SPX Hankison 600 Series User manual

600 Series

Electric Demand Drains

Models: EDD 601-04, EDD 602-04, EDD 603-04, EDD 604-04

FORM NO.: 7428306 REVISION: 09/2013 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

CONTENTS

GENERAL INFORMATION......................................... 1

1.0 FUNCTION .......................................................... 1

2.0 INSTALLATION .................................................... 2

3.0 MAINTENANCE................................................... 6

4.0 TROUBLESHOOTING GUIDE............................. 7

5.0 ENGINEERING DATA .......................................... 8

6.0 DIMENSIONS ...................................................... 8

7.0 COMPONENTS ................................................... 9

WARRANTY

1

GENERAL INFORMATION

1. Do not exceed max. operating pressure (see type plate).

NOTE: Maintenance work must only be carried out when

the device is not under pressure.

2. Only use pressure-proof installation material.

The feed line (1/2”) must be firmly fixed. Discharge line:

short pressure hose to pressure-proof pipe. Please

ensure that condensate cannot squirt onto persons or

objects.

3. In case conical connectors are used on the inlet side,

avoid excessive tightening of the connectors.

4. For locking or holding in position during installation, use

spanner area at inflow point.

5. The electrical installation must be carried out in compli-

ance with the valid regulations.

NOTE: Maintenance work is only allowed when the device is

in a de-energized condition. Electrical work must always be

performed by a qualified electrician.

6. Do not operate the device when there is a danger of

frost.

7. The Series 600 condensate drain will only function when

voltage is being applied to the device.

8. Do not use the test button for continuous draining.

9. Do not use the Series 600 condensate drain in hazardous

areas (with potentially explosive atmospheres).

10. Only employ original spare parts, otherwise the guaran-

tee will no longer be valid.

1.0 FUNCTION

The condensate flows through the feed line (1) into the

Series 600 condensate drain and accumulates in the hous-

ing (2). A capacitive sensor (3) continuously registers the

liquid level. As soon as the container is filled, a fixed waiting

period begins during which more condensate accumulates.

After the waiting time has expired the pilot valve (4) is then

activated and the diaphragm (5) opens the outlet line (6) for

discharging the condensate.

When the Series 600 condensate drain has been emptied,

the outlet line is closed again quickly and tightly without

wasting compressed air.

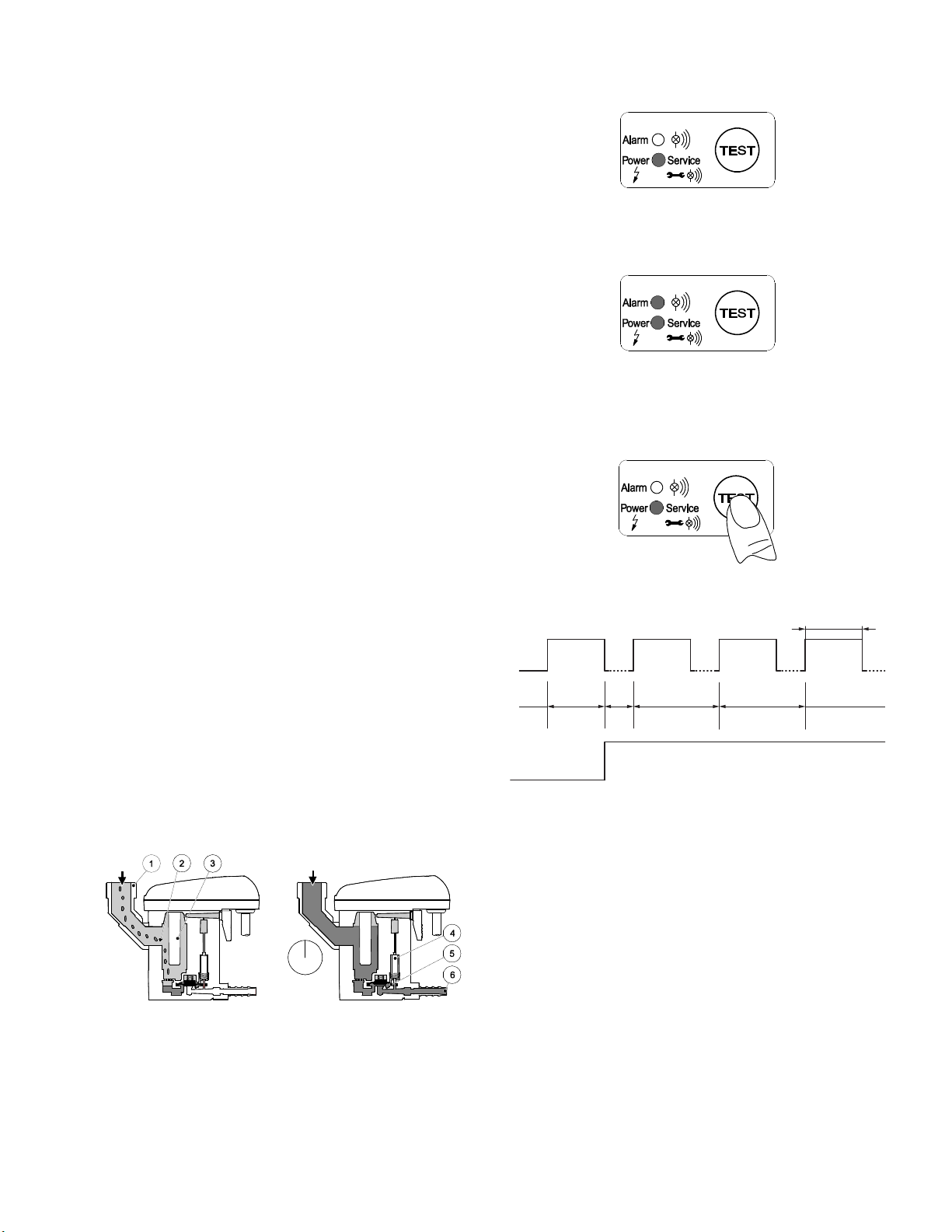

Ready for operation / Power on

The operating states of the Series 600 condensate drain are

indicated by two LEDs.

Malfunction / Alarm

If the condensate discharge is not functioning properly, an

alarm mode starts which is indicated by the flashing of the

red alarm LED.

Test function

1. Test of valve function and manual drainage: briefly press

button.

2. Test the alarm function (see below): press button for at

least one (1) minute.

Switching sequence of valve in alarm mode

Alarm signal via potential-free contact.

Alarm-mode function:

If normal conditions have not been restored after 1 minute,

a fault signal will be triggered:

• AlarmLEDashes.

• Alarmsignalswitchesover(canbetransmittedvia

potential-free contact).

• Valveopensevery80secondsforaperiodof60

seconds.

Once the fault is cleared, the Series 600 condensate drain will

automatically switch back to the normal mode of operation.

Malfunctioning could be caused by, e.g.:

• Mistakesduringinstallation

• Droppingbelowthenecessaryminimumpressure

• Excessivecondensatequantities(over-loading)

• Blocked/shutoffoutletline

• Extremeamountofdirtparticles

• Frozenpiping

60 s

60 s

80 s 80 s20 s

2

2.0 INSTALLATION

Only the displayed installation position of the Series 600 con-

densate drain valve is permissible. Never install in a horizon-

tal or any other tilted position.

• Feedpipe(1)andballvalve(2)atleast1/2‘’

• Nolterorscreeninfeedline

• Slopeinfeedline>1%

• Onlyuseballvalves(2)

• Operatingpressure:

Models 601 & 603 min. 18 psig max. 230 psig

Models 602 & 604 min. 12 psig max. 230 psig

• Shortpressurehose(4)xedonapressureresistantpipe

• Foreachmeterofrisingslopeintheoutletline(5),the

required minimum pressure will increase by 1.5 psig.

• Theriseoftheoutletline(5)mustnotexceed17feet

• Laycollectingline(7)3/4”with1%ofslope.

• Leaddischargepipe(6)fromthetopintocollecting

line (7).

• Priortothestart-up,alwayscarryoutaleaktestand

verify the correct engagement of the control unit.

Incorrect Installation Correct Installation

NOTE: Pressure Differences

Each condensate source must be drained separately.

Incorrect Installation Correct Installation

NOTE: Deflector Area

If drainage is to take place directly from a line, it is advis-

able to arrange the piping so that the air flow is diverted.

Incorrect Installation Correct Installation

NOTE: Continuous Slope

Water pockets must be avoided when laying feed line.

Incorrect Installations

NOTE:NoVentingLine

Do not install a vent line for a Series 600 condensate drain.

Installations, where a venting line is normally required, are

impossible in this case. Use another suitable drain valve.

3

2.1 Electrical Installation Notes before wiring:

1. The mains voltage must correspond to the permissible

voltage on the type plate.

2. For the supply voltage, a reliably accessible separator

must be provided close-by ( e.g. power plug or switch),

which separates all current-carrying conductors.

3. Atalow-voltagesupply(<50VAC/<75VDC),onlyusea

protectiveextra-low-lowvoltage(PELV).

4. Please ensure that the installation is carried out accord-

ing to the valid regulations.

5. Observe the terminal assignments.

6. DO NOT install when the device is energized.

7. Remove screws (1) and remove the upper part of the

cover (2).

8. Unscrew the threaded cable connection (3), remove

the plug (if there is one), and guide the cable (4) for the

power supply through.

9. Connect the cable (4) with terminals X1 (1.1, 1.2) (5).

10. Install the cables as shown (see also terminal assignment

in the following text).

11. Tighten the threaded cable connection (3) with a slightly

sealing effect.

12. Re-install the upper part of the cover (2) and tighten the

screws (1) finger tight.

Terminal assignment supply voltage (operating voltage)

X1 X2 X3

1212312

phase

neutral

normally open

common

normally closed

external test (IN1)

GND

1.1

1.2

2.1

2.2

2.3

3.1

3.2

• X1.1 Lmainsconnection

• X1.2 Nmainsconnection

L = Outer conductor

N = Neutral conductor

Terminal assignment low voltage (operating voltage)

X1 X2 X3

1212312

power

power

normally open

common

normally closed

external test (IN1)

GND

1.1

1.2

2.1

2.2

2.3

3.1

3.2

• X1.1 PowerSupply

• X1.2 PowerSupply

4

Connection of the potential-free contact and of the

external test:

1. Selection of the suitable cable.

2. Connect to X2 and X3 as shown.

3. Installation steps are the same as for the power supply

connection.

4. If the potential-free contact carries voltage that is dan-

gerous in the case of contact, a corresponding separator

must also be provided, as described above.

5. When using the potential-free contacts and the external

test connection, ensure sufficient clearance to the other

parts of the unit, or suitable insulation in accordance

with valid regulations.

6. When using a multiwire, common line for the connec-

tion of the potential-free contact and the external test,

this line must be suitable for the highest occurring volt-

age and the intended temperature range with regard

to its nominal ratings. (e.g. nominal range ≥300Vand

service temperature ≤1°C and ≥60°C.

Terminal assignment of the potential-free contact of

the external test

X1 X2 X3

1212312

power

power

normally open

common

normally closed

external test (IN1)

GND

1.1

1.2

2.1

2.2

2.3

3.1

3.2

Alarm / potential-free contact

• X2.1 N.O.

• X2.2 COM.

• X2.3 N.C.

N.C. - COM.

Contact closed during malfunction or power failure (fail-safe

principle).

N.O. - COM.

Contact closed during normal operation.

The contacts X 2.1 - 2.3 are potential free.

External test / remote control

• X3.1 externaltest(IN1)

• X3.2 GND

Contacts connected = test active = discharge

Contact open = test inactive

The contacts X 3.1 - 3.2 are NOT potential free.

NOTE:Foralow-voltagesupply(<50VAC/<75VDC),only

useaprotectiveextra-low-voltage(PELV).

Tighten the threaded cable connection with a slight sealing

effect.

2.2 Electrical Data

Supply voltage

(see type plate)

24...48VAC±10%(50...60Hz)/18...72VDC±10%

or

95...240VAC±10%(50...60Hz)/100...125VDC±10%

Power

consumption

P=0.6...3VA(W)

Recommended

cable-jack diameter

Ø 5.0... 10 mm (0.20"... 0.39")

Recommended

wire cross-section

Spring loaded

terminal

(voltage supply/

relay)

0.75...1.5 mm2(AWG 16...20)

Recommended

wire cross-section

Screw terminal

(voltage supply)

0.75...2.5 mm2(AWG 14...20)

Recommended

wire cross-section

Spring loaded

terminal

(external test)

0.75...1.0 mm2(AWG 18...20)

Recommended

wire cross-section

Screw terminal

(relay/external test)

0.75...1.5 mm2(AWG 16...20)

Connection data of

the potential free

contact

Switch to load *)

AC:max.250V/1A

DC: max. 30V/1A

Connection data of

the potential free

contact

Switch to low

signal *)

min.5VDC/10mA

Connection data

of the external test

contact

ontheunitside5VDC;switchingcurrent≥0.5 mA

Protection class IP 67

Overvoltage

category

II

VAC=Valternatingcurrent

VDC=Vdirectcurrent

*) The switching of loads means that the properties of the

contact are no longer suitable for the switching of low

signals.

5

2.3 Electrical Diagram

Pos: 52 /Beko Techni s che Doku mentati on/Inst allation/BEKOMAT/E-Sch ema @ 0 \ mod_1233758178163_2901.docx @ 13497 @ 1 @ 1

Electric diagram

6

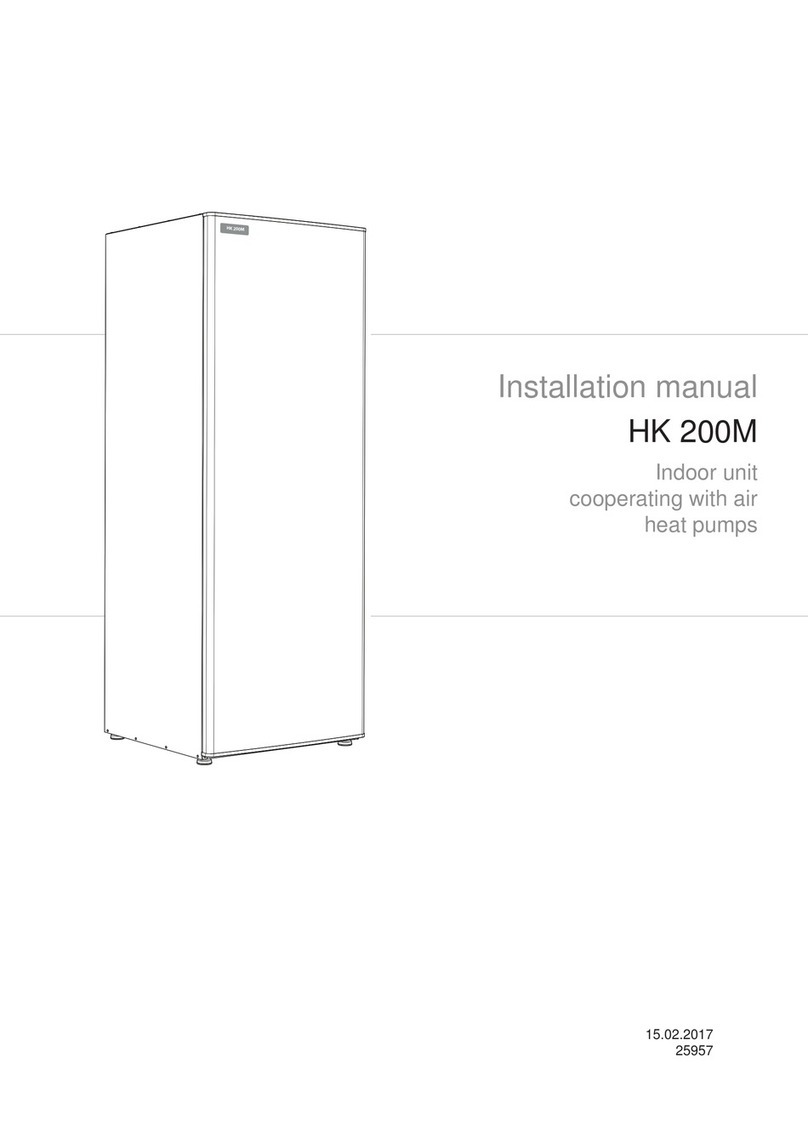

3.0 MAINTENANCE

Beforemaintenanceworkalwaysensurethatthedeviceis:

• pressurelessand

• de-energized

Maintenance recommendation:

1. After 8,760 operating hours or one million switching

cycles, a maintenance message is released.

The green power LED flashes. Afterwards, or at the lat-

est after one year (8,760 operating hours), replace the

service unit (5) .

2. Prior to replacement of the service unit, a reset needs to

be carried out. The control unit is released by actuating

the arresting hook. When removed, the TEST button

below the LED must be pressed for at least five seconds.

3. Remove the control unit (1) by pressing the arresting

hook (2).

4. Unfasten from the outlet (3).

5. Remove the design shell (4) (if there is one) using a

screwdriver (10).

6. Detach the service unit (5) from the tubing at the inlet

by removing the union nut,

OR

remove the screws (6) from the angle nozzle (7).

OR

remove the screws (8) at the intermediate adapter (9)

and remove the latter from the service unit by pulling it

downwards.

7. Check whether or not the new service unit (5) goes with

the control unit (1).

8. Reassemble new service unit (5) in reverse order. Do not

over tighten screws (8).

Installation of the control unit on the service unit:

1. Check whether or not the service unit (5) goes with the

control unit (1).

2. Check whether or not the sealing mat (11) and the con-

tact springs (13) are clean, dry, and free from impurities.

3. Introduce the sensor (12) into the sensor tube plate (14).

4. Hangthehook(15)ofthecontrolunit(1)inthesensor

tube plate (14).

5. Press the control unit (1) against the service unit (5) and

snap into place.

Start-up subsequent to maintenance measures:

Always perform prior to the start-up:

1. Leak test of the screwed connector.

2. Check of the electrical connections.

3. Check of the correct engagement of the control unit.

7

4.0 TROUBLESHOOTING GUIDE

Symptom Possible Causes Corrective Action

No LED lights up Power supply faulty

Power supply board defective

Check voltage on the ID plate

Check wiring (external and internal)

Check plug connections

Check the circuit boards for possible dam-

age

All LEDs are continuously on Failure during the start of the program-

ming

Circuit board defective

Separate the device from the supply volt-

age. Restart after 5 seconds.

Check the circuit boards for possible dam-

age

Test button pressed, but no

condensate discharge

Feed and/or outlet line shut off or blocked

Worn parts (seals, valve core, diaphragm)

Control printed circuit board defective

Service unit defective

Minimum pressure not reached

Maximum pressure exceeded

Check feed line and outlet line

Replace worn parts

Check if valve opens audibly (press test

button several times)

Check printed circuit boards for possible

damage

Check operating pressure

Condensate discharge only

when the test button is

pressed

Feedlinewithinsufcientslope;cross-

section too small

Excessive condensate quantities

Service unit extremely dirty

Lay feed line with adequate slope

Replace the service unit

Device keeps blowing off air Service unit defective or dirty Replace the service unit

8

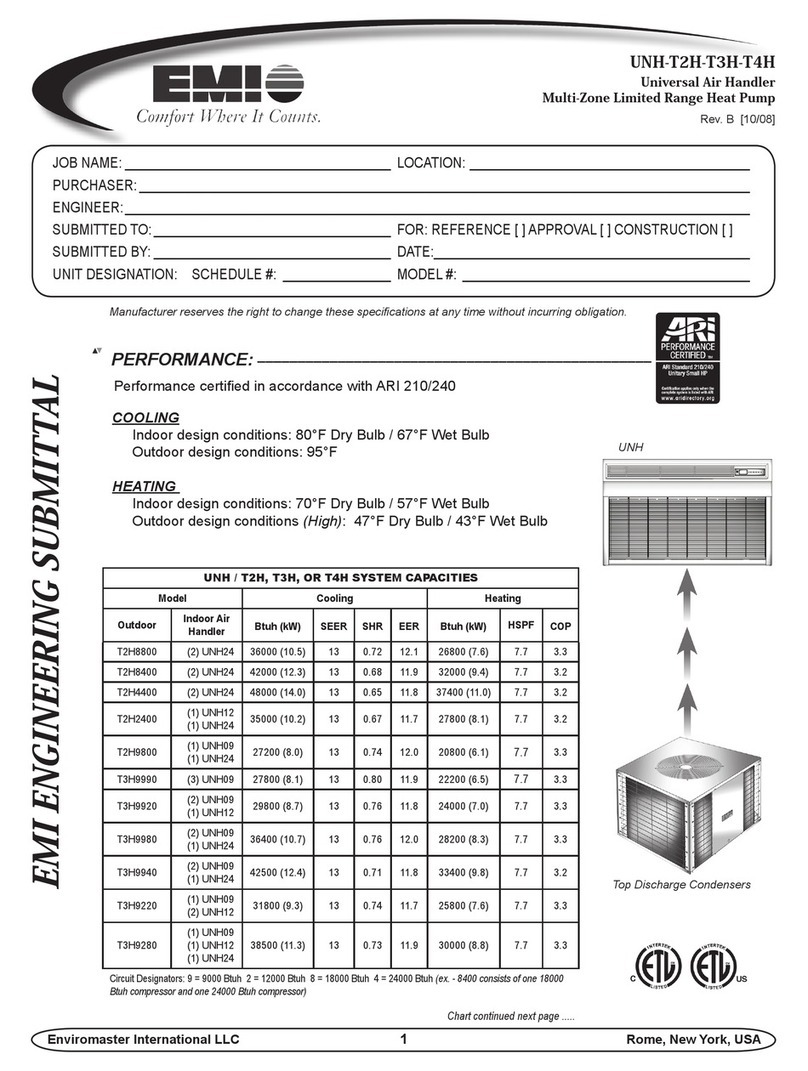

5.0 ENGINEERING DATA

6.0 DIMENSIONS

2.87 (73)

6.48 (164.7)

7.05 (179)

4 - 8 Nm

4.63 (117.6)

3.49 (88.6)

INLET

5.12 (130)

OUTLET

inch (mm)

ALARM

SIGNAL

ELECTRICAL

CONNECTION

INLET

Models 601 & 603 Models 602 & 604

Min. / Max. Operating Pressure

(see type plate) 18 PSI / 230 psi 12 PSI / 230 psi

Min. / Max. Air Temperature

(see type plate) +34°F / +158°F +34°F / +140°F

Condensate Inflow 1/2" NPT 1/2"BSP

Condensate Outflow 1/4"NPTwith3/8"BarbedHoseConnector

Weight (empty) 2.2 lbs.

9

1. Screw 3.5 x 10

2. Upper part of cover

3. Cord packing 2 x 352

4. Circuit board

5. Sensor

6. Lower part of the cover

7. Cable bushing

8. Sealing mat

9. Service unit

10. Hose connector Ø 1/4

11. O-ring 20 x 2

12. Intermediate adapter

13. Screw M6 x 12

14. O-ring 14 x 1.78

15. Angle adaptor G 1/2

16. Design shell (N/A: Models 603 & 604)

7.0 COMPONENTS

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL

IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

WARRANTY

The manufacturer warrants the product manufactured by it, when properly installed, operated, applied, and maintained in accor-

dancewithproceduresandrecommendationsoutlinedinmanufacturer’sinstructionmanuals,tobefreefromdefectsinmaterialor

workmanshipforaperiodofone(1)yearfromthedateofshipmenttothebuyerbythemanufacturerormanufacturer’sauthorized

distributor, or eighteen months from the date of shipment from the factory, whichever occurs first, provided such defect is discovered

andbroughttothemanufacturer’sattentionwithintheaforesaidwarrantyperiod.Themanufacturerwillrepairorreplaceanyproduct

or part determined to be defective by the manufacturer within the warranty period, provided such defect occurred in normal service

and not as a result of misuse, abuse, neglect or accident.

The warranty covers parts and labor for the warranty period. Repair or replacement shall be made at the factory or the installation

site, at the sole option of the manufacturer. Any service performed on the product by anyone other than the manufacturer must first

be authorized by the manufacturer. Normal maintenance items requiring routine replacement are not warranted. Unauthorized service

voids the warranty and any resulting charge or subsequent claim will not be paid. Products repaired or replaced under warranty shall be

warranted for the unexpired portion of the warranty applying to the original product. The foregoing is the exclusive remedy of any buyer

ofthemanufacturer’sproduct.Themaximumdamagesliabilityofthemanufactureristheoriginalpurchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATUTORY, AND IS

EXPRESSED IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE.THEMANUFACTURERSHALLNOTBELIABLEFORLOSSORDAMAGEBYREASONOFSTRICTLIABILITYINTORTORITSNEGLIGENCEIN

WHATEVERMANNERINCLUDINGDESIGN,MANUFACTUREORINSPECTIONOFTHEEQUIPMENTORITSFAILURETODISCOVER,REPORT,REPAIR,

ORMODIFYLATENTDEFECTSINHERENTTHEREIN.THEMANUFACTURER,HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSS

OFUSEOFTHEPRODUCTOROTHERINCIDENTALORCONSEQUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHER

ARISINGFROMBREACHOFWARRANTY,NEGLIGENCEORSTRICTLIABILITYINTORT.

The manufacturer does not warrant any product, part, material, component, or accessory manufactured by others

andsoldorsuppliedinconnectionwiththesaleofmanufacturer’sproducts.

SERVICE DEPARTMENT: (724) 746-1100

SPX

1000 Philadelphia Street

Canonsburg, PA 15317-1700 U.S.A.

P: (724) 745-1555

F: (724) 745-6040

www.hankisonintl.com

Improvements and research are continuous at SPX.

Specifications may change without notice.

ISSUED 09/2013 Form No.: 7428306 Revision: None

COPYRIGHT ©2013 SPX Corporation

600 Series

Electric Demand Drains

Models: EDD 601-04, EDD 602-04,

EDD 603-04, EDD 604-04

This manual suits for next models

4

Table of contents

Other SPX Heat Pump manuals

Popular Heat Pump manuals by other brands

NIBE-BIAWAR

NIBE-BIAWAR HK 200M installation manual

Riello

Riello AARIA START Installation and technical service instructions

Kronoterm

Kronoterm WPLV-09-S1 NT installation manual

Daikin

Daikin Altherma 3 R F EHFH03S18DJ3V Operation manual

Zodiac

Zodiac POWER FORCE Series Instructions for installation and use

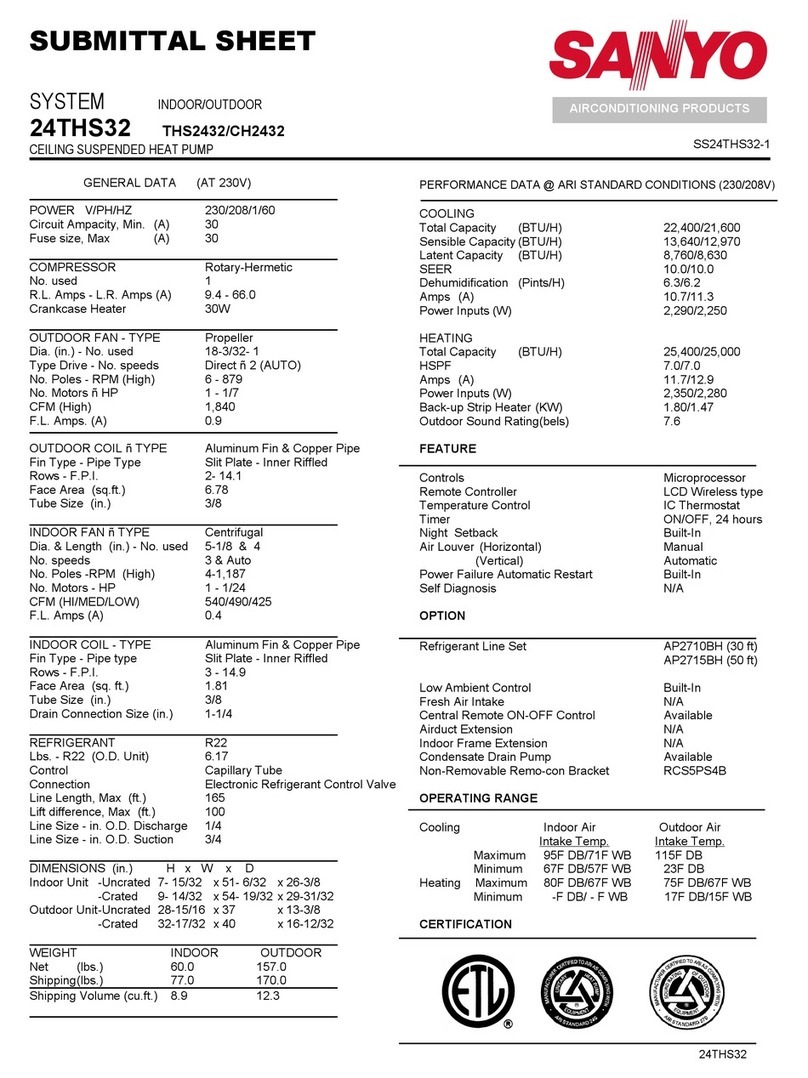

Sanyo

Sanyo THS2432 Submittal sheet