Squirrel Systems Squirrel Workstation 8 Operating manual

Squirrel Workstation 8

SQ-2020

Operator and Service

Manual

Revision 1.0

Preliminary Release

Caution: Changes or modifications to this equipment, not expressly approved by the

manufacturer could void the user’s authority to operate the equipment.

Information in this document is subject to change without

notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or

mechanical, for any purpose, without the express written

permission of Squirrel Systems.

©2003 Squirrel Systems. All rights reserved.

Squirrel Workstation 8

Records of Revision

Date Reference:

Page,

Paragraph,

Drawing No.

Revision

No. Comments Check

and

Approval

Mar 31/05 Rev 1.0 Initial Release D. O’Brien

TABLE OF CONTENTS

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION................................... 1-1

INTRODUCTION............................................................................................ 1-1

SPECIFICATIONS ......................................................................................... 1-2

ACCESSORIES ............................................................................................. 1-4

WORKSTATION 8 DIMENSIONS ................................................................. 1-5

PRODUCT DESCRIPTION............................................................................ 1-7

CHAPTER 2: DISASSEMBLY and ASSEMBLY........................ 2-1

General Servicing Precautions................................................................... 2-1

Service Equipment and Parts List.............................................................. 2-1

Removing the Front Cover......................................................................... 2-5

Replacing the Front Cover ......................................................................... 2-7

Removing the Mag Swipe Reader.............................................................. 2-7

Removing the ISIS Badge Reader (Optical Reader) ................................. 2-8

Removing the ‘DG41 LCD Assembly (Mounting Bracket) from the Rear

Internal Shield Assembly.......................................................................... 2-11

Disassembly of the ‘DG41 LCD Assembly............................................... 2-13

Removing the Touch Screen Sensor (Overlay) ............................. 2-13

Reassembling/Replacing the Touch Screen Sensor (Overlay) ..... 2-14

Removing the ‘DG41 LCD from the LCD Mounting Bracket.......... 2-14

Disconnecting the LCD Data Cable ............................................... 2-16

Removing the Open Frame Inverter............................................... 2-16

Reassembly.................................................................................... 2-17

Base Bottom Disassembly ....................................................................... 2-18

Disconnecting the Power Switch Cable from the Motherboard ..... 2-18

Disassembly of the Internal Shield Assembly ................................ 2-19

Removing the Internal Shield Assembly out of the Base Bottom

Plastics................................................................................... 2-19

Removing the Power Switch Cable and the Power Switch.... 2-19

Removing the Intake Fan....................................................... 2-20

Removing the Motherboard from the Internal Shield Housing2-21

Resetting CMOS for Squirrel Defaults ................................... 2-22

Removing the Card Guide Rails............................................. 2-23

CHAPTER 3: INSTALLATION ................................................... 3-1

GENERAL GUIDELINES............................................................................... 3-1

ELECTRICAL POWER REQUIREMENTS.................................................... 3-2

LOCATION AND MOUNTING POSITIONS .................................................. 3-2

I Preliminary Release 3/24/05/R1.0

TABLE OF CONTENTS

PROPER INSTALLATION OF MOUNTING HARDWARE............................3-3

Tilt Stand (92-205) Installation....................................................................3-3

Adjusting the Tilt Stand...............................................................................3-6

Mounting the Workstation 8 to a Wall Bracket (92-207).............................3-8

Wall Mount........................................................................................3-8

Counter Sunk Mount.........................................................................3-9

HOST/SERVER COMMUNICATION PROTOCOL........................................3-9

ISIS BADGE READER CONFIGURATION .................................................3-10

CABLE LOCATION LABEL - I/O INTERFACE..........................................3-10

TYPICAL WORKSTATION & PERIPHERAL SETUP.................................3-12

FINAL TESTING OF THE INSTALLATION.................................................3-13

Powering it On...........................................................................................3-13

Screen Contrast........................................................................................3-14

Volume Control .........................................................................................3-14

CHAPTER 4: MAINTENANCE....................................................4-1

CARING FOR THE WORKSTATION 8..........................................................4-1

General Cleaning........................................................................................4-1

Cleaning the Credit Card Reader ...............................................................4-2

CHAPTER 5: TROUBLESHOOTING .........................................5-1

CHAPTER 6: APPENDICES.......................................................6-1

APPENDIX A: ESD WORK-STATION...........................................................6-1

Maximum Allowable Resistances and Discharge Times for Static Safe

Operations ..............................................................................................6-2

ESD Work-station Do’s and Don’ts.............................................................6-2

Prime Sources of Static Electricity in an Electronics Work Area................6-3

Field Service - ESD Prevention ..................................................................6-4

Field Service Kit..........................................................................................6-4

APPENDIX B: LCD HANDLING ....................................................................6-5

ESD Protection............................................................................................6-5

Mechanical Force and Strength..................................................................6-5

Handling the LCD........................................................................................6-5

Cleaning......................................................................................................6-6

Storage........................................................................................................6-6

Ingestion and Injury Warning......................................................................6-7

APPENDIX C: HANDLING CIRCUIT BOARDS ............................................6-8

APPENDIX D: PORT SIGNAL PIN ASSIGNMENT.......................................6-9

II Preliminary Release 3/24/05

TABLE OF CONTENTS

APPENDIX E: TOUCHSCREEN SENSOR ................................................. 6-10

Cleaning ................................................................................................... 6-10

Specifications ........................................................................................... 6-10

APPENDIX F: MOTHERBOARD PREPARATION ..................................... 6-12

Foil Taping the Rear Shield Casing (89-541)........................................... 6-13

Foil Tape Specifications........................................................................... 6-14

APPENDIX G: ............................................................................................ 6-15

Connector Descriptions............................................................................ 6-15

Jumper Descriptions................................................................................. 6-16

Jumper Settings Information .................................................................... 6-17

APPENDIX H: BUTTERFLY SHIELD SCREW.......................................... 6-21

APPENDIX I: LCD BRACKET PREPARATION FOR MOUNTING THE

LQ121S1DG41 DISPLAY............................................................................ 6-22

3/24/05 Preliminary Release III

GENERAL INFORMATION

CHAPTER 1:GENERAL INFORMATION

The General Information Chapter includes three sections:

•Introduction

•Specifications

•Accessories

•Product Dimensions

•Product Description

INTRODUCTION

This publication is intended to provide technical support information for Squirrel

systems installers, field service technicians and depot service technicians.

Information in this manual includes:

•Specifications for electrical power requirements and interface cable

installation.

•Installation guidelines for mounting hardware and procedures pertaining

to the Wall Bracket and Tilt Stand

•Assembly and disassembly procedures.

•Configuration and adjustment of communication protocol, display

attributes and other features.

•Troubleshooting and repair procedures.

Only authorized SQUIRREL personnel with proper training and equipment such as

Anti-static Kits should attempt the disassembly procedures described in this manual.

1-1 R1.0 Preliminary Release 3/24/05

GENERAL INFORMATION

SPECIFICATIONS

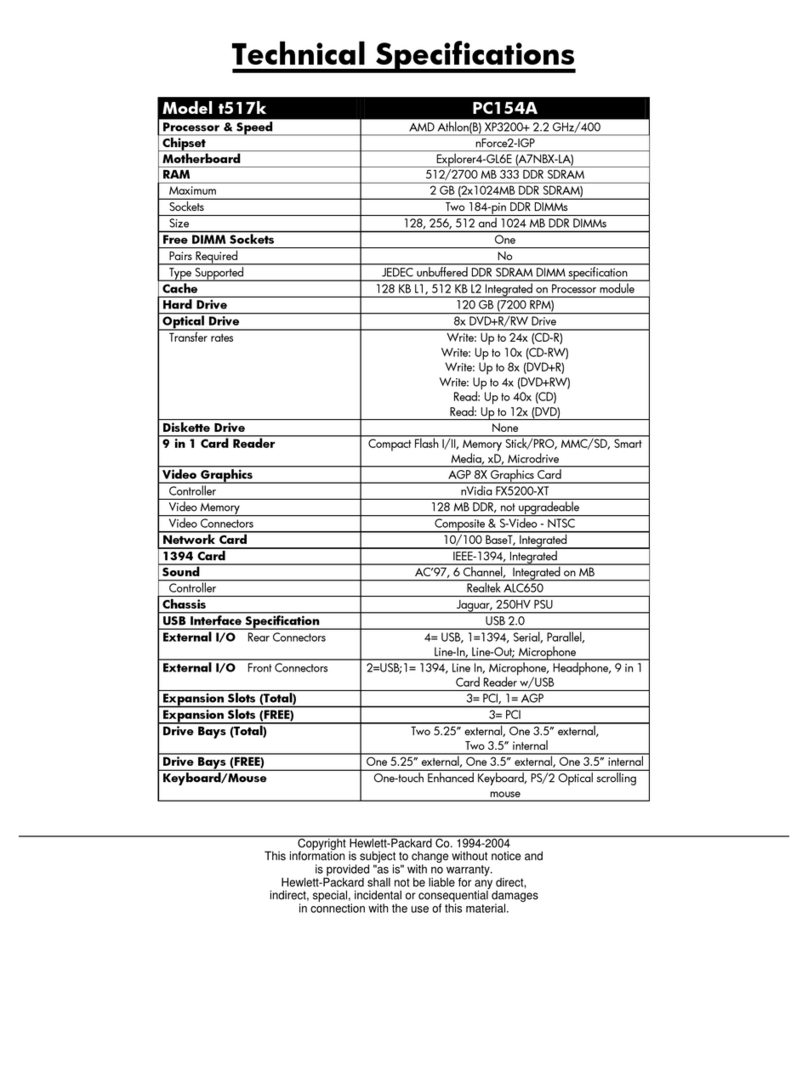

Standard SBC

Functions PROCESSOR Intel Celeron 850 MHz or Pentium 3 up

to 1GHz

- Socket 370

BIOS - Standard Award® PC 256 KB Flash

BIOS

- Includes ETHERNET LINUX boot

ROM

SYSTEM CHIPSET VIA VT82C694/VT82C686

SECOND LEVEL OF CACHE On-board 512KB

RAM - two 168 - pin DIMM sockets

(supports up to 512MB SDRAM)

PARALLEL PORT - One parallel port (LPT2)

onboard/internal access, supporting

SPP/EPP/ECP/ parallel mode.

SERIAL PORTS - COM 1 & 2 External

RJ11: RS-232

- COM 4 External

RJ11: RS232 & supports +5V

power

- COM 1,2 & 3 Onboard

2x5 Header: RS-232

KEYBOARD CONNECTOR Mini-DIN keyboard connector

PS/2 MOUSE CONNECTOR PS/2 mouse – onboard/internal access

VIDEO CONNECTOR Internal shrouded header to support a

CRT monitor

WATCHDOG TIMER Software enable/disable. Time interval of

1.6 seconds generates system reset in

the event of program failure

USB Two onboard/internal access USB1.1

Ethernet Interface CHIP RTL8139C

ETHERNET INTERFACE 10/100 BASE-T/TX, RJ45

1-2 Preliminary Release 3/24/05

GENERAL INFORMATION

Flat Panel / PCI

SVGA Interface: CHIPSET C & T 69000

- 2 MB integrated memory

DISPLAY MEMORY 2 MB on-board memory

DISPLAY TYPE - 12.1” Color TFT – Hi Brightness LCD

- Resolution: 800x600

Touchscreen

Interface OVERLAY 5 Wire 12.1” ELO-Touch Analogue

Resistive overlay

Cash Drawer

Interface: CASHDRAWERS Supports 2 cash drawers.

(RJ11 connector)

Peripherals Devices MAGNETIC SWIPE Bi-directional read Track 1 & Track 2

Software

Compatibility SOFTWARE POS SquirrelOne

External Power

Supply Adaptor INPUT REQUIREMENTS - 100 VAC – 240 VAC

- 50-60 Hz (International)

- UL and CE

OUTPUT REQUIREMENTS - +12V, DC @ 5.5 Amps

- maximum power rating: 60 WATTS

CONT.

POWER CORD LENGTHS - input approx.: 40” (1016mm)

- output approx.: 72” (1830mm)

SIZE (DIMENSIONS) - L x W x D:

132”(5.20mm)x58”(2.29mm)x

30”(1.18mm)

- Weight: 0.66 lbs (300g)

3/24/05 Preliminary Release 1-3

GENERAL INFORMATION

Mechanical and

Environmental OPERATING TEMPERATURE 50°to 105.8°F (10°to 40°C)

OPERATING HUMIDITY 5% to 95% relative humidity

WEIGHT 12.47 lbs (5.64 kg) WS on stand

7.10 lbs (3.22 kg) WS only

ACCESSORIES

ETHERNET CABLE Standard

CHECK PRINTER COMMUNICATION

CABLE Standard

EXTERNAL POWER SUPPLY WITH

POWER CORD Standard

CASH DRAWER CABLE Optional

CUSTOMER DISPLAY TOWER CABLE Optional

ADJUSTABLE TILT STAND Standard

MAG SWIPE (CREDIT CARD

READER) Optional

1-4 Preliminary Release 3/24/05

GENERAL INFORMATION

WORKSTATION 8 DIMENSIONS

3/24/05 Preliminary Release 1-5

GENERAL INFORMATION

Side Dimensions

External Power Supply Dimensions

1-6 Preliminary Release 3/24/05

GENERAL INFORMATION

Product Description

Touchscreen

Optical ID Reader

Badge Card Slot

Magswipe

Reader/Slot

Adjustable Stand

and Backplate

Air Exhaust

Area

Power Switch

Ke

y

board Port

Internal Intake

Fan Vents

3/24/05 Preliminary Release 1-7

GENERAL INFORMATION

1. Power Jack – AC/DC Power Supply Adaptor is connected here.

2. Ethernet Port – 10/100 Base – T/TX, RJ45 Jack for SquirrelOne Network

Connection.

3. COM 4 – RJ12 Interface Jack configured for default Customer Display

Tower.

4. Cashdrawer Port – RJ12 Jack provides Dual Cashdrawer Output.

5. COM 2 – RJ12 Interface Jack configured for default POS printer.

6. COM 1 – RJ12 Interface Jack configured for default POS printer.

Refer to Appendix D for port signal pin assignment.

Wall Mounting Bracket Slots

Serial Number

Label

Sales & Service

Label

Workstation’s Ethernet

MAC Address

6 5 4 3 2 1

Stand Back

Plate Mounting

Holes

Cable Location Label

1-8 Preliminary Release 3/24/05

DISASSEMBLY AND ASSEMBLY

CHAPTER 2:DISASSEMBLY AND ASSEMBLY

General Servicing Precautions

The following are general precautions that should be taken by technicians when

servicing the Workstation 8 product. Please refer to APPENDICES at the back of

the manual for a detailed explanation.

•A safe EDS protected work area is required to service the

Workstation 8 product to prevent damage to sensitive

components from static discharge. Refer to APPENDIX A.

•Extra care needs to be exercised when handling and cleaning

the LCD to prevent any damage. Refer to APPENDIX B.

•Circuit boards need to be handled and stored with care to

prevent any ESD damage. Refer to APPENDIX C.

•Opening & Closing – all cabling needs to be arranged so that

they will not be pinched or interfere when you open and close

the workstation case for servicing.

Service Equipment and Parts List

The following equipment is required to service the WORKSTATION 8 according

to this manual:

•Anti-static mat with ground-wire and wrist strap – safe ESD work

area

•Side cutters

•#1 and #2 Phillips screwdrivers

•Multimeter

•Magnetic head cleaning card (SQ-2940 pkg of 10 OR SQ-2941

pkg of 50)

•Scissors

Disassembly Instructions

When disassembling the workstation make sure the workstation is turned off and

disconnected from all cabling and peripherals.

3/24/05 R1.0 Preliminary Release 2-1

DISASSEMBLY AND ASSEMBLY

Reassembly Instructions

Reassembling is the reverse of the disassembly process. Use care to ensure

that all cables and screws are returned to their proper positions. Check that no

loose parts have been left inside and everything is properly installed and

tightened.

A list of modules and/or their sub-assemblies:

Module / Sub-Assembly Part Number

Workstation 8 for SquirrelOne with Power Supply and

Stand SQ-2020

Workstation 8 for SquirrelOne with Power Supply and no

Stand SQ-2021

Workstation 8 for SquirrelOne without Power Supply and

Stand 92-800

AC / DC Power Supply (no AC cable) 31-038

AC Power Supply Cord 78-010

Touchscreen Overlay/Sensor SQ-2523

LCD Assembly (LQ121S1DG41 LCD) & Shield Top

Note: Primarily for field servicing

92-241

ISIS Badge Reader Kit SQ-2899C

Magswipe Reader SQ-2902

Motherboard – SBC

Comes with 64M RAM

SQ-6593

Table 2.1 Module / Sub-Assembly Parts List

2-2 Preliminary Release 3/24/05

DISASSEMBLY AND ASSEMBLY

Various cables, screws and miscellaneous parts

Part Description Part Number

Cable RJ12 to RJ12 Interface

Use: COM1

COM2

COM4

SQ-7035

Cable CATS Ethernet Patch

Use: SquirrelOne SQ-7706

Cable RJ12 to RJ45 Printer Interface

Use: COM2 SQ-7345

Cable Cash Drawer

Use: DRW SQ-7175

Dual Cash Drawer Adaptor 95-026

Plastic Split Tubing (per foot) 77-040

#6-32 X 1” Pan Head Phillips Screw

Front to back housing 82-009

#4 Star Washer

For LCD mounting and motherboard 83-003

Screw #4-40 x ¼

- LCD to mounting bracket

- Motherboard to rear shield

- Inverter to LCD mounting bracket

82-004

Screw #4 x ¼

For card guide rails 82-068

Screw #4 x 3/8

To secure magswipe reader 82-067

Display Backplate 89-540

Rear Internal Shield 89-541

LCD Data Cable 76-245

LCD Back Light Cable 76-208

Table 2.2 Miscellaneous Parts List

3/24/05 Preliminary Release 2-3

DISASSEMBLY AND ASSEMBLY

Power Switch 74-020

Power Switch Cable 76-338

Plastic Card Guide 99-608

Black Cable Tie 86-015

Fan 91-070

ISIS Cable 76-301

Adjustable Stand with Weight Assy 92-205

Base 92-195

Back Plate 99-604

Wall Mount Bracket 92-207

Rear Workstation 8 Plastic Housing 99-618

Top Workstation 8 Plastic Cover 99-622

WS8 High Touch Strip 99-623

ISIS Badge Rdr Kit SQ-2899C

#6-32x1/2” Phil Black Screw

For Fan to Rear Shield 82-608

Table 2.2 Miscellaneous Parts List

2-4 Preliminary Release 3/24/05

DISASSEMBLY AND ASSEMBLY

To remove the Front Cover:

This procedure requires a #2 Phillips screwdriver.

Removing the Front

Cover

1. Place the WORKSTATION 8’s front of the unit face down on the

anti-static mat. Ensure that the mat is clean of debris that could

scratch or damage the workstation.

2. Remove all 10 screws that secure the front cover to the bottom

housing as shown in the picture below.

3. Carefully hold the front and rear housing together and turn the

unit over right side up.

4. Carefully lift off the front cover to expose the internal

assemblies.

3/24/05 Preliminary Release 2-5

DISASSEMBLY AND ASSEMBLY

Front/Top Cover Front/Top Cover

Front View Back View

LCD Optical ID Reader

(Isis Badge Reader)

Magswipe

Reader

Base Bottom Housing Sensor/Overlay LCD Mounting

Bracket

Power Switch

Spray coated with

copper loaded paint for

EMI/RFI shielding

2-6 Preliminary Release 3/24/05

This manual suits for next models

1

Table of contents