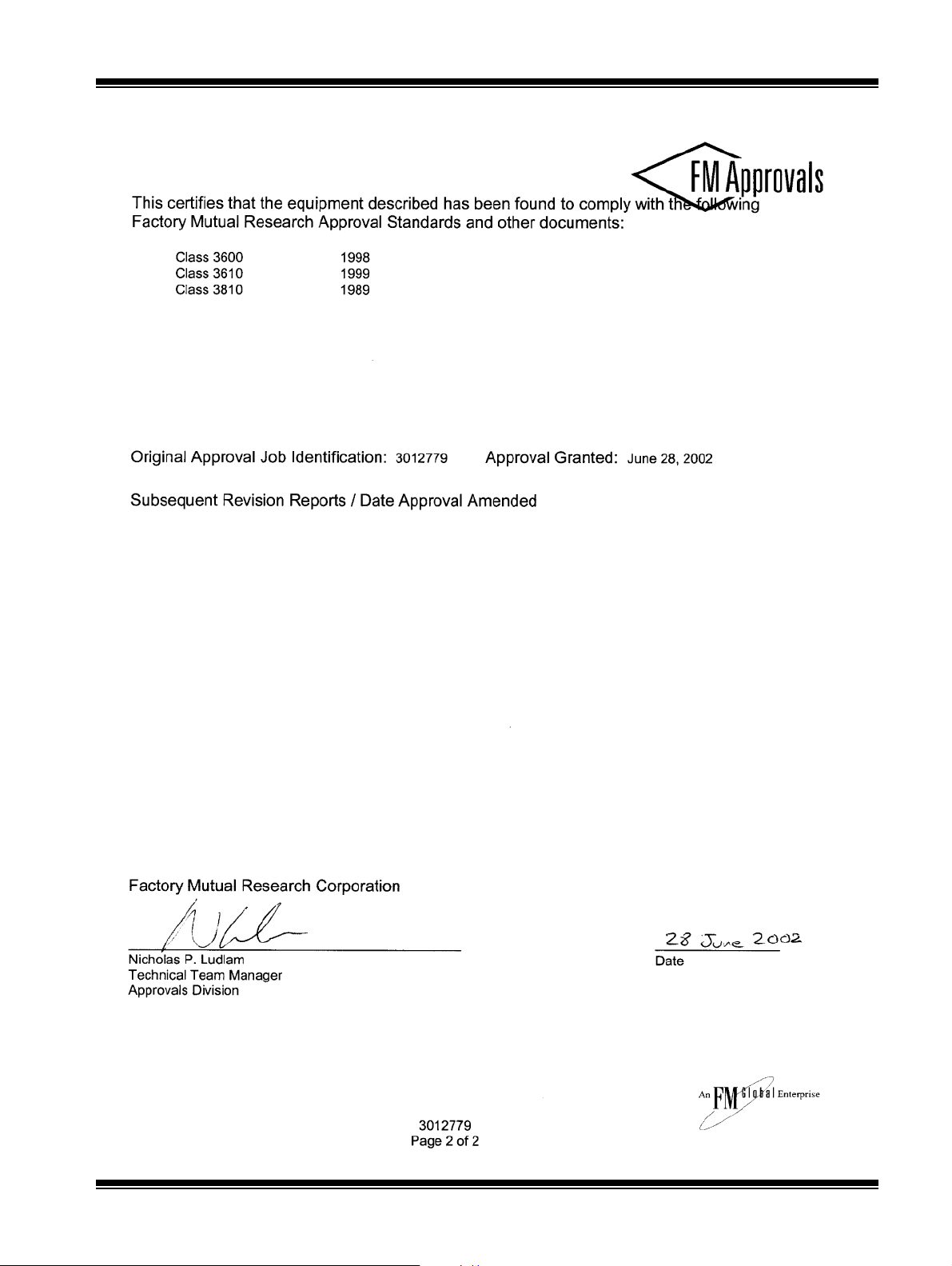

1.4 FM CERTIFICATION

1-5

P374 System User Manual Section 1

© Pearpoint Ltd 2-9

1-6

Section 1 P374 System User Manual

© Pearpoint Ltd

2-10

1.5 EMC COMPLIANCE STATEMENT

FCC CLASS B RADIO FREQUENCY INTERFERENCE STATEMENT

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment to an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

DOC Notice (Canada Only)

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus as set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant

les limites applicable aux areils numeriques de Classe B prescrites dans le

Reglement sur le Brouillage Radioelectrique edicte par le Ministere des

Communications du Canada.

EUROPEAN COMMUNITY RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and complies with the following harmonised

standards:

EN 50082-2 Provisional Immunity Standard encompassing static,

RF, and line borne transient immunity.

EN 50081-1 EMC emission standard.

EN 61000-3-2 Line Borne Harmonic Distortion

1-7

P374 System User Manual Section 1

© Pearpoint Ltd 2-11

1-8

Section 1 P374 System User Manual

© Pearpoint Ltd

2-12

1.6 INTRINSICALLY SAFE CONSIDERATIONS

The Pearpoint P374 system has been designed to be Intrinsically Safe even when

faults occur or when the equipment has been damaged due to misuse. However,

there are situations where the operator can cause a fire hazard if the following

guidelines are not adhered to:

Equipment earthing

The equipment must be operated at the same electrical potential as the subject

being inspected. This means that the P374 system and the subject being

inspected must be joined together electrically otherwise it is possible that a high

potential might exist between the equipment and the subject. Here are a few

examples:

Underground pipework. If the P374 is operated from a mains supply rather than

a generator there is usually no problem as any buried pipework will be at mains

earth potential ensuring that there is no potential difference between the camera

and subject. However, if the equipment is operated using a generator rather than

a mains supply then there is a possibility that a potential difference exists

between the P374 system and the pipework. As a general rule the potential

difference will not be sufficient to cause a problem as the P374 camera is

insulated to a voltage of greater than 500V. However, it is good practice to

ensure that the P374 system is bound to the same potential as the subject, this is

because an operator may build up a certain amount of static electricity and this

may be discharged through the P374 system.

When working with a generator it is imperative that the generator is earthed, this

can be done via the generator earthing point (see the generator manual for this

information). An earth wire must run from the generator to the subject, in the

case of underground pipes this can be an earthing stake. Where working on oil

platforms the metal structure of the platform can be used. If your generator does

not have an earthing point then an additional earth wire must be run from the

distribution connector (see your dealer for details).

When working with mains power ensure that the equipment is properly earthed,

be aware that some extension leads only carry 2 conductors for Live and Neutral

and miss out the earth conductor altogether. Also be aware that some isolating

transformers do not continue the earth conductor through between input and

output (although this is rare); ensure that the transformer you are using has a

continuous earth.

When working with the 12V supply input it is imperative that the negative

conductor is earthed. Quite often the 12V supply is derived from a motor

vehicle, this means that the P374 earthing system is connected to the chassis of

the vehicle and thus the P374 will assume the same potential as the vehicle. It is

well known that the chassis of vehicles can carry high voltages due to static

build-up and this voltage will be conducted to the P374 unit. For this reason the

chassis of the vehicle must be bonded to the subject being inspected, usually (in

the case of underground pipework) this means that the chassis of the vehicle is

connected to a ground-stake.

1-9

P374 System User Manual Section 1

© Pearpoint Ltd 2-13

1-10

Section 1 P374 System User Manual

© Pearpoint Ltd

2-14

1.7 RETURNS PROCEDURE

If any equipment has to be returned to Pearpoint for repair or servicing, please

note the following precautions to be taken to ensure safe passage:

Always contact your service agent in advance.

Retain the original packaging material and re-use wherever possible.

If the original packaging material is not available, select a heavy duty

cardboard box and make liberal use of bubble pack or polystyrene

material to cushion and prevent movement of the component.

Clearly identify all equipment with the customer's name and address.

Where relevant, attach "Fragile" and "This Way Up" labels to the

packaging.

To the outside of one box, attach a copy of your order or work

instructions.Enclose these in an envelope, including your name and

address.

Never transport generators with fuel on board.

Always clean all contamination from the equipment prior to sending it to

Pearpoint.

Flexirods must be securely retained within the coiler or transportation

cage.

Equipment should be insured for carriage damage or loss.

1-11

P374 System User Manual Section 2

© Pearpoint Ltd 2-1

2. SYSTEM PREPARATION AND CONNECTION

2.1 INTRODUCTION

The P374 is a colour inspection system specifically designed for intrinsically

safe inspection needs. The P374 is a solid state, high resolution colour camera

which is fully immersible and can travel down pipes up to 60 metres (200 feet)

in length. The P374 camera operates from a Intrinsically safe low current

supplied through the coiler.

A variety of skids allow inspection of pipes from 25mm (1") to 100mm (4").

2.2 OVERVIEW

The system provides a self-contained video inspection system including camera,

rod, power supply and video monitor. When connected to a mains power supply

or a 12V supply the unit will be fully operational with the simplest of

preparation. The system also provides the means to play-back recorded media on

the integral LCD monitor by connecting any composite video source (PAL or

NTSC) to the 'Video in' BNC connector on the underside of the electronics

enclosure, video from the unit may also be recorded from the 'Video out' BNC

connector. The unit is supplied with a video text-writer, this can display the

users' text messages on-screen along with the cameras' distance measurement

and the date and time (this is updated automatically). The system is fully water

resistant to IP55, allowing for total wash-down of all components for cleaning

C

Do not use a high pressure water jet on the camera and electrical housing,

as there is a possibility of equipment damage.

The coiler is constructed from durable, cast aluminium and all parts are designed

for low maintenance.

2.3 CONNECTIONS

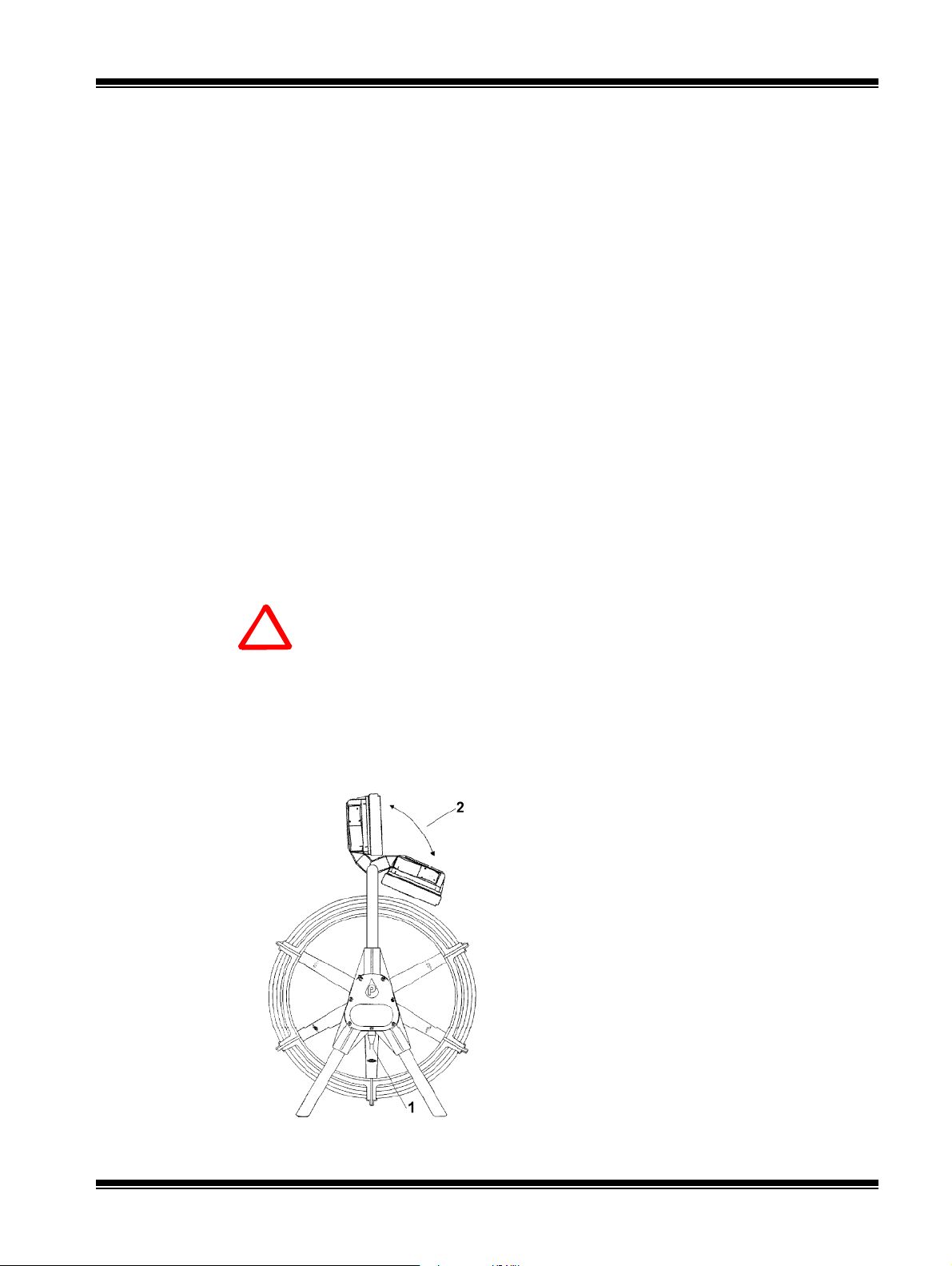

The system is very easy to prepare for use.

1. Ensure that the Power Lead is firmly plugged

into the socket (1) (see Connectors Diagram)

2. Push the monitor to the up-right position (2).

3. The P374 will power up as soon as it is

connected to an electrical supply.

4. If you wish to connect a VCR to your system, to

record or playback your survey the BNC

connectors are situated adjacent to the mains

cable (item 1) (see Connectors Diagram). You

will require a BNC cable which can be supplied

by Pearpoint as an option. When connected to

Video IN, the monitor will automatically display

your survey video.

5. If you wish to power your system from a 12V

DC supply, the socket is situated adjacent to the

mains connector (1). The cable will connect to a

Vehicle Cigarette/Cigar Lighter and is available

with the equipment as standard.

Section 3 P374 System User Manual

© Pearpoint Ltd

2-2

N

Connectors Diagram

FRONT

MAINS POWER INPUT

12VDC INPUT VIDEO INPUT (TO VIDEO RECO

VIDEO OU

T

(FROM VIDEO RECORDER)

On powering up, the Pearpoint message will be

displayed briefly and the camera and lights will

operate. The system is now ready to use.

A pull-out sun shade is available to reduce the effects

of bright sunlight on the monitor.

2.4 SET MONITOR DISPLAY

For the best quality monitor picture it is best to view the

monitor straight-on, the picture quality will degrade when

viewed from different angles.

You can adjust the quality of the displayed picture by using

the monitor set-up controls situated on the left hand side of

the monitor.

You can turn the knobs to adjust the brightness and colour

of the picture to suit your own requirements.

NOTE. The Hue control is for NTSC systems only.

2.5 ROD COUNTER SYSTEM

The rod counter display appears in the centre of the screen. The rod counter

requires calibrating on a regular basis to maintain accuracy.

NNOTE. Should the counter run outside calibration the message "counter

needs cal" will be displayed. You should carry out the procedure

detailed below.

P374 System User Manual Section 2

© Pearpoint Ltd 2-3

2.6 ROD CALIBRATION

1. Ensure all the rod is returned to the coiler.

2. Press the [ZERO] button and hold for five seconds. The message "press

again to cal" is displayed, release the [ZERO] button.

3. Press the [ZERO] button again. The message "cal complete" will be

displayed.

C

Pearpoint recommends the system is calibrated before use or on a daily

basis.

It is also advisable, on a regular basis, to confirm the absolute accuracy of

your counter by means of a physical check of rod length. This involves

calibrating the rod, setting the counter to zero, and pulling 20m (60 ft) of

rod from the coiler. You can compare the physical measurement with the

rod counter reading displayed on the screen. The displayed rod length

should be within ±60cm (2 ft) of the physical length.

2.7 ZERO THE ROD COUNTER

The rod counter can be set to zero at any time. This is useful if you wish to

restart your survey at a particular point. To zero the counter:

1. Press the [ZERO] button three times in quick succession. The counter will

read zero.

Table of contents

Other SPX Digital Camera manuals